Everything posted by notlimah

-

New truck!!

Yea I'm trying to walk the line between open enough so I see fuel pressure change when it's happening but not so much to where it's flucating when it shouldn't

-

New truck!!

So the fluctuation is happening at idle (no grids running) or even when cruising with solid throttle input. I expected a psi drop under acceleration but not just random readings during those other times. Is that normal with these bigger pumps?

-

New truck!!

Ok so gauges are in. Went for a test ride and was seeing either a rock solid gauge as in, wasn't moving under hard accelerating or anything or it would wander +/-2psi when I opened the needle valve a little more. I've teed into the fuel line about where to stock fuel filter is. Can too much 1/8 line for my gauge cause weird readings? Is my tee too close to the VP? Was solid pressure actually accurate? I'm taking her to work tomorrow so I'll have more info later

-

New truck!!

Yea that's what I should've done. I think it would've started the first time around but the lines were pretty open. Once I tightend them down so they were just snug she fired right up.

-

New truck!!

Thanks Mike. Apparently this truck wants you to crank for a while before it'll get fuel to the injectors. My 99 I could just bump and the lift pump would push fuel up to them. Anyways, cranked for about 10 seconds, tried to fire. Went out and snugged down the injectors since I knew the next go she'd start and I didn't want fuel to get to crazy. Next crank fired right up!

-

New truck!!

Ok guys need help!! I have the FASS installed, I'm getting fuel to the vp, have my injector lines cracked but no fuel is coming out of injectors so obviously no start. Wtf?!

-

New truck!!

Both valid points for sure. If the hose failed I think I'd be getting a tow regardless. I'm more concerned about being able to shut down fuel leaking into the cab quickly if that were to happen.

-

New truck!!

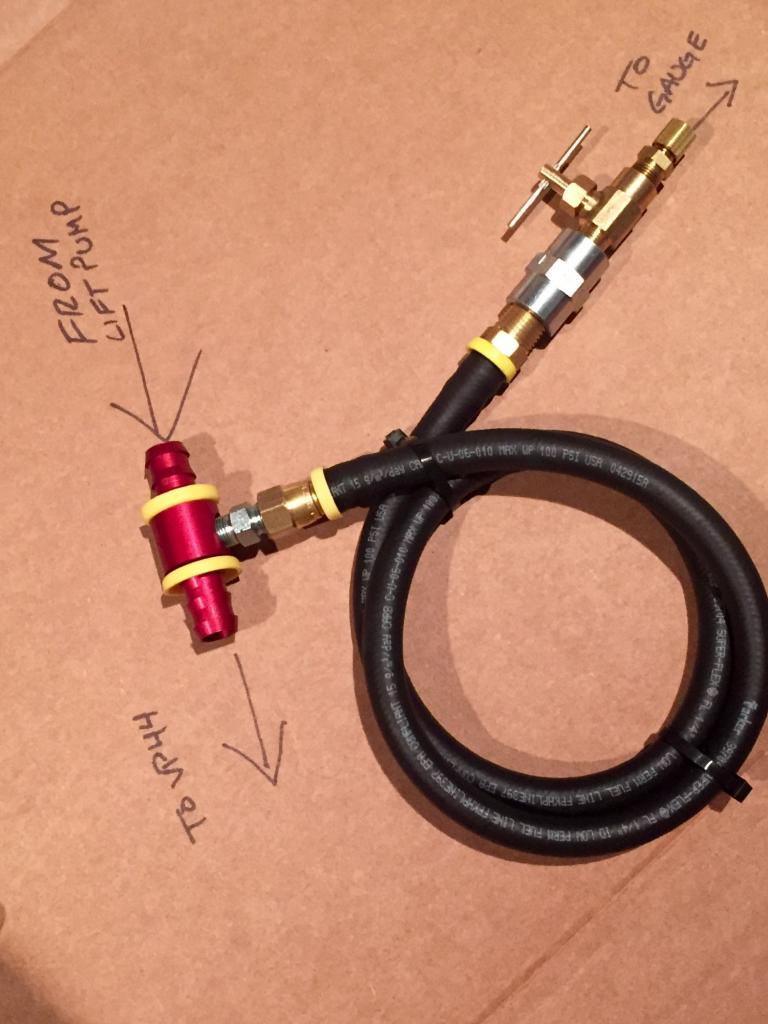

Alright well I made some headway tonight but started a lot later then planned so I lost day light pretty quick and the weather wasn't the greatest. Needless to say I don't have pics for now. But the pump lines are layed out in the truck how I like them, just need zip ties. FASS is mounted and looks pretty good I think. All that's left is to put the new jic fittings into the VP. Then it's on to gauges. I'm thinking of running this setup for my fuel pressure gauge. This is how I want to tap into the fuel line. Whatduya guys think? Will it work? My idea behind this is to mount the needle valve in a more conviniant spot. Since I'm not using the stock fuel filter housing I figured I'd try mounting somewhere that works better for me in case I have an emergency shut off situation. Pics coming soon and more to come!

-

Teardown and Rebuild

Oooooo shinyyyyy

-

What gets your adrenaline flowing?

Yea I hear ya! I have a good view of an engine and there's been plenty of times I've called back the flight engineer to look at something 'leaking' Not the funniest conversation to be having at 300ft 900nm from land!

-

What gets your adrenaline flowing?

You have a warning light?!

-

New truck!!

Yea I did a mock up mount last night to get a visual of how things would look and I think it'll clear everything and it'd be out of the way of the tire spray. Hoping to get the FASS and gauges installed today and finally be able to drive the truck again!

-

New truck!!

If it weren't for the skepticism over the Airdog systems, I would've done the same. I'd go out of my way to support guys like Eric in our industry but to me there wasn't enough certainty in that system to justify going with them.

-

New truck!!

Thanks guys. I'm 99% sure it's not punctured so I'll double check one more time before giving it the go ahead. I'll have more pics of the whole install later. @JAG1 No bench vise but I'd like to see how that was done!

-

New truck!!

Need some feedback real quick guys! Officially unpacked and got the FASS pump dressed up with all the fittings and what not, only to realize I have a dent on the bottom on the fuel filter. Is this enough to warrant a new one or am I good to go?! I'm already looking for local replacements if neccesary.

-

Changing rear differential fluid in a AAM axle

Nice write up! What did you use to pump the fluid in?

-

New truck!!

***PROGRESS REPORT*** Well got these fuel module reinstalled in the tank. Of course as soon as I snugged it down I panicked and couldn't remember if I plugged in the electrical connector inside, so off it came! (Of course it was plugged in) Used the ol harness hoist maneuver to get the tank back up under the truck I'd highly suggest that you shave down your forward most tank strap. It makes it possible to get the strap out without loosening the carrier bearing bolts. I probably should've trimmed more off since I still had to muscle it into place but it was still doable with all the carrier bearing bolts fully tightened down. Anyways, tanks still slung under the truck loosely so I can route hoses for the FASS tomorrow. Started to route the wiring but these little s@!#s broke! Both the ones supplied from FASS broke so it was off the ACE I went It wasn't a huge problem, and my fault but set me back enough that I killed all my remekning daylight. So tomorrow I'm hoping to get the FASS wiring and tubing done tomorrow and should make good headway on the gauge install as well. I'm not planning on teeing into the stock fuel filter and I don't need to cut the filler tube so I'm hoping that saves some time. Anyways, more to come!

-

New truck!!

That's pretty much what I was planning on doing as well! I want easy access for filter changes but don't want road junk flying into it.

-

Teardown and Rebuild

Those are pretty nice numbers!

-

Under seat storage

Yea exactly why in looking to swap it. Most people say it's really hard to find a used even in junk yards. I'm talking with my dad no about machining a bracket so I can add it to my 02

-

I have a dream...........

It's a nice lookin rig for sure, but the deal breakers for me... Those g dang decals! No cummins (which I know have never come in the power wagons, but still)

-

New truck!!

I thought the same thing. I mean, I'm not sure what alls workable on the carter and what's "for show" sort a speak, but it's pretty crazy what a difference they are. Good to hear! Hoping to get the fuel module back in tank and tank back on the truck tomorrow! Anyways, more to come!

-

4wd System Refresh np241DHD rebuild.

Don't worry, I forgot to fully close my hood and was cruising down the 2 lane highway before it decided to pop open, with the wife in the car. It was a little harder for her to not notice that one!

-

4wd System Refresh np241DHD rebuild.

Just a loose wheel rolling down the road?!

-

New truck!!

Ok @dripley & @BBHD I think I'm trackin with what you're saying. You just used the OEM suction lines, just used a quick connect and added it to them. Either way I think were all ending up with the same result, just taking different ways of getting there! Mine is 1/2 suction via the drawstraw, 1/2 return from the FASS via extra fitting/straw, and the OEM return from VP/engine to the OEM return port up top. So here's an update on my slow progress (its tough getting work done with a 14week old at home!) So I got my module finalized with wires clipped that I don't need anymore, the OEM suction hose gone, and put a small yellow rubber screw cap on the end of the OEM suction line. I filled it with JB weld and slid it over and let dry, that way no debris would be able to get inside. I'm hoping I have enough hose to run my return and supply lines to the FASS since my fitting are facing the opposite way, but I'm sort of limited with where they can go due to stock fittings. Should work out no problem, and worse comes to worse I'll order more hose. Oh and if anyone was every wondering the size comparison between the stock carter, in tank pump and the FASS, here ya go!