- Replies 12

- Views 4.5k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 4 posts

-

wil440 3 posts

-

Dieselfuture 1 post

-

Great work! 1 post

Popular Days

Most Popular Posts

-

That type of cast is generally more friendly to welding then engine blocks. I've had pretty good luck with mig welding. Just a small weld build then grind the weld to get rid of the pits and weld agai

-

I’ve seen my Dad braze cast iron and build up worn parts many times with bronze rod and torch.

-

I would feel pretty confident with a hard facing electrode. They make them for cast iron but my guess is that is cast steel. They use that hard facing rod on machine buckets so it’s pretty darn tough.

The Beast NV4500 has a issue with getting stuck in 4th gear.

Now I know @dripley mention his shift issue for his NV5600 where the steel tip was worn out and had to replace the shift tower. Now for the NV4500 I've been hanging up with 4th gear if I shift too aggressive from 5th to 4th. If I do hang the shifter up I've got to pull the shift tower up to free it and then shift all forks back to neutral. Then reinstall. When I heard about Dripley and his issue I only looked at the shift tip for the NV4500 and didn't see why. Well my trip back from Parma with the wheels I got stuck in 4th gear again about 8 miles from home.

Yesterday morning I got up and tore it down again to reset the stick and looked carefully at everything and finally found the issue.

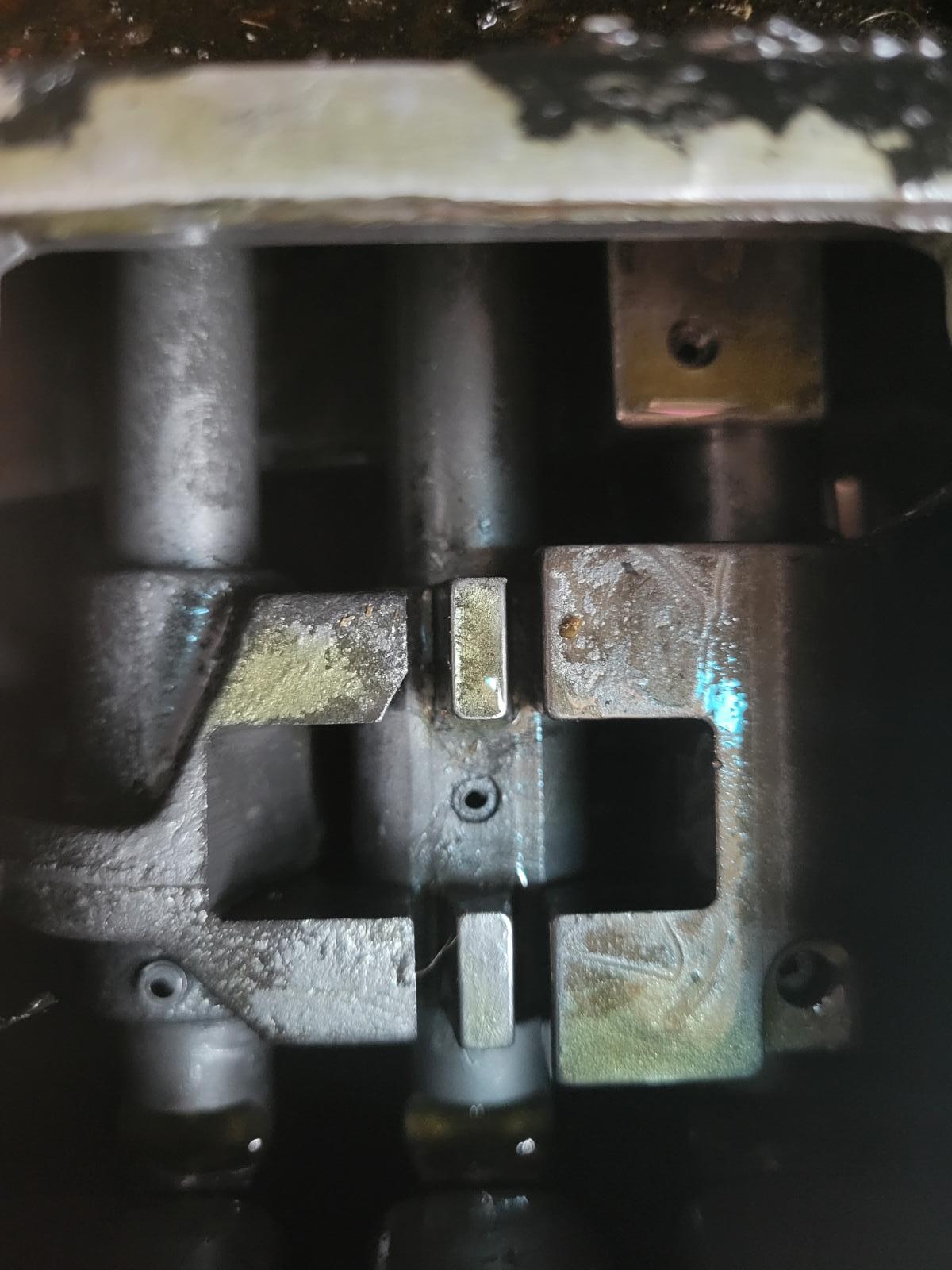

Now look on the left fork which is 5th and reverse. Now the center rod moving up is 4th gear. You can see it would be super easy to cram the shifter tip between that rounded off corner and the 4th gear fork. All those years of driving back and forth to Ontario, OR. 432k miles currently.

Take notice to the wore off corner this always the shifter to sneak between the fork and jam up. I know that fork head is cast iron. I was thinking if I can find a good local welder and put a bit of metal back on that corner then file it back to make it square again. Anyone think this is possible?

Edited by Mopar1973Man