Everything posted by TFaoro

-

Miss at all RPMs

- Miss at all RPMs

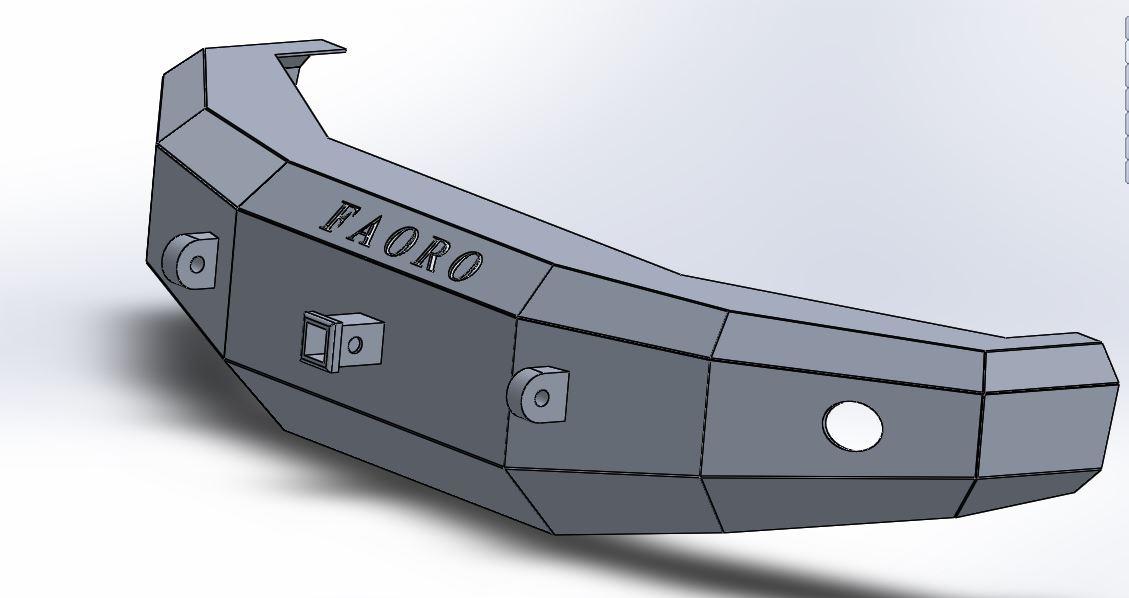

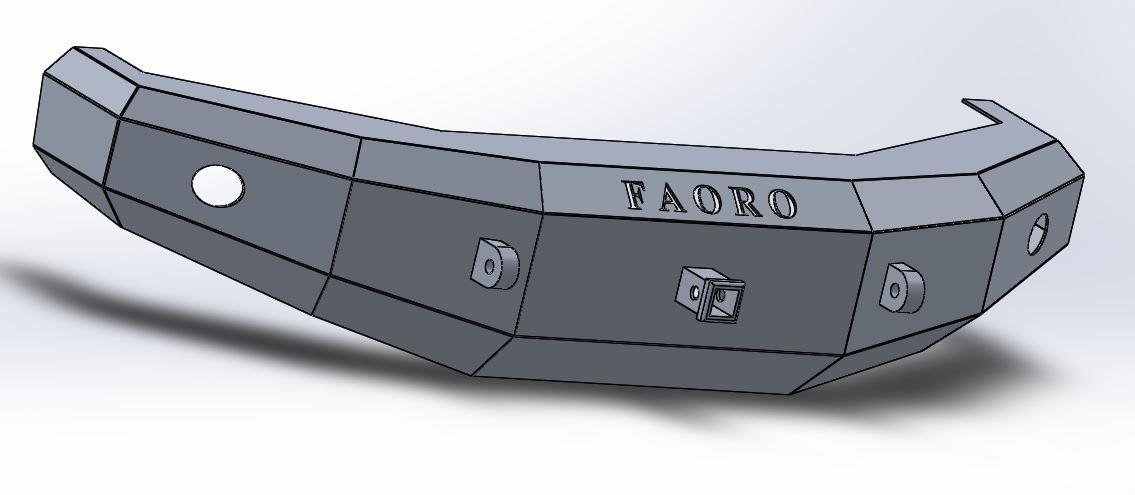

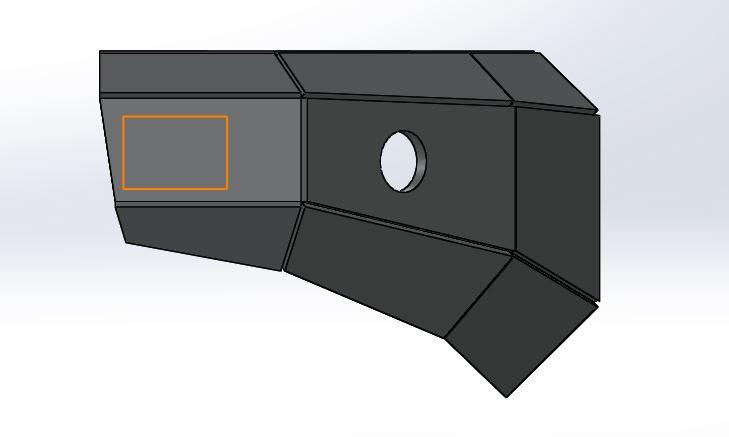

Nope... I don't like how the winch bumpers stick way out there. I'm sure I could easily modify it to fit one though From what I have seen most shops don't have SolidWorks, so I would have to give a drawing of all of the parts then it could be drawn into whatever program they have. It shouldn't take too long as half of the parts are just flipped duplicates. I have not finished designing the mounts or the bracing yet.. I just have the front look done. It is made of 26 pieces of 3/16 steel.- Miss at all RPMs

I used SolidWorks for the design. I looked on the internet for hours and couldn't find something I liked so I combined multiple designs into one. I will never use a winch, and almost all of them come with winches, and they are HUGE. I want something tough but looks sleek and doesn't weigh down the front end. I really like the look with a bull bar on there, but I am constantly doing engine mods so it could become a PITA to work around! Once I have my truck back and can make all of the measurements necessary I will finalize the design. If I do happen to build one and have a good design that people like I may consider selling the design. As for sticking in a brand that is probably the easiest part of the whole design!- Miss at all RPMs

Well while I am waiting to get this thing back I decided to start designing my summer project (Hopefully). I plan to add mounts for shackles and possibly a bull bar... What are your thoughts?- MoparMello: Cooling problem

Just hold the pressure washer at a 90 degree angle and there shouldn't be any problems! Have done this with all of my vehicles and farm equipment- MoparMello: Cooling problem

I used simple green and let it soak for an hour or two. Then ran up to the local gas station and used the pressure washer- Miss at all RPMs

Paint guy says he has to buff it this weekend.... Looks like it will be another week before I can get anything done!- VP44 help

DAP is very good about waranty! You should have no problem with them.- Miss at all RPMs

- Miss at all RPMs

That's what I'm hoping- Miss at all RPMs

Well I ordered 2 new cross over tubes and a new set of O rings for them from DAP today.. Just in case I have one or two that are plugged.- Miss at all RPMs

Just to clarify a bit... I have not been able to drive the truck around since the injector install, but like stated above this miss was prevalent before the injector install. When idling and on 6cyl high idle I have Zero smoke coming from the exhaust and no blowby with the oil fill cap off (With new and old injectors). With the old injectors while driving there was no excessive smoke of any color from the exhaust. The knock seemed to quiet down some with higher RPMs though. When idling with the new injectors all 6 runners coming out of the manifold were hot, leading me to believe it is not a complete miss, but more of a partial miss and a cylinder not getting enough fuel. The turbo lights just fine and easily pushes 45+lbs of boost (Makes me think it is not a flattened cam at least not on the exhaust side.) I don't have excessive smoke wile idling or revving engine when it is hot or cold (Cam not flattened on intake side because there is air getting in to burn fuel) There is no blowby, which I know is not a definitive test for whether rings are broke or a piston is cracked, but I would think there would be some. Without testing some things I will not know for sure but I am fairly convinced it is a fuel supply issue. With a VP that has less than 10k, always fed 2 stroke, FP at 19 idle and minimum 10 at WOT I don't think the VP is shot already. The injectors are new from DAP so they should be good. This only leaves cross over tubes- Miss at all RPMs

No leaks right at the head, and I believe they are seated well into the injectors because of the procedure I used to install the injectors. (Snugging the injector line before tightening the injector hold downs)- Miss at all RPMs

Just spoke with John. He seemed to have the same idea of it being a fuel supply issue. Really hoping it is a simple cross over tube issue!- Miss at all RPMs

He hasn't been on since September... I would love to borrow it though. MoparMan can you PM me his number or something so I can get a hold of him? I tried cracking the lines and can not tell exactly which hole is causing the miss. I have a pretty sharp ear for those things and just can't rule out which one.... But to me it seemed like #3 or #5. I will give the "feel" a test as well. I guess if it is something clogging a crossover tube it is likely that more than one hole got debris in it.- Miss at all RPMs

Alright guys I am experiencing a miss at all RPMs. It is pretty noticeable near the engine with a knock, but is extremely noticeable at the exhaust. It is easy to feel that the exhaust is "puffing" per say. Now I just replaced the injectors with a new set of 125hp sacs, but the miss was prevalent before the injector swap. The swap did not make a difference. Everything sounds the exact same as before the swap. I have fuel squirting out of each connection at the cross over tubes while running. MoparMan and I spoke on the phone earlier and have decided to take a systematic approach to resolving this issue. Ruled out: 1. Injection pump: Always supplied good pressure, less that 10K miles and miss seems to only be in one cylinder. 2. Injectors: Swap made no difference. Possibilities (Almost endless): Burnt/ broken valve, broken piston or piston rings, clogged cross over tube, valves way out of adjustment I should receive the truck Friday from being painted and I can start diagnostics. The plan: 1: Pull valve cover and quickly check valve lash - just make sure somewhat close to spec. 2. Use an infrared heat gun on the exhaust manifold right were it come out of the head to try and narrow down which cylinder is missing. If that does work I will pull the cross over tube and replace it (I already have 1 new one that will ship out Monday). If that does not fix the issue I will do a compression test on that cylinder to determine if it is the bottom end or the head. If the heat gun does not find a "cold" cylinder I will pull all injection lines and cross over tubes, then clean each tube and try to determine if there is debris in one of them. If I can not find debris in any of them I will replace them with the new one, one at a time. If that proves inconclusive I will perform a compression test on all 6 cylinders. If any of the cylinders are low on compression I will pull the head and determine what is wrong internally. Any suggestions on the procedure or something else I can do to diagnose what is wrong with this thing??- Fuel Line Question

Eric from where? Not trying to hijack this thread, but do you guys think I could have such big pressure drops because I have the stock line and banjos running from the stock filter housing to the VP?- high idle test

http://articles.mopar1973man.com/2nd-generation-24v-dodge-cummins/26-engine-systems/436-high-idle-detecting-if-the-ecm-has-been-enabled-for-high-idle Read here. You need a 39,000 - 100,000 ohm resistor- Master parts diagram or software?

I need a beater! I am going to have to be all careful with this one when I get it back from paint.....- Master parts diagram or software?

If I wasn't in college I would buy it from you!- Smarty UDC Tuning

The other version was 1.3, so yes this is newer. Thank you for the help! I'm sure I will have many more questions for you in the future!- Smarty UDC Tuning

I am looking at the one you posted on this site. I just did a google search to find it. Do you have a more recent one?- Smarty UDC Tuning

I believe he left the rail pressure on the stock setting. What pressure can he run without hurting the injectors? They have 150k on them. The tips probably have 5-6k. Thanks for the tip! any other tips are appreciated if you have any. What is the tune that you have in your excel spreadsheet? It looks far from stock.- Smarty UDC Tuning

That makes sense! He has an edge insight CTS that he monitors with and the rail pressure is always between 21 and 23k while at WOT. I can get actual numbers if you are interested. Looks like he should start saving for a dual CP3 setup as well... His goal is 650-700hp with the twins and bigger injectors- Smarty UDC Tuning

The higher tunes have noticeably more power but he is way out of turbo. It still howls black smoke even after the turbo lights on the highest setting. His plan is for an s475 when Christmas comes. You really think the cp3 is already maxed out? He's going to be pretty upset that he dropped that much money and he can't go much higher Rail pressure doesn't drop at all?? The tips I can see being maxed, but he want's another turbo a. nd studs before going with bigger injectors. - Miss at all RPMs