- Replies 68

- Views 11.2k

- Created

- Last Reply

Top Posters In This Topic

-

Evan 25 posts

-

Gregturley 21 posts

-

Dynamic 5 posts

-

JAG1 4 posts

Most Popular Posts

-

Before starting any modifications to increase line pressure let's first see if what was discussed on TDR has any merit. My torque convertor lock up clutch went bad and I sent it to @Dynamic for a te

-

Here's the build sheet and I upgraded the torque convertor to a Goerend 15SS Air temp 91°F Transmission fluid temp 165°-190°F Line pressure, transmission in drive : no throttle stop

-

Read through this

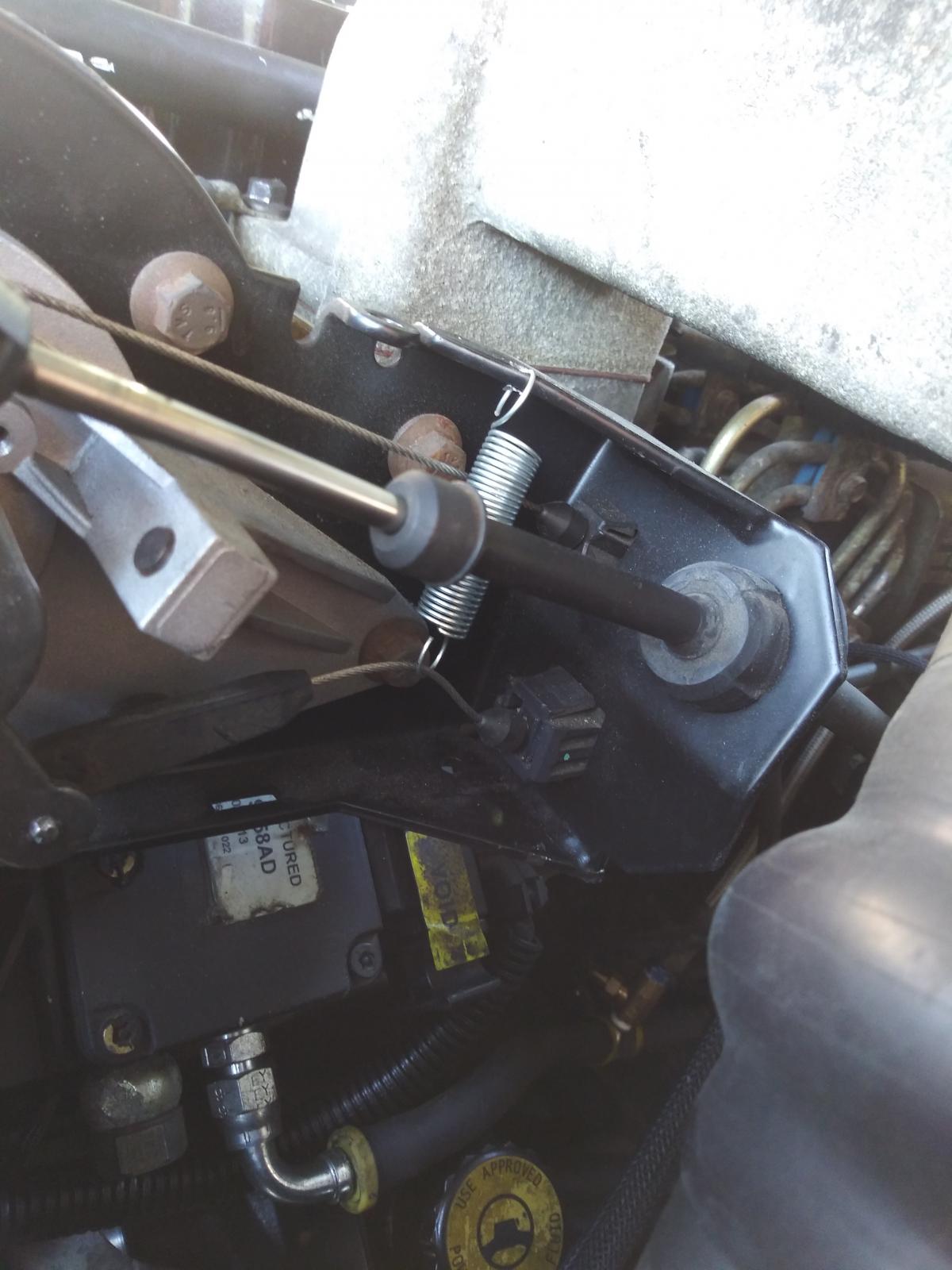

@Dynamic This one is seeking your advice. I can't afford one of your valve bodies or a converter right now so its time for a shift kit. Transmission was rebuilt to factory specs by Cottman Transmission about 25,000 miles ago, before i bought it. Works fine, no slipping or other issues. I use it for a daily driver with occasional hauling/towing, max load of 10,000lbs. I have installed Sonnax accumulator piston, second gear super servo, billet band strut and anchor, Rostra transducer & OD/TC solenoids, Borg Warner pressure solenoid, LPW deep pan, and adjusted bands and TV cable. I do not like how these transmissions shift. To me they shift too soft. I like a trans that shifts firm to hard. In my toys i always run a manual reverse valve body or a trans brake. I don't want a manual VB in the truck but i would like much firmer shifts. What shift kit and/or other mods would you recommend? Please keep in mind funds are limited. Can't do a VB or converter at this time. Trying to stick with pan off stuff. Any help/advice is greatly appreciated.