- Replies 16

- Views 13.2k

- Created

- Last Reply

Top Posters In This Topic

-

Evan 4 posts

-

Mopar1973Man 3 posts

Mopar1973Man 3 posts -

Dynamic 3 posts

-

JAG1 2 posts

Most Popular Posts

-

Flexplate to crank: 105 lb/ft

-

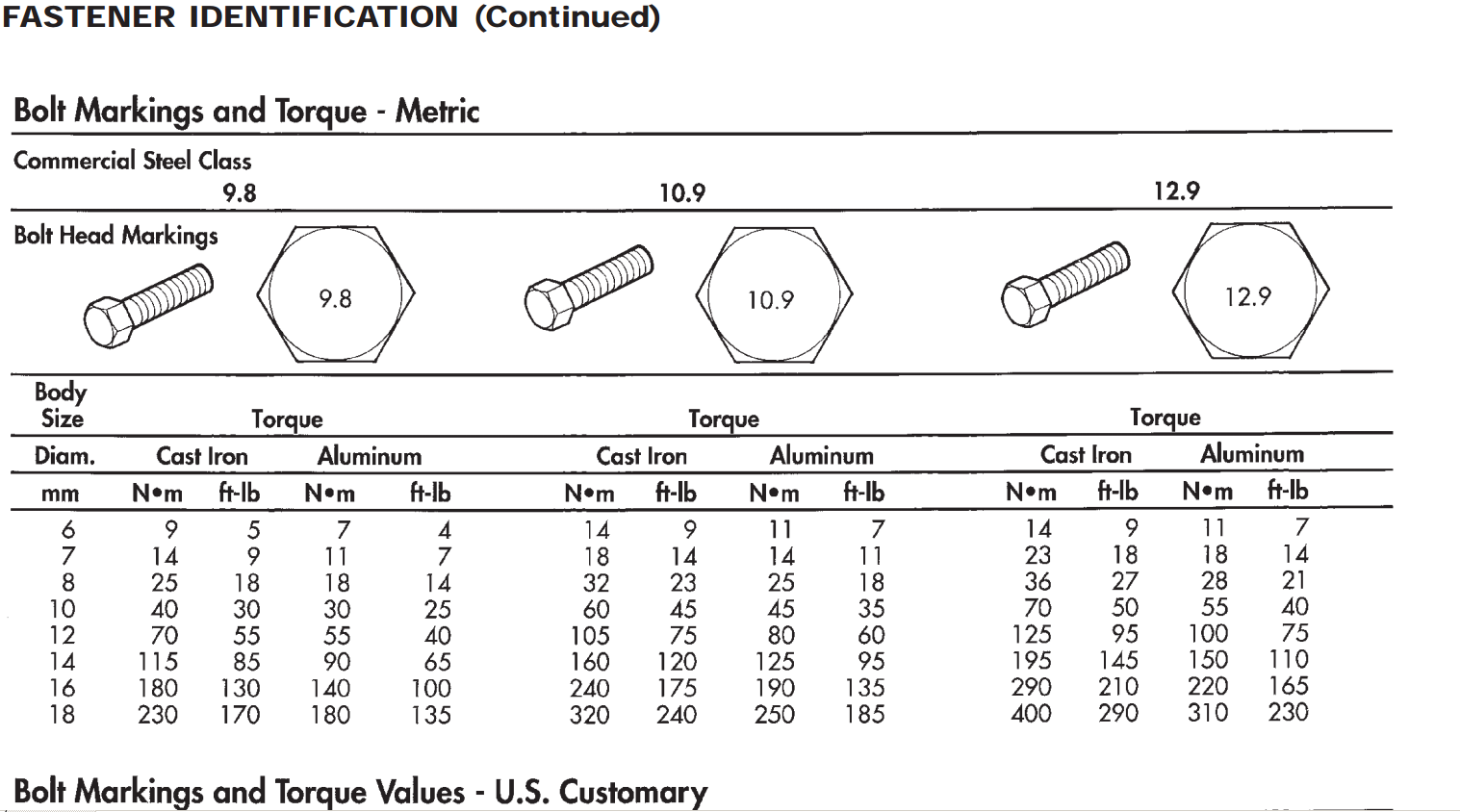

IBM, I agree I found both of the different references you found.... I think the bolts are M12. Need to know the class of bolt. (and materials to be fastened) Metric 12.9 (s

-

The converter to flex plate bolts torque to 38 lb/ft.

When looking up the tightening specification for installing the bolts that hold the flywheel or drive plate to the crankshaft I found two different values. In the engine section under "Crankshaft Oil Seal - Rear" the tightening torque given is 101 ft. lbs. In the "Automatic Transmission 47RE- Torque Specifications" chart the number given is 55 ft. lbs. One of these is a mistake; which one is right?