- Replies 45

- Views 11k

- Created

- Last Reply

Top Posters In This Topic

-

sooxies 11 posts

-

dripley 10 posts

-

Mopar1973Man 9 posts

-

JAG1 6 posts

Most Popular Posts

-

Pull the tubes and retainers then crank the engine over. You might end up with 6 holes in your hood but I guarantee they'll come out really fast.

-

Are you using something to pry up with? Not recommended. I cut a piece of heavy pvc pipe or pvc straight coupling cut to the right length and fits over the injector with a big washer on to

-

Do you have the crossover tubes removed?

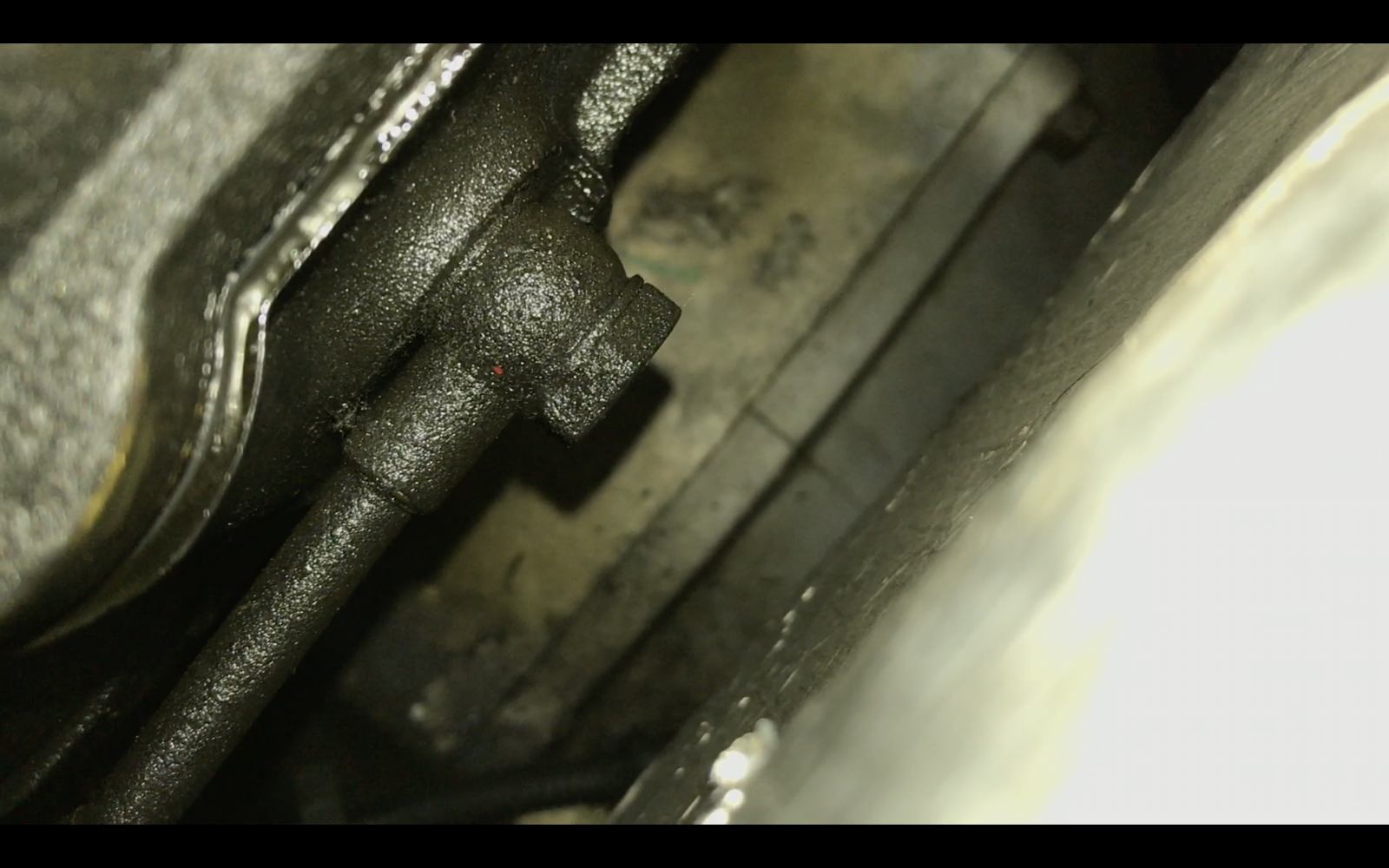

Well every project I take on appears to give me headaches...I'm beyond stressed . I cannot get any of my injectors to budge (I've tried 1,2,3,4). I can rotate them in their slots but they will not lift up. All my strength and they will not move up a millimeter. I also cannot get my number five fuel line to disconnect from the crossover tube. I'll add pictures later but some of the nuts on the fuel lines are corroded which I suspect the issue to be with that (weird because it was California truck for 17 years). The corrosion spread to the threads on some of the fuel tubes but I'm replacing them anyway.

. I cannot get any of my injectors to budge (I've tried 1,2,3,4). I can rotate them in their slots but they will not lift up. All my strength and they will not move up a millimeter. I also cannot get my number five fuel line to disconnect from the crossover tube. I'll add pictures later but some of the nuts on the fuel lines are corroded which I suspect the issue to be with that (weird because it was California truck for 17 years). The corrosion spread to the threads on some of the fuel tubes but I'm replacing them anyway.

My only other option would be to just button everything back up temporarily. But I really don't feel comfortable reusing these feed tubes...worried it's just going to leak like hell. They aren't damaged/scuffed or anything but the corrosion worries me. I may just have to tow it to my mechanic and have him try to do it because I'm getting too stressed out and I'm low on ideas. Things shouldn't be this hard but that's the way it is. I'm trying not to go crazy...pray for me

Edited by sooxies