Leaderboard

-

- All areas

- Events

- Event Comments

- Files

- File Comments

- File Reviews

- Images

- Image Comments

- Image Reviews

- Albums

- Album Comments

- Album Reviews

- Blog Entries

- Blog Comments

- Cummins Articles

- Cummins Article Comments

- Cummins Article Reviews

- Vendors

- Vendor Comments

- Vendor Reviews

- Ads

- Ad Comments

- Ad Reviews

- Policies

- Policy Comments

- Topics

- Posts

-

-

Tractorman

Yearly Subscription11Points1,543Posts -

DPD

Monthly Subscription4Points4Posts -

PilotHouse2500

Yearly Subscription4Points445Posts -

20016speed

Monthly Subscription3Points8Posts

Popular Content

Showing content with the highest reputation since 12/24/2025 in all areas

-

Fuel psi problems

2 pointsGive details of your bucket test. Have you ran the engine while drawing fuel from the bucket with a separate power source to the lift pump? I'm having a hard time with believing it to be a VP44 overflow valve problem. Did the FASS representative explain with detail on exactly how an VP44 overflow valve problem would adversely affect lift pump pressure? Also, if there is a restriction in the fuel supply anywhere in the lift pump circuit (especially the suction side), then unpredictable fuel pressure could be expected. What it the GPH rating on your lift pump? John2 points

-

New Kicker Speakers for Beast!

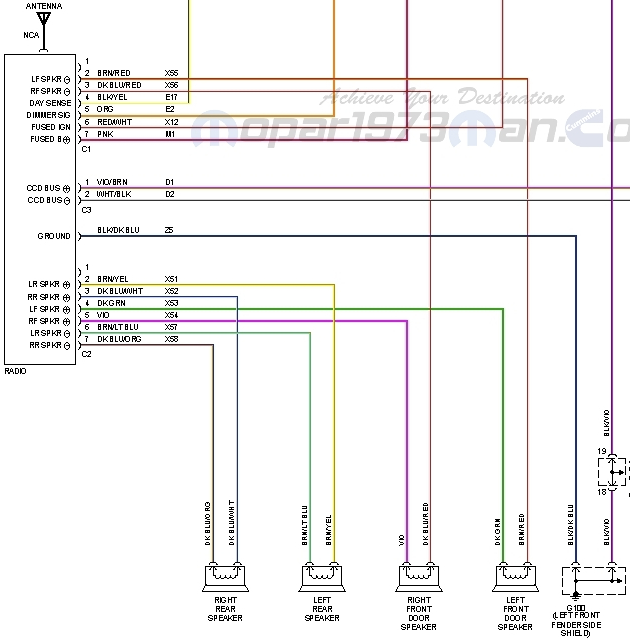

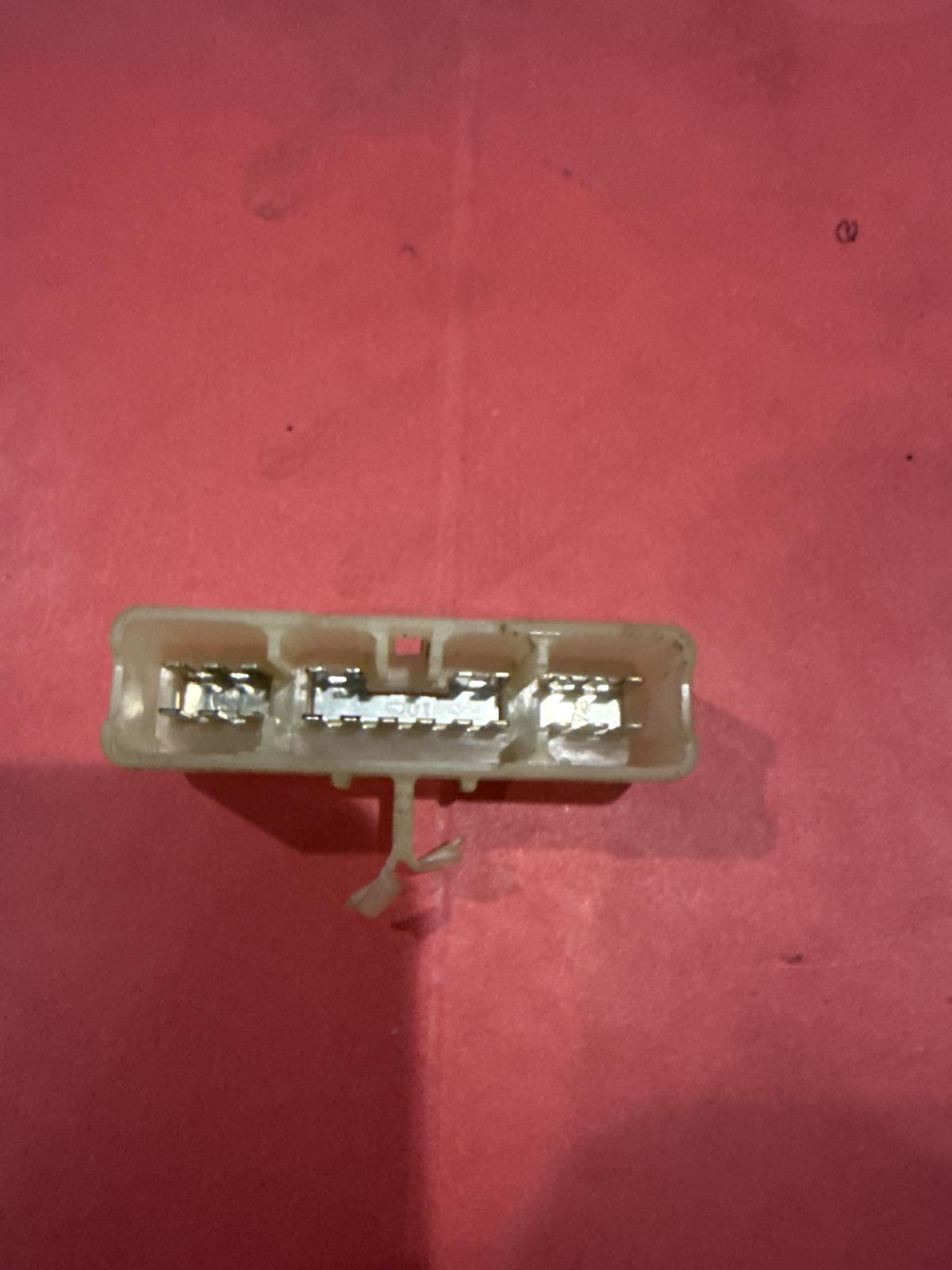

2 pointsYup after all the years and miles driven I've had a bad speaker on the passenger side. @Tweety Bird said, "Get this fixed! Time to get new speakers in Beast!" @Tweety Bird and I went to a stereo shop in Lewiston ID to look at speakers and prices. Great quality is really pricey say like $350 for a pair of speakers that really sound rich in frequency. Being budget mined I jumped over to Amazon and found. Kicker Dodge Ram Truck 1994-2011 Speaker Bundle - CS 6x9 coaxial Speakers, and CS 5.25" coaxial Speakers. Yeah Dodge and there strange wiring schemes. I'll list out the positive and negative wiring for each speaker. You can see I cut the factory OEM speaker plug off and wired in the new blade style terminals. Be aware of the polarity of each wire and speaker lug. In this set, the Kicker makes the ground with a black strip, and the positive lug is marked red. Left Front + Dark / Green Left Front - Brown / Red Right Front + Violet Right Front - Dark Blue / Red Left Rear + Brown / Yellow Left Rear - Brown / Light Blue Right Rear + Dark Blue / Orange Right Rear - Dark Blue / White2 points

-

Fuel psi problems

2 points@Tractorman Those o-rings are square cut and you would need to order from Cummins for replacement. Might be a good idea.2 points

-

Fuel psi problems

2 pointsOn my truck the tee at the back of the head started to leak fuel about 15,000 miles ago (at 390,000 miles). At the time I had the transmission out while doing a clutch job and I noticed the leak. The connections were loose, so I just tightened the them from below. They have never leaked since. A leaking tee fitting (even if it's only leaking air) can cause long cranking times, but it will not affect fuel pressure after the engine is running - so, not likely to be your problem. I haven't tried accessing the tee fitting from the top of the engine. I would probably remove the valve cover and use a mirror to inspect the connections and then blindly reach around the back of the head to tighten them. John2 points

-

Heat exchanger

2 pointsThe factory heat exchanger not only cools transmission fluid, but all so heats the fluid to operating temperature in cold weather. With the average winter low temperature of 9°F in your area it would be prudent to retain the heat exchanger for winter drivability.2 points

-

Axle delete kits

1 pointAwesome! Thank you much. It will be a bit till I get there, so I might have questions down the road. Excellent write up!1 point

-

Current & upcoming website policy changes, a must-read!

Hello everyone!! Our progress with all the adversity that smacked us 😲 during 2025 has been gradually getting better. I have been out of the scene due to all the tasks demanding my attention. But...back to concentrating on the responsibility of this website to make it better with some basic housekkeeping. We plan to work on several areas of the website this year. I, myself, will be dealing with one huge undertaking...reviewing the Articles to improve the verbiage in effort to provide clarity or revise the content, of course, with the assistance of the infamously knowledgeable Mopar1973man!! (so many of them! 😳 Yikes!) Gotta get rid of those virtual cobwebs 🕷️😂 So...keep checking the updates or look at my progress notifications. I will notify when I have completed each area...so be patient as I work on them.1 point

-

Heat exchanger

1 pointOver the past 15 months I have just about completely rebuilt everything on my 2003 Dodge Ram 2500 and the one place which provided me with all the information I needed to solve problems, such as your 48RE failing mysteriously with no warning signs to direct you in fixing it, is the Cummins Forum website -- (39) 03-07 Powertrain | Cummins Diesel Forum There are some very good experienced highly skilled members there who know the 48RE inside and out and I am quite sure they will point you in the right direction. There are many good posts provided on the 48RE. And perhaps the owner of this website will provide excellent advice as well. I have learned a great deal of essential information here such as fixing my torque converter cycling problem using his info and links to other sources which provided exactly what I needed.1 point

-

Heat exchanger

1 pointI have my 48RE built heavy duty at a local shop which specializes in 48REs which cost about $6K and is now capable of towing the truck's maximum weight and also can handle 1000 hp. However, my truck will never have more than 650 hp, if that. The 48RE when built correctly addressing all known weaknesses is an excellent transmission. I added a Full Send Diesel trans cooler unit which keeps the fluid temps in the 120-140 degree range.1 point

-

Axle delete kits

1 point@Mopar1973Man , the article is done. It is awaiting your approval. John https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation/transmission-transfer-case/low-range-2wd-cad-conversion-r758/1 point

-

Transmission Article - Low Range 2WD CAD Conversion

For those who own trucks with a CAD (center axle disconnect) front axle, this article will explain the benefits of remotely controlling the CAD operation and will also provide information on how to make the modification. For those who are not familiar with a front axle CAD unit, the following description may help. OEM vehicle - manually shifted transfer case (with CAD) - Theory of Operation The CAD front axle has three axle shafts - a driver side axle shaft, a passenger side axle shaft, and a short center axle shaft. The passenger side axle shaft and the center axle shaft can be connected or disconnected by the CAD unit. The center axle shaft is called the intermediate axle shaft in the photo below. The CAD unit is a vacuum motor that controls a splined sliding collar to lock the right axle shaft to the center axle shaft. There is a switch at the end of the CAD unit that allows illumination of the 4WD indicator lamp in the dash. 2WD Selected - front driveshaft does not rotate and CAD is disconnected. This feature minimizes front axle friction at highway speeds. 4WD HI Select on-the-fly - As the transfer case shifter is being pulled into the 4-HI position, a synchronizer in the transfer case brings the front driveshaft up to speed. As the shift is completed, a vacuum valve inside the transfer case actuates the front axle CAD unit and locks the passenger side axle shaft directly to the center axle shaft. 4WD indicator lamp is illuminated. 4WD LO Select - Vehicle must be stopped. Select 4WD LO. 4WD indicator lamp is illuminated. Something worthy of noting - when 2WD is selected, the front drive shaft stops rotating, the left and right axle shafts are still rotating (driven by the wheels), and the center axle shaft is still rotating, BUT in the opposite direction (because of the differential). This is the reason that when 4WD Hi is selected, the synchronizer in the transfer case brings the front driveshaft up to speed first. When the front driveshaft is brought up to speed first, then all three front axle shafts are rotating at the same speed and in the same direction. Now the CAD unit can connect the passenger side axle shaft to the center axle shaft. 2WD-LO Conversion (parts needed) Toggle switch - two position maintained switch with physical lockout Humphrey 4 way / 2 position, 1/8" NPT, spring offset, vacuum solenoid valve Model 410/12 VDC Appropriate length of vacuum tubing and 16 gauge automotive wire and wire connectors. This conversion separates the operation of the transfer case manual shifter and the CAD vacuum controlled shifter. The external vacuum ports of the vacuum valve (inside the transfer case) will be disconnected and plugged. A new vacuum solenoid valve for the CAD unit operation will be installed in a location of choice. A fused switch will be installed to operate the new CAD vacuum solenoid valve. A vacuum supply line will be routed to the CAD vacuum solenoid valve. Two vacuum lines will be installed to connect the new CAD vacuum solenoid valve to the CAD unit. Instructions for operating the new conversion are as follows: 2WD High - The transfer case selector must be in 2WD and the CAD switch must be turned off and locked out. 4WD High - Vehicle must be stopped. The CAD switch must be turned on. The 4WD indicator lamp will illuminate (truck may have to be moved slightly to engage 4WD lamp). From this point forward the transfer case can be shifted from 2WD to 4WD or 4WD to 2WD on-the-fly. 2WD Low - Vehicle must be stopped. Shift transfer case into Low Range. Leave the CAD switch turned off and locked out. The 4WD lamp will not illuminate. 4WD Low - Vehicle must be stopped. Shift transfer case into Low Range. Turn on CAD switch. The 4WD lamp will illuminate (truck may have to be moved slightly to engage 4WD lamp). Tips The 2WD Low Range can be very useful, especially for backing trailers in tight spaces, whether loaded or not. This is true for manual and automatic transmissions. You can basically idle the rig while backing very slowly in tight turns without the wheel hop associated with 4WD. Also, when traveling off-road on very steep and twisty terrain with varying traction conditions in low range, you can shift from 2WD to 4WD or 4WD to 2WD on-the-fly. Just leave the transfer case in 4WD and operate the CAD switch - "Off" for 2WD, "On" for 4WD. Always unload the engine (ease up on the throttle) when making the changes to allow the CAD unit to slide the shift collar easily. The CAD switch has a physical lockout to reduce the chance of accidental operation. When the switch not going to be used, always engage the lockout with the switch in the "Off" position. Enjoy the conversion! View full Cummins article1 point

-

Pilothouse/RAM3500 build

1 point

-

Axle delete kits

1 pointPersonally, I would keep the CAD unit in place. I did so and turned it into a 2WD / 4LO truck - very beneficial for slowly backing heavy loads in tight areas. I purchased and installed a vacuum solenoid valve and a toggle switch with a lockout (switch shown below). I bought my truck new and did this conversion over 20 years ago and over 300,000 miles ago. It has never failed and the 4WD indicator lamp works as it should. John1 point

-

Wiring gremlins on an 2002

1 pointPlug condition is good, I just had the two swapped mistakenly, caused back feed issues as the wire connector paths are different. I did use dialectic grease before putting the dash back in, thank you for the advice though1 point

-

Wiring gremlins on an 2002

1 pointWhat is the condition of the pins in the other plug by chance? Any oxidation of the connector? Might be an idea to use some dielectric grease to help keep the dampness of the cab in the winter months from affecting the ground connection from oxidation of the pins.1 point

-

Wiring gremlins on an 2002

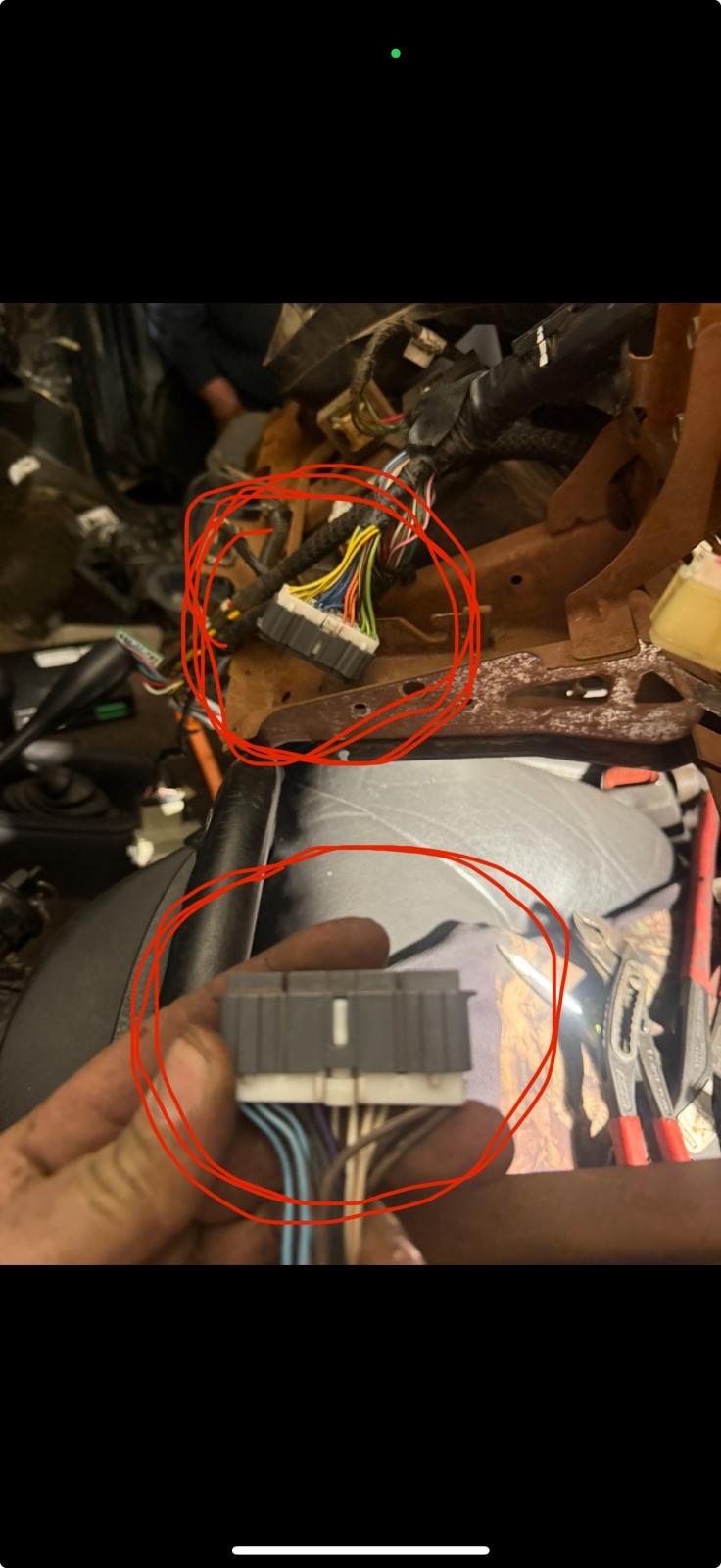

1 point1 point

- Wiring gremlins on an 2002

1 pointWelp I figured it out. I accidentally swapped the common ground plugs/junction connectors behind the dash. Added pictures and circled.1 point- Wiring gremlins on an 2002

1 pointWow! I have to commend your perseverance to get as far as you have. Good description of your issue. I don't have much offer at the moment. I think you may be right in regarding a previous owner thinking there was a dash wiring problem. Electrical ground problems, back feeding problems, and short circuit problems can be some of the most challenging electrical issues to solve. I think I would put my first focus on finding what is causing the 15 amp park lighting circuit fuse to blow under certain circumstances. You find that, then maybe everything else will fall into place. Also, I would look for any evidence of other accessories (especially lighting) that may have been wired by a previous owner. Do you have a wiring diagram to work from? John1 point- Pilothouse/RAM3500 build

1 point- Fuel psi problems

1 pointIt will give you time to clear your mind and come up with a good diagnostic approach. Possible issues to keep in mind: intermittent fuel supply blockage, especially suction side of lift pump large amount of air in fuel system (not likely) intermittent power to lift pump faulty lift pump (pressure regulator issue) When things get difficult to diagnose for me, I change tactics and try to prove what is working CORRECTLY, not what is working INCORRECTLY - a process of elimination. This method will sometimes get the issue resolved sooner than focusing on things that one might think is wrong. John1 point- Fuel psi problems

1 pointThen 2 things. Quadzilla only programs a running truck. There is the ability to see live data that's about it. OBDII code reader like OBDLink MX would be a good option.1 point- Fuel psi problems

1 pointSo the pop off fuel from all 6 injectors will bleed off inside the rail in the head that exits the head at the rear of the engine. Then the second line is the return of the VP44 which is the second line to return to the tank. This is what the square cuts o-ring will seal at the rear of the head. I'm talking the return of either of a FASS or AirDog fuel systems use a check ball and spring to control fuel pressure and flow back to the tank for seperating the air bubbles and fuel excess return is on this line. The fitting in the pump will have a black plastic check ball and a spring.1 point- Fuel psi problems

1 pointActually, you can open this up. The return line to the filler neck to the tank is the fitting you remove, and behind that is a spring and check ball. Just be aware the check ball is plastic and could wedge it way down in the coils of the spring. This is why the sudden change in fuel pressure and then later it pops back up when the vibration shakes it loose again. Here is my new spring for Thor. Yes, you are correct, those square cut o-rings are for the return tee in the rear of the engine on the driver side.1 point- Fuel psi problems

1 pointYou could just disconnect the fuel pump relay to test a warm start condition. Rig up a jumper wire to hold in your hand while you start the truck - that way you can control when the lift pump runs (or doesn't run) for your test. At least, it would let you know if too high lift pump pressure is causing your long crank on a warm start. John1 point- Mr. And Mrs. Michael S. Nelson has occured!

Congrats, may you both have many years of harmony together as you rebuild life the way you prefer it to be. Stay Strong.1 point- Heat exchanger

1 pointYeah, up here in Idaho, we see upwards of -20℉. Automatics up here are rather rare, and manuals are more typical. The guys here are right that you should consider keeping the factory transmission fluid cooler or replacing it with a more modern transmission cooler in its place. The factory cooler has issues with rusting and leaks over time.1 point- Understanding stock Quadzilla

1 pointI typically drive on level 3. I'm not fond of many of the tunes I've seen, as they tend to ramp up aggressive amounts of fuel way too early and try to push the power out. My tuning aspect is more built around daily drivers, milder fuel curves, and main power is up above the 10 PSI or 15 PSI realm, nothing below that.1 point- Pilothouse/RAM3500 build

1 pointMeh, while my hours available in the shop will decrease, the nice bump in pay makes it worth it. Ill just not be able to putz as much as I have been. All in all it was a good "bad" thing.1 point- Fuel psi problems

1 pointThe tech is probably referring to the 14 psi overflow valve in the VP44 injection pump. This pressure control valve is very reliable and I am almost certain it is not your problem. People have replaced this valve because of not understanding how the fuel system works, and then found after replacement, their symptoms didn't change. Even if the overflow valve failed (as in opening at a lower pressure), it would have little or no effect on lift pump pressure. All fuel that enters the VP44 must pass through in internal fixed displacement vane pump. This pump is regulated at 100 - 300 psi depending on engine rpm and engine load. Because the internal vane pump is fixed displacement, additional fuel cannot be forced through it regardless of lift pump pressure. Both Airdog and FASS lift pumps use a ball and spring check valve to regulate fuel pressure by recirculating any fuel that is not being used by the injectors and the VP44 cooling system. If the lift pumps are high volume pumps (which yours probably is), then a lot of fuel has to recirculate, in fact more fuel recirculates than gets used. The pressure control valves on these lift pumps are usually not of high quality and the ball and seat can take a beating, which can cause symptoms that you are experiencing. I am surprised that the Tech didn't mention this. I would be looking at two possibilities for low / erratic lift pump pressure. Check the condition of the ball, spring, and seat in the lift pump. Check for any restriction / leaks in the low pressure fuel supply. Pay special attention to the suction fuel lines from inside the fuel tank to the lift pump. Many people that have observed erratic lift pump pressure have stretched the spring in the lift pump's pressure regulating valve for a bit more tension. For some it gave desired results. John1 point- Fuel psi problems

1 pointI believe you're experiencing a suction side air leak. Double-check the suction line side fittings, make sure they are snug and clean in the fittings. Let me know what type of hardware you're using. The other part could be that you have a return line leak? Like, possibly a crossover o-ring issue or maybe injector o-ting. Sounds weird, but I've done a head gasket after the head came back, cleaned the baked injector o-rings would weep air in, allowing the system to drain, making a hard start. I've see nthis with crossover tube o-rings as well. Make sure to double-check the return tee in the rear of the engine; it might be weeping air into the system while parked.1 point- Understanding stock Quadzilla

1 pointTJ at 1badvp44 does good work. I had him write me a street tune just before my quad and ecm committed suicide. The truck ran much better than with any tune I had written.1 point- Suspension fun!

1 pointIt’s time to “spring” into action! 8 leaf 4000 lb pack 2 leaf 1150 lb overloads New shackles (All from Rockauto) I used 4” blocks from ProForm Fabrication (they’re also tapered to get the pinion angle straight too). I didn’t want the *** end to sit up super duper high so to compensate for the thicker pack I used slightly shorter blocks (my oem blocks are 4.5” tall). Old leaf pack is 2” thick and the new ones are 3-9/16“. The bolt by the fuel tank is not really an issue. Just cut it off flush with the hanger and you can drive it all the way in without hitting the tank. You can fish it out with a magnet and then put the new bolt in from the outside. I used locally made 5/8” ubolts and my old Barnes4wd top plates to keep the flip. For the eyelets I used 5/8”x 5” fine thread bolts with stover nuts. Removed the old bump stops since they do nothing now. My truck is a 2001, so it’s time for new springs. I can’t use airbags because unless it’s the c&c kit my gooseneck hitch interferes with the mounting plates. Also the c&c kit sits on the oem block pedestals and I don’t have those anymore now. Next up: Rebuilt NV5600 & clutch from LRG. Enjoy!1 point- New Kicker Speakers for Beast!

1 pointSame speakers I put in my truck three years ago. They sound all right. My son says I should put a small base thumper under the seat so that I can "feel the music". Just what I need to go deaf faster.1 point- Suspension fun!

1 pointI have the 6 spd so I’m not changing anything that way. I’m buying a new 3 axle toyhauler that’s about 44’ long and 16k lbs. I’m gonna buy some extended Synergy rear sway bar links and the Timbrens as well just to make it as bullet proof as possible. I actually ended up reusing the oem blocks so I could use Timbrens, the taper is too excessive and no matter how you install it the pinion angle is too far off. That’s a mistake on my end I though it would correct this. The oem blocks made everything perfect again. Most likely crack the frame but the springs should be fine :)1 point- Suspension fun!

1 pointHave you had a chance to tow something yet? Or are you waiting to do the trans first? A few years ago I took off my rear sway bar. To soften the suspension a bit. With my 6,000lbs travel trailer it was fine. A year a go we picked up an 8,500 dry fifth wheel. Climbing the grapevine with a little wind was not fun. Had to cruise at 35-40 mph. Not saying I could have kept going at 55 mph+ with the rear sway bar but I’m sure it definitely would have helped stabilize the load. A couple months ago I replaced the end links and bushings on both front and rear. I do have Timbrens on as well back when I took the rear bar off. . Just wondering if I need to replace my rear springs and bushings to eventually. Truck has 298,000 miles on the clock. You know just barely broke in. 😎1 point- Heat exchanger

1 pointI recommend keeping the heat exchanger but replace the OEM unit with the one Full Send Diesel designed, which is an all-billet solid unit with two totally separate areas which cannot rupture and cause crossover contamination between the coolant and the trans fluid. These units also cooler far more efficiently due to being solid billet design. Combine this unit with their heavy duty high flow transmission cooler and your transmission will remain cool even in the most extreme conditions. My coolant temps with sensor in the deep pan never gets above 150 degree in the month of August in Florida.1 point- Mr. And Mrs. Michael S. Nelson has occured!

Funny part of this marriage. I had to have the cancer and the ostomy bag to meet Suzanna, my wife. If I'd been a healthy person, I'd never have met her. She enjoys the thought that I dealt with my depression with makeup artistry and cosplay. This helped me deal with the health crisis (bladder cancer and chemo treatments) I was dealing with at the time. I started making up artistry back in 2022 as a fun thing for the weekend. Now it's part of my daily dress code. Suzanna has enjoyed the interactions I get everywhere I go, hence why the photo above shows us both enjoying the makeup work, and will continue to grow together with our own art. The makeup artistry is what captured her eye that day, and why we are together. Being we both went through our own hell, we plan on holding the celebration next year in late spring or early summer. Hopefully, by July 25th 2026, we can be on top of Heaven's Gate, where you have to drive through Seven Devils Mountain to reach this mountain top.1 point- Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

After 18 years of interesting CTD enthusiasts and transmission specialty outlets all contributing their method, or fix, to the well known TC lock unlock syndrome, I can no longer remain silent. Extensive review of many posts regarding TC lock unlock, the rerouting methodes, the add on filters for APPS and last, but not least,...the "tin-foil hat" brigade. I do realize that each individual or company that contributed to the vast amount of information on the web had good intentions and I must acknowledge that some of the procedures caused me to closely examine what these people were trying to do. I believe it is well known that even a blind mouse occasionally finds a morsel of cheese. Again, as it is well known @Mopar1973Man was the only entity who positively identified the instigating source of this key issue. My entry today is not about alternators...it is about what Daimler/Chrysler did in regard to production of these Cummins powered platforms and the complete disregard of common sense Electronic Engineering. Please note, this applies to automatic and manual transmissions as each platform is plagued in the same manor with different quirks. This Blk/Tan #8 gage wire is quite critical in the scheme of things. It is contained within a 1" plastic conduit passing along the front of the engine. It contains water temp sensor leads, air conditioning leads, alternator/PCM leads and the #6 gage alternator charge line to the PDC. This #8 gage Blk/Tan passes over the top/backend of the alternator and is "eventually" connected to the Auxiliary Battery (passenger side) negative terminal. This snapshot of the Factory Service manual documents "four critical ground leads" that are "spliced" in an unconventional method. This photo depicts the three #18 gage wires and the single #14 gage wire entering the shrink-tubing where the "crush-splice" occurs. This bundle exits the large plastic conduit below the VP44 This again is a most disturbing depiction of the Daimler/Chrysler method of splicing critical ground leads and then routing this across the top of the alternator and "eventually" bringing this to ground reference. This photo depicts where this #8 gage Blk/Tan first connects on the way to "eventual" ground...yes this is the Auxiliary Battery tray connector. Please note: it is spliced again and joins the PCM circuit board grounds...which are critical in their own nature...and "eventually" terminate at the negative post of the Auxiliary Battery's negative terminal. This photo is very interesting, it is the Factory Service manual and the assembly line documentation follows this as a road map in the matrix during production. Please NOTE the title "NAME" to each battery...I looked at this for a considerable amount of time before I realized the assembly line coordinators tried to work with the documentation from the Engineering Staff to "make it as it looks"...Could this single oversight be the reason of a four foot ten inch critical ground wire combination traveling the distance to "EVENTUALLY" terminate at ground? From a basic engineering standpoint regarding ground...you "NEVER CHOOSE THE PATH OF EVENTUAL GROUND" !!! It is to be the shortest and most concise connection in reference to ground...this is biblical in ALL ELECTRONICS...including pickup trucks. ! Here is the Factory Service manual documenting the PCM circuit board reference ground starting as a pair of #14 gage wires being spliced into a #10 gage bundle and arriving at the Auxiliary Battery through another connector that joins a #8 gage wire that is "splice-joined" under plastic conduit in a Y configuration joining the rouge #8 gage "after passing over the alternator" traversing the entire engine compartment from the driver side of the vehicle. Seriously I have been drinking excessively, most recently, due to the nature of this blatant discovery. This is the hidden Y splice at the Auxiliary Battery where the "mess" EVENTUALLY terminates for ground reference. This photo shows the correct "HOLE" of where to apply ground for the VP44, ECM and the PDC...note the logical location It took a little research to find the size and proper thread-pitch. Metric M5 with a 5/16" hex head is perfect This is where you apply a fresh "quality" #6 gage ground and terminate this at the Main Battery negative post on the drivers side for absolute ground reference for the VP44 and ECM This is a very short and concise reference to ground. This is the corrected procedure for a rather critical ground. The two largest wires originally contained within the 1 inch conduit are no longer present and located well away from the alternator. My alternator B+ "charge" line is now a #4 gage line directly connected to the Auxiliary Battery and when my new battery terminals arrive and they are secured, I'll provide photos of a completed Master Power Supply System within this engine bay. With these corrections, I would hypothesize that a poor ripple specification on a given alternator would be overcome by the immense capacitance of the parallel batteries and would become less prone to causing the dreaded TC lock/unlock for automatics and cruise-control abnormalities for the manual transmission platforms. The #8 gage Blk/Tan passing over the alternator as an "EVENTUAL" ground is gone...the PCM, ECM, VP44 and the PDC are now grounded in accordance of standard Electronic Engineering practices. Respectfully W-T1 point- Heat exchanger

1 pointCould a guy put a full flow directional valve in diverting the fluid either through the block mounted cooler during winter months and then shut the valve during summer months? Maybe run the summer hose circuit through a derale cooler with fan under the chassis?1 point- Heat exchanger

1 pointI would say keep it and replace the damage heat exchanger for the transmission.1 point- 2nd Gen CB/HAM Radio Installation

I don't do much on the forums anymore, but I thought somebody might benefit from documenting what I consider a proper radio installation for a 2nd generation Ram. Honestly it will probably be almost identical for any extended cab Ram. I purposely built this using materials anybody can get from the big box stores and truck stop radio supplies. Materials List: Qty 1: 3/4 in. x 36 in. Plain Steel Square Tube with 1/16 in. Thick Qty 1: 1 in. x 36 in. Plain Steel Flat Bar with 1/8 in. Thick Qty 1: 2 in. x 36 in. Plain Steel Flat Bar with 1/8 in. Thick Qty 1: 6 in. x 18 in. 16-Gauge Plain Steel Sheet Metal Qty 2: M8 1.25 20mm Bolt Qty 2: M8 1.25 Nut Qty 2: M8 Flat Washer Qty 2: 5/16 x 3/4" Bolt Qty 1: Wilson 305-830 18' Belden Coax Cable with PL-259/FME Connectors Qty 1: TruckSpec TS-101ADLN Thin Double Groove Mirror Mount with SO-239 Stud Connector Qty 1: 1/4" Split wire loom Qty 1: 3/8" Rubber Insulated Metal Clamp Qty 1: 6" Zip Tie (yes only one) Qty 1: #8 x 3/4" Phillips Washer HD Tapping Screw Balkamp 665-2837 Qty 1: FireStik K-1A Push-n-Twist quick disconnect (this is required) Starting with the antenna: 3' Firestik II Looking down the stake pocket: What the antenna mount looks like. You will be tempted to buy the larger four bolt mount. Don't as you can not get it in the pocket. Even this little guy takes some fiddling to get it down there. In the item list are two 5/6" bolts. This is part of the trick getting everything to fit. Separate the clamp, then you have to tap the antenna side holes to accept the 5/16" bolt. This serves two purposes. 1. You have zero chance of getting a nut on a bolt inside the stake pocket. 2. It reduces the possibility of hardware physically interfering with the coax. Things are tight in there. To make this work you have to assemble the now threaded mount, the firestik quick connect and the coax in one shot. Anything that has to be tightened to the mount must be done so prior to dropping it into the stake pocket. Here comes the painful part. Drilling holes. These are the very first holes I have ever drilled in this truck. Antennas are about the only reason I will punch a hole in a vehicle. Per the picture you can see I used the outer clamp from the bracket. This serves a couple purposes. 1. Expands the clamping area to provide better support for the mast and reducing the possibility of metal fatigue. If you don't have a bed liner grounding will also be improved. 2. It acts as a spacer to keeping the bolt protrusion to a minimum. Use a step drill bit anytime you are drilling sheet metal. Much cleaner holes. The holes are over sized in the bed to provide adjust-ability to aid vertical antenna placement. Drill the top hole first. Attach the bolt and clamp on the inside of the bed. Use that to locate where the bottom hole should be located. Then drill the bottom hole. Now we have to think about coax routing. You will be tempted to route the coax through the oval opening to the outside of the bed. This could be done, but I don't recommend it. At least not using the coax I identified in the material list. It is good coax, and has a really good strain relief boot for the antenna end. It doesn't want to make that initial turn easily. You might consider a 90 degree connector except you can not get the coax, connector and the mount installed and slid into the pocket. My solution? Another hole... and you already know I don't take that lightly. BUT... there is one upside. If you set your mount at the same height or even a little lower as I did that heavy duty boot on the coax slides right into that hole. You will also notice some discoloration around the bottom of the stake pocket. That is a white paint marker. Every hole gets deburred and paint applied. I got to the bottom of that stake pocket blind since I'm not a contortionist and have a fat head. The end result is a nice straight coax run. So I'm up to three holes so far. What's one more between friends... Cables should be secure. If left to flop around at best they break. At worst (in my opinion) they chafe on body structures eventually removing paint and then promoting corrosion. Drill a hole for the cable clamp. Secure with a nice #8 body screw. That is the last hole for this project. (I lied, there are two more) Picture shows the transission from the bed to the cab. Nice gentle loops were made. The split loom stays static allowing the coax to move within it, but the coax will not be moving. Pic at the very back of the cab. Route coax through support structure. Add split loom Picture of the coax routed through the very front cab support brace before it makes a turn to head up towards the entry point in the A pillar. Add a zip tie to the emergency brake cable. Picture of the coax exiting the front support brace and making the turn up towards the entry in the A pillar. Single piece of split loom is used here all the way up to the entry point. Trying to get a good shot of where it enters the cab is challenging. But there is a body plug below the the main door wire harness. The plug can be easily accessed by removing the interior kick panel cover. Highly recommend using a 5/16" hollow punch to make the hole in the body plug. This makes a clean tight hole for the coax to run through. Picture of the coax finally making its way into the cab. Not pictured, but add split loom where it will be pressed against the notch in the sheet metal. I added it until it met the carpet. makes it look a little more factory. From there route the coax to the interior side of the emergency brake cable under the carpet. Continue keeping the coax to the interior side of the factory wire loom. Pictured is where the coax runs back to about the center of the front seat and makes its turn for the center of the truck. Picture of coax exiting under the drivers seat with the factory wiring, and my sub-woofer speaker wire. Finally here is the end of the run. Run the wire under the center section of the drivers side seat frame then you are ready to terminate on the radio. Routing the coax this way eliminated sharp bends. It is secure. Best of all it uses all 18' of coax. No excess coils tucked away somewhere. So at this point you saw a glimpse of the radio mount. Here is a better shot. Unfortunately I misplaced the pictures of the mount before it was installed. Here is a shot from the passenger side. On both seat mounts there are two holes in the inboard rails. On my passenger seat there is an existing bar tying the inboard and outboard rails together. I utilized the factory hardware to attach the 1" vertical flat bar. I removed that cross bar so I could use a transfer punch to get the hole locations in the 1" flat bar. You could just as easily hold the bar in place and mark from the rear with a sharpie. Now onto the radio mount plate. This is also where customization occurs depending on personal preferences radios, etc. My design allows for this. You will notice I used three bolts to secure the 16ga sheet metal. The idea is most anybody I know whom is into radios change them out frequently. Using a mechanical fastner here allows different plates to be made for any radio or preference. The plate can even remain with the radio since the bolts are spaced one inch from the edge and one in the center. No trial fitments for new plates. Radio mount bracket. You might be tempted to try and bend the flat bar to the desired dimensions. Unless you do that for a living don't even try it. Using the 2" flat bar I cut the tabs to the desired height, and the base to the desired width. I drilled the tab mount holes. Then I silver soldered them together. Yeah everything you see that doesn't have a visible fastener was silver soldered. It was kind of fun going that route. Don't like how a tab sits? Made a bad measurement? Little bit of heat and you take it off and make another. Something not quite straight, or maybe you want to angle the radio more than you thought. Little heat, and re-position. I have access to MIG and TIG, and can tell you silver soldering is a pretty good route to fabricate with. So the bracket is all 2" flat bar. That gets built as a unit. then I silver soldered that to the 16ga sheet metal. I placed a small bend in the sheet metal where they join. I did this to place the radio within easy reach (my hand almost falls right on it). It also improves the readability of the display. I debate on if I put enough angle on it, but I will probably leave it as is. For the grand finale? I mounted a remote speaker under the passenger seat. I cut a section of the 3/4" square tube long enough to match the speaker mount. The tube fits inside the brace U channel providing a square surface for the speaker mount to attach to. I decided to attach the square tube with 1/8" steel pop rivets. Drill the brace from the rear in order to hit the center of the rib. In the picture you can tell the right rivet head was peened. In the end both were peened and then painted. I wanted a smooth fastener so passengers couldn't catch a finger on a screw or bolt head. Well maybe a few more parting shots. 73 Everybody.1 point- Pilothouse/RAM3500 build

0 points"Tanks" will live under the bed between the running boards and rear wheels. I approved the color so he can start final sand and get it on parts. I'm guessing 1 to 1.5 years yet till on the road. Life has changed, Cummins is exiting the hydrogen markets and my division was nuked, as was my job. I did find a new job already, but my hours won't be as kind to personal time, so things will get slower.0 pointsThis leaderboard is set to Boise/GMT-07:00 - Wiring gremlins on an 2002