- Replies 33

- Views 6.1k

- Created

- Last Reply

Top Posters In This Topic

-

wil440 10 posts

-

CUMMINSDIESELPWR 4 posts

-

Tractorman 4 posts

-

Mopar1973Man 3 posts

Most Popular Posts

-

No not really. I have a DTT Assassin mechanical pump, bone stock truck except for a quad, no other way to go, FP goes UP with RPM not down, pushes fuel through 2 micron Cat filters easily and removes

-

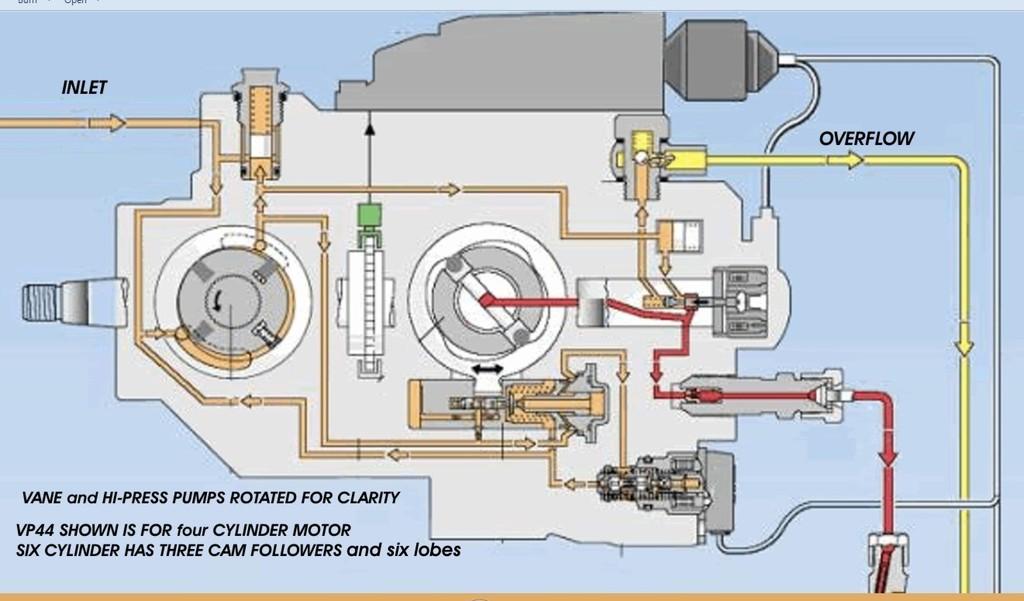

fuel boss or mechanical pump vote here. bone stock trucks will get the vp44 killed by a weak lift pump. its basically a known fact that you MUST upgrade lift pumps on these trucks, stock or not

-

I have run the in tank pump like the 3rd gens. It was no better than the block mounted pump. The VP trucks just are not the same as the 3rd and 4th gens and require different things. The in tank might

So, basically what the title says. I'm interested in mixing and matching bits from a later gen sending unit, in my 2nd gen's. I'm not running any power mods, and lately my fass drp has had intermittent defueling at highway speed. Continued after changing fuel filters.

Truck has 370k+ miles on it, big stock, the most recent 150k have been mostly highway.