Everything posted by Mopar1973Man

-

CP4 pump recall

More on 5th gens... https://www.tiktok.com/t/ZTR51sDUN/ Be aware FASS fuel system will void your warranty.

-

Midna's build

If the valve guides are worn the the seals will fail rather quickly. This is due too much valve stem wobble.

-

No start after Pac Brake install/Now VP electrical issue

Key fob security locking you out? I've seen some that ditched the fob and quit using then have the security prevent start up. Another is the ASD Relay which could prevent start up.

-

2001 Dodge Ram 3500 Transfer Case

Everything more or less. With a time crunch I need quick turn around being they needed the truck last week just get the new case or a kit would be about the same time being nothing is in stock. Getting the rebuilt unit only take me 0.5 to 1 hour to install.

-

CP4 pump recall

Yeah CP4 pumps are being recalled and Dodge dealers are installing CP3 as a fix. https://www.tiktok.com/t/ZTRPvcdjK/

-

2001 Dodge Ram 3500 Transfer Case

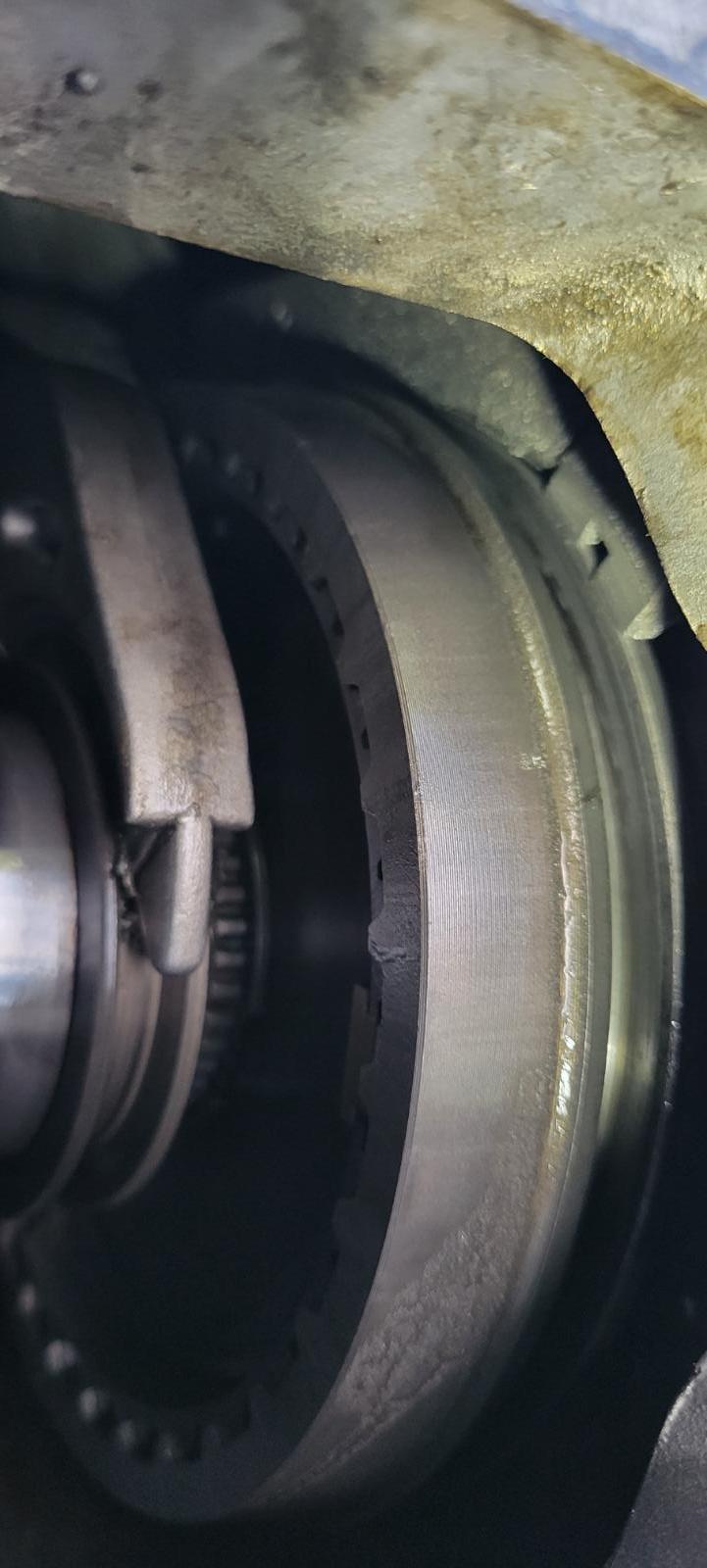

Yeah I've got a previous customer back. The white Dodge that I did the AirDog had a problem with 4WD and it wasn't locking in. First thought was CAD axle issues but after testing the transfer case and seeing if the shaft locks nope. Something wrong it the transfer case. I pulled the drain plug nothing came out but 4 drops of black thick oil. Removed the transfer case and open the inspection plate and ther is broken metal, plastic, and pieces. I'm heading to Boise Transmission warehouse to get a reman transfer case Tuesday morning.

-

Clarkston Trip

Ok. I've got to jump in. As for the cooler. So @Honey Badger started complaining about her ribs being sore. I responded totally serious and told her "At least you didn't get a cooler up your . Earlier that day is was traveling down Thain Grade and light changed on me I stabbed the brakes and this big white cooler slams into the back of my seat. So I got a cooler up my . It was the timing and the way I said it that we laughed for nearly a full hour last night. Yeah finally died off at 3am and the woke up at 8am. Yeah we partied hard last night and now back to business. Time to do the shopping today and head home.

-

Towing, Turbos, and Quads

Personally too many upgrade turbos too soon and/or too big of a turbo. Just consider myself running 150 HP injectors on a stock HX35W which is 54/60/12. I can see how 58/72/12 would spool fast being the turbine is larger and gives the leverage to spool that small 58 compressor.

-

Tennessee

Sorry to announce, due to HoneyBager's continued heath issues, I am canceling the trip to Tennessee. While she is improving, the doctors feel such a long trip could cause a relapse. We are planning to try again next year.

-

How hot are you?

Yeah we've been hot here all summer long. Even yesterday I was changing oil on Minnie it was 95°F. Then cleaned out inside, and vacuum, etc. Figured to check the freon levels and added another 2 cans. Now this morning we are packing up and heading to Lewiston for another restock trip being prices are better in larger cities. Lewiston is only 750 feet above sea level so it going to be hot today.

-

Towing, Turbos, and Quads

Just remember I'm using a stock HX35W with 150 HP injectors tuned by Quadzilla and no EGTs problems even with towing my RV to California catching up with @JAG1 and @IBMobile. Just notice the elevation is fairly flat and EGTs are low. When your properly tuned and the right hardware you shouldn't produce any heat. Biggest problem is incorrect final ratio because of oversized tires on 3.55 gears.

-

Coolant temp gauge bad or ecu failure?

Unplug all mods. Then re-test. If it's still showing incorrect then test your wiring. Typically the ECT and IAT should be the same at key on and no start.

-

F'ing Ford Ranger

Nice old Ford tractor. I love that old Ford equipment. Back then they made good stuff that people could fix and keep going.

-

F'ing Ford Ranger

Yeah I did. Now Mark he's renting my guest house and he's doing brake job on a Ford car and he's cussing and throwing tools. He's all pissed off spending 2.5 hours screwing the rear caliper piston (driver side) in so can install new brake pads. He asked me to see if a local shop had the tool. Found one and still took him all day to do brakes on that Ford. He's now like me he doesn't want to work on Fords any longer. Another one... I was running up for the final day to work on the Ford Ranger. Turned off on Mission St in McCall ID heading for @Honey Badger place and Grandma in a Ford Explorer nearly rear end Thor (2006 Dodge 3500). FORD - For Only Retarded Drivers. Another one... I was heading up to @Honey Badger place to bring her down for the weekend. I was heading up Goose Creek Grade which is a 7% grade with a speed limit of 45 MPH. I'm cruising Minnie (1999 Dodge Grand Caravan) at about 40 MPH and run up on another Ford Explorer and the driver is cruising 12 to 15 MPH. Stacking up traffic. 5 miles of this bull chit. FORD - For Only Retarded Drivers.

-

What doing tonight? Spark plugs on 5.9L Cummins

I should ask napa counter guys to get spark plugs for a Cummins.

-

What doing tonight? Spark plugs on 5.9L Cummins

What you never seen a 5.9L Cummins with spark plus, Cummins plug wires? Neither did I till that video.

-

What doing tonight? Spark plugs on 5.9L Cummins

https://www.tiktok.com/t/ZTRPUjUkS/

-

F'ing Ford Ranger

Well it's done. Transmission is all bolted out and driveshafts hooked up. What a pain in the . Unbelievable the amount of crap you have to remove to reach bell housing bolts. It was a challenge to get into the pilot bearing too. 4 days to swap transmission and transfer case. I'm taking a day off after 4 days of 12 to 14 hour work days in exhausted.

-

F'ing Ford Ranger

Last night I worked till the sun went down 5 hours just trying to stab the clutch but still haven't got the pilot bearing. Today I'm going back for my 3rd day hopefully get it stabbed and start bolting it up. Please if anyone sees me drive or working on a Ford please shoot me. Absolutely the worst vehicle made and sold in the USA.

-

How hot are you?

Just as I left for McCall to head to work this evening it was 98°F.

-

Traction Bars for short box 2wd

ATF+4 scares the heck out of me I really do need to change the fluid in Thor very soon. When your working the transmission climbing grades it heats up quickly and gets even thinner. That was another reason I went away from the factory fluid which is no better than 10w-30 engine oil. Yeah it might make for easy shifts but the protection isn't as good. I want the fluid to cling to the bearing and syncro's not to be slung off and leaving a thin film.

-

F'ing Ford Ranger

Well I know I said I was going back to doing just Dodge Cummins. When you have @Honey Badger uncle asking if I can help him change a manual tranny in a Ford Range I thought is small and light should be easy. Nope. What a pile. So much crap to remove including the front fender shield and the front tire to reach the bell housing, the though to pull the transfer case off... Nope you can get the top 3 bolts. Another time when ford made it so bad it would be better to remove the cab so you can actually reach all the bolts and do it much easier. Since I'm working in @Honey Badger yard it going to be a fun one to finish up.

-

Engine Article - Engine Oil Pan Gasket Replacement

Awesome suggestion I'll keep that in mind when a cam replacement comes.

-

How hot are you?

Too hard to reach on a 45 degree slope without wiping out a building or having it roll out to the highway. Most of my back yard had been logged already. Hence why I gotta go out to the forest to get mine.

-

How hot are you?

Yeah and no. With all the fires that have burned its rather long hauls to get good firewood. It's like 30 to 40 miles to get to firewood.