Everything posted by mopartechnician

-

ABS codes? How do I retreive them?

Honestly 95% of the abs codes are cause by rear wheel speed sensor

-

Multiple Codes (10), Rough Idle....

Clear the codes and see what comes back

-

24 valve cooling system problem..very wierd..check out!

If you have the thermostat out, replace it, and my cap is 15. Manual says 14-18. Both are cheap replacements and are common to go bad.

-

guage install

$400 raptor now or $1200 vp44 and $400 raptor later, if you haven't already taken out the vpThe low pressure lights are one of the worst ideas ever. I always laugh when people think they are the answer, well 5psi is way to low. Too bad they didn't make one that lit up around 15psi.

-

24 valve cooling system problem..very wierd..check out!

Just like diesel4life said, my suspects would be thermostat, water pump, or radiator plugged with oil

-

AirDog 2 165 install

Correct. Where the old supply line hooks into the top of the module is now where you hook up the ruturn for the airdog

-

200,000

Are you on your original injectors?

-

AirDog 2 165 install

Well, at first I didn't drop the tank but I missed the part in the instructions that said you might have to drill a 1/4" hole in the old supply line in the tank because it is now used as a return and the line could have a check valve inside it restricting flow.

-

Radio and Programmer stopped working at same time

Every company always tries to blame it on something else besides the their own product

-

Lift pump

Honestly just unhook the supply line off the cp3 and run a hose to it down to the container, that's what I have done, but I actually have the right tools and that is pretty much what it does

-

Lift pump

FLOW TEST. 1. Remove the fuel pump supply banjo fitting from the fuel injection pump. 2. Install Miller Tool #9014 fuel system test fitting into the fuel injection pump. 3. Connect one end of a section of fuel hose to the test fitting. 4. Put the other end of the fuel hose into an empty fuel container. 5. Use the scan tool to actuate the fuel lift pump. 6. While the lift pump is running, move the fuel hose from the fuel canister into a 1000ml graduated cylinder for 10 seconds. 7. Read and record the amount of fuel in the graduated cylinder after 10 seconds. 8. If you have more than 430ml in the graduated cylinder after 10 seconds, the test has successfully passed. 9. If you have less than 430ml of fuel in the graduated cylinder, inspect the fuel supply line from the fuel tank to the fuel filter housing and the fuel supply line between the fuel filter housing and the high pressure fuel pump for signs of damage, replace as necessary. If no damage is found, replace the fuel filter and retest. 10.Verify the Screened Banjo Bolt at the outlet of the fuel filter is free of debris. If debris is found, rinse screen with water, blow dry and reinstall. Retest vehicle. If flow meets specification then trace back the source of debris, if flow is still below spec repair damaged component.

-

Lift pump

There are a couple different things that cause hard starts on common rails. First is the lp which is tested in flow not pressure. Next are injectors causing fuel pressure to bleed back or not spray correctly to fire

-

Extreme cold!!!

I'm just east of you in western Nebraska and we usually get national news for lows since we sit in a bowl. Anyways, I use a magnetic heater that sticks to the oil pan and the block heater. I run them on a timer set for 1.5 hours before work and only idle my truck for less than 5 minutes (kicks into high idle after 30 seconds). I have always wanted to try one of those ceramic heaters that plug into the aux outlet.

-

AirDog 2 165 install

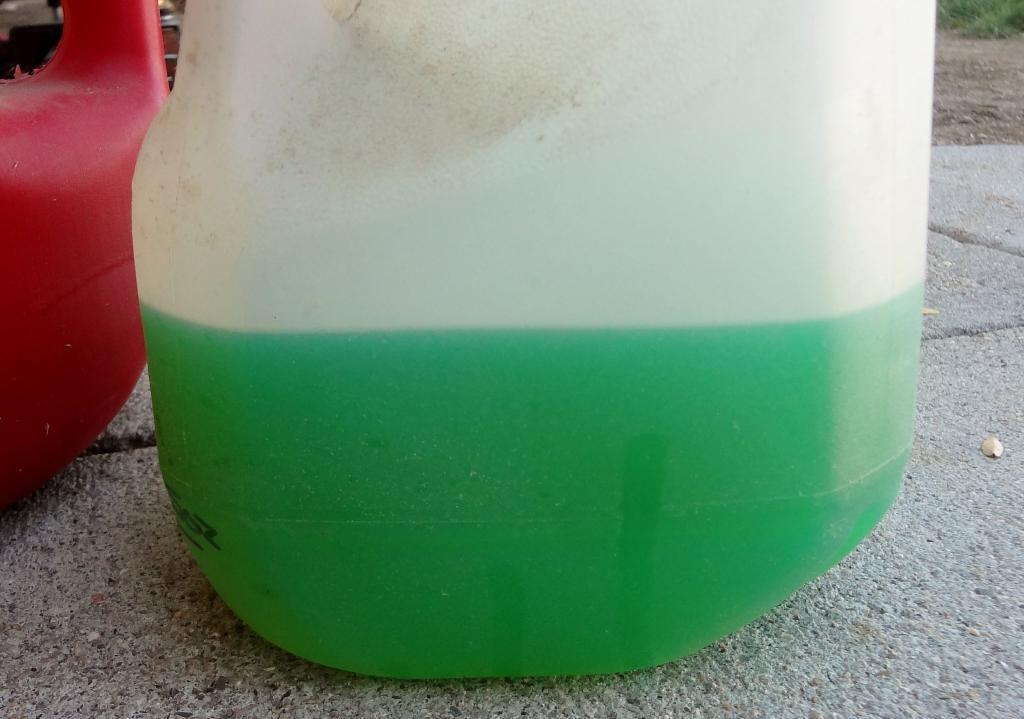

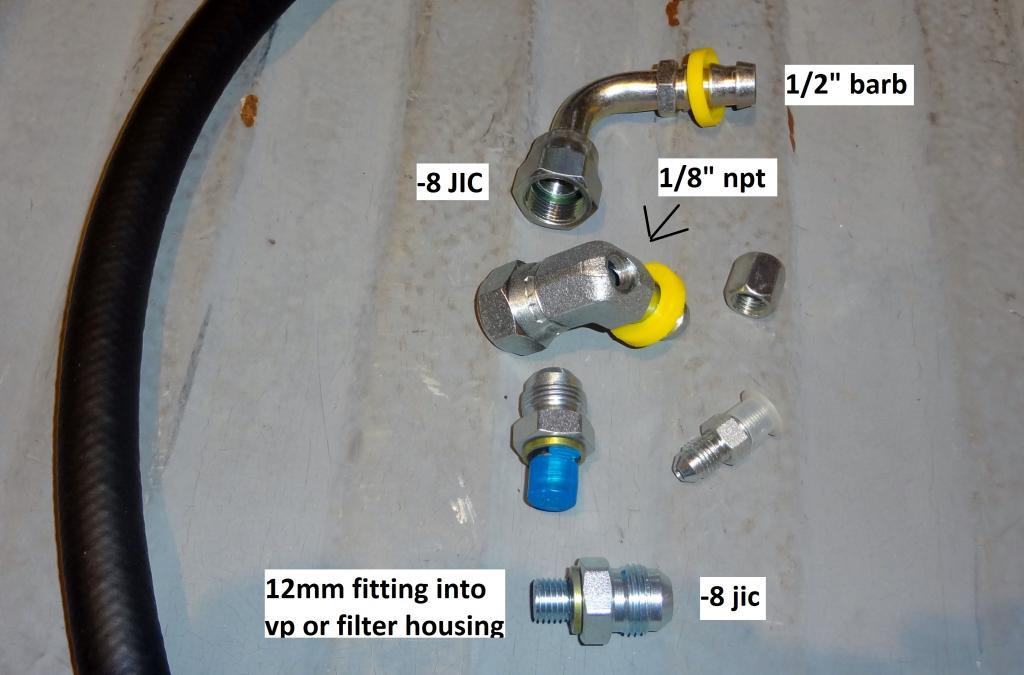

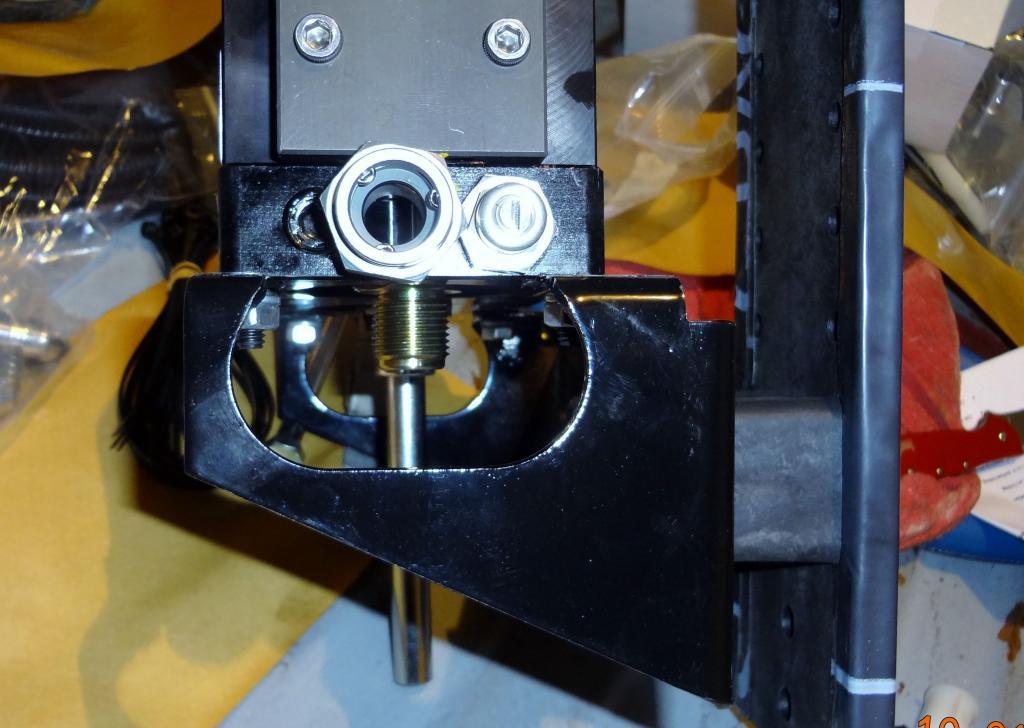

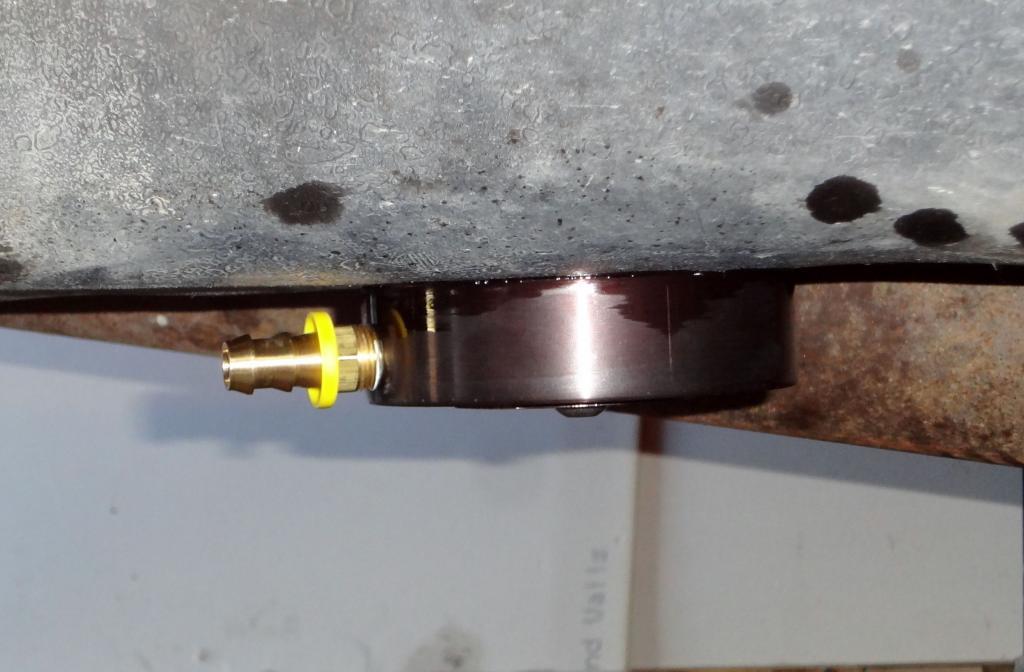

Ok, I did this 3 weeks ago so I am just finally getting around to doing my write up. I know people have concerns with the airdog/raptor issues, but hey, somebody has to see if they are fixed. I have no concerns about these pumps, as I have never had any problems getting warranty on customers raptors. Also, I have an electronic gauge as well as a quick release fitting for a mechanical gauge to check pressure whenever I need to.First things first here are the partsAirdog and hardwareHere is the sump kit by Bean's dieselFirst thing I did was drain the tank through the fuel filter housing drain into 5 gallon buckets and jumping out the lift pump wires to control the flow.Here is what your fuel looks like when you mix 2-stroke oil at 128/1Now time to put together the Airdog pump and fittings, I used some bituthene around the plates that mount to the frame and also between the actual pump and its mounting bracket to dampen any vibrations/noise.I ran all hoses and wiring, that ran up to the engine bay, through the frame rail to clean up and protect them. I also ran the fuel line into the stock filter housing to keep the extra filtration as well as the water separation. (I don't believe the fuel heater does much good)Next I installed the Vulcan big line kit, here are all the fittings and sizes to help clear up anythingThis is the fitting that will go into the vp44 and the bottom of the filter housing.These are the elbows that will hook into the previous fittings. The one with the 1/8 fitting should go on the vp44 fitting.Here is the glowshift maxtow gauge I got, its an analog as well as having the digital number readout. I am not to happy with the gauge as the needle looks like a windshield wiper when you are driving and have the throttle on anything off idle. I think the sensor is way to sensitive because with a mechanical gauge, the gauge only drops 1 psi at WOTHere is the fuel snubber that came with the fuel pressure gauge, this or a needle valve is a must to keep your pressure sensor safe from the hammering the vp44 does.Elbow with adapter and snubberNow onto the fuel sump. They say to drill it right below the stock fuel module, so I cleaned up the tank really well. After drilling the pilot hole with the provided hole saw, I let any fuel drain out that was still in the tank. After it stopped dripping, I finished drilling the hole and cleaned up all the shavings. After I drilled the hole I think drilling under the stock sender is not the best as it interferes with the installation of the sump.Sump all installedSump is roughly 1" tall and sits above the frame rail. Yes something could hit it and tear it off but I rarely go offroad so I won't be worried about it.And finally, its installed. This is my attempt to show how far everything hangs under the truck and the protection it has.Final thoughts, so far so good. As I said earlier, with the mechanical gauge, I only drop 1 psi at WOT with my setup and chip on highest setting. Don't believe there will be any gains in mileage, but I now know I have great fuel pressure (19-20psi) and great filtration.

-

Oil pump housing failure, probable rebuild...

I have only seen one oil pressure/pump problem and that was a delayed pressure build up that took about 15 seconds to build pressure then it would be completely fine. I havn't even heard of any oil pressure problems.

-

filters??

There is the filter god. I also fixed my messed up filter number in my first post. Gotta remember not to quote part numbers off the top of my head

-

Fuel pressure gauge..

You can use the same banjo bolt for getting fuel as used in vp trucks

-

Radio and Programmer stopped working at same time

yep, that's what took out IOD but question is, what fuse did you have your cts powered by (or is that powered through the obd port?)

-

Radio and Programmer stopped working at same time

Without looking im guessing the same fuse that powers radio powers the chip

-

Radio and Programmer stopped working at same time

What fuse is powering the edge?

-

6.7 run away

How did you clean the intercooler? Anytime we had run away trucks chrysler made us replace the intercooler. My guess if the turbo is shot and feeding oil into intercooler. Injectors are rare to stick open and even if they did, the cp3 wouldnt be building any pressure

-

filters??

Baldwin pf7977 i think that is the right number Here is my setup i built http://www.cumminsforum.com/forum/3rd-gen-powertrain/477364-my-2-micron-fuel-filter-setup.html

-

High idle

http://articles.mopar1973man.com/2nd-generation-24v-dodge-cummins/29-tsb-technical-service-bulletins/85-tsb-18-019-01-cold-idle-engine-warming

-

High idle

It can't be done on manuals, there is an option in the drb to enable high idle and all they have to do is click a button. They are full of it because we enabled it on every brand new truck that we inspected.

-

Terrible luck with Raptor.

This sump is only an inch tall. There is many things hanging lower that it. I know a couple of people that offroad with their sumps and havnt had any problems