Leaderboard

-

- All areas

- Events

- Event Comments

- Files

- File Comments

- File Reviews

- Images

- Image Comments

- Image Reviews

- Albums

- Album Comments

- Album Reviews

- Blog Entries

- Blog Comments

- Cummins Articles

- Cummins Article Comments

- Cummins Article Reviews

- Vendors

- Vendor Comments

- Vendor Reviews

- Ads

- Ad Comments

- Ad Reviews

- Policies

- Policy Comments

- Topics

- Posts

-

-

Tractorman

Yearly Subscription80Points1,543Posts -

Mace

Monthly Subscription37Points67Posts -

Sycostang67

Monthly Subscription27Points614Posts -

PilotHouse2500

Yearly Subscription21Points445Posts

Popular Content

Showing content with the highest reputation since 01/24/2025 in all areas

-

Subscription

6 pointsWelp, just ponied up for another year, and I've got to say that this one of the better expenses that I have. The amount of technical knowledge, experience, and willingness to share is outstanding and needs to be supported. For those of you who use this site for information and advise (as I do) remember, it costs money to keep it up and running. Mike and his Mods aren't trying to make money, they're just trying to cover costs. For less than $10 bucks a month we can maintain this site, and continue to have access to one of, if not the best sites for our trucks. Remember, information not shared, is information lost. Mark6 points

-

Adding inline power steering filter with system flush update

On September 6, 2016, I wrote the article "Adding inline power steering filter with system flush" and posted it in 24 valve 2ed generation/Axles, Suspension & Brakes. This is the follow up to that article. Update...7/25/2025 It has been 8years 9months and 44,888 miles since I installed the Magnefine filter and flushed the power steering system, so it was time to flush the power steering fluid and replace the filter again. I used an oil syringe fluid evacuator pump this time to remove and refill the fluid at the power steering pump. The picture below shows the first time the fluid was removed from the system It took 5 remove, refill, and run engine for 4secounds to get the fluid to this clear color, about 2qts. Here is the filter cut open. It looks like the filter could last 60,000+ miles before changing. There was just a fine film on the magnet.4 points

-

ECM failure

4 pointsBig thanks to you for getting those computers back to me. Also, I messaged Mike on here this morning and he was a phone call away in no time helping me source this issue! That’s a community This is why I really enjoy this forum. In the beginning we had Dave Fritz/Dodgeram.org, now we have TDR (to some extent). Finally we have this place where all the mysteries have been solved. Don’t forget Mike as we discussed: You may perish of cancer but the forum lives forever, so you live forever!4 points

-

Subscription

4 pointsThank you for the wonderful comment. Truth yes it's still paying to keep the server alive and keep paying the bills. Remember Mopar1973Man.Com is the LAST PRIVATELY OWNED WEBSITE left. I'm not owned by a corporate clearing house like Cummins Forum which is owned by VerticalScope Inc. Or DieselBombers which is owned by Internet Brands. All these other websites are corporate owned groups.4 points

-

Electric vacuum pump

3 pointsElectric Vacuum Pump Conversion: I have deleted my OEM vacuum and power steering pump(s). Instead, I have modified it by replacing it with a midrange setup for steering assist; however, I still need vacuum in order to activate the HVAC controls and to activate my exhaust brake. Although the OEM factory pump never gave me any issues and supplied all the vacuum I needed to work, such as the HVAC and the exhaust brake, the OEM Power Steering did. I have replaced the OEM Power Steering Pump multiple times. In all cases, the pump would not maintain enough pressure and turning the wheels at a stop during idle was almost impossible. Compound that with the inevitable oil leak between both pumps, I figured there was a better system. So, this is where the "midrange" setup comes into play. The 24V ISB was used in multiple applications (not just Dodge). Even though they were not used in another pickup, they were used in midrange sized trucks like Freightliner FL60 &FL80, Ford 650 & 750, Kenworth 370, motor homes, bread trucks, etc, etc. It was the engine of its era. Trucks with vacuum controlled cruise should work also. This particular modification applies to my setup only; (the midrange setup for steering assist). My cruise is ECM controlled. I have the non CAD front axle, so my vacuum demand is limited. On SD applications, they use it to lock the front hubs and HVAC on their trucks. So I feel it should work on any of our vehicles. I used the same pump from the SuperDuty and 3rd Gen RAMS (same pump). I picked it up from Rock Auto along with a Mating Connector. I drilled 3 holes and mounted it on the fuse box cover, in an easy to service spot. For plumbing, it goes to a control manifold for the EB, and tees off into the OEM vacuum line on the firewall. I do not use a reservoir like FORD uses, but you could run one if you desire it. For power, it gets fused voltage from the PDC power stud, which is also the relay supply power (pin 30). The relay trigger is controlled by a fuse tap in one of the PDC fuses, that is hot only when the key is on, so it does not run all the time. The pump has an internal governor, so when it reaches its vacuum threshhold, it shuts off. If it is always running, you most likely have a leak that you need to repair first.3 points

-

Recent upgrade

3 pointsI thought I’d share my recent drivetrain upgrade I put in my 01’ 3500 (SRW converted) 6 spd. On transfer case side of things swapping a NP271D in is pretty common for a 2nd gen. I wanted to take it one step farther. It took some trial & error finding what parts will work and what doesn’t. It’s pretty much a modified Ford design. I found a used 08’ NP271D and rebuilt/modified it. Eliminated the leaky Dodge slip yoke tail housing and utilized the rear fixed flange yoke setup from a 06’ NP273F. I bought the rebuild kit, some updated parts & specific seal installers from TorqueKing4x4. I also installed the Ford style companion flange on my Dana 80 along with a new washer, nut & seal. ***Snap-On # M3586 is the correct thin walled 1-7/8” socket if you ever need it.*** Initially had a 5” aluminum driveshaft but the Sonax slip yoke kit is quite expensive so I had a 4” steel one locally made and upsized it to 1480 greasable ujoints (OEM are 1410). T/case fits perfectly. There’s 1/8” of clearance at the frame and no contact at bottom of cab. The 2nd Gen linkage rod (11”) is a tad short so even set at max travel the shifter will be off just a touch. So I replaced it with the 3rd Gen 16” one and now it’s perfect. I don’t have the cad Dana 60 so the momentary ball switch from the old NP241D-HD just swaps over to make the 4wd light come on. I have the LRG trans crossmember so I didn’t have any interference with the front driveshaft. APPS delete ✅ Midrange power steering ✅ Electric vacuum pump ✅ Next project: Dynatrac high pinion 35 spline Dana 60 3.73 gears with an electric locker… Enjoy!3 points

-

Flashing WTS light

3 pointsMike if you lived closer I would kiss you. I had to remove the t-case boot to replace some wires and left it in neutral. 🤦♂️3 points

-

Flashing WTS light

3 points

-

Flashing WTS light

3 pointsWell the news isn’t good, after talking with the folks at GoECM they have confirmed the processor is bad in my ECM and is not repairable. Thankfully they are applying my repair cost towards the purchase of a new(reman) unit. I would assume this may be why the ACS repair didn’t work. I don’t know enough about these things to know if they would have been able to test this in depth. Their cost was much cheaper than GoECM so I’m not going to say anything negative about them. According to the info ACS sent me it sounds like they tested and repaired the parts I knew weren’t working. I’ll update again when I receive the new ECM and get it installed.3 points

-

Flashing WTS light

3 pointsI hope they find what the problem is. Please let us know how it works out with this ECM repair shop so we can update the article "List of Verified and Reliable PCM/ECM Rebuilders" in the 24 Valve 2ed generation engine section.3 points

-

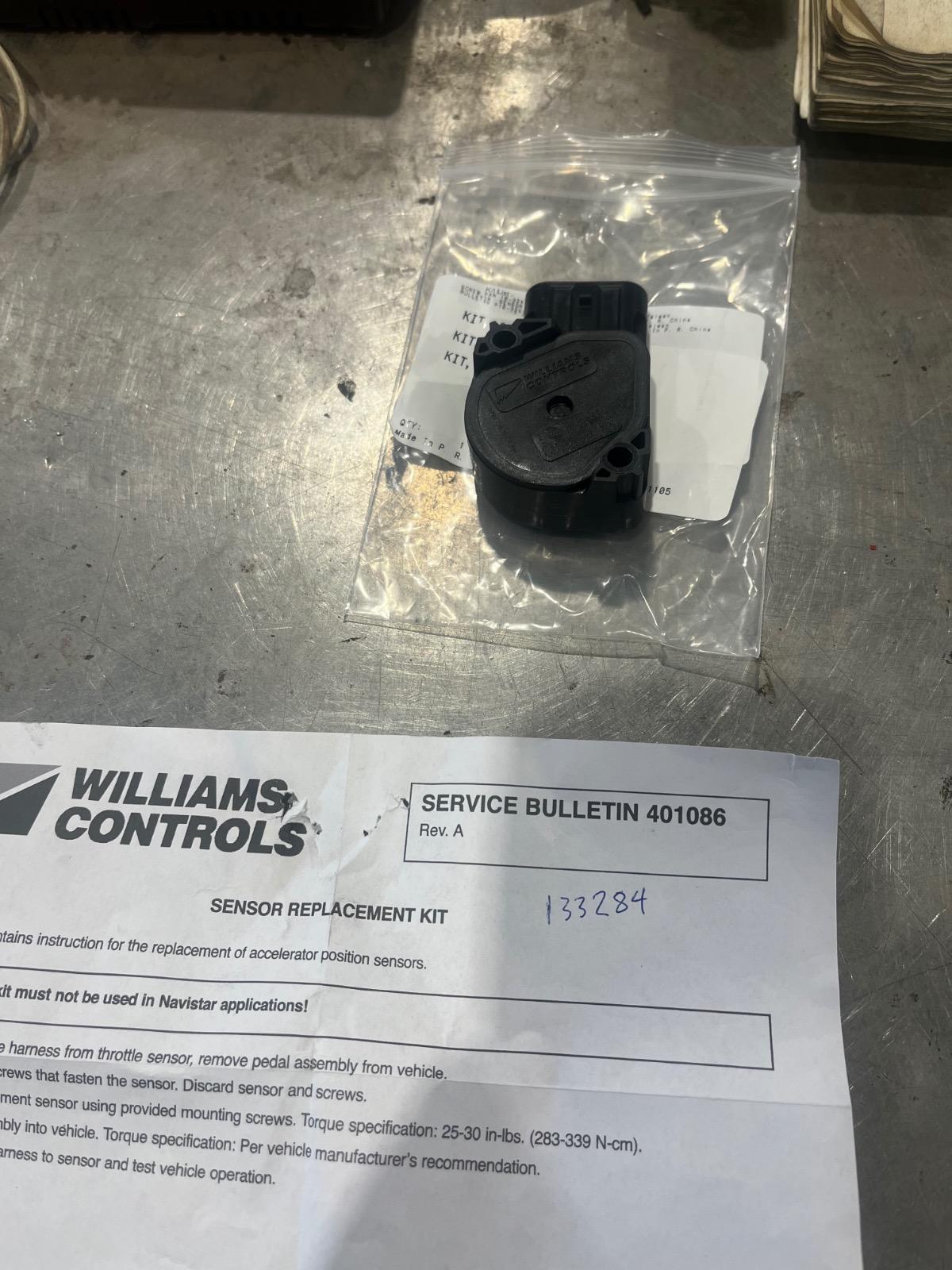

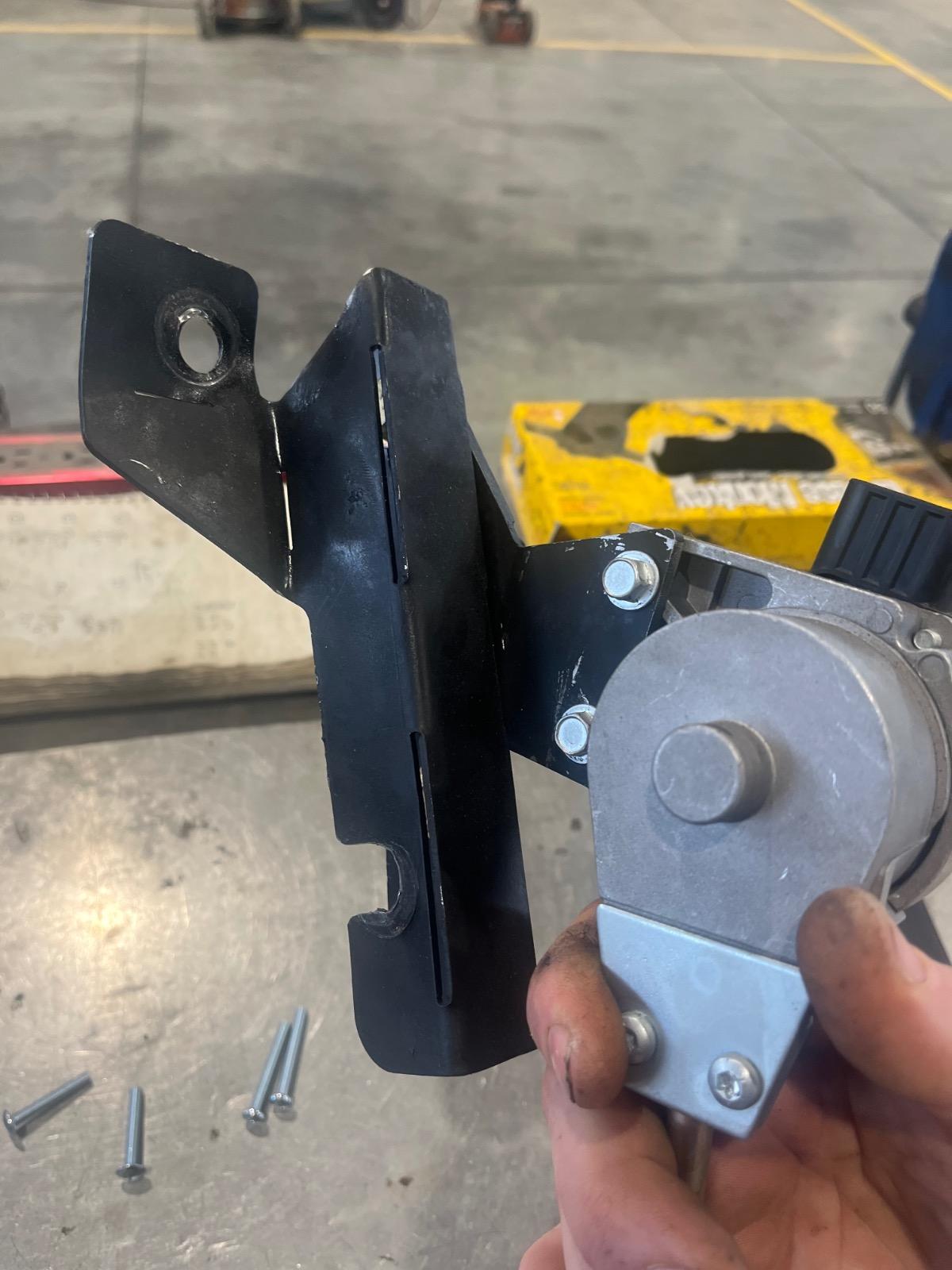

APPS relocation

3 pointsThis is a tech article regarding those who (like me) think the oem spot for the apps is not ideal. Exposed to outside elements, heat, vibration and potential corrosion, moving it inside was most practical. Non Dodge/ midrange applications of Cummins 5.9 24V ISB’s all have their TPS/APPS inside the cab, mounted on the pedal assembly. So nothing is changing on the apps operation, just moving it. This mod does not works on trucks that are auto/use vacuum for cruise. The auto trans kickdown cable is attached to the bellcrank assembly. As with the vacuum solenoid setup too so if you can live without them then it will work. Parts needed: 699-5101 pedal assembly (2x) 6 pin Duetsch connectors kits Zip ties Grommet 6’ of 6 wire harness Tools needed: Duetsch connector terminal pliers Wire strippers Making the mount will be up to you. I can show you pictures on how I made mine but it’s just a one off. Either way you need to mount it inside. First, disconnect the 6 pin Duetsch connector from the apps, remove the bellcrank assembly from the cylinder head. Cut off the cable and discard. The oem pedal assembly will need to be removed and the oem mount has a pivot pin on the bottom that’ll twist out with some channel lock pliers. Once you mount your new pedal to the mount and it’s installed all that is needed is how to control via ecm. So a 6 wire jumper harness is needed. I would HIGHLY recommend removing and tossing the apps that comes supplied with the new pedal and install your current one in its place. I can’t guarantee its quality. If you need an apps, a Williams Control 131973 or 133284 will work perfectly (Timbo is just a repackaged WC). Available from any oem truck dealer (I.e. Kenworth or Freightliner). On your engine side of your harness you need to make a 6 pin male Duetsch connector. Ensure you new connector kits have the locks in them, some kits do not come with them for some reason. YouTube or Google can provide a video on how to use Duetsch connector pliers, they’re super easy to use. Using the hole in firewall that the original pull cable went through install a grommet to prevent rubbing and feed your harness through. If you prefer to drill a hole the same size of the connector body you’ll need a 7/8” drill bit. **It’s easier to make the harness, THEN crimp the new terminals on after feeding it through the oem firewall hole for a cleaner look.** Cut your 6 wire harness to length and crimp on the terminals, install the connector body and plug it in. Theoretically the engine doesn’t know where the apps is so it will work. Make sure you mate up each wire in its proper spot on each connector, if you mess them up a CEL will come on/non functionality of the apps. Secure the harness to various points with zip ties so it’s rigid. This provides a clean look and more room in the engine compartment for future servicing. Start the engine and test. Throttle response should be crisp since there is no cable anymore that has slack as it wore.3 points

-

ECM failure

3 pointsWanted to show something here. Here’s the new APPS, number on it is 133284, same as the Timbo. Even though I ordered a 131973 this is what comes now. You can buy these at any truck dealership. Here’s a pic of my relocation bracket.3 points

-

Hello Everyone!

3 pointsI would like to introduce myself to all of you. I met Michael last July in Meridian, Idaho at a medical facility. He had a follow up appointment for his urostomy/ileostomy, while I was getting wound care treatment for my ankle. We briefly met at this place once before but had not been able to chat. On this particular July day, we had a few minutes to chat. As I learned more about Michael's life, I realized that he is an amazingly unique person with a kind heart and good old fashioned values. Upon listening to how he sacrificed on behalf of his mother's need for dialysis in the midst of dealing with his bladder cancer, I began to highly respect and admire this wonderful man. He genuinely cares for people. I knew he was amazingly unique...and I did NOT want to lose track of him. So...I asked for his phone number immediately after he was called in for his appointment. I wanted to know more about him. The crazy thing is that I was adamantly resolved to never get involved with another man at that time! However, we have NOT been apart for more than a few consecutive days since the time we met up at his house shortly after our encounter in Meridian! My interest grew even more when I learned he's a Diesel Mechanic. I was already familiar in auto mechanics, as my dad was an auto mechanic himself doing it as a hobby. I come with a small background in basic auto mechanics...my dad graciously taught me how to do a few maintenance repairs on my own car. To further expand my knowledge base, I have recently joined the Mopar1973man website as Michael's partner, another site administrator and his "soon to be" wife! Our plan is to get married this Spring! We have discussed a few exciting ideas that we would like to implement in the future. We are also working on improving this website for all of you. Be safe out there on those roads!! And...stay tuned!!3 points

-

47RE kicking out of O/D

3 pointsWT mod should be done in full first. I don’t have much troubleshooting experience with autos as I have the 6 spd but from what I understand a lot of issues are solved when the mod is done. At least you can rule that out.3 points

-

Help with Quadzilla 3 cylinder/6 cylinder box

We were right, the harness itself was wired incorrectly. IAT and ECT plugs reversed. New harness arrived and problem solved! 3 and 6 both work with correct values displayed.3 points

-

Driving with 5th gear removed

3 points@Mopar1973Man It looks like he has the updated main shaft already. I purchased several of my transmission parts from Allstate Gear online. The 5th gear nut I used was their "super nut" kit that cane in the master rebuild kit that I bought. I has to replace all 3 shafts, input shaft, counter shaft and the kit came with the full spline updated main shaft as well. My trans was trashed. The main shaft bearing in the front took a massive dump and trashed everything. Also, get a big torque wrench! As Mike mentioned, the 5th gear nut needs to be torqued to 300ft/lbs. DO NOT use a chisel and hammer and think it's good. It isnt. I post some pics of mine below. The carnage More carnage New input shaft and counter shaft New counter shaft in place, reused the small reverse idler. Case has been cleaned here also New main shaft installed, also replaced the tail housing with a cast iron piece. OEM was aluminum and had the mount holes hogged out of round. Now, the shift ring or collar that I have circled in this pic are important! I installed the ring backwards. If you look closely the ring is flat on one side and has a tapper on the other. The flat side has to go toward the large gear to the right as shown in the pic. Due to installing that ring backwards I do not have the use of 1st gear. I don't need it unless towing and I will pill it and make it right, just haven't yet. Hope all this helps!3 points

-

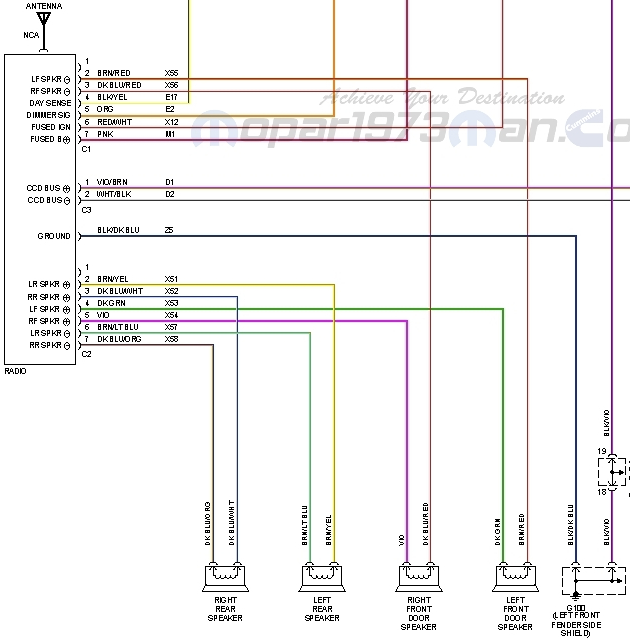

New Kicker Speakers for Beast!

2 pointsYup after all the years and miles driven I've had a bad speaker on the passenger side. @Tweety Bird said, "Get this fixed! Time to get new speakers in Beast!" @Tweety Bird and I went to a stereo shop in Lewiston ID to look at speakers and prices. Great quality is really pricey say like $350 for a pair of speakers that really sound rich in frequency. Being budget mined I jumped over to Amazon and found. Kicker Dodge Ram Truck 1994-2011 Speaker Bundle - CS 6x9 coaxial Speakers, and CS 5.25" coaxial Speakers. Yeah Dodge and there strange wiring schemes. I'll list out the positive and negative wiring for each speaker. You can see I cut the factory OEM speaker plug off and wired in the new blade style terminals. Be aware of the polarity of each wire and speaker lug. In this set, the Kicker makes the ground with a black strip, and the positive lug is marked red. Left Front + Dark / Green Left Front - Brown / Red Right Front + Violet Right Front - Dark Blue / Red Left Rear + Brown / Yellow Left Rear - Brown / Light Blue Right Rear + Dark Blue / Orange Right Rear - Dark Blue / White2 points

-

Fuel psi problems

2 points@Tractorman Those o-rings are square cut and you would need to order from Cummins for replacement. Might be a good idea.2 points

-

Fuel psi problems

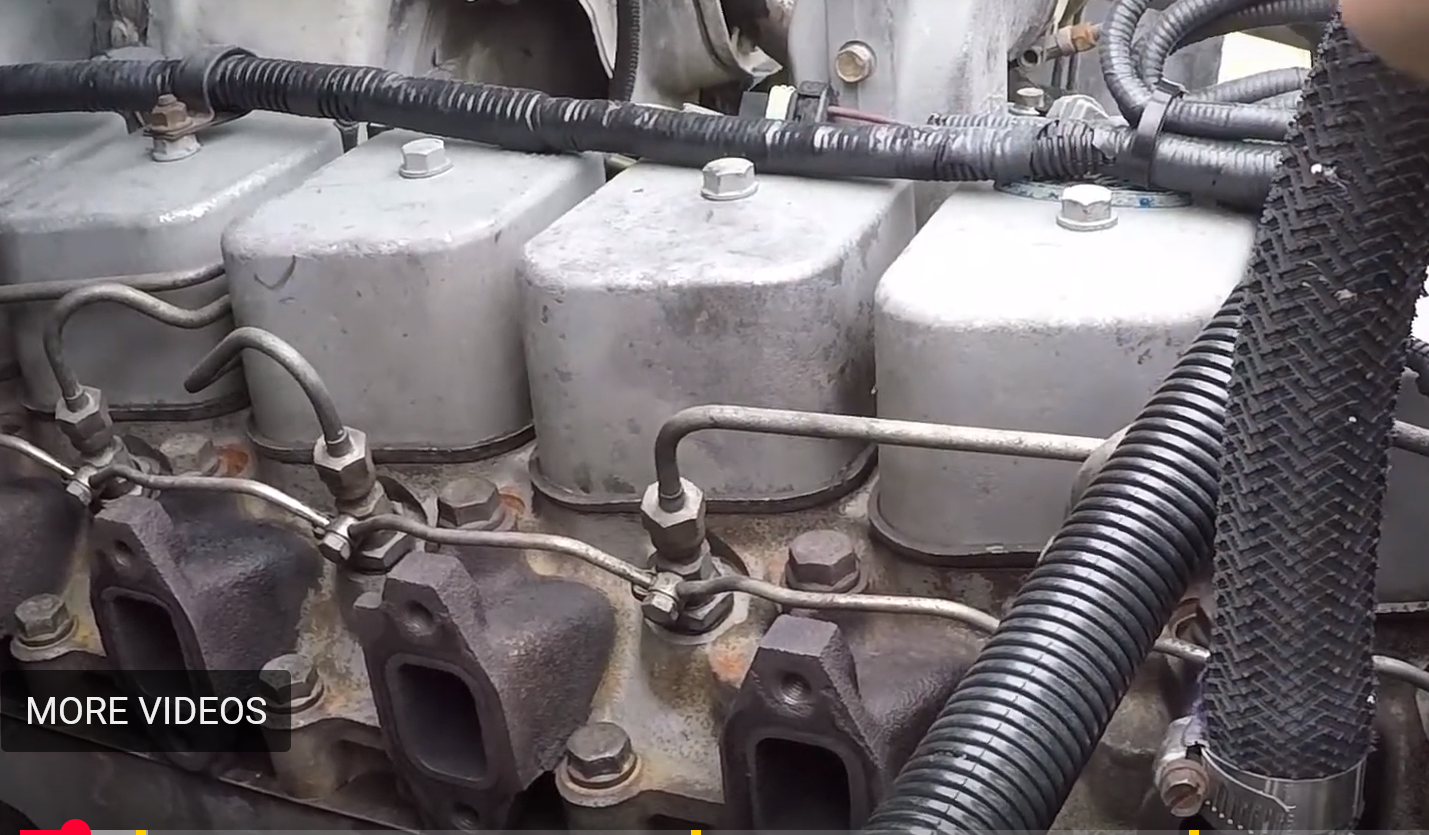

2 pointsOn my truck the tee at the back of the head started to leak fuel about 15,000 miles ago (at 390,000 miles). At the time I had the transmission out while doing a clutch job and I noticed the leak. The connections were loose, so I just tightened the them from below. They have never leaked since. A leaking tee fitting (even if it's only leaking air) can cause long cranking times, but it will not affect fuel pressure after the engine is running - so, not likely to be your problem. I haven't tried accessing the tee fitting from the top of the engine. I would probably remove the valve cover and use a mirror to inspect the connections and then blindly reach around the back of the head to tighten them. John2 points

-

48re won't move

2 pointsBut..., before you replace any parts - make sure the transfer case shifter is NOT in neutral. Just sayin'... John2 points

-

Electric vacuum pump

2 pointsHe removed both units and installed a gear driven power steering pump directly onto the accessory drive gearbox. He also installed a remote power steering pump reservoir. Here is a link to his original post regarding the conversion. You will need to scroll through the whole post as he talks of other conversions, as well. I made the same conversion myself - very happy with the results. It's nice having an accessible see-through reservoir. The direct mount power steering pump definitely out performs any of my previous pumps, including the OEM pump. John2 points

-

Flashing WTS light

2 pointsGlade to hear it. This means that GoECM fixed what ACS could not. A big plus for GoECM.2 points

-

Tracing disappearing oil

2 pointsas always, I get freaked out if my truck is "down" and opted for the fastest (most reliable) fix. This is why I try to be proactive about maintenance instead of reactive.2 points

-

Flashing WTS light

2 pointsAfter some thinking and talking to the wife, I’ve decided to send the ecm to someone else. I think the problem with ACS may be that their repair is based solely on the information I give them. The shop that fixed my turbos recommended a place they use out of Texas. I called them today and they test and check the entire unit. Just found out today my daughter can’t take drivers ed for a few more months so I’m gonna use the money we saved for that to get it done.2 points

-

Tracing disappearing oil

2 pointsSadly I have nothing to "work" it with... it is back to daily driver status... I may hook onto the trailer and go pickup some firewood but even that isn't "working" it like I KNOW the truck likes. :) and the NOT WET status inside and down stream from the turbo is what most perplexed me... I was expecting "wet" as well.2 points

-

Tracing disappearing oil

2 points:) only 300 miles so not really put it to a test yet.... but I haven't noticed any more peppiness. But you have to remember, my turbo was creating boost... just sending oil along with it.... so I am seeing the same boost levels.... I don't expect much to change minus not consuming oil.2 points

-

Tracing disappearing oil

2 pointsSO... new turbo installed, apparently (only a 100 miles in) I no longer am losing oil. A few things to note... NO ONE knows what the "w" is for on the HX35w, I"m calling it "W" for WING... because the HX35 has a bracket for the waste gate which won't work on our trucks... the true "W" does. After I ordered my Rotomaster Reman Stock Turbo 99-02 I did find some actual "W" turbos for less... but considering I had to send mine back for a core $560 was not bad...just knowing it was all American... $250 and not sending my core in would have been nice, I could have rebuilt it myself and had a backup for when the Chinesium turbo failed.... I did paint some items to match. Here are the photos. One of which was the OLD oil drain into the crank case... I THOUGHT the wastegate tubing was going to come in blue... so I'll replace it later. IT BLEW BLACK smoke the first 10 miles, I am pretty sure that was just getting rid of the soot that had built up in the tail pipe.. because after it ran clean.2 points

-

Tracing disappearing oil

2 pointsObserving soot at the end of the tailpipe is normal for this era of truck, especially if you have larger than stock injectors. Disconnect the compressor discharge plumbing from the turbo and inspect for an oily mess. Then, disconnect the exhaust band on the exhaust side and inspect for the same. It is possible. The hone pattern intentionally put into the cylinder walls is used as a mild abrasive to condition the outer wear surface of the piston rings for the first 1,000 miles or so of driving. During this period of time, the best mating of the rings to the cylinder wall will occur, resulting in the least oil consumption and least engine blow-by. Using a slippery synthetic oil during break-in reduces the effectiveness of the abrasive characteristics of honing the cylinder walls - it will have a more likely effect of polishing the piston rings and the cylinder walls, resulting in more oil consumption and more engine blow-by. Try performing the oil cap rattle test for the poor man's method of checking engine blow-by. John2 points

-

Flashing WTS light

2 pointsJust remember just one wire pinched in behind part, bolt, or bracket could do it. I had one where the PCM burned up because one wire was rubbing on the trans dipstick tube and fried the voltage regulator.2 points

-

Flashing WTS light

2 pointsThey listed a ton of possible causes for failure to check. Basically every sensor on the truck, damage to the harness, TSB’s, faulty grounds, etc. The truck ran perfectly and has for the last ten years when I pulled into the garage so I had no clue what to even look at. I did check some of the harness and found one tiny hole in a wire possibly from a probe, it wasn’t close to touching anything but I wrapped it up anyway. If I have time this weekend I plan to go through the whole thing and check all the grounds and fuses.2 points

-

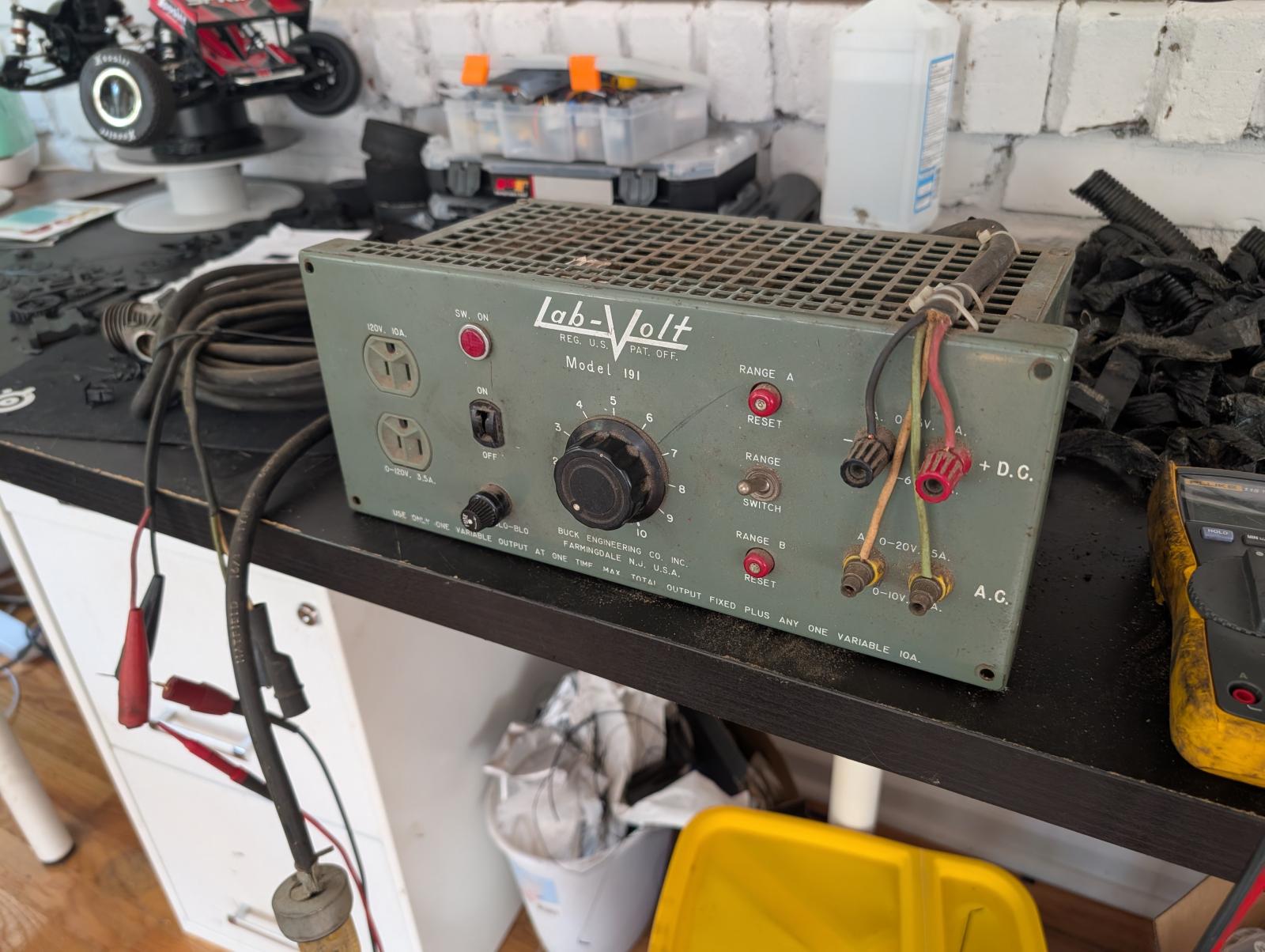

Mysterious Knock on VP44 Truck – Need Help! No one can figure this out!

So far I have found nothing! It's not difficult, just time consuming. I have this old power supply that I'm using to help load test the wires! Good to know! Im a cheap *** and prefer to struggle my way through this LOL.2 points

-

Problem with idle cut off

2 pointsLooking back on the thread, Mike mentioned this a few days ago “Remember Bosch stock injectors are NOT made as a set. You could have low end of 293 bar you the high end of 327 bar. This can affect idle performance. Ihigh suggest AGAINST using stock injectors. Buy+50 HP from any good injector shop and they are balanced as a set within 2% of flow rate” I still think it’s very likely both sets of your injectors have been mismatched. I learned this the hard way over the past year or so. Had your same stall issue after I ordered and installed a matched set from the same outfit that did Mikes injectors. Pulled them out, had 2 shops pop test them and they ranged from 290 to 330 bar (both shops showed same numbers on each injector). Pulled them back out, send them back and told them specifically what I wanted (310 bar-I believe they set them up at like 308 normally) they sent them back and I had them independently tested again and they were still off-not as much but by then I was mad. Keep in mind this was a “premium” set, not their normal budget injectors. I tossed those and went with the Mach 1 from Flux bc the owners are still directly involved with building their injectors and they’re perfect. For whatever reason my 2000 model is very sensitive to matched/balanced injectors and it sounds like yours is too. This shows my truck stalling after shifted intro reverse. On a slight hill, if the initial fuel input didn’t create enough force to back it up it would just drop and stall. The pics below show the idle RPMS from 2 different tuners. Roughly 750.IMG_6135.mov IMG_6162.mov2 points

-

Different thickness injector washers?

This photo is of a typical 12 valve engine. No crossover tubes. Fuel line are connected directly to the injectors, so injectors can be shimmed. John2 points

-

Problem with idle cut off

2 pointsHi everybody, it s ok. The truck works now..... intéressant is no cut off.... The culprits: rebuilt injectors 75hp more, and tps ( I don t understand why it worked before... electronic 😁😁, like the vp44 😓😓). Thank you very much for your great help ! ! If one Day you go at Monaco send me a mail , it s with great pleasure !2 points

-

Pilothouse/RAM3500 build

2 points2 points

-

Issues with 47re Linkage

2 points

-

Ford 6.7L issues

2 pointsYou guys!...., that piston is not in backwards - that cylinder is only supposed to be used when backing up! - John2 points

-

Electrical Article - APPS relocation

2 pointsThis is a tech article regarding those who (like me) think the oem spot for the apps is not ideal. Exposed to outside elements, heat, vibration and potential corrosion, moving it inside was most practical. Non Dodge/ midrange applications of Cummins 5.9 24V ISB’s all have their TPS/APPS inside the cab, mounted on the pedal assembly. So nothing is changing on the apps operation, just moving it. This mod does not works on trucks that are auto/use vacuum for cruise. The auto trans kickdown cable is attached to the bellcrank assembly. As with the vacuum solenoid setup too so if you can live without them then it will work. Parts needed: 699-5101 pedal assembly (2x) 6 pin Duetsch connectors kits Zip ties Grommet 6’ of 6 wire harness Tools needed: Duetsch connector terminal pliers Wire strippers Making the mount will be up to you. I can show you pictures on how I made mine but it’s just a one off. Either way you need to mount it inside. First, disconnect the 6 pin Duetsch connector from the apps, remove the bellcrank assembly from the cylinder head. Cut off the cable and discard. The oem pedal assembly will need to be removed and the oem mount has a pivot pin on the bottom that’ll twist out with some channel lock pliers. Once you mount your new pedal to the mount and it’s installed all that is needed is how to control via ecm. So a 6 wire jumper harness is needed. I would HIGHLY recommend removing and tossing the apps that comes supplied with the new pedal and install your current one in its place. I can’t guarantee its quality. If you need an apps, a Williams Control 131973 or 133284 will work perfectly (Timbo is just a repackaged WC). Available from any oem truck dealer (I.e. Kenworth or Freightliner). On your engine side of your harness you need to make a 6 pin male Duetsch connector. Ensure you new connector kits have the locks in them, some kits do not come with them for some reason. YouTube or Google can provide a video on how to use Duetsch connector pliers, they’re super easy to use. Using the hole in firewall that the original pull cable went through install a grommet to prevent rubbing and feed your harness through. If you prefer to drill a hole the same size of the connector body you’ll need a 7/8” drill bit. **It’s easier to make the harness, THEN crimp the new terminals on after feeding it through the oem firewall hole for a cleaner look.** Cut your 6 wire harness to length and crimp on the terminals, install the connector body and plug it in. Theoretically the engine doesn’t know where the apps is so it will work. Make sure you mate up each wire in its proper spot on each connector, if you mess them up a CEL will come on/non functionality of the apps. Secure the harness to various points with zip ties so it’s rigid. This provides a clean look and more room in the engine compartment for future servicing. Start the engine and test. Throttle response should be crisp since there is no cable anymore that has slack as it wore. View full Cummins article2 points

-

Hello Everyone!

2 points

-

2006 Dodge Ram 3500 - Thor Project

2 points

-

New Life and New Body with issues...

2 pointsKeep working the issues! I know there are several new sleep apnea options out there that are way less of a PITA than the standard old school options were.2 points

-

Hello Everyone!

2 pointsYup it is true. Strange enough I was in full makeup when we met both times. She enjoys my artistry of my makeup and wigs which she continues to encourage me to learn more about the art. Yeah after I did give Suzanna my number it seemed like there was so many questions and so much to talk about most of our phone calls went till 2am most nights. Strange some night we still just talk till early hours. Yes it's true we plan on getting married in the spring of the year. Suzanna was amazed by what I've created with Beast. She enjoys good Cummins power. Now we both want to build into 3rd and 4th Gen lines hence why the active work on Thor to attempt to give me time to repair Beast which is nearly 500k miles now. There is a lot going on with software changes, server changes, and even things on the site. Suzanna and I are going to fix the website up and bring more newer generations to the article database. Right now I'm just cleaning up after moving servers to cut operational costs.2 points

-

Driving with 5th gear removed

2 pointsSorry for the late update. I was able to replace 5th gear and make it home without issue. It was a heck of a lot harder to torque that nut to spec than expected, but I got it and it seems to be holding fine for now. Thank you everyone for your help!2 points

-

Help with Quadzilla 3 cylinder/6 cylinder box

Not a problem and your welcome always here to support the Cummins family.2 points

-

Headlights, tail lights, and turn signals blink

Give Module masters a call in Moscow Idaho. https://mopar1973man.com/vendor.htm/vendor/module-master-r8/2 points

-

Pilothouse/RAM3500 build

2 pointsI had a feeling that you would go back to the first running board after you had better results with the second running board. That's not "OCD" - that's a "good decision"! - John2 points

-

Hi everyone

2 pointsI'm alive and cancer free yet. I go in on Jan 28 for testing make sure my cancer doesn't return.2 points

-

1999 Dodge Grand Caravan - Minnie - Electrical weirdness

Armature shaft binding when cold. See if tapping on the housing frees it up.2 points

-

Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

After 18 years of interesting CTD enthusiasts and transmission specialty outlets all contributing their method, or fix, to the well known TC lock unlock syndrome, I can no longer remain silent. Extensive review of many posts regarding TC lock unlock, the rerouting methodes, the add on filters for APPS and last, but not least,...the "tin-foil hat" brigade. I do realize that each individual or company that contributed to the vast amount of information on the web had good intentions and I must acknowledge that some of the procedures caused me to closely examine what these people were trying to do. I believe it is well known that even a blind mouse occasionally finds a morsel of cheese. Again, as it is well known @Mopar1973Man was the only entity who positively identified the instigating source of this key issue. My entry today is not about alternators...it is about what Daimler/Chrysler did in regard to production of these Cummins powered platforms and the complete disregard of common sense Electronic Engineering. Please note, this applies to automatic and manual transmissions as each platform is plagued in the same manor with different quirks. This Blk/Tan #8 gage wire is quite critical in the scheme of things. It is contained within a 1" plastic conduit passing along the front of the engine. It contains water temp sensor leads, air conditioning leads, alternator/PCM leads and the #6 gage alternator charge line to the PDC. This #8 gage Blk/Tan passes over the top/backend of the alternator and is "eventually" connected to the Auxiliary Battery (passenger side) negative terminal. This snapshot of the Factory Service manual documents "four critical ground leads" that are "spliced" in an unconventional method. This photo depicts the three #18 gage wires and the single #14 gage wire entering the shrink-tubing where the "crush-splice" occurs. This bundle exits the large plastic conduit below the VP44 This again is a most disturbing depiction of the Daimler/Chrysler method of splicing critical ground leads and then routing this across the top of the alternator and "eventually" bringing this to ground reference. This photo depicts where this #8 gage Blk/Tan first connects on the way to "eventual" ground...yes this is the Auxiliary Battery tray connector. Please note: it is spliced again and joins the PCM circuit board grounds...which are critical in their own nature...and "eventually" terminate at the negative post of the Auxiliary Battery's negative terminal. This photo is very interesting, it is the Factory Service manual and the assembly line documentation follows this as a road map in the matrix during production. Please NOTE the title "NAME" to each battery...I looked at this for a considerable amount of time before I realized the assembly line coordinators tried to work with the documentation from the Engineering Staff to "make it as it looks"...Could this single oversight be the reason of a four foot ten inch critical ground wire combination traveling the distance to "EVENTUALLY" terminate at ground? From a basic engineering standpoint regarding ground...you "NEVER CHOOSE THE PATH OF EVENTUAL GROUND" !!! It is to be the shortest and most concise connection in reference to ground...this is biblical in ALL ELECTRONICS...including pickup trucks. ! Here is the Factory Service manual documenting the PCM circuit board reference ground starting as a pair of #14 gage wires being spliced into a #10 gage bundle and arriving at the Auxiliary Battery through another connector that joins a #8 gage wire that is "splice-joined" under plastic conduit in a Y configuration joining the rouge #8 gage "after passing over the alternator" traversing the entire engine compartment from the driver side of the vehicle. Seriously I have been drinking excessively, most recently, due to the nature of this blatant discovery. This is the hidden Y splice at the Auxiliary Battery where the "mess" EVENTUALLY terminates for ground reference. This photo shows the correct "HOLE" of where to apply ground for the VP44, ECM and the PDC...note the logical location It took a little research to find the size and proper thread-pitch. Metric M5 with a 5/16" hex head is perfect This is where you apply a fresh "quality" #6 gage ground and terminate this at the Main Battery negative post on the drivers side for absolute ground reference for the VP44 and ECM This is a very short and concise reference to ground. This is the corrected procedure for a rather critical ground. The two largest wires originally contained within the 1 inch conduit are no longer present and located well away from the alternator. My alternator B+ "charge" line is now a #4 gage line directly connected to the Auxiliary Battery and when my new battery terminals arrive and they are secured, I'll provide photos of a completed Master Power Supply System within this engine bay. With these corrections, I would hypothesize that a poor ripple specification on a given alternator would be overcome by the immense capacitance of the parallel batteries and would become less prone to causing the dreaded TC lock/unlock for automatics and cruise-control abnormalities for the manual transmission platforms. The #8 gage Blk/Tan passing over the alternator as an "EVENTUAL" ground is gone...the PCM, ECM, VP44 and the PDC are now grounded in accordance of standard Electronic Engineering practices. Respectfully W-T2 points

-

Heat exchanger

2 pointsThe factory heat exchanger not only cools transmission fluid, but all so heats the fluid to operating temperature in cold weather. With the average winter low temperature of 9°F in your area it would be prudent to retain the heat exchanger for winter drivability.2 points

This leaderboard is set to Boise/GMT-07:00

.thumb.jpg.9c48aa8f6cc163d8202f09ef46255c5f.jpg)