Everything posted by Stanley

-

New Injector knock/ping, 3rd set!

Yea I read kinda the same stuff, tubes are ok with stock. Idk which way I'll go on that... So what do I make of the tank pressure? The vapor "smoke"? Contribute that to the pump as well?

-

New Injector knock/ping, 3rd set!

I don't think it would work to well, essentially the injectors would just suck the lines dry cause it can push/handle large amounts out but the pump can't fill lines/tubes back fast enough for next round. At least that's the way I see it. I mean if someone's done it with large lines and knows what to expect I'm all ears. I'm gonna have to inspect my stock lines and I'll post pictures.

-

New Injector knock/ping, 3rd set!

Well it just came about. After all this time idk if it would do it now?

-

New Injector knock/ping, 3rd set!

I have stock lines, idk if there any good, I assume that there the original ones from truck. Also have 1 new set of cummins oem tubes and 1 used, 1 set of used stock injectors (unknown status). I might have to take pics of lines and see what yall think. I read some where that you could run the bigger tubes just not the lines. I guess since I have oem ones I might as well use them. I think stock tubes and lines are good for quite a bit of HP before needed swap. Wonder who would want those lines and tubes? Might put them on here for sale.

-

New Injector knock/ping, 3rd set!

I guess I forgot about my .093 lines and tubes....

-

New Injector knock/ping, 3rd set!

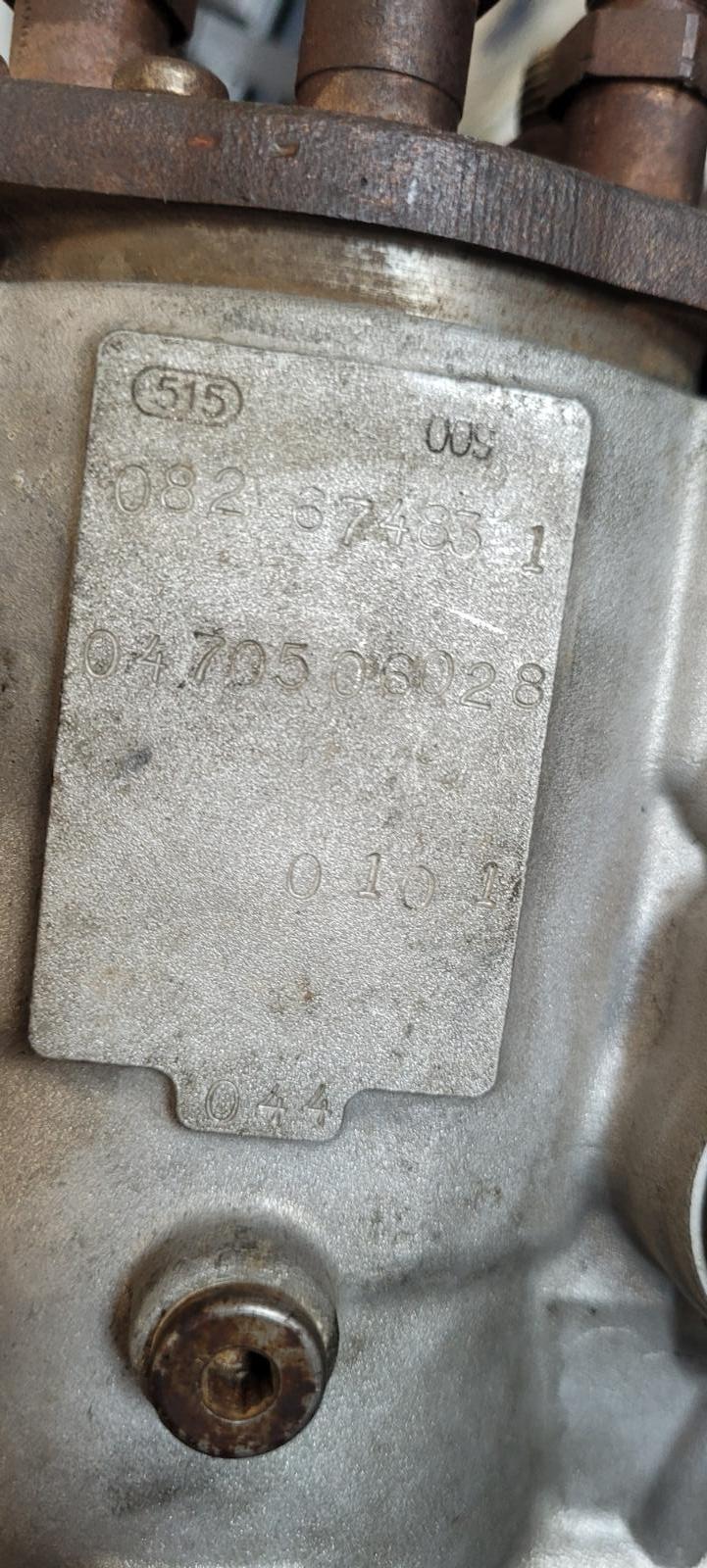

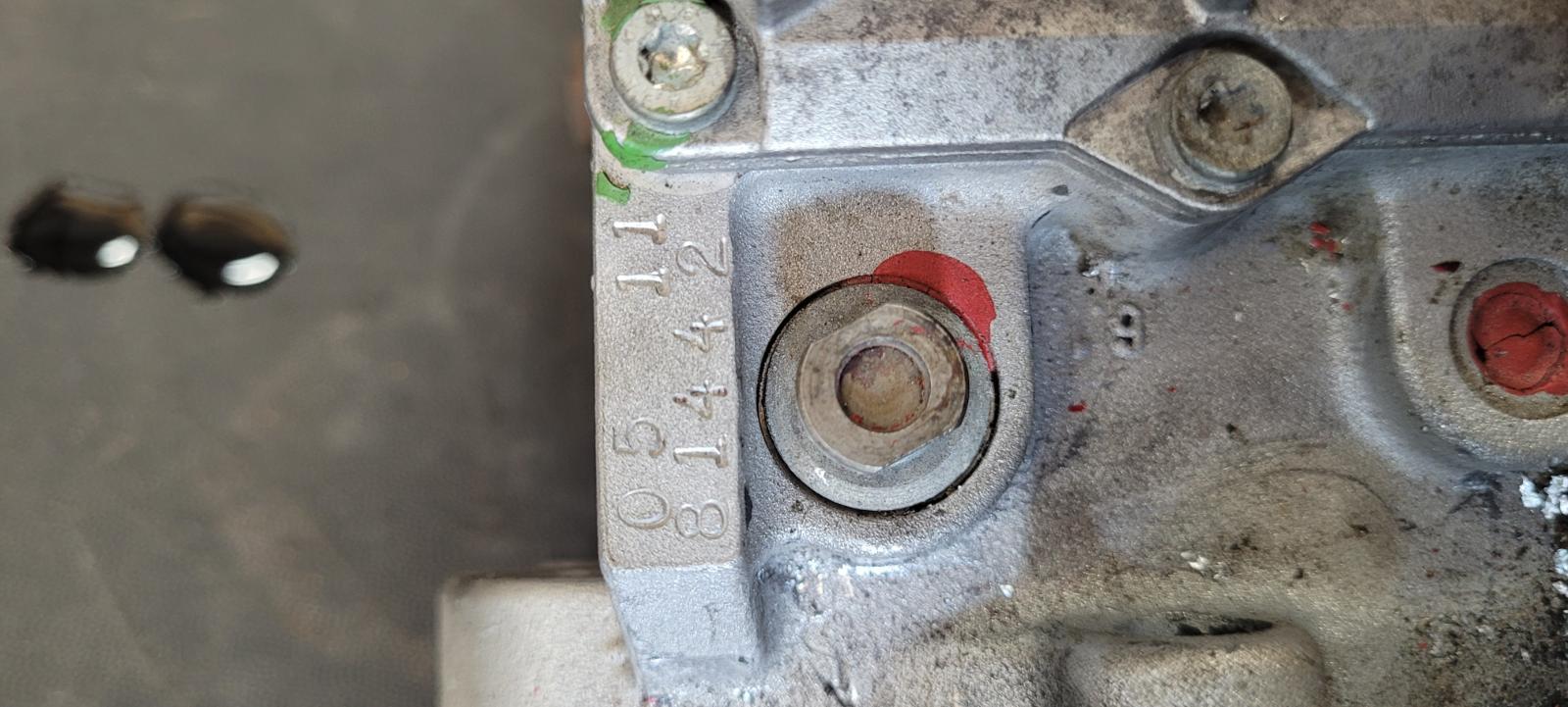

Well I dont want any codes lol But Id like more power on top for hwy rpms etc. I think I have to assume that this is what happened locking up. Code now plus hard starts and the knock - to which is safe to say was caused by pump? And I should ease my mind and not think the worst now? @dieselautopower here is some pics of pump when I previously took it off. Doesnt say 028DF but who the heck knows... Would this be ok for a core? And keeping those 6x13's in there with that new SOVP should be doable for awhile aye?

-

New Injector knock/ping, 3rd set!

Well if what @Mopar1973Man was saying about him having a knock and it being at full advance it could have been the pump going just not saying or showing anything. No, didnt have any of those codes on the key cycle*. Yea it did follow on the first set. This seems just like a huge mess that may have finally just exploded to the root issue idk... I guess ill have to start fresh with new pump I understand SOVP is the way to go instead of HOVP that these 6 speeds had. I guess I might as well as, which pump is better than the other. @dieselautopower I obviously been looking through your pumps... Kinda curious who actually went with the 2 year warranty pump vs 1 year. Also I have read mixed opinions if you will that the stealth cover is OK to use on pump with out voiding warranty, I suspect this is false... @dieselautopower is there a pump you have that would be ok to tap out of the box? I guess running with no tap on the quad wouldnt be to bad with bigger injectors?

-

New Injector knock/ping, 3rd set!

No I was saying that before pubg came about lol...However I do play call of duty sometimes 😁 Your meaning stock timing on bad pump making knocks in the injector correct? Not the timing from quad...

-

New Injector knock/ping, 3rd set!

Last time I looked at the data log portion in the quad (not exported) it showed 100% engine load. I'll have to re-check it for maybe a more recent one? Well mid way through typing that I went out and messed with the truck just now, turned on quad monitor and just mulling over things. Re-checked codes via key-switch..........guess what! Winner winner chicken dinner with the 0216 code of DEATH Now... I am no means saying this is the cure all or the main problem. I didn't get/see this till today. Would a bad pump make a KNOCK or make injectors PING-TING? FYI, I claim the term ping-ting as a proper term and verbage for this site. It's also fun to say!

-

Well it finally happened! QUADZILLLLLA

Prior to current issues it "seemed" to get better with more timing for me also. Just by bumping it up one in each rpm range while driving, just trying for better results. But now I'm back to square one.

-

New Injector knock/ping, 3rd set!

I put the bigger 7x15's in thinking that the pump was just blowing out the smaller 6x13's being it was the 3rd set of them, unlikely it was a injector failure 3 times but can't rule it out. Now since this mess idk... Why am I not having smoke with one of the biggest injector made for a vp44? I'm still not completely convinced it's a dragonflow but I have to think it is to keep my sanity! @dieselautopower I haven't sent back the 2 sets of "cores" yet. I was wanting to see if it happen to be something else and re-try those 6x13's. All else fails and new pump is needed a sovp would still work with those 6x13's according to Mitchell. So I could do that. I'm sorry this is such a mess, I really appreciate you guys working with me and Mitchell being so understanding and helpful!

-

New Injector knock/ping, 3rd set!

Temps yesterday were maybe 50*-60* Didn't drive the truck before hand, it was just idling maybe some revs here or there just while recording videos. I can't really smell anything anymore thanks to covid crap, but what I could gather it smelled like just diesel vapor, wife didn't notice it being different but idk if she knows what smells are what when it comes to automotive haha. Yea , NO smoke lugging and the egts through the roof just normal driving. It's hard with noises being recorded for diag purposes. There is a ping/ting in there definitely noticeable while driving just hard to record it? Maybe I'll try some different things for better audio.

-

New Injector knock/ping, 3rd set!

@Great work! I usually look in each bore to check for washers and gunk then a little spritz of brake clean before installing injectors. But I will check again for sure. I thought about driving mad alot of times lol. Then I thought well if I can find what it is before I blow a hole in the block I'd be money ahead. I been reading some stuff here and there on other forums some stuff @Mopar1973Man posted back in 2014, on the tank it could be cracked head or leaking injector seal or plugged vent or something. I hope and don't think it's a head issue cause it just started with the new injectors but ? Needless to say I'm scared at this point. Don't know really which way to go.... My new bore scope camera from snap on, the end is to big to get down into bore to inspect pistons... 🤬 I'd like to do so... Got a compression test adapter ordered so I'll run a test when it gets here. I hope the audio in the videos is good enough to differentiate noise from motor. If not I can do different ones or I have a few audio apps I can try.

-

New Injector knock/ping, 3rd set!

Ok... I held off long enough. Trying to figure out everything an I can't figure it out. 4th set of injectors now at (7×15's) Stock setup on quad (zero) truck doesn't smoke at all for the most part. Biggest injectors for vp44 and no smoke? Even lugging it? Truck also gets really hot egts really fast, that's just slowly getting up to 60mph I can see 1000* to 1200* no problem. Granted I can contribute that to big injectors but along with no smoke. I also have that ting/ping/knock again. Now I'm thinking worst case! Bent Valve, piston slap, you name it. But when where and how? Everything started after first injector swap.... Could a bad vp44 cause a ting or ping at injector? Cause them to go out? I'm seriously thinking about buying another vp44 again due to unknowns with it and obvious situation here. Also noticed today that I have pressure and smoky vapor coming from fuel fill... bad cap? Drove down the back road and back with cap off and it was still there... I have attached videos of the ping/ting and fuel vapor. Anyone wanna come down and help me figure this out? I'm at a total loss currently. This is getting old, I just wanna drive the dang thing... Please help!! tank-vent-video cummins-noise-video cummins-noise-video-1

-

New Injector knock/ping, 3rd set!

Test.... Will not let me post or upload

-

Well it finally happened! QUADZILLLLLA

@jag what is your timing on yours? Hotrods add timing too right?

-

New Injector knock/ping, 3rd set!

@YeaImDylan yes I have the .093 lines and tubes, they are required for the df pump. Also required size injectors for the bigger pump, the 7x15 and 6x18 arepretty close to the same. You have to be pretty careful with ends of lines and tubes, they knick easy and can get deformed. Here at John deere we don't re use lines or tubes just cause of deformation and just cause it's required. Not saying it's right/wrong or you should do it but I personally I have reused mine on this one and many before multiple times, just gotta be careful.

-

New Injector knock/ping, 3rd set!

Well here's the new injectors. Got a lope to it, clears up sometimes but barely touch the throttle and back at it. Really really really need to figure out this timing crap, it's gonna drive me bonkers! 7x15's Lope

-

W-T Ground mod, kinda confused? Quick Help.

Yea I'll search around more tomorrow. For now I just used the stud for wiring harness clamp on vacuum pump. Prolly just a good aye?

-

W-T Ground mod, kinda confused? Quick Help.

Yea not looking so good for bolts..... is there an M5 on the truck I can rob till I find another? Or I got a 1/4-20 tap....

-

W-T Ground mod, kinda confused? Quick Help.

I might have to use the standard equivalent/kinda close for now. I have no idea where to find a M5 bolt lol. And I have 30ft wall bolt bin! Never ran across one... maybe Amazon haha.

-

W-T Ground mod, kinda confused? Quick Help.

Thanks. @IBMobile helped me out a bunch. I think I have a handle on it now

-

W-T Ground mod, kinda confused? Quick Help.

Also the ground spot by vp44 I assume this is just a hole to mount ring terminals to, connecting wire from battery to here thus making the ground. Cause the housing where the bolt would go is aluminum. Alot of this is not stated so I'm just making sure this is what is actually happening lol.

-

New Injector knock/ping, 3rd set!

@Silverwolf2691 this makes things very difficult and tricky...

-

New Injector knock/ping, 3rd set!

Well the 7x15's are installed. I set quad to 0-off. Will drive and see what happens in a bit. I need to figure out what I'm missing on this W-T mod... got a thread open in it. Will data logging with everything off-stock show what timing is doing ? Maybe it will help?