Everything posted by Haggar

-

Intermittent Coolant Loss?

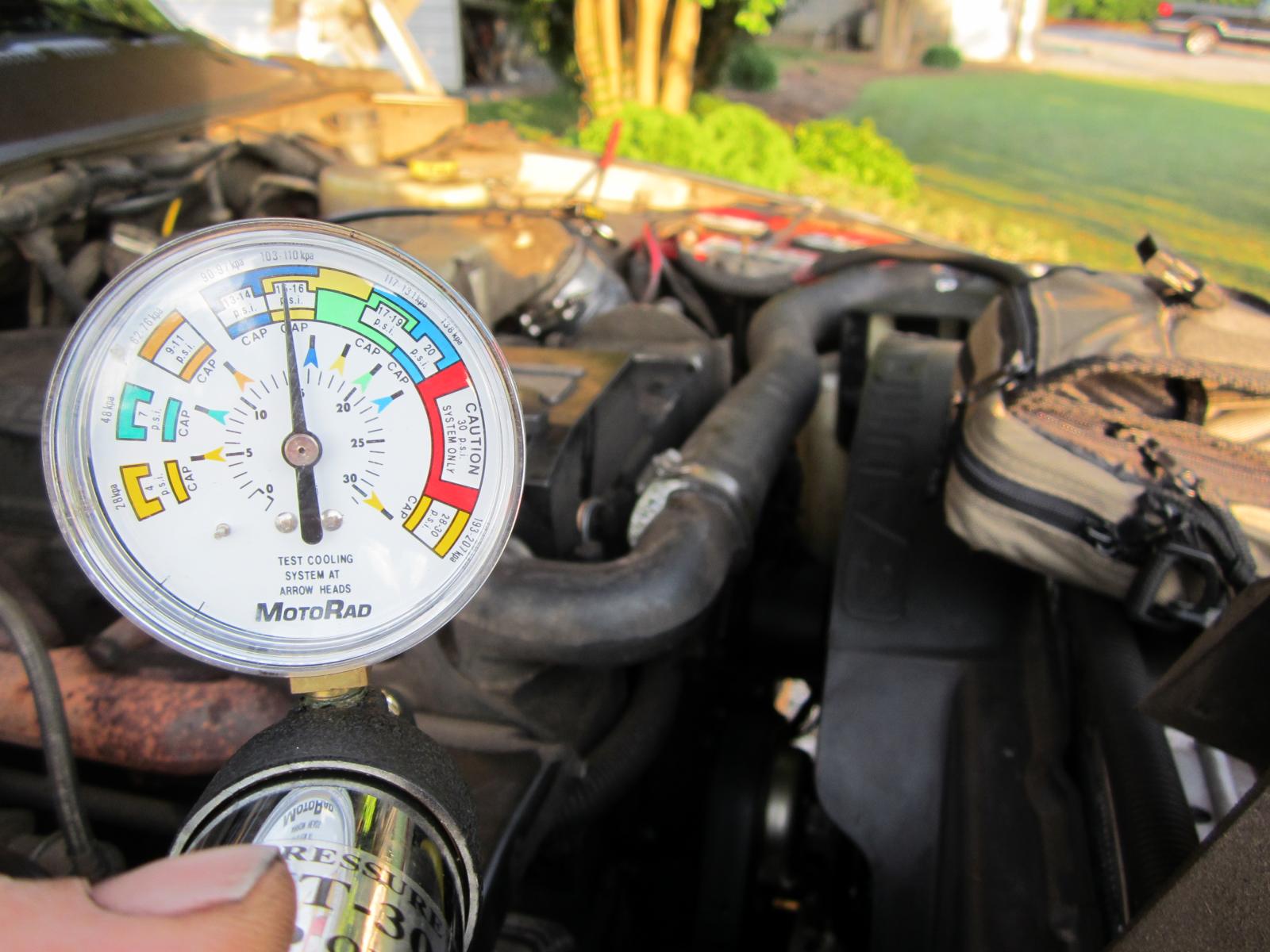

Arod, I had a similar issue. It will only leak when the pressure gets above a certain PSI. In the first picture, the pressure is only 10psi. As I pumped up the system towards 15 psi, you can see the hose connection at the housing bubbling. Find/borrow/buy/rent a radiator system presser tester.... they are handy for jobs like this. Good Luck, Hag

-

Oil leak

ltz, Clean the side of the block really well and let it dry. Use flour (yes flour) all over the side of the engine. (you just throw it on there) go for a drive. since the flour is very white, fresh oil leaks will stain the flour. It doesn't stick well on vertical surfaces but enough should hang on the gaskets and in the cracks to help you see it. I also wondered (but have not tried) if NDT developer would work (it is bright white, sprays on and is usually not too hard to remove...) Hope that helps you find the leak! Hag

-

Cold weather starting problems

One thing I think i noticed in this thread, Double check the batteries! Part of the compression formula is speed. Cranking speed comes from voltage. Older batteries or poor connections, cause a higher voltage drop so starting speed drops.... (we also have the cold oil and other higher mechanical drags.) I was hoping there was a cummins spec sheet like on the stationary motors showing minimum cranking speed. It seems we need at least 150rpm and closer to 175rpm. You may want to warm your batteries. That may make a big difference. Here is a neat sheet attached on calculating what size batteries we need and here is a nifty video on voltage drop Hope you get it figured out! I have a couple batteries here at the house right now (not including the ones in the truck) That will hold 12.6 volts all day, but the minute I try to start, they drop to about 6v.... If the car lights off I am in good shape, but if for some reason I need a second crank, they won't make it..... Happy New Year!!! starting amps calculator.pdf Note, at about the 9 min mark they show a list. It says if you drop below 9.5 during cranking, batteries are bad. ( looking for a voltage/speed curve for starters...)

-

Happy New Year and conversation with engineer

http://www.scheiddiesel.com/blog/the-result-of-installing-a-cummins-turbo-diesel-inside-of-a-66-chevy-impala/528 I also thought there was one of the big magazines (car craft, hot rod....) that put a cummins in a '65 impala. But maybe it was the duramax..... grrr. Happy New year!

-

No power!?!

Cueball, This is one of the main troubles with the OBD II system and the sensors that report to it. ALWAYS remember: the computer THINKS the information is TRUE, even if the data makes no sense. The computer only checks to see if the sensor reports a value that is out of a specified range. If the computer sees the value in the proper range it makes the ASSUMPTION the information is true. It does not use logic to relate that information. (ie, it does NOT go "hey we are at 90% load and have been for 5 minutes, why has the coolant temperature not changed or going down?) So a map sensor that reports a value in the normal range and is stuck there, even though it should "know" that the range should have changed with engine load, it says everything is all okiedokey and therefor no CEL or codes are set. This is why it is so important to let the human brain see the actual values and apply logic to the values. (now i will get on my horse to say this is why all these points and ranges should be easily found and verified. The OBD system is not very self diagnostic.) HTH Hag

-

New Speakers

Hawk, You don't mention in your sig if you have the upgraded stereo (with the tweeters in the pillar I think) or if it is a quad cab or not. But fronts should be the same either way. I like crutchfield http://www.crutchfield.com/ Put in your vehicle information, go to speakers, then look at the list of speakers. There will be an information thingy below each one that say "it fits" with a green check mark. click it. It will show you what bracket will come with the speaker to make it fit and tell you of any other modifications needed. If you still bomb, call them. I have always had superb service from them. (and all the brackets, wiring adapters etc are part of the price. you don't have to select them individually and make a mistake.) On the speaker end, the replacement speakers never have the same connector as the factory, so do be prepared for that. HTH Hag

-

Morning Pic For Today...........Post A Pic around your place.....

My sons are JEALOUS!!!!!!! Hope it is not too slick for you! Be careful and stay warm! Hag

-

Fuel return line

lol, using me as a standard of crazy or not.... this may not be a good plan... Leave it as we agree! That way when those nice young men in their clean white coats come to take me away, they won't grab you too! You could extend it with some stainless tubing if you needed, but I totally agree (and you guys are colder than us) the energy available to mess with this stuff is an inverse exponential of the temperature! Have a great one! Hag

-

Fuel return line

Yep!!!! nice work with paint!!!!! I wanted to do that but didn't have the time. (so I wrote a book.... in my mind that worked easier...) Yes that is exactly what happens with your short return line. "one end" of the hose comes out of the water, so air can go in and drains the whole thing. Longer tube that keeps it submerged will solve a whole lot of that. Hag

-

Fuel return line

Guys, There is no pressure if there is no resistance to flow.... Think on that for a second. If you took all your injector lines loose and ran the vp, how would the diesel look coming out? would it shoot across the room and cut a hole in a wall like a pressure washer? or would it dribble out or maybe just go across the valve cover and land on the passenger fender? (when we bleed the injector lines, they dribble and might spray a little bit, but only when you are close to tight. They do this because there is no resistance, and resistance builds as we close the connection to the injector) (I am attaching a picture of GM 6.5 type injectors (also on ford tractors and other things. See the small rubber hoses? That is the "high pressure fuel return". The pressure drops so quickly, that hose is fine even though its POTENTIAL pressure is in the 1,000s of psi.) The VP only makes pressure when it sees the resistance of the injector. The vp puts a volume of fluid out. When that volume of fluid is greater than the springs in the injector, the injector opens forcing fuel into the cylinder. As the VP is ending that cycle for that injector, the volume of fuel reduces so the springs in the injector close the injector. The slight bit of high pressure fuel that is left over from the event, but not enough to make the injector open, spills into the rail in the head and goes back to the tank. The reason that this fuel flow does NOT seem to have pressure is: The return line has little to no restriction, so there is no pressure, just volume. This circles us back to since the return rail and fitting at the back of the head are the highest points, any air that comes in immediately helps draining the whole system... The check valve that is on the outlet of the VP is not perfect and it has a little bleed in it, so there is nothing to stop it from completely draining. Air at the back of the head,will basically drain everything. You can model this at home. Take a pail of water(diesel would be better, because viscosity matters, but is messy) and some clear tubing (cheap PVC stuff at the hardware store is perfect). Put all of the tubing in the water and slowly maneuver it until there are no air bubbles. Now leaving the ends of the tube under the water, lift the center of tubing as high as you want. Do air bubbles ever develop? Now take one end of the tubing out of the water. Does it allow air to come in? Do air bubbles develop? now poke a hole in the tubing. What happens to the water? Now take some measurements and lay the hose like it rides in your truck, pretend the bucket is your tank. Hold the return end 6" above the level of water in the bucket. have the mid part of the hose about 12" above the pail. (not the water level in the pail, the pail itself) (12" is what i estimate the head collector fitting is in height relative to the top of the tank) what happens to the water? Where does air go to? you can put a tee and such to model it completely. now factor in JAG returns to the neck.... well above the tank height. Put a droop in the line for his situation and make a leak at the same point..... Its a great idea! even with a small leak up high, he traps a bunch of fuel down low minimizing the trapped air! My $0.02 MERRY CHRISTMAS!!!! Hag

-

Looking for 3rd gen calipers

While were here, and CSM is starting on our Free Body Diagram.... Lb for Lb, changing Rotor diameter will not effect the MPG like tires will. It comes back to the inertia, not just the straight weight added... The radius of the mass change of the tires is much further out when compared to the radius of the mass change of the calipers. so the inertia will be completely different. The distances for calculating inertia are squared functions, so you get a parabolic relationship of radial factors in the equation. In simple terms, mass added near the axis of rotation has a exponentially smaller effect on inertia, than the same mass added evenly a a longer radius. ( It is very similar to the ratchet and cheater bar used earlier.... except that is direct ft*lb.... inertia is ft^2*lb...) I am going to make some popcorn too.... Merry Christmas!!!! Hag

-

GREAT video explaining driveline angles

Heresy I say!!!! You must do all the calculations for the position, velocity, and angular acceleration by hand!!!! Otherwise all those differential equations we did will not get used!!!! Where was this video when we were trying to explain this problem to someone a year or so ago... I know we spent 3 or 4 pages trying to convey this concept and still not sure we did a good job.... Great find! Hag

-

Morning Pic For Today...........Post A Pic around your place.....

That is the Little Bradley falls. Saluda NC. Just East (south physically but east on I-28) from Ashville. This is right past the top of Saluda grade if you are familiar with I-26. The Big Bradley is a 200' waterfall/Rappell. Hope to do that in the spring. Jolsen, my boys are so envious! They want snow so bad this year!!! (I am hoping for just some rain at the moment!!) Hag

-

Morning Pic For Today...........Post A Pic around your place.....

Awesome pictures! Sorry mine are not a sunset or rise, but we had fun! (smoke here has been bad from the forest fires, so the moon has been cool colors, but super limited visibility.)

-

Billet Flexplate and Washer

I like Shigley, I do have a few others around if you need some more reference. He did a lot of the best modern research on bolted connections. You are looking for "Slip critical" calculations. It will get you in the ball park. HTH Hag

-

Billet Flexplate and Washer

From an engineering aspect, if there is not a clearance problem with using the washer, I would absolutely re-use it. Make sure it is flat and that you torque properly. Remember the flex plate is NOT supposed to transfer the torque through putting those bolts under a shear stress. The complete torque transfer is from the Compressing/clamping strength of the mating surfaces. make sure the surfaces are clean and burr free, and that the bolts can easily achieve the torque. (hand test the bolts into the end of the crank.... if you cannot screw them in with two fingers easily, correct the stretched bolts, or damaged/dirty internal threads.) Make sure that the bolts do not bottom out or the shoulders interfere with proper clamping. HTH Good Luck! Hag

-

Ever been to south Carolina?

Hex, pm if you want to come down and visit. I lived just north of Charleston, in a very rural area west of Georgetown. Having been in both Idaho (best friend lived in Buhl for a few years) and the low country of SC, they are very different but similar at the same time. I think you need to visit some. The mountains are not close and are different, much older, smoother and covered in significantly thicker forest. The low country of SC is swampy. no other words for it. We are actually camping and canoe/kayaking this weekend in the swamps. (I presently am closer to the mountains now.) I am going to attach a couple pictures. One is a quick snap I took near Linville gorge on our way to go rappelling, one is the boys at a sliding rock the mountains, one is my oldest in a kayak going through a cypress knee, and the other is a sunset from a barrier island looking back over the intercoastal and towards the mainland. I added a couple more of us setting up a rappel looking into the gorge and one getting gear on looking away from the gorge. These mountains are 3 to 5 hours from Charleston. I try to avoid the Charleston area... too many people. But it is a great place to keep the boat to go fishing. HTH Hag

-

Fuel tank and In-tank pump vs engine mounted lift pump help

You could test with the in cab switch, but IBM and Drip are right... Scary to have it setup without an auto shutoff. If you wanted, you could put a pressure switch in the oil system (there is an un-used threaded boss in the oil filter housing). This would prevent pump during starting, but allow it to run while engine is running. When engine stops, so does the pump. If your ECM is no longer outputing the Fuel pump power, but nothing else is wrong with the ECM yet, this might be a good patch until it fully dies. Good luck! Hag

-

TIRES

I just have to say I have really liked my wardens so far. I have 3 vehicles with them. ( I have friends with 3 more sets. 2 on 6.5 diesel Suburbasaurus and one on a toyota 4 runner. ) No problems. I tow heavy with rattle monster too. I used them (tires of the re-mold process) on my dirt track and autocross cars in the late 80's and early 90's. Especially for autocross, they were amazing! I could get a killer soft compound, and still have DOT validity (The class I was in I could not use "race only" tires). I am not saying that they can't have troubles, but new tires from the big guys can too. http://www.nhtsa.gov/Vehicle-Safety/Tires/Firestone-Tire-Recall (I don't think that was all Firestone's fault btw.) http://www.michelinman.com/US/en/help/safety-recalls/ltx.html http://www.arfc.org/tires/ If you get to see the re-molding process, it is darn good. (waaayyy different from the old system our parents (ok most of our parents) warned us about.) It keeps quite a bit of tires out of the land fill too. Spend your money where you are comfortable. I am presently happy with the products from treadwright. Hag

-

Hydro Boost rebuild issue

Doug, you can check for a restricted return by just blowing through the return line with the power steering reservoir cap off. (do it with it on too, to check that it is breathing properly... we ran into a plugged one the other day causing troubles.) The easiest problem for this to happen is somehow the rod from the pedal to the hydroboost was not put back properly. (the rounded end didn't go into the little socket just right.) Did you remove the booster push rod from the brake pedal? or did the ball come out of the back of the booster? On the GM hydro's the input rod has to be removed from the brake pedal and taken out as an assembly with the booster. A careful measurement of the rod length is made before disassembly. I am not sure how the dodge comes apart. (The FSM says to remove it this way.) If this is how it came apart, were you able to get the input rod back installed in the proper place? (relative overall length?) HTH Hag

-

First Time Death Wobble

Leather, it is the nature of the beast. And like dripley said, you have fixed 80% of the common problems. So it's hard to say what is still possibly a problem. I noticed in your original post, you didn't say anything about new upper control arm bushings. I would try at least a good pair of tires on the front (all 4 don't) have to match. I would also do a better job of checking the toe. With the same tires on the front, inflated to the same pressure, clamp a 3 foot piece of square tubing to each wheel. low enough so you can pass a tape under the truck to measure the ends, but high enough so you are not on the "bulge" of the tire. (you really want to go rim to rim, but that takes a bit of fabricating...) I got these pictures from IH8MUD dot com Either will work. Angle iron is a bit weak, and is not always straight. On the one with a tire on, be careful not to do the ratchet strap so tight to bow the straight edge. (this is why i like square tubing better. I also check it with a straight edge first.) Use math to get your angles from the measurement. Total toe is 0.10 degrees +/- 0.10 degrees. If your straight edge is 4' long, the difference between the rear and front measurement should be approximately 0 to .168" or zero to 5/32". HTH Hag

-

First Time Death Wobble

Quote from tire rack's tire tech pages. "Increasing the amount of positive caster will increase steering effort and straight line tracking, as well as improve high speed stability and cornering effectiveness. Positive caster also increases tire lean when cornering (almost like having more negative camber) as the steering angle is increased. What's the downside to positive caster? If the vehicle doesn't have power steering, a noticeable increase in steering effort will be felt as positive caster is increased. Other than that, the effects of positive caster are pretty much "positive," especially increasing the lean of the tire when the vehicle is cornering while returning it to a more upright position when driving straight ahead." In our 4x4 trucks you almost can't get to the point of too much caster angle. There just is not enough factory adjustment. And "too much" just adds steering effort not controlability issues in fact controlability is better not worse. Back to where our problems arise.... wow. as ride height changes in bounce and rebound, the axle moves laterally, (the track bar is attached to the frame...) depending on how far the axle is moving, caster and camber is changing (the axle housing is rotating about the instant center of the control arms...) Toe is changing.... due to both lateral axle movement and the fact that the steering box is attached to the frame. These are movements in a perfect world. Add in the fact that there are loosenesses associated with each mechanical component (more when worn or loose...) and it is a nightmare of who is to blame, or is it a combination. (I didn't bring in spring rates, tires (can be a HUGE issue, especially if they have their own spring rate that can drive the issue.) shocks and sway bar (which can change spring rates.... I noticed you mentioned it, but usually it only comes into play when turning... but Mike's description of what he saw, left/right tire fighting each other, should be damped by sway bar, not excited by it.) anyway i think i have made this just about clear as mud. HTH Hag

-

Low fuel pressure light that light up around 12 psi plus psi?

Stewart warner offers 10psi and 15psi. Looking through Honeywell for an adjustable, but prices getting high... Saw the Stewart Warners on summit. But kind of pricey. never used part deal, but this looked reasonable (if part deal is a good vendor.) http://www.partdeal.com/veethree-single-circuit-pressure-switch-10-psi-nc-12-24v-with-1-terminal-d780923.html?zmam=74973193&zmas=1&zmac=4&zmap=77224207&gclid=CJrA06-nns8CFURlfgod4G4DDw You may want to check Zoro too. GL HTH

-

RV275s

lions and tigers and bears oh my.... http://www.hotrod.com/articles/ccrp-0905-hemi-engine-swap-guide/ tomorrow I hope I can get this topic back on track, but I had to digress.....

-

Fender or Door

Leatherman, After some of your thoughts Friday, I paid attention to my doors. The drivers door will stop "easily" closing about 1/2" before latching. (passenger does not at the moment....) What is causing it is the Foam trapezoidal piece at the base of the A-pillar. (center screw through foam) I just took some paper and laid it in the jam in different spots until it pinched. If that is the case in your truck you will notice it hits a curved part of the door inner structure, so a slight movement in the door will make a dramatic change in the spring pressure of the foam. If you get the door right, adjust the foam a bit. (I am thinking this foam is for an auto open feature, or a way to load the door against the hinge a bit so it won't rattle. You can see that it is not for sealing the door or anything like that.) HTH Hag