- Replies 43

- Views 6.2k

- Created

- Last Reply

Top Posters In This Topic

-

LorenS 12 posts

-

Threadzy 9 posts

-

Mopar1973Man 7 posts

-

Me78569 4 posts

Most Popular Posts

-

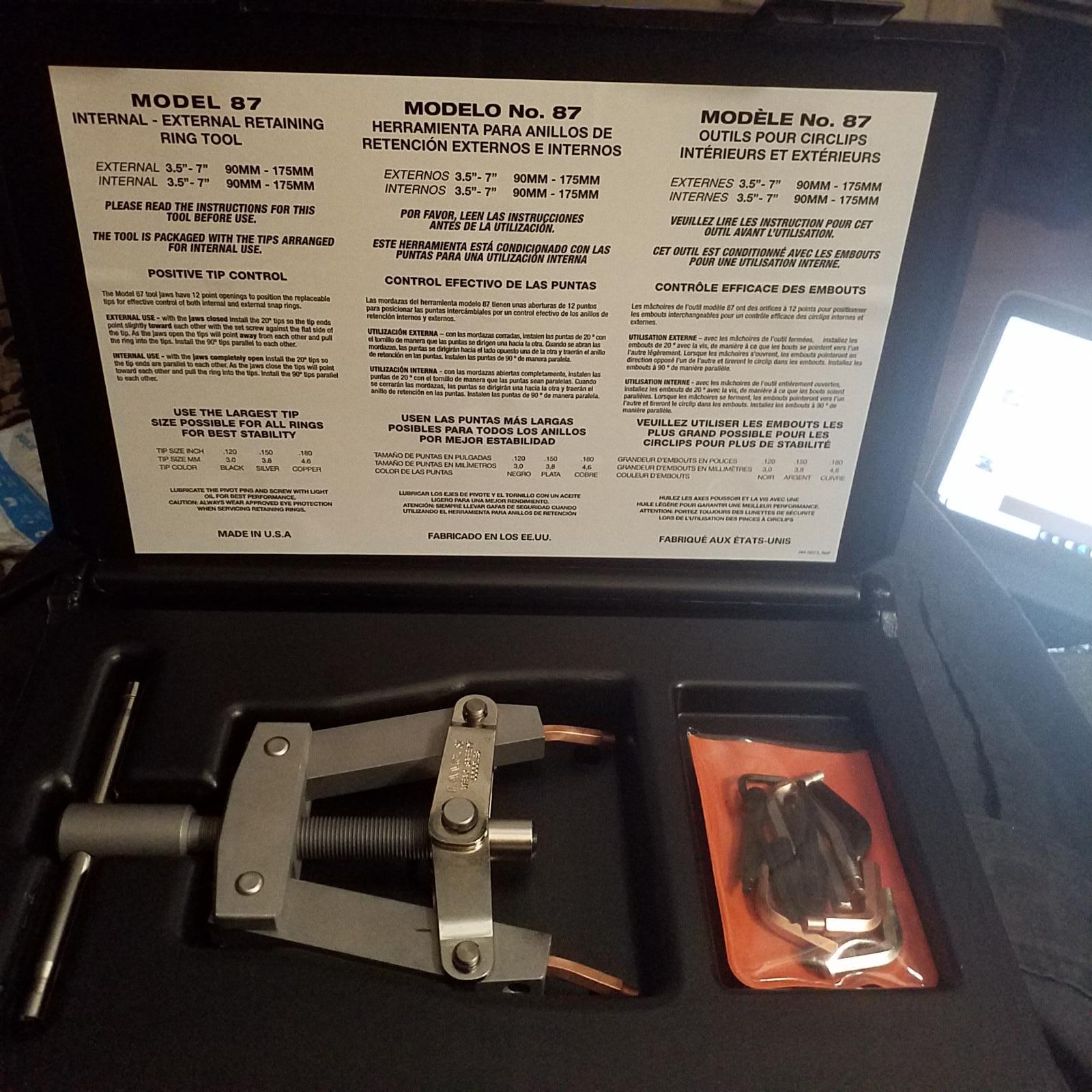

I would like to thank @Joe_Poolfor the info on toold. Picked up the Lang and it looks very suited to the job,

-

Here are 2 tools that work quite nicely: Lang 87 (USA made) and ATD 4031M (Taiwan, but well made) In the pictures the blue handled one is the ATD. I prefer the Lang, but they

-

A buddy came over this afternoon so I got the new turbo on and my new Diamond Eye 4" exhaust installed. I did NOT do anything for the waste gate, it's just wired shut right now. My HY-35 gate has

Does anyone have good knowledge of what the turbo angles should be? As best as I could estimate on my truck with the current turbo installed (due to rust, certain components will be destroyed upon removal - and I don't have a spare vehicle right now) it seems:

"around" 20 degreesfrom horizontal. EDIT: I'd say I would up more around 25 degrees or a little steeper to keep everything very well aligned and no stress on the rubber boot.I would like to change the turbo back this weekend, and really want to get my turbo clocked correctly this evening so I have just one less thing to worry about after taking a Sawzall/smoke wrench to certain parts of my truck. I have failed so far at getting that compressor snap ring back in, so once it gets back in I don't want to have to make corrections!

Any help appreciated! I don't have the right tool to measure that compressor discharge flange angle. I removed the boot/elbow one evening this week to measure the angle, but then discovered I haven't the right tool to do so. @dripley this may interest you once I get the data. Hopefully we can further refine the path blazed by @Blueox01 so BenzeForce can just offer these turbos already setup for our application.

Edited by LorenS

tag Dripley, etc.