- Replies 18

- Views 4.6k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 3 posts

-

dripley 3 posts

-

notlimah 3 posts

-

Leaky88 3 posts

Most Popular Posts

-

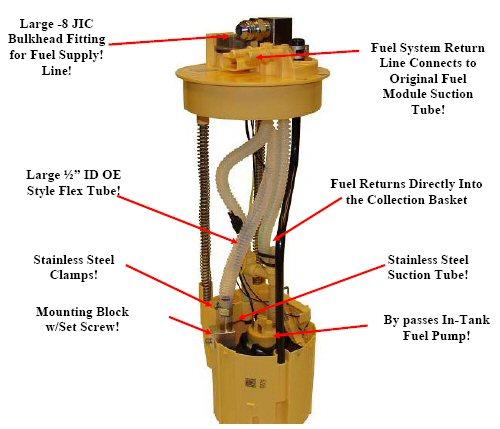

@notlimah that picture was pre- 1/2" return install. The new return line goes deeper into the basket, and I do notice some slight cavitation at the 1/2 tank mark. (though 1/2 tank on the gauge for me

Hello,

I'm certain many have changed out the Draw Straw to 1/2" but I don't seem to be finding discussion on it.

Could someone please direct me to a discussion or documentation on doing it?

Thanks.

Leaky