Everything posted by WiscoRedkneck

-

Power-lok time to rebuild or replace?

Hmm maybe I have the year wrong, I know it's a high pinion. Everything had to be hand built took alot of trial and error. Based on the mock up chassis everything will bolt right in

-

Power-lok time to rebuild or replace?

I believe it is just a 70 nothing special besides a busted posi. The front has a Detroit in it at the moment but is waiting for its major upgrade that has been years in the making, I have a heavily modified Dana 60 kingpin high pinion with Detroit Elocker out of 77 high boy 250 built for coil springs. The thing is probably indestructible but cost me an absolute but load of money to build a road I'd rather not venture down again.....

-

Injector install questions

Mine wouldn't go without a helper he cranked I cracked and closed as I got fuel even after that it took a bit of cranking to fire off and it ran like crap for about a minute now runs like a top as others said don't get discouraged the pay off is worth the frustration.

-

Power-lok time to rebuild or replace?

I'm sure it's metal on metal or pretty close. @Evan love to try but can't risk it this truck is my tool that must go anywhere needed whenever it's needed, I'm a contractor that deals with salvage and loss recovery, your worst day, (flooding tornadoes fire or what not) is when my company must and will prevail to ease your pain of loss, failure is not an option. I will likely just throw a Detroit at it and call it a day. Yes the fleet will be growing so soon enough maybe I can experiment.... lol

-

Injector install questions

Did you get it to start? Mine took a lot of convincing to get going again open one set of three lines crankit until fuel comes out close those open next 3 crank close after fuel present I left engine hook off but replaced bolts with spacer @dripley you nailed it on my way home the intake horn to intercooler boot pipe clamp failed installed new nice and tight now much improved performance

-

Injector install questions

The only confusion for me was I put a brand new set of the same injectors as before and it smokes more than before egts go higher under load but drop off quicker so I thought I fixed the dripping injector/injectors and or fuel leak into the cylinders. Based on performance and idle I have a great improvement there, just egts spike and more smoke so not sure if all is well.

-

Injector install questions

So dumb question I just swapped out old rv275s for new one's first time doing this myself as well. I put all injectors in and new tubes in one at a time then installed hold downs. Yes there is a gap, bled system through cracked lines then tightened line to spec after hold downs and valve cover were reinstalled and truck was running and really good to boot. Now I have no visible leaks and the truck runs 10x better but with the exact same injector in a brand new body with new tubes I am laying down about twice as much black smoke as before is that normal do they need to "break in" do I have a internal leak I'm not seeing. Truck runs great no weird egts just more smoke than before with worn out injectors.

-

New Injectors?

I'm that guy who didn't follow those recommendations and at 270k with a weird noise that came about I adjusted the valves and fixed the slight tick knock thing. I found out the previous owner did them at 100k per conversations with him. Knowing what bad and good sounds like you can almost tell by sound when it comes time to adjust the rattle box just gets more noisy..... That being said I am in the process of putting another new set of rv275s in this weekend. So far this set has about 310k previous owner put rvs in at 70kish. Definitely has an injector miss, but I never once had an issue with rvs if I go compound turbos I will go bigger but 35/40 hybrid turbo rv275s and a smarty and she will pull 20k no issues and the truck can still get out of it's own way if you know what I mean. Best stepping stone injector imho

-

Power-lok time to rebuild or replace?

So I'll start off by saying that I should have been more diligent on axle oil changes (once a year if towing/hauling heavy like most of us do)and that's likely what landed me in this position. That being said I didn't find anywhere on this site, articles about diagnosing, repairing or just general info. So at this point I have a chattering rear end but only on tight corners loaded or backing trailers, I tried the simple things new fluid new limited slip addative, to which I didn't gain much. Now my questions are: How much time do I have left before this thing grenades I only need two-three weeks. Rebuild the power-lok and if so what would be a recommendation for parts sourcing, should I go stock clutches, gears, seals and bearings or go aftermarket or just do clutches and nothing else. I can find clutches alone for a hundred dollars or a whole gear kit for about 385 all new Dana Spicer components, or do I source aftermarket parts from places like Yukon gear for less money but are not Dana Spicer components. Understand that even though I can do this in my driveway I will not rebuild an axle on my only working vehicle by myself it will be taken to a friend's shop who can have a half day turn around. He's also the one saying if I do anything I should just buy a new center section with posi or locker. Because after I buy all the parts needed there's still a chance the power-lok carrier may not come all the way apart or may be worn to the point of needing to be replaced. At that point a new carrier housing plus rebuild kit plus cost to rebuild and reinstall could be as much as 50% more than an aftermarket carrier, so he says. What do you guys think. Thanks, Ben

-

Help broken axle U-joint

Success, truck trailer and I are back home safe. Well all I can say is the only thing that went off without a hitch was getting the hub assembly off, since that was changed with the rotors a few weeks ago. Everything else sucked the axle shaft didn't want to come out at first, issues with the aftermarket locker I have in there can't say why but we had to wiggle the center section while someone pulled on the axle. Once out the clips were rusted in place well the last two remaining , apply heat and they came free. So now about that press fit/rust weld, apply heat add oil try again (fyi were are using an inducer coil or something like that so no torch) tried to separate the beast which should be easy right he's got a "100 ton" farm built press. Well it's got a gauge that said we hit 55 tons and nothing he wasn't sure if he wanted to push harder on it. We figured let time do its work so during a sit down enjoying a frosty beverage I about **** myself as did everyone else when it let go haven't heard anything sharp bang louder than that was that I can recall. Put everything back together in no time at all and enjoyed a 3 hour ride home.

-

Help broken axle U-joint

Thanks my assistant/employee is on his way up here with tools to try and pull the axle shaft here in the parking lot I found a local that has a press and he is willing to let us use to try the repair I have already acquired a new part. The more I think about it these may actually be the original's with 378,000 miles on them.

-

Help broken axle U-joint

So both front axle u-joints had about 250,000 on them one blew near civilization got that one fixed didn't think about the other side at the time since I found a shop in the town I was staying at to fix it that day they slipped me in and got it done a half hour before they closed so then the other side blew coming through a mountain pass and now I'm in a hotel with no options for repair and wondering if I could do this in a parking lot with no press. Otherwise for the first time in 15+ years of owning the truck I will have to abandon it until Monday when shops in this town (Boscobel WI) open. Any suggestions? Sorry if I put this in the wrong section

-

Homemade bumper

Old leather belt and/or stirrups salvaged from saddles have always worked wonders for me. heck the passenger side is set up so you can pull it out and let it hang or toss it under the seat seen 300 pound people use it no issue. I will feel pretty bad if it breaks on someone....

-

Homemade bumper

Weight in the back has never really been a concern of mine since the roads out here suck and I like my teeth.... 1/2" was probably a bit overkill IMHO I'm using all 1/4 or at most 3/8s thick material. That being said everything I am doing is designed to fail the way I want and all of the structure is triangulated or built as a parallel box beam frame design. I.E. the smash bar is 2x31/4 wall with two pieces of 1x11/4 wall tube stagger welded inside the 2x3 then capped by 3/8s thick angle with a flat stock extensions welded on to create the crumple zone on the bracket and inside the smash tube. Seams like alot but the whole assembly weighs less than 60 pounds and the dress cover going over the top will also weigh 40-60 pounds. Then the winch will probably weigh more than both combined.

-

Homemade bumper

Do you have just brackets holding the box bumper on, or do you have an incorporated smash bar behind? I suffered the same fate as you except mine was a hit a run I was not in the vehicle. I had a nice 3rd gen factory bumper on there at the time with just brackets. Long short they crumpled and smashed the bumper into my bed causing far more damage than expected. I planned to reuse a 3rd gen bumper in good shape at first since they look good on a 2nd and have room for the rear winch. But after building a sufficient smash bar I concluded that I am going to completely fabricate a new bumper cover kinda like yours. Except for me I am utilizing a hidden crossmember and crumple zone to mount the bumper instead of brackets. Either way it looks good I'm a carpenter by trade but can still make a decent weld.....

-

Leaf springs/ replacement broke

Haha us used to salty suck of the salt belt has come up with some creative home remedies over the years. Such as clearance aisle synthetic motor oil of any flavor into a garden sprayer and cover every nook and cranny with oil doors fenders wheel arches I mean everything I have no rust on the newer body that has spent 5ish years up hear now with almost 380,000 miles. That being said you are right it is a constant fight, this spring I'm setting aside 500 per month for four months to repair deer strike damage rock chips and broken bumper plastics along with replacing and repainting the tail gate which is heavily damaged and also a sorta fit certain fit pos.....

-

Leaf springs/ replacement broke

Thanks for the information I went to a spring shop here in Wisconsin to replace the passenger side. That side was done years ago and has now broke again, that spring has maybe 1/3 of the miles on it compared to the drivers side that is now also broke. Do any of you know how well these options you suggested will hold up? Mind you this truck has a 60/40 life meaning less than half of the time I am on inprovded or paved roads. I will have to call Benz and check out superlift

-

Leaf springs/ replacement broke

Last fall I broke a leaf spring mid pack in the spring pack on the drivers side. That spring pack according to the manual needs the tank dropped ugh. So I used a heavy duty rubber strap to hold it together and it has worked fine so far. Now the passenger side broke(I would take a dirt road over how bad these paved roads are) unfortunately that one was the last spring before overload and that pack is less than 5 years old(replaced this side once already). Any suggestions to temporarily fix? Or.... Can someone please recommend a quality source for a replacement set and any suggestions for ease of removing drivers side spring would be appreciated thanks.

-

Everyone post a picture of your truck!

Still -26 here in Wisconsin somehow winter arrived here in Wisconsin with fury around mid January wind chills are close to 50F below I'd post a new picture of my truck but haven't put my replacement bumper on... some dumb broad ran into me with daddy's Escalade in a parking lot. I was walking out of the store watched it happen and then due to distance watched her drive away leaving parts of the Escalade in the parking lot at least I got the plates...

-

Block heater

Block heaters are like drinking their good in moderation but if your truck can't start at -10 or even -20 without a block heater then you've got issues IMHO. That being said I'm spoiling my truck with a block heater right now and usually once we hit -5f I break out the timer, cord and plug her in... Now around Christmas I have to switch to 5w-40 Rotella synthetic merely because I like under 5 second oil pressure build times. My truck is a bit aged and needs injectors a little drippy or bad spray on start up causes hard starts with no block heater at -10 and won't start right now without a heater at -20(I'm sure with enough cranking and grid cycles I could get it to go but why). That being said I also agree with Mike what do you do in the field. For me it is simple ensure you have a winter front in your grill and lower bumper inlets(some will disagree with that...) also knowing how to park preventing wind push dont nose into snow banks either(obviously those are situation dependent) lastly I have a black frost guard blanket that I lay on the hood and cover the grill hold it on with magnets. I got the truck good and warmed up on a -20f day last year and used those techniques and the truck started on a single grid cycle after sitting in a field for 14 hours at -22f don't know if I would like to try that now in her condition... Now it did have good sun for most of that time and was parked tail to the wind, but alot of these trucks running right and doing what you want just comes down to good technique. IMHO

-

05 Cummins starts barely runs from south now -13 in Wisconsin

Cables seem to be in good shape but cable ends don't get tight enough for my liking Smarty cable is good, batteries are 12.9 equal between both. I didn't anticipate the temperature to get that cold I have now put Justice Brothers diesel fuel anti gel to both trucks the 05 sat in a heated garage overnight its running the way it supposed to again. It has a Fleece performance cheetah turbo and 100hp dagger injectors which I'm new to as well. What is a dagger injector We got 18" of snow coming in so I'll be messing with the Smarty tomorrow.

-

05 Cummins starts barely runs from south now -13 in Wisconsin

Ok first things first I know the truck is fairly modified but don't know the full details so I'll try not to miss anything. Truck is an 05 Dodge Ram 2500 4x4 Cummins turbo diesel 325hp 48re. 190,000 Modifications: Head studs fire ringed head Hamilton cam don't know specs Snow performance water meth kit S and b air cleaner and afe air horn DPS exhaust manifold Different turbo still vgt so we were told Smarty tuner stacked on an edge but is currently stuck on stupid..... Probably different injectors still waiting on conformation from previous owner Dad bought truck for kid, kid got fired and was in deep needed money so he sold the truck to us. It had no block heater cord that was put on this morning. Symptoms, Cycled grid heaters started truck started as it always has since it got brought to Wisconsin it got down to -23F last night. We went to move it to a heated garage to install cord at this point the truck had gone to 6cyl high idle put it in gear pulled out of the driveway made it a quarter mile before the truck died restarted the truck fine this time no high idle so I gave it throttle and it would run great then sputter and choke out finally got it running enough to make it to the garage three miles away when I was behind the truck it was constantly blowing black smoke and would occasionally blow a puff of thick black smoke and sometimes white. Get it to the shop plug the smarty in with the intent to return it to stock settings and all I get on the screen is per 99. Have no clue what that means it also has new batteries and nothing added to the fuel.

-

47RE advice

So I don't have your problem but I'm struggling with a new built transmission having lock up troubles every once in awhile it would throw a code long short I found that one of two batteries had gone bad and voltage between the two batteries was not always stable or same voltage at each battery, waiting on warranty replacement battery to see if that fixed everything 100%. For you though how bought u joints(mainly axles)transfer case and axles. when was the last time you changed fluids in those systems could be low fluid levels. Im sure you know but bad u joints cause poor 4x4 engagement and weird issues alot of times vibrations and weird crap affecting other systems. Hope that helps

-

OB2 port failure and O/D switch failure

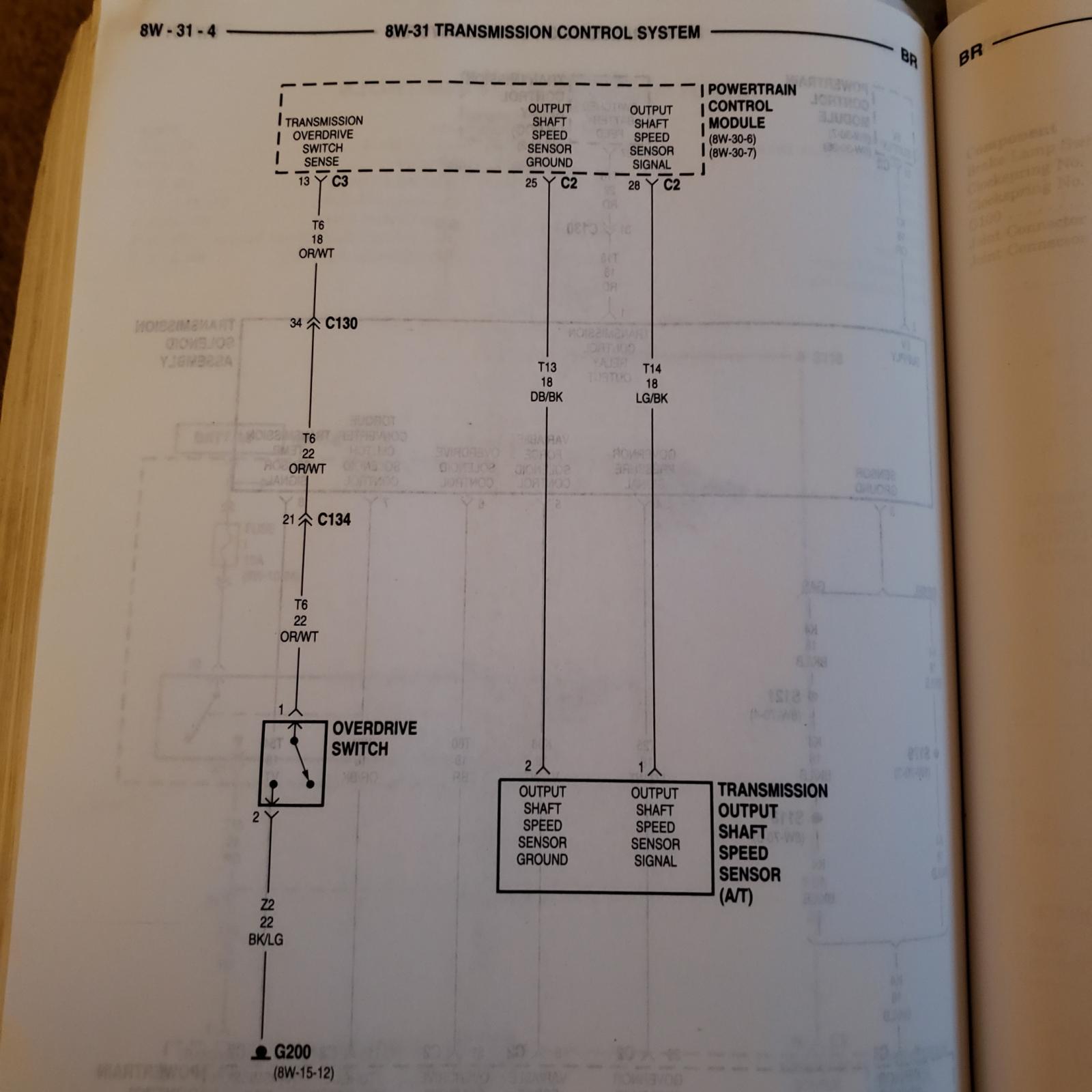

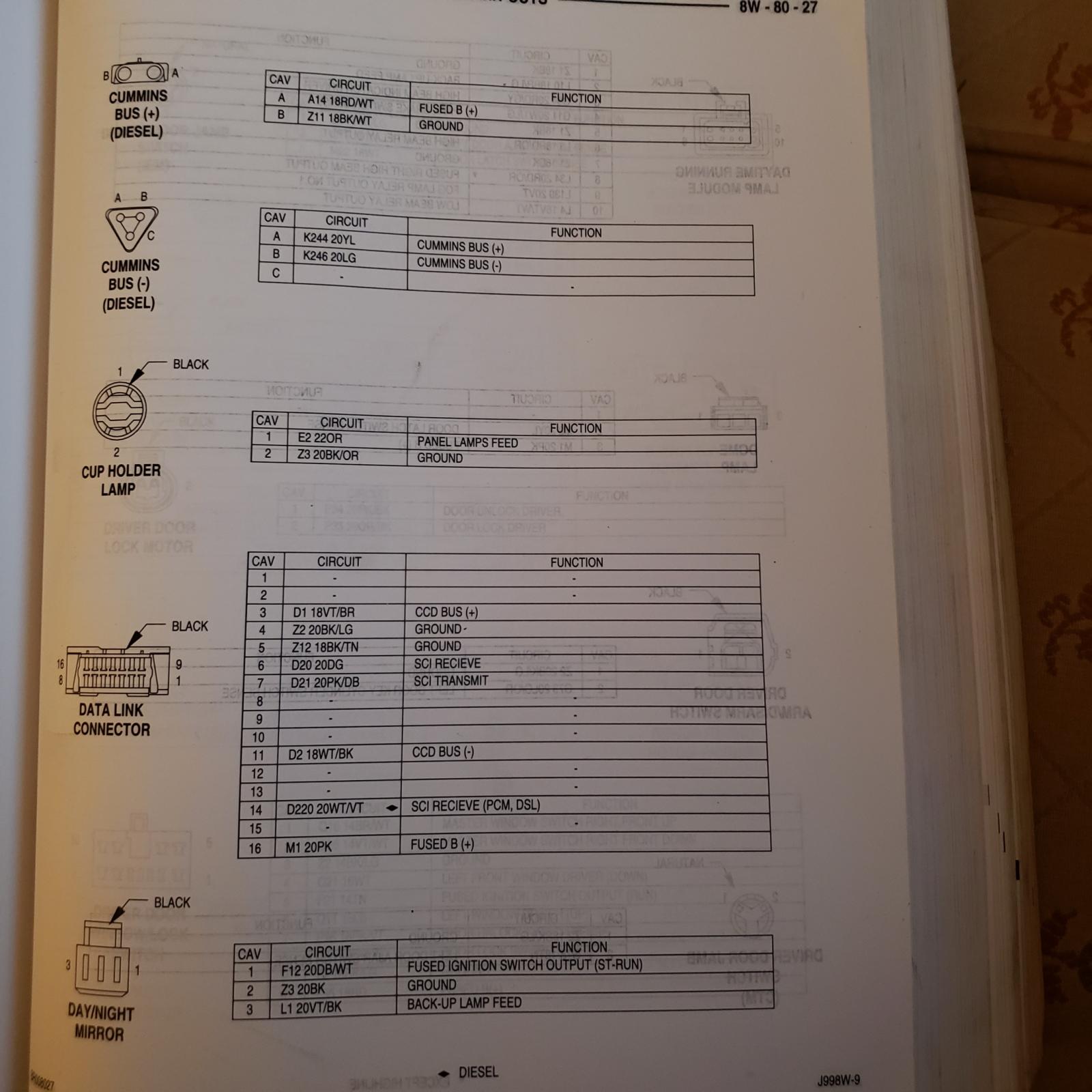

Ok, so pretty confused right now and hoping for clarification. Btw it's a bit of a read... What happened, lost control of o/d switch/ could not disengage but trans acted normal, where I am at we have had some flooding so on my way to work in the dark I missed some high water around a bend and went through it at speed no deeper than the axles not even ten miles up the road o/d hunting began got to work a few miles down the road and called the builder of the transmission, this trans has maybe 20k on it and is still under warranty. He told me to come straight there after work finished work heading over to him trans acted normal again. My immediate thoughts were weather pack/sensor problem so we decided to plug in a scanner and see what she said. Long short three different scanners later no communication with pcm yet power present and all fuses good. So we started manual diagnostics and found a bad casing on the output shaft speed sensor so we replaced it just because. Now at this point stumped as all get out dead obd2 port and no control over o/d we went up the road to another builder who deals more with allison and has a built Cummins pulling truck for his opinion. Talked over a bunch of ideas and decided to try his snap on scanner no comm he looked at me and said I think you have wiring problems to figure out. So today I started working through started simple fuses first all good then I went on to thinking with 363,000 on the truck maybe I'm having pcm trouble so what's the easiest way for me to eliminate that possibility. After consulting the book I found that with two small blade screw drivers you can pull the O/D button and test the O/D on off feature with a jumper wire this way testing wiring and overdrive sense in pcm, based on wiring diagram from book, everything works as it should. Now to the OBD2 port I will state at this point I already know the pin out and have tested the port to find ccd+ bus signal prong dead. Throw my meter on again to get a baseline and see if anything changed and some how it did, ccd+ bus came back either by coincidence or somehow the bad O/D switch caused that pin to not have signal. Question is do I still have other problems yet it just seams weird a switch would kill the OBD2 port.

-

Everyone post a picture of your truck!