Everything posted by Mopar1973Man

-

99’ 24v Alternator Went Bad, Possibly Fried PCM/ECM/VP44?

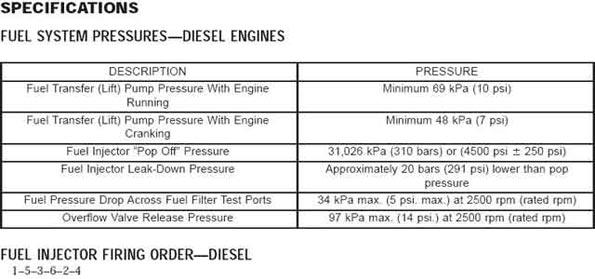

I lost my first VP44 at 50k, stock fuel system with only 7 PSI. This was the start of the website and the very first article. I installed a AirDog 150 shortly after that VP44 failed and kept 14 to 20 PSI that got that VP44 to last 243k miles. Still going on this VP44 at 451k miles. So in nearly half a million miles only installed two VP44. With the stock filter in place I'm polishing my fuel through the AirDog and the stock filter. As for the P0216 code it's more lubricity than fuel pressure. The piston galls up and sticks or seizes up. 4 ways to kill a VP44 1. Low fuel pressure even the Dodge FSM states 10 PSI minimum. 2. Low fuel lubricity Bosch states <460 HFRR or less, US fuel is 520 HFRR. 3. High AC noise from alternator. 4. Poor filtration.

-

1999 Dodge 2500 4 wheel drive/ Electrical Drain

Addon. We unplugged the PCM and central timer and 50A battery fuse. Draw is gone. Plug in any of the above the draw is back. So I'm assuming PCM and central timer have issues. Another addon... just talked to the customer and just going to put a cutoff switch.

-

1999 Dodge 2500 4 wheel drive/ Electrical Drain

I've been helping too. It's got the draw on the 40A trailer fuse in the PDC. As mentioned the trailer brake controller has be replaced. Then we separated the trail light loom and no change so the draw is in the cab.

-

Delayed start - longer turnover.

Let me dive in... Cranking fuel pressure should be 7 to 12 PSI. If it is above 12 PSI it will create a hard start issue. Running fuel pressure should be 14 to 20 PSI. 14 PSI is the minimum to keep the overflow valve open fully and keep return flow going. Above 20 PSI you take a risk at blowing the pump seal out. Yeah I'm sure there is people out there past 20 PSI but I've seen just 22 PSI blow the front seal out. As for an AirDog 100, 150, 165 all use a power relay to supply power and keep the stress off the ECM electrically. Injectors if they have over 100k just replace them. Injectors typically get low pop pressure and get slightly higher idle. Check your engine load at idle warm if close to zero then the injectors are shot.

-

99’ 24v Alternator Went Bad, Possibly Fried PCM/ECM/VP44?

Ok the best I can say alternator wise have your alternator bench tested. If it doesn't pass then its time to replace. Now as for the voltage regulator its inside the PCM. You need to pull the field lead and start the truck. The blue lead should show +12V and then the green should show -12V (or ground). This should only be present when the PCM sees tach signal from the ECM. If there is still charging issues then your going to need to send the PCM to a rebuilder like @Auto Computer Specialist have them test and repair your PCM. I've also got to ask did you do a W-T ground wire mod yet? If not I highly suggest you get this done very soon.

-

1999 Dodge Grand Caravan 3.3L - Fuel Gauge & Cruise Control Issues

Still going to need the book I've also got a cruise control issue it won't set. The Cruise on/off switch works I've ohm tested the "set" switch and it works but not actually working. I just swapped a working cruise servo from a 1996 Dodge Dakota still doesn't work. I've even opened the old servo and it has a small 1/4 tear in the rubber diaphragm. Hence the swap I did. The wet carpet was (past tense) windshield was rotten at the top the glass has been replaced and the metal repaired. Then it was door seal wasn't in the proper track and sealing. Then the HVAC case was leaking on the passenger side because the cowl trough was plugged and would drain so it would slosh the water in the air intake. Also fixed. Why I'm looking for the book is to find the ground location. I would have to pull up both driver seat and passenger to even roll the carpet back to even look. I could roll the edge up a bit but not much. I've really not seen any leaks since but I still need to find the interior ground location for a 1999 Dodge Grand Caravan 3.3L Pushrod engine. Minnie has been a wonderful little rig and been seeing between 25 to 30 MPG. Barely a 4,200 pound vehicle (yup I've scaled it).

-

1999 Dodge Grand Caravan 3.3L - Fuel Gauge & Cruise Control Issues

Hey I'm hoping someone can find me a wiring diagram for "Minnie". I've got a weird issue with the fuel gauge that usually depends if the carpet got wet or damp in the front. When it does get wet the fuel gauge will drop to EMPTY and chime the low fuel light. Once it dries out again the fuel gauge works as designed. The sender is working correctly and not wore out but dropping the signal to the dash to display how much. I'm figuring its a ground wire but I don't want to tear the entire vehicle apart without a wiring map. Just did about 30 minutes of Google hunting and turned up nothing.

-

99’ 24v Alternator Went Bad, Possibly Fried PCM/ECM/VP44?

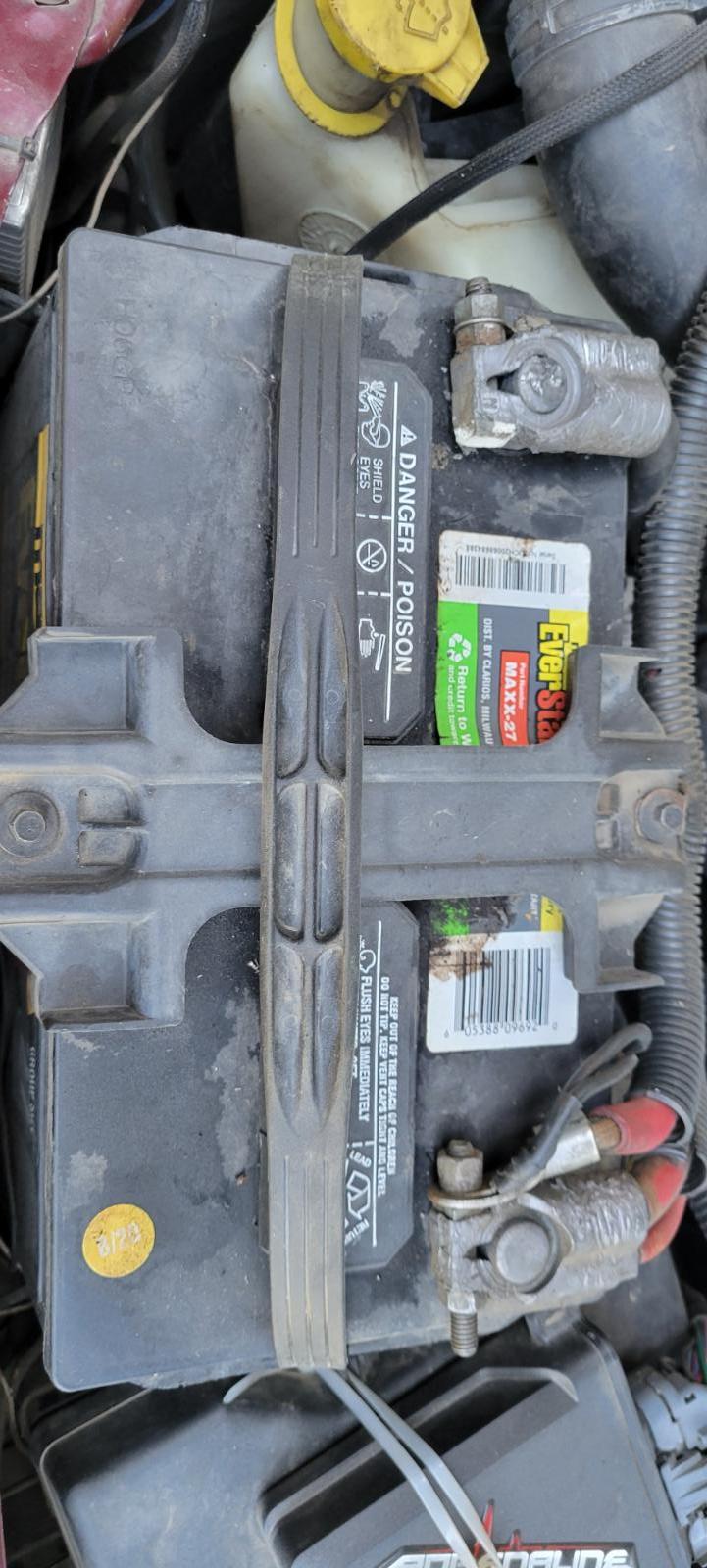

Really? Hmmm... 451k miles later still going. The only battery issue I had was the old starter was having issues and acted like the batteries were dead but after installing the new rebuilt starter, which was my factory OEM starter it started once quick and strong, then the solenoid plunger stuck and wouldn't let go. I have to remove and free the solenoid plunger and been working since. No it didn't arc and stick but wedged the plunger pin inside. Here very soon with winter coming Beast will be my daily driver. It has to be top notch and operating perfectly. Both batteries as they are right now. Dirty as well. Looks like power washing and oiling needed just a small spot of oxidation.

-

99’ 24v Alternator Went Bad, Possibly Fried PCM/ECM/VP44?

Nope. Never happened with me... I do wash off the batteries with a power washer and then reapply after the washing.

-

47re line pressures when engine braking

You might want to look back at my post I did look up the viscosity of ATF+4 and its thinner than you think. I was editing my post to add this information. Yes I do understand the viscosity differences between gear oil and crankcase oils. Still in all I do understand that thinner oils do create less drag but do they cling to parts under stress and protect at extreme loads and highway speeds or are they just slung off the parts from centrifugal forces? Like when I look back towards true racing they use some seriously thick fluids to keep everything lubed up. Just food for thoughts...

-

2001 Dodge 2500 Heat Exchanger Replacment

You might want to look at the ISSPro EV2 Trans Temp gauge for the fan controller. You can get the USB program cable and program the optional relay for a set temperature to turn on the fan and then set your warning light even higher. I thought if I ever install a ISSPro in like Minnie the 1999 Dodge Grand Caravan I would set the fan for 170*F and then warning light for 200*F. This way the fan comes on when needed and not on a toggle switch or keyed hot lead. This allows for quick warm up of the transmission and still protects for working load temperatures.

-

47re line pressures when engine braking

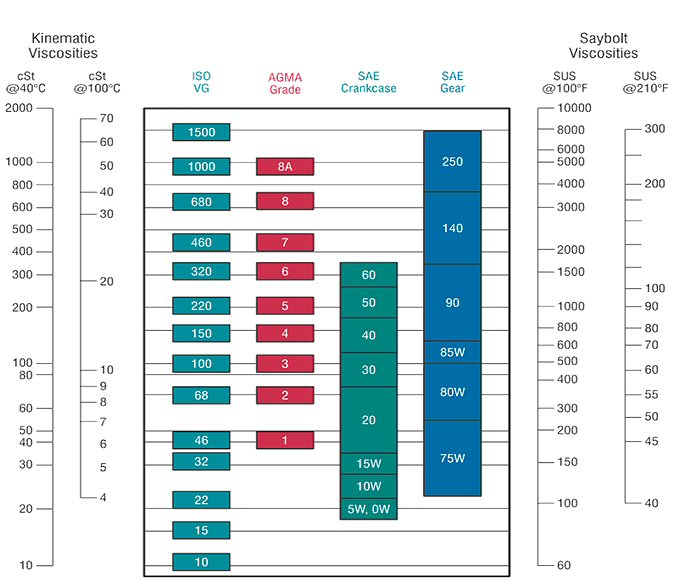

One of the weird things about automatics. They run a super thin fluid and expected to lube, cool, and be a hydraulic fluid for handling bands and clutches. I know some others have experimented with using tractor hydraulic fluids to better lifespan for performance reasons. I've seen several dump the ATF+4 and use tractor fluids. Again this will only work with modified transmissions. Don't take this as a working solution but I've seen people looking for fluids that don't thin as much with working temperatures under heavy stress. Side note (all manual transmissions) this is why I dropped the factory 75w-85 transmission fluid (actually 10w-30 engine oil for viscosity) in NV4500 in Beast and switch to 50 SAE Trans Fluid its actually 90 weight gear lube GL-4 rated. Same reason I don't want to have it thinning out under heavy loads. Another reason I'll be dumping the ATF+4 out of Thor (G56 Trans) and reloading with 50 SAE trans fluid. Better cling to the gears and bearings and doesn't thin out under heat of heavy stress. Just looked up the viscosity of ATF+4... Which is like like so thin... Look below at 40*C is 34.4 which is like 15W engine oil, then at full temp 100*C it falls off the scale at 7.5.

-

99’ 24v Alternator Went Bad, Possibly Fried PCM/ECM/VP44?

First let me ask a few dumb questions... Q: What are the only two materials that sulfuric acid can be contained in? 1. Glass 2. Plastic Q: What is plastic made from? 1. Oil So if you keep the terminals wet with just engine oil the corrosion will never happen. To this day I still have my factory battery terminals and they are still in super good condition. I've never had to clean them (wire brush or chemical cleaners). Engine oil will leave just a thin oily film that battery acid will not eat through. It doesn't get on your clothes like the red spray coating that stain. Not like grease that you end up getting on your clothes too.

-

Red Head steering gear boxes?

Saginaw boxes, if the pitman arm is stuck the way I've removed the pitman arm is remove the sector adjustment cover and then let the shaft hang through. Bring the pitman arm nut flush to the tip and lay and 2x4 on top and hit with a BFH. Typically falls out the other side.

-

Rear Pinion Seal (re-lash?)

Might help to use ARP stud assembly lube, clean the nut threads and the stem threads and coat with ARP lube, then torque it up. That lube helps to reach your torque amount much easier.

-

Coolant temp gauge bad or ecu failure?

Or ODBLink MX which is the newer series.

-

Coolant temp gauge bad or ecu failure?

Temps are normal. I run 193 to 197°F typically and could see 215 to 220°F before fully lock of the fan then it kicks I cools to 197°F. Then unlocks. I know once past 225°F the cluster will trip the check gauge light, chime and the gauge will peg at 240°F. It will not display any temp other that 240 till it drops below 225 again.

-

Factory Heated Seat Replacement

@IBMOBILE-JEN is not that bad.

-

Factory Heated Seat Replacement

Sounds like you can do a bit of sale for what you got for what he needs.

-

A/C getting warm after two recharges

Compressor front seal behind the clutch might be leaking which will not always have green dye.

-

RIP Her Majesty The Queen

There is dirty laundry every where. I'm sure if you check other countries you'll find the same problem.

-

CP4 pump recall

I might have a bad lift pump on Thor so it's not uncommon for in tank lift pumps fail on CR engines. Just a pain in the to deal with.

-

endless NV5600 problems.

First off I don't believe in the big brand oil hype. I ditched factory spec'ed oil being they are TOO THIN I'm running Mobil 50 SAE trans fluid or Valvoline 50 SAE trans fluid which is 90 weight gear lube. Designed for Eaton Fuller 10 speeds. 5 gallon bucket cost way less than AMSOil or Redline again too thin. I'm going to dump the ATF+4 out of Thor and load with 50 SAE trans fluid. Again I don't use pre bled hydraulics being most off the time I've got to pull it all back out and rebled the entire system. Happens more than you think. I don't like the adjustable hydro's as pointed out In my last post. I've got Valair clutches on both trucks are dual disc zero issues. Beast is the performance dual Thor is the Quiet Towing Clutch.

-

endless NV5600 problems.

.. and hyperextending the throw out bearing through the fingers of the pressure plate. Not fond of adjustable hydraulics. More and more people think they can adjust the pedal position. It's the amount of throw on the throwout bearing. Be very careful and adjust it properly.

-

How hot are you?

A state away I'm at 40*F for a low and currently 59*F. I've gotta run to NAPA and get a ball joint to finish a project. Signs of a heavy winter is starting to show its face already here. I'm McCall it was 35*F at @Honey Badger place in Lake Fork. Won't be long till snow will fly.