Everything posted by IBMobile

-

Guess what this is

You should be thankful, it's more than I got.

-

Who likes and cooks true BBQ???

Count me in. I'll bring the potato salad and beans.

-

Guess what this is

A shorted 40 amp relay.

-

Landmark photo's

- B&W Hidden Goose Neck Hitch Installation

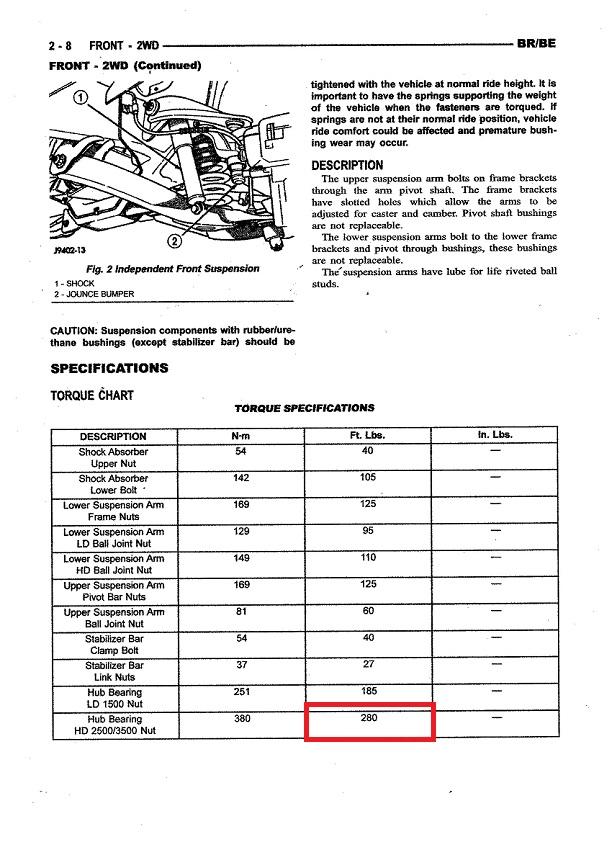

If that bracket is leaning in right now then shimming the upper bag bracket out with the with the hitch bracket and flat stock will make it sit straight or out just a hair. I'd be looking at where the bolts are for the air bag brackets so as not to interfere with the hitch brackets and the release handle.- Spindle Nut Torque Specs

- B&W Hidden Goose Neck Hitch Installation

How far does the ball hitch bracket go behind the upper air bag mounting bracket. Maybe have a lower bracket fabricated to the needed off set with anyneeded spacers at the upper bracket.- HORRIBLE HORRENDOUS mileage

MAP sensor giving false reading causing the ECM to command more fuel at the VP?- Alternator AC test results

If Dodge used solder then a prop 65 label would have been needed on the dash to sell them in California.- New Injectors?

I'm running the same as @01cummins4ever but with an Edge EZ and use the truck 90% of the time for towing up to 9k pound trailers. I really like the boost of power with out overwhelming the drive train.- Airdog problems... again...

Since you have already replacered the fuse and relay have you checked all the wires and connections? Did you check if the ECM is suppling power to relay terminal 86 when you bump the starter and the pump doesn't run?- Truck dies with hard acceleration

It never did it before with the same set up so what changed? Do you have a draw straw fuel pickup? What size fuel lines are run from the tank to the VP44? What is the fuel pressure when you do a burn out? Where can you do a burn out in Vegas with all the traffic and red lights?- Alternator AC test results

Do the W-T ground mod first then test AC voltage again. Some people have seen a good reduction in voltage after the mod was done and did not need to fool with the alternator diods.- 2001 Back-Up lights on all the time

NO! But, check your switch and it's adjustment first. Oil is in general an insulator but the type of base oil, how it was refined, the type of additive package, along with the type and concentration of contaminants will affect oil to conduct electricity. This ability to conduct electricity in oil is measured in picosiemns/meter (ps/m). Where clean SAE 10W-40 oil is >2000 ps/m and insulating fluids are rated at 12 ps/m.- 2001 Auto Trans Fluid Change or Flush

Flushing is the best way to exchange all the fluid but the pan still has to be removed to replace the filter and adjust the rear band. You need to be careful with a severely neglected transmission. When the fluid is so old that it is black I don't recommend a flush. I've had several people, over the years, call me saying they took their car in for a trans flush and 2 days later the transmission was junk. If the fluid is that bad I would drop the pan change the filter and refill. If the transmission is still holding together after 10k miles drain and refill then every 30k after that.- 2001 Back-Up lights on all the time

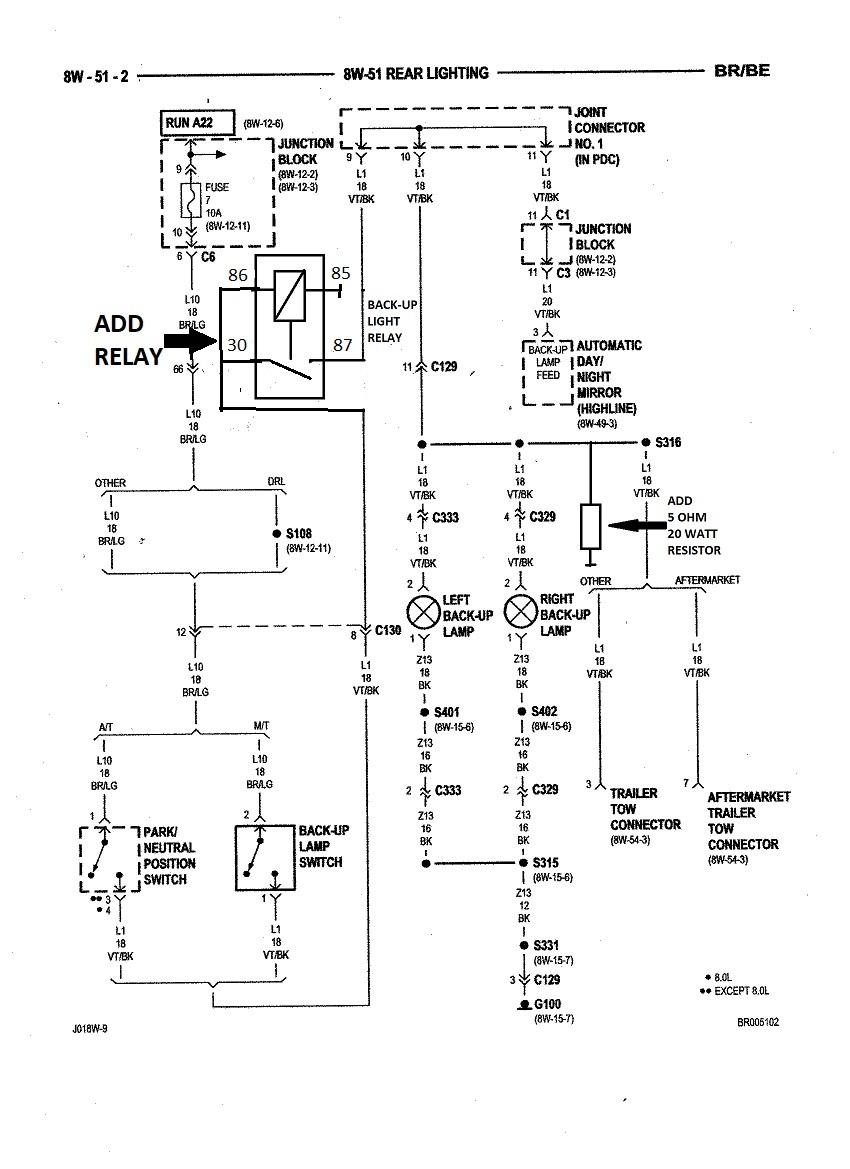

Two ways you could fix the problem, that I can think of, with out going through all the volt, ohm, amp calculations. The first way is to put a resistor in parallel with the back-up lights to mimic a light blub and absorb that leaking power as you suggested above. The other way is to put a relay in the back-up light circuit this would keep any power from going to the lights until the back-up switch is closed. If a resistor was put in series either before or after the led blub then the blubs would be dimmed.- Landmark photo's

- Fuel Pressure High!

I have a switch to turn on the grid heaters or run the signal through some resistors to fool the ECM. I'm working on another simpler bypass that I hope to install on one or both of @JAG1's trucks. If it works OK then I'll do a write up on it around the end of May.- Fuel Pressure High!

There is no under the hood label denoting emission controls like you find on gasoline engine models stating if it meets Federal or California standards. The basic rule for which light duty diesel vehicle to test is 'if it has an ECM/PCM in it then it needs to be tested'. When the inspection station tests the vehicle they interrogate the ECM/PCM through the OBII port. If the check engine light is on, a fault code is pending, a fault code is stored, or the monitors are not set the vehicle fails the test. In the past with just the Fuel Boss running and the electric fuel pump totally disconnected I have seen fault code P0230, Transfer Pump Circuit Out Of Range; this is why I put the relay in for the ECM to trigger and keep the fault code at bay. I just now tried to induce the P0230 code by removing the lift pump rely and starting the engine with my code reader plugged in to the OBII port. I found no code set at this time but have left the relay out and will drive it that way to see if code will reappear. It may take a while because this is the first time in 2 weeks that I've started the engine and it was over 4 week before that.- Fuel Pressure High!

My system is set up with the electric pump but not used but with the ECM triggering the relay. The check engine light in this truck would come on if this was not done. I need the light to stay off due to Calif. SMOG testing. The relay option B was used, see below, and the 10 AMP fuse is remove to keep the fuel pump from running. When the electric fuel pump is needed to prime the system, the fuse is reinstalled.- Useful mods/custom stuff

@pepsi71ocean here it is.- Big change in my life...

- Fuel Pressure High!

I have just the opposite problem. Over the years the fuel pressure at idle has been decreasing. The pressure at idle was 17 psi and has now gone as low as 13 psi, when first started on a cool morning, and will settle at 14 psi. The fuel pressure will jump to 18-19 psi when off idle. This Fuel Boss system, when new, also dropped fuel pressure due to black pieces of hose rubber getting stuck in the pressure relief valve.- Head gasket replacement

With that many miles on the turbo It might be a good idea to inspect it for play at every oil change from now on.- Useful mods/custom stuff

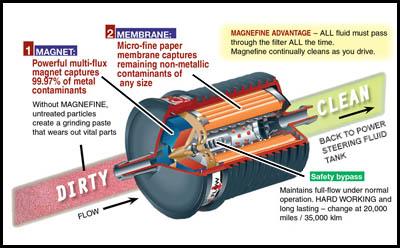

One of the mods I've done is to add a filter in the power steering return line. Hopefully that will increase the longevity of both the power steering pump and the hydroboost unit. Second mod was to wire the truck for video feed from the 5th wheel. This view out the back window of the 5th wheel allows the drive to monitor the trailer being towed behind the 5th wheel, also when changing lanes if the trailers are clear, and aids in viewing behind clearance when backing up. Installing the mystery switch with brake release was a big help in towing. - B&W Hidden Goose Neck Hitch Installation