Search the Community

Showing results for tags 'timbo apps'.

-

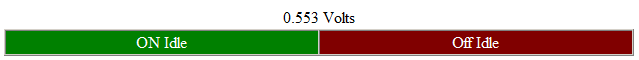

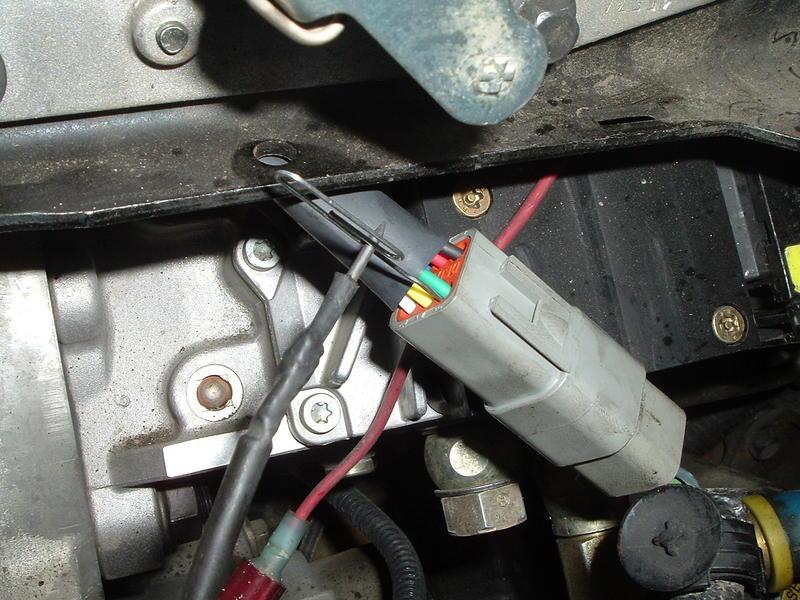

Installing A Timbo's APPS Sensor What's needed? -Timbo Apps - 10MM socket and wrench - T20 torx - Paperclip - Mutlimeter Timbo gave me a Timbo APPS sensor to install on my truck and try out. So I'll tell this much its built much better than the factory ~$450 dollar Dodge stock APPS sensor! I will say it works with the exhaust brake and is high idle ready with no compatibility issues. Timbo APPS sensor has no effect on these options and will continue to work as usual. What I love about the Timbo APPS is the fact there is no longer a need to for adjusting voltage for the APPS to function correctly or probing the PCM or ECM sockets.. And for you Timbo you need some serious Props for coming up with a simple fix for our tucks! My hats off to you sir! But Here is my quick version write up of how to install a Timbo APPS sensor. 1. First you must remove the plastic cover over the bellcrank assembly. There is 2 plastic screws inside a expanding plug. You must remove the plastic screw without pushing against them. Kind of tricky but it can be done. 2. Then grab a 10mm socket and remove all 6 bolts holding the black plate to the mounting on the block... 3. Unplug the old APPS sensor. 4. Remove the 2 Torx screws holding the stock APPS sensor. This part I kind fudge over Timbo idea and made it simple. I grab a pair of pliers grab the head of the screw and broke them loose then used a T20 bit to finish removing. This way there is no worry about stripping the heads out. 5. Replace the APPS sensor with Timbo APPS sensor in the same position and line up the slot with the bellcrank tab. Use the supplied screw. Just before you finish tighten the screw turn the sensor fully clockwise to remove extra twisting slack. (As seen in this picture) 6.Plug in the wiring and re-assemble the APPS sensor plate again with the 6 bolts. 7. Now adjust for slack. Use the supplied paper clip and insert it in the green port on the plug. Turn your key ON and look at the voltage. Now using the screw on the bellcrank stop (one towards the front) adjust till the voltage rises the back off till you hit your original mark plus 1/2 turn. Since mine was .633 I turn till it rose and the backed off to .633 and then another 1/2 turn. Your all set! WARNING! Don't try to adjust the voltage to the voltage on the tag of the old sensor. This is not required nor should be done. Timbo's APPS has no voltage to set to. Also don't bother to try and probe at the PCM this is not required ether! Take notice the final voltage on the DMV (Digital Volt Meter) is no where near the voltage listed on the old stock APPS. 8. Disconnect your batteries and do a APPS Reset. Mopar's Notes: Anyway's, just thought you could put a comment at the bottom of your Timbo APPS write up to tell people that the voltage/set screw adjustment isn't REQUIRED but certainly nice to do to avoid a dead spot at the top of the pedal movement. - Derrick Lucas

- 3 comments

- 1 review

-

- 1

-

-

- timbos

- apps sensor

-

(and 1 more)

Tagged with:

-

Does anybody have to reset the Timbo Apps on a Bi-Weekly basis? It has been happening now for 3 months. I disconnect battery for about 2 hours, then i reset the APPS and truck runs fine, then two weeks later i am having the same issue. Any feedback would be appreciated

- 9 replies

-

- apps sensor

- resetting apps sensor

-

(and 1 more)

Tagged with:

-

So I had a annoying slight surge when not under load at highway speeds. I did some research on this and a few other sites and ordered up a Timbos APPS. It got here in only 4 DAYS. I couldn't believe it. I can't get stuff here from Calgary in 4 days and thats only 200 miles away. Anyway got it installed, surge is totally gone and it feels like the first half of throttle is crisper now too. Great instructions and packaging too. Thanks TIMBO!!!

-

I need some help with my 2001 Cummins. I have recently had some dead pedal issues with my truck and took my truck in to a diesel specialist and had him test my injector pump. My injector pump is fine according to him but he found that my waste gate was stuck on my stock turbo. While trying to free the gate, he noticed my turbo was cracked so I purchased a new after market turbo.Last year I replaced the stock exhaust to a 4" exhaust, added a new lift pump (Raptor) and all of my guages.So, while pulling my 5th wheel last weekend, I noticed some funny shifting patterns and sort of dead pedal syndrome. My friend told me his father in law had issues with his Superchip, I also have a Superchip so I disconnected it and no shifting issues anymore.I still have no power though while pulling my camper. Contantly downshifting even on the smallest hills. My new turbo came with a plug to try and trick the map sensor so I installed that and I still have the 0234 code saying turbo boost limit exceeded. Is this why my truck has no power??Anyone have any ideas of what to check or look at?Thanks

- 10 replies

-

- apps sensor

- boost leak

-

(and 1 more)

Tagged with:

-

Ok fellas I need some help again!!!:banghead::banghead::banghead: Driving my ole truck down the road, an she started acting funny! So I started watching the gauges and everything is running ok, except the apps. The apps will be maintaining about 25% and then it will drop to 0% , and then it will pick back up an take off like nothing was ever wrong! There is no check engine light and no codes. With the engine off I can pust the pedal and it will build from 0-100 slowly or all at once! Could the tps or apps be going out on me?

- 13 replies

-

- alternator

- apps sensor

-

(and 1 more)

Tagged with:

-

So, i have just installed my new APPS that i received in the mail the other day. Everything checked out fine, truck idles smooth, CEL turned off, and everything except, i cycled the ignition for the heck of it and noticed all 3 codes i had listed before are still there. My questions are...- Am i back to square one?- Do i need to manually reset the codes?- Will these codes reset over time by themselves?Any help is appreciated.Thanks,Dave

-

Hello all, I am new to this site and wanted to kick something around maybe get some feedback and troubleshooting help. When i would turn on the truck, i would usually let it idle for awhile. I would put it in “D”, push on the gas, the truck would start to travel, than it will suddenly get the case of the "dead pedal" and then kick into gear. This started in a sporadic fashion. It then led to a daily ritual to get to work having to rev-up the engine in order for the truck to move. I have briefly explained below how I got to this point. The beginning of this story is as follows: I initially replaced the fuel lift pump when I first got the signs of white smoke coming out of the tailpipe and the engine stalling out with my check gages notification on the dash (5 years ago). I replaced the lift pump, the problem went away for about 2 years (no codes). The white smoke eventually came back, so I replaced the lift pump again and the white smoke went away again and lasted for 2 years (no codes). I replaced it with a third and changed out the filter (1 year)(no codes). I finally got the case of the dead pedal and replaced my VP44 at 189,000 miles (figured it was time since I did not get any codes and read bluechip diesels overview). I installed the VP44 and finally got a companion code P1693 when i tried to start it up. I finally pulled the codes from the PCM and got the P0122 low voltage APPS code. I replaced the original APPS with a TIMBO and I now I have intermittent dead pedal. I also have the loss of power like if I am towing something at take-off. I punch the gas violently than the truck finally starts to sputter and then go away and begin to function properly and picks up speed. On the interstate, the truck runs fine once I start traveling at a constant speed. This behavior only occurs initially at rest or when I slow down and then punch the gas. I have questions that may or may not relate to my problems, which are as follows: [*]When i replaced the VP44, did i somehow take it off its timing? [*]Does this mean my ECM is the culprit and not the VP44? [*]Can i rule out the transmission due to not pulling any load? [*]Did i purchase a bad OEM VP44? When I installed the TIMBO Apps, I smelled burnt plastic that eventually went away. I am attributing it to that new plastic smell. I also noticed that when I hooked up the voltmeter, I got a reading of .510. I followed the instructions and when I turned back to ½ a turn as instructed, I ended up at .510 again, is this right? (the original apps has .521 VDC) Do I need to set it at .521, .498, or leave it at .510? I have recently replaced one of the batteries (drivers side), but still have the original battery on passenger side. Can it be related to the problem that I have? Do I need to replace that battery as well? Any and all comments are welcome. I thank you for your feedback in advance.

- 93 replies

-

- apps sensor

- dead pedal

-

(and 1 more)

Tagged with:

-

I have heard alot about "Timbo" and the remarkable price of his replacement APPS. Is there a site to order from or contact info for him? Thanks for any help.:banghead:

-

The APPS sensor has 2 Idle validation switch pins, pins #2 & #6 anybody know which is Idle ON and Idle OFF(or Throttle ON)

-

Ok Gang... I just had a wonderful phone conversation with Rburks this morning and his chasing his problems with his idle well he happen to mention the fact he did the APPS voltage adjustment and I like "OMG not again!" There is a article on the Internet that is wrote up wrong and need to be corrected and stopped. Problem #1 - Voltage on label Everyone is trying to hit this voltage dead on... DON'T! This is the voltage that the APPS sensor goes from ON idle start to OFF idle state. You voltage MUST be BELOW this number. Like on mine the voltage is .519. Don't set the voltage at this set it below this mark say .480 to .490 because as you add in voltage gain or loss during normal operation of the truck it might cross the mark and go off idle and you end up with idle set at 950 to 1000. Then find out your exhaust brake, high idle and a few other things don't work! STOP! Don't set the voltage to the voltage on the label this is WRONG! Like the timbo APPS you adjust to to the point you cross the dead zone and back off below this point 1/2 turn. Reason why is to keep the APPS from accidentally going to OFF idle state. As long as the voltage in the APPS sensor is below this state the the ON idle signal is given to the ECM and the APPS signal is basically ignored and idle programing is used. Like for my example here the voltage on the tag is .553... Now if the alternator or voltage of the system change a little bit you going to have issues of the voltage crossing back and forth over this boundary. Please set your voltage BELOW what on the tag by about 0.020 volts to insure the voltage is low enough to put the APPS sensor in ON Idle state. Problem #2 - Where to measure the voltage? I do know why they started measure the voltage at the PCM in concerns of the TQ Conv Lock up problem but this is wrong too. Now if you go over to my wiring diagrams here... http://mopar.mopar1973man.com/cummins/2ndgen24v/wiring/wiring.htm And now look at Page 1 and look at the PCM on the right at pin #23 you see its labeled ACC PEDAL POS. You think this is tied to the APPS?! Nope... Now switch back to page 3 now at look at the ECM on the right you find the wire at pin #28 on the ECM label ACC PEDAL POS SENS... But now look at all 3 pages this this Orange/Blue wire doesn't connect to the APPS sensor at all but it does pass the information to the PCM after it passes through the ECM (if there is any processing). So now look at Pin #25 on the ECM and you'll see it has a direct connection with the APPS. So if I was going to adjust the stock APPS sensor for voltage I would measure right at the APPS sensor or at the ECM pin #25 which happen to be Light Blue/back wire pin #3 on the APPS. STOP! Don't measure your APPS voltage at the PCM this is WRONG! Measure the APPS voltage at the APPS like Timbo does to if your going for better measure it at the ECM. By the time you measure the voltage at the PCM there might be a minor voltage loss so the voltage at the ECM will be high so hence most people complain about high idle, and other issues! Problem #3 - How to adjust the APPS sensor? There is no need to yank the sensor apart and mess with the 2 torx screw on the back you can obtain all the adjustment you want in the set screw on the bellcrank. But once again don't adjust for the voltage marked on the label... Make sure to flick the throttle bellcrank to WOT ans let it snap back to idle a few times and check you voltage again if the voltage is changing constantly the APPS sensor is wore out and no amount of adjusting is going to fix this problem. STOP! Don't bother messing with the 2 torx screw just adjust the set screw on the bellcrank.

-

HELLO EVERYONE, I HAVE A 2001 2500 4x4 SLT WITH A CUMMINS ANYWAY IT STARTED ABOUT 6mnts AGO WHEN THE FACTORY WIRE TIES HOLDING THE HARNESS BROKE. EVERY NOW AND THEN I WOULD GET A CHECK LIGHT FOR APPS OUT OF RANGE.I WOULD UNPLUG AND RESET IT BE OK FOR MAYBE A MONTH AND THEN THE NEXT TIME YOU WOULD START IT BE ON AGAIN. WELL NOW I GET A DEAD PEDAL ONCE IN AWHILE AND MY FUEL MILAGE SEEMS TO HAVE DROPPED. I ORDERERD A TIMPO APPS YESTERDAY I BELIEVE THAT SHOULD HELP IF NOT IT WONT HURT. DO YOU ALL THINK I'M ON THE RIGHT TRACK.THANKS

-

Can the idle speed on a 24 valve 2nd gen cummins be adjusted? If so how? My truck idles at 740-750 rpm, I would like it to idle around 800 rpm so it don't die when shifting into drive. The truck has a Low Stall TC and it is causing the truck to die when shifted into drive. If I hold the rpm to around 800 it don't stall. Does it warm or cold. Yes, fuel pressure is there (17.5), CKP was replaced 15 months ago, IAT and MAP are new, grounds and batt connections are clean and tight, batteries are well charged, alt is putting out 13.58 volts at the batt. See this thread for history: http://forum.mopar1973man.com/showthread.php/1584-Problems-Stalling-when-shifting-to-drive-and-hard-starting-when-hot.-Ideas Thanks Jim

- 23 replies

-

- apps sensor

- idle adjustment

-

(and 2 more)

Tagged with:

-

Well Gang... Timbo gave me a Timbo APPS sensor to install on my truck and try out. So I'll tell this much its built much better than the factory $400 dollar APPS is! I will say it exhaust brake and high idle ready. This APPS sensor has no effect on these options and will continue to work as usual. What I love about the Timbo APPS sensor is the fact there is no longer a need to hit a particular voltage for the APPS to function correctly or probing the PCM or ECM sockets.. And for you Timbo you need some serious Props for coming up with a simple fix for our trucks! My hats off to you sir! But Here is my quick version write up of how to install a Timbo APPS sensor. 1. First you must remove the plastic cover over the bell-crank assembly. There is 2 plastic screws inside a expanding plug. You must remove the plastic screw without pushing against them. Kind of tricky but it can be done. 2. Then grab a 10mm socket and remove all 6 bolts holding the black plate to the mounting on the block.... 3. Unplug the old APPS sensor. 4. Remove the 2 Torx screws holding the old APPS sensor. This part I kind fudge over Timbo idea and made it simple. I grab a pair of pilers grab the head of the screw and broke them loose then used a T20 bit to finish removing. This way there is no worry about stripping the heads out. Notice the screw heads have tool marks... 5. Replace the APPS sensor with Timbo APPS sensor in the same position and line up the slot with the bell-crank tab. Use the supplied screw. Just before you finish tighten the screw turn the sensor fully clockwise to remove extra twisting slack. 6.Plug in the wiring and re-assemble the APPS sensor plate again with the 6 bolts. 7. Now adjust for slack. Use the supplied paper clip and insert it in the green port on the plug. Turn your key ON and look at the voltage. Now using the screw on the bell crank stop (one towards the front) adjust till the voltage rises the back off till you hit your original mark plus 1/2 turn. Since mine was .633 I turn till it rose and the backed off to .633 and then another 1/2 turn. Your all set! 8. Disconnect your batteries and do a APPS sensor reset. http://mopar.mopar1973man.com/cummins/2ndgen24v/apps/apps.htm Actual article with pictures here... http://articles.mopar1973man.com/2nd-generation-24v-dodge-cummins/26-engine-systems/39-timbos-apps-installing

-

02 2500 5.9 driving through the road block all legal like, went to accelerate and truck started bucking horribaly. ck eng light came on so limped home, scanned ecm p0122/ installed new apps assembly from autozone, no change, found ecm reading apps but would fall off intermitantly then return. so read tcu and found apps signal smooth with no glitch. so i replace ecm no improvment, checked wiring and added ground wire on apps sensor no problems found, hooked all up set voltage on apps sensor now i have no apps reading on ecm and eng. revs wide open when brought off idle, tcu still showing good apps reading. i ordered timbo apps today, and will try but if i read schematic right, apps signal goes into ecm and out to tcu and if tcu still reads right why would ecm keep throwing code. anyone want to try this one

-

Ok I was going to have a friend help in stall this but he is as reliable as rain atleast around here,and we are in a drought. LOL Oh and he works for the sheriff dept. LOL LOL Can anybody help with this.I have read instructions but :confused: and it seems you need two people?

Rate The Author

Please take the time and give the author a 1 to a 5-star rating for the information you have gained from anywhere on the website. All forum threads, articles, etc. If a members post is good information please don't forget to tell them "Thanks" or "Like"

Rate Us On Google

Please take the time and visit our Google Review page and give us a review of our services.

Tip Jar

If Mopar1973Man.Com has helped you with quick and timely information for your repair please consider tossing a tip in the Tip Jar