Everything posted by WiscoRedkneck

-

TCC lock-up issue with a screwy T.P.S

Back in July I lost ECM output for my lift pump. I tested for AC noise at that time and had no issue so I corrected and added a fused power source and now it runs off a switch. BTW alternator is believed to have the same milage as the chassis which is 332,732 Two weeks ago to transmission started having issues with torque converter clutch lock up it was hunting a lot. I threw a scanner on it and started collecting live data. I find out my accelerator pedal position sensor will not register over 80% at wide open throttle. At this point I was very confused so I started testing more things including A/C noise again and the alternator is still fine my batteries are fully charged and the app sensor is a 2 years old Mopar unit. I have recalibrated the sensor as well as removing battery cables over night. By the way my alternator putting out .01 volts ac occasionally it goes to .02 on the meter. Where do I go next how can I bench test the sensor it's self, then are the transmission problems from this sensor or something else?

-

Dodge Dana 60 high steer

Gotcha I understand now the one I know of converts you from ball joint to Kingpin but still gives you high steer arm which currently is unavailable Have you thought of removing your axle cutting the spring perches off of it and swapping in 1990 axle after you convert it from leaf springs to coil springs the sale of your current axle might make that swap next to nothing out of pocket besides actual building of the axle be ie. changing gears, lockers or any other added features you might want. Food for thought a friend has a 2001 Jeep that has that exact conversion in it plus a 3.9 Cummins https://racine.craigslist.org/pts/d/1990-dana-60/6315863675.html

-

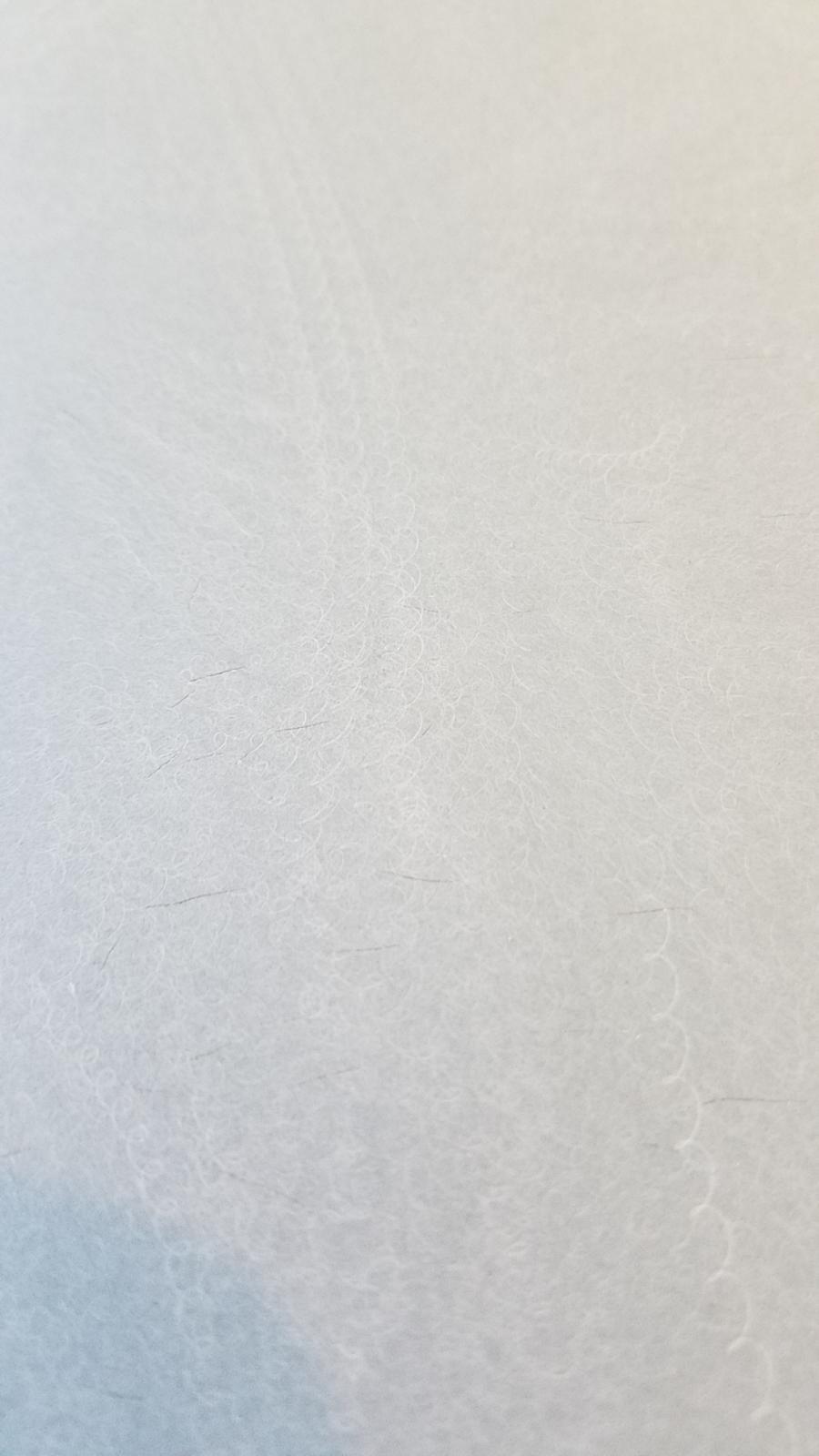

Fiberglass Topper cracks

Hahaha I'll pass, thanks for the words of motivation, I have a long weekend ahead of me prepping and sanding hopefully we will start building more primer this weekend I was running a 102-degree fever this week so I was a little out of commission The one crazy thing about this that has just driven me off the wall is the difference in hardness between the fillers, coating's and fiberglass it makes sanding very difficult. If you're trying to sand partially on fiberglass and partially on fiberglass filler just don't it won't work for crap even coats of filler build up to cover everything is just about the way to go. Oh and on your tooling gel coat sanding I feel your pain some of the fillers I'm using right now don't sand well with anything over 60 grit, I have found shaping them with 40 Grit and then stepping my way up to 220 is the only way to do it but when you're using 220 you're barely taking out anything maybe some sanding scratches here and there but that's it no shaping of any form no Feathering next to nothing at all

-

Dodge Dana 60 high steer

Sorry dumb question but off-road manufacture's often have conversion knuckles available for Dana 60's as it's a very popular axle and they can be found for under 600 for a pair. Is there a reason these won't work for you? A Dodge Dana 60 is a stout and reliable axle, some argue that it had the highest shaft strength of D60 axles until the 05 Ford d60. Switching to cable actuation is definitely the way to go. Only downfall I can think of is the early Dodge Dana 60 had 30 spline shafts.

-

Fiberglass Topper cracks

Thank you, it always seems like time is never on our side I got the front feet formed now I just have to body work and then and primer block sand, primer, sand repeat until your arm falls off and just maybe by next weekend I'll have color on the thing just a small task Here's the ugly side of bodywork enjoy the pictures The last two pictures are of the one that is just about finished

-

Fiberglass Topper cracks

Never thought this project was going to take this long or be this difficult it's been a learning experience and so far what I found is everything that I've done I'm going to appreciate in the end. I can tell you this I'm going to be very upset if this thing ever gets damaged. Since I posted last quite a bit has happened the topper in the back has been formed to the rear ladder rack feet. I have laid the fiberglass pads that will support the front foot pads, my dad and I plan on molding those foot pads this afternoon. I have the rest of everything shaped and smoothed out with 220 it's ready to continue building primer coats. I have removed the third brake light and smoothed that out to increase topper strength since that was hacked in by the P/O. There will be metal bow's that are glassed-in to the inside down the road to increase structural stability, I will be using 1708 biaxial fiberglass fabric it's a form of structural fiberglass. At this point we've added over 150 lb to the topper in both fiberglass and Kevlar reinforced resin based fillers.

-

Wheels and Tire Setup

Sorry I forgot to mention earlier a friend of mine has this set up it is 285 75 16 3rd or 4th gen hubcaps with a 1/2 or 3/4 inch spacer in the rear he plasti dipped his wheels it's a nice looking setup but when your air down tires for trail riding the dual tires rub. By the way that truck has a leveling kit

-

Where do I find a genuine HX35W turbo?

5 years back I could still go to Cummins parts for an hx35 but for 2200 list I took a pass went and had mine rebuilt/ hybridized can't say it's still available or what it'll run now

-

How much does my truck/trailer weigh?

After an issue with the law last year it was weighed at a D.O.T scale 7/8 tank of fuel no spare tire(don't ask part of reason for D.O.T inspection) myself one bottle Jack and impact weighed out at 6938 truck is a 1999 Quad cab short bed 4x4 auto, axles are 60/70 tires are 285/70/17 3rd gen fleet wheels no topper stock bumpers and suspension

-

Fan belts squeaks

Cummins oem brand tensioner and a gates belt is running quiet and eliminated the shut down squeak. I was so used to the shut down squeak it took a friend who owns a Cummins that heard it shut down to tell me it didn't squeak and he wanted to know how I did it.... He runs the gator back as well and swears by it he says it's the only and last belt you should have to put on. his 93 GMC still has the same gator back 20 some years later granted he's only put about 150k on that belt but that is more than expected for a belts lifespan

-

Lost ECM output to lift pump

Airdog FRRP 100 thanks IB I will wire it up that way. It's getting a mechanical lift pump this winter because I absolutely hate these electric lift pumps

-

Lost ECM output to lift pump

I believe so, so this is common then? Is ECM failing or does that large aftermarket pump cause an overdraw on the factory ECM output causing the failure?

-

Lost ECM output to lift pump

Changed fuel filter cracked line bled system tightened line started truck fuel pressure came up then 3 seconds later it went to zero shut truck off. Checked for air lock then voltage and founds 2 volts output from ECM called air dog they instructed me to wire to 12v switched and this is common. Tried that all issues resolved for now.... Had to leave for a trip so I decided to run it hooked as such truck performed as expected that was a week ago. My issue is this does that mean the ECM is failing is there a way to find out I have never had one sign of ECM issues until now Second is I often use the trucks radio when parked in ACC. and the fuel pump continues to run any suggestions on where to wire the pump to?

-

Carli suspension Starter Kit

An alignment should center the axle because the truck wouldn't go straight down the road. End links yes they are required and for street highway driving a safety issue. Now the control arms you could maybe get by without but remember you have a triangulated suspension so adding height pulls the axle back thus uncentering the axle front to back causeing rubbing and a harsh ride not to mention spring will likely be canted on its perches again not safe. Any other questions fire away

-

Timbren

Another option is to find a leaf spring supplier and replace your rear leafs, mine came from Babcock springs I believe they are progressive and they have a 1 inch lift. Below is my truck with 285's and about 500 pounds in the bed it honestly rides better than any 2nd gen I've been in, and level with 2500 pounds in the bed.

-

Cooling issues/plugged radiator

Friday after work I was able to examine the radiator and I found the radiator filled debris and what not(used video scope light and mirror). Now later that night at a gathering I ran into an old friend who happens to be a off road heavy equipment mechanic so I asked what he reccomends, his response "it's easy happens all the time we'll link up Sunday and get it fixed" t So today we started and finished in under an hour and a half. I started by spraying the radiator down with a compressed air degreaser wand from the front pushing back towards the engine btw the wand fit quite well in between radiator and intercooler let it soak 5 minutes spray engine side towards intercooler wait 10 minutes then repeat the front going back towards engine now wait 25 minutes. Blow out front with radiator wand going back towards engine. Now take a hose and start rinsing from engine side going out you can get between 75 and 85 percent of the radiator with the shroud still on you just need to wiggle around soak everything until water is clear. Use radiator wand and blow from in between radiator and intercooler towards engine then go the other way once most moisture is removed start engine. Also added 190° thermostat back into system and added coolant for that lost in thermostat change. Results, Engine temp indicator sits right on top of the number 1 just below the 190 center point indicator were as it used to sit on the 9 or the zero plus now it's steady as can be. The fan kicks on for at start up but I'm yet to have it kick on excessively like it did before the cleaning, IMHO i feel this way is effective at cleaning a plugged radiator is it perfect probably not but it worked

-

Fiberglass Topper cracks

I tend to agree but I also believe that comes from you and I being self critical and we know what we want it to look like. I planned to start building primer up today but ran out of reinforced filler and the parts store is out until tomorrow back to my holding pattern.

-

Fiberglass Topper cracks

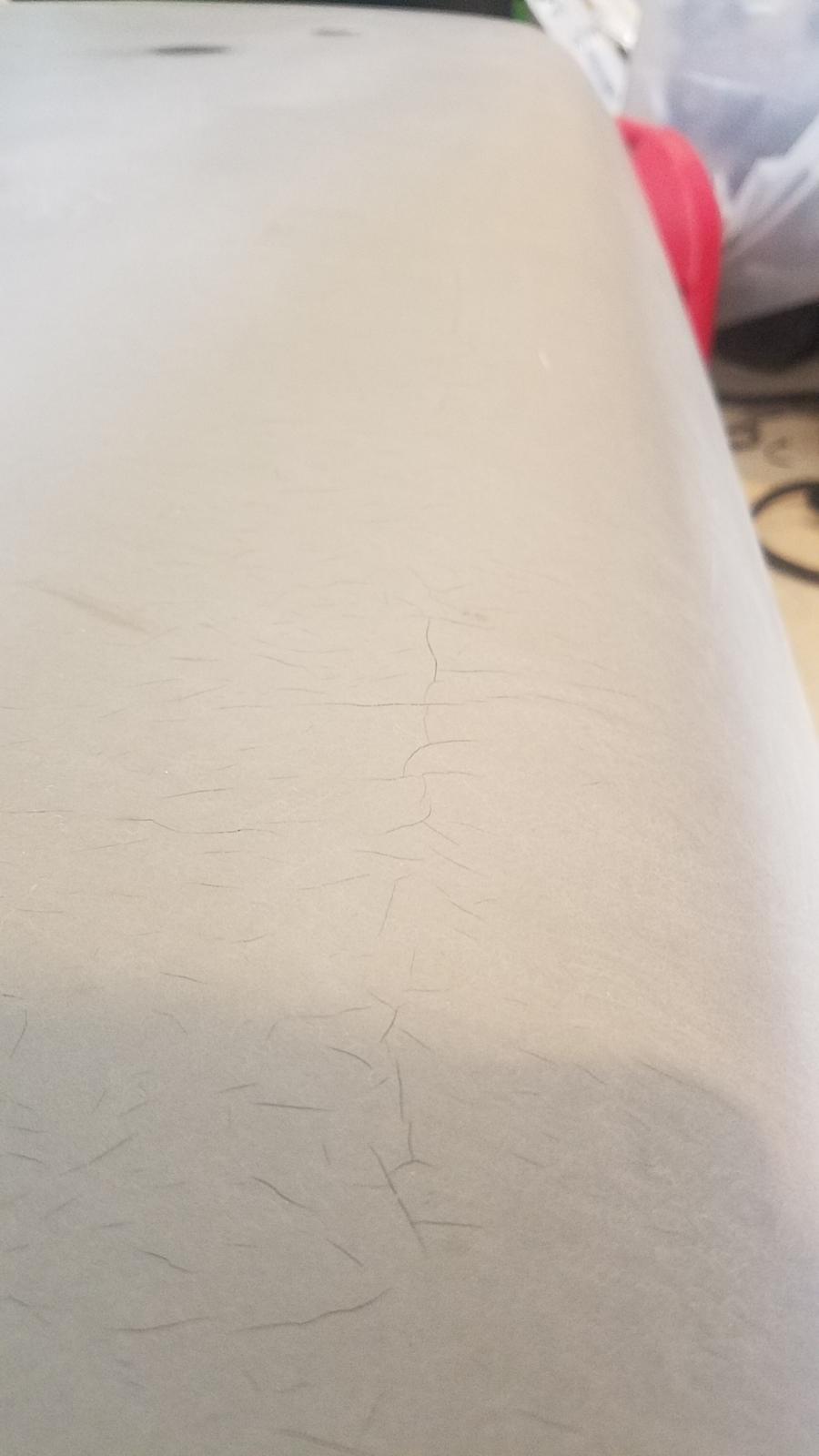

Ended up sanding off all of the resin in order to get it flat and took off a lot of gel coat in the process as well. It's kinda funny looking since it's 2 different shades of gray now that I sanded a lot of the gel coat off will be filling cracks with seam filler that has small Kevlar strands in it the start building it up with primer Forgot these close up is in between rack mounts on drivers side still a few very small cracks (almost invisible with out a light) but they are filled with resin

-

Cooling issues/plugged radiator

@Hawkez no I have not pulled the radiator ever and with 327,000 I think it is due. I will pull it out this weekend and inspect it. @TFaoro it is a Napa brand clutch fan I was leery about it as my last one I got for the old Durrango took 3 trys to get one that worked right. No I'm not loosing coolant fyi and the ccv tube hangs below the radiator now it got fixed about 75,000 miles ago.

-

Cooling issues/plugged radiator

Since I got the truck back on the road abouta year ago I have been fighting cooling problems. FYI the truck sat torn apart for almost 3 years and endured me moving twice during the process. When I first got it going it started to overheat sitting in the driveway at idle on a 95° day. I found a bad water pump replaced that and flushed the system. I try to flush the system once a year, after I replaced the pump I was good or so I thought. The truck would sit at 190 and with a large trailer it would creep up but never overheat and it was only at slow speeds. I replaced the clutch in the fan and made an improvement and now when the engine revs up you can here the fan so that was bad for awhile . Yesterday it climbed well past 190 again so I let it cool down and pulled the thermostat and still at idle at 90°degrees ambient temperature it still goes past 190 at idle but drops down after I start moving. I'm thinking plugged radiator but I don't know any more... any thoughts?

-

Fiberglass Topper cracks

@SilverMoose thanks for the pointers and education, thanks for all the extra ideas as well really helps get the old brain rolling. So I'm kind of pot committed with the resin over the gelcoat/filler but can still grind off if I have to. The biggest problem right now is I have 12 days to complete repairs paint topper and install. I leave on the 25th and the 32 foot box I will be pulling will hurt my driving performance greatly with out the topper, not to mention I have a cooling problem that I have been fighting for awhile now and I thought I had it licked when I put the new clutch fan in but over 85° pulling hard it the gauge clears 190 On another note the resin filled all the small cracks and almost all of it gets sanded off during blocking now the big cracks in the corners I think are just going to have to be ground down to glass and re coated.... there's the topper and rack before I started sorry it's a bad picture And here is the other topper that got owned by a tree Ignore the KN Sticker p.o. had that on there I just never removed it, the topper was electric blue but I rattled canned it black in two hours.

-

Fiberglass Topper cracks

So we opted to sand everything to 100 grit and at this point the first layer of resin is on I will block it out with 100 grit and apply a second coat as all the cracks didn't fill up all the way. any thoughts are appreciated... after this I can't add any more pictures but will keep you updated with progress

-

Shocks

Just got mine back from the shop whole new front end and some upgrades(heavy duty ball joints, oversived sway bar end links, and track bar) I also ended up with Billstein 4600's cheaper than Rancho and recommended above the similar price Monroe gas shock. So far I can say is this truck handles better than it ever has and I can honestly say I don't know if any one thing made a vast improvement but all together the steering is tight enough and responsive enough that it'll take a bit of getting used to.... and btw it's nice to actually feel the suspension doing it's job versus having to keep your mouth open so you don't chip a tooth when you hit these sink holes and or missing patches of road

-

Fiberglass Topper cracks

My leer truck cap on my Dodge that I installed a fully welded steel ladder rack on top is stress cracking. I work construction and tree farming so the rack was over built and overloaded probably more than once. Now that you know what I did wrong I'll tell you what I want to do... I found a quart of Toyota army green leftover from jamming out the truck before sending it to paint, so I figured might as well fix the topper and finally paint it to match the truck. Last weekend I sanded most of the old paint off one side was done with 150 one side was 60(I'll explain in a moment.) Now that the paint is stripped I'm seeing pretty deep stress cracks, and the fiberglass topper has a complete 1/8 inch skim coat of light weight filler. Now explaing the sanding one side was done with 150 to investigate issues once the problem was found. I talked with my dad and a couple of car guys and they all said sand it with 60 re resin the topper and smooth out with filler or grind off all the filler and repair the fiberglass that is cracked then rebuild filler. I plan to keep the rack so inside the topper we will be classing in metal arches to take the load down to the bed rails. My concern is will I have massive amounts of block sanding if I sand to 60 a re resin it seems really rough. Here are some more pictures I had someone suggest just using Kevlar reinforced filler and just filling in the cracks the side that got hit with 60 almost removed all the small cracks but the big ones on all 4 corners weren't affected

-

1997 12 valve purchase

Thank you for all the replies, I went and looked at the truck and long story short I pretty much ran away... he said he had all the nuts and bolts then proceeded to open a large storage container of about 500 nuts bolts and screws all lumped together no labels. Truck had a turbo fire as well hence all the missing wiring, no dash and new turbo. It is a half ton cab as well no big deal but the cab is clean and bed needs new metal or a donor....