- Replies 29

- Views 11.8k

- Created

- Last Reply

Top Posters In This Topic

-

dripley 8 posts

-

Dieselfuture 5 posts

-

int3man 3 posts

-

milradioman 2 posts

Most Popular Posts

-

Ok I know several members have done this mod and said it was easy. It sure is easy. It takes about 2 hours from start to finish to complete this project. You'll need the terminal lugs and the metric b

-

Yes I heard about a guy that found his to have a bad connection, kind of loose and was causing transmission hunting. When he soldered the two wires together it went away. But, now we know a lot more a

-

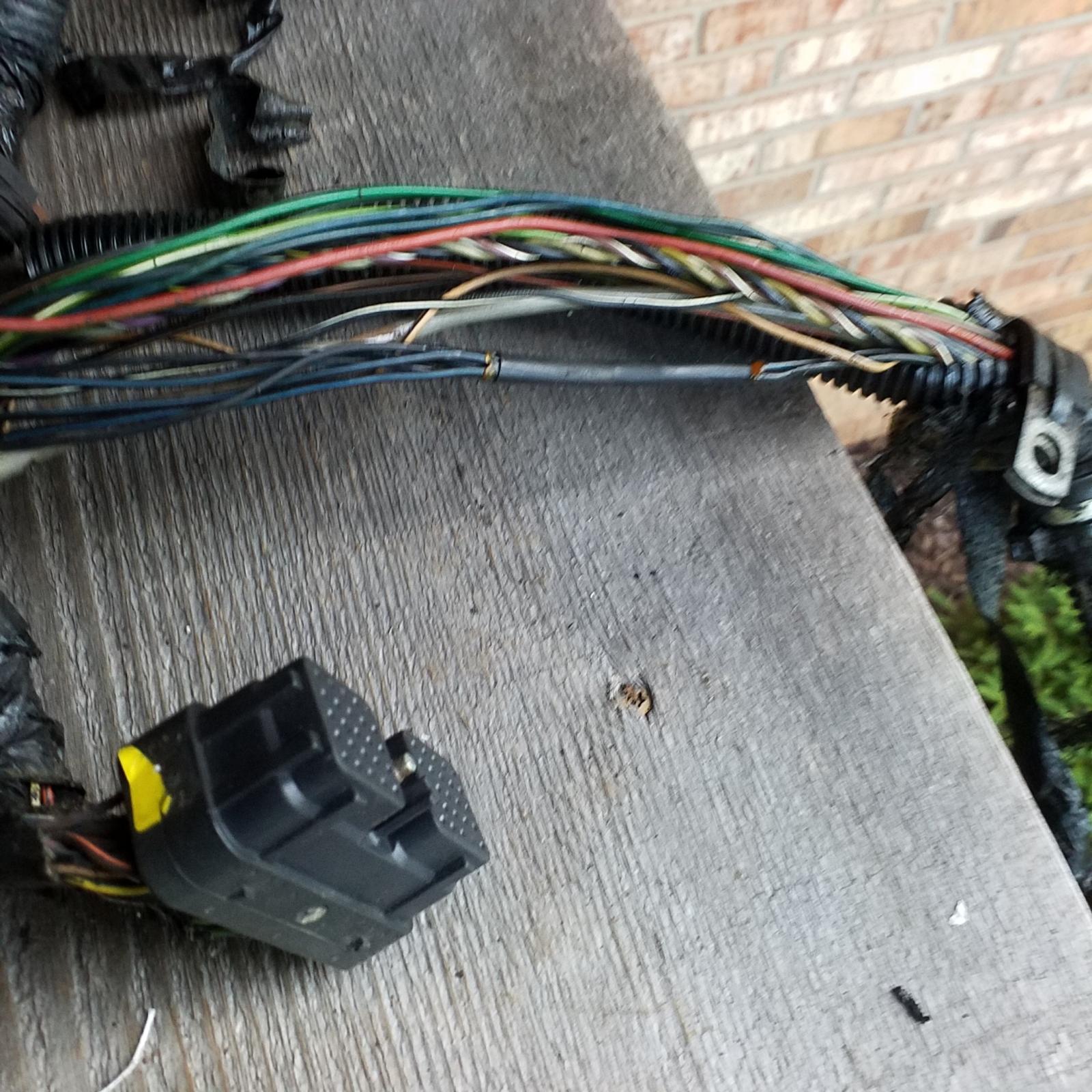

Here is the splice, about 8" from the ECM plug going toward the VP. There is another splice of the 5v signal to the the MAP and oil pressure sender/switch that might be my issue but I have not fo

Soon to come... W-T simplified ground mod article. I did mine without buying very much stuff at all... All wire was reused!

Edited by Mopar1973Man