Everything posted by dripley

-

Low Air Flow and Smoke/Burning Smell from Vents

Genos, I think, carries a filter you can install over the cowl or you can remove the cowl and add some screen to help keep it out. I personally have not done either but other members here have. I am sure they will be along.

-

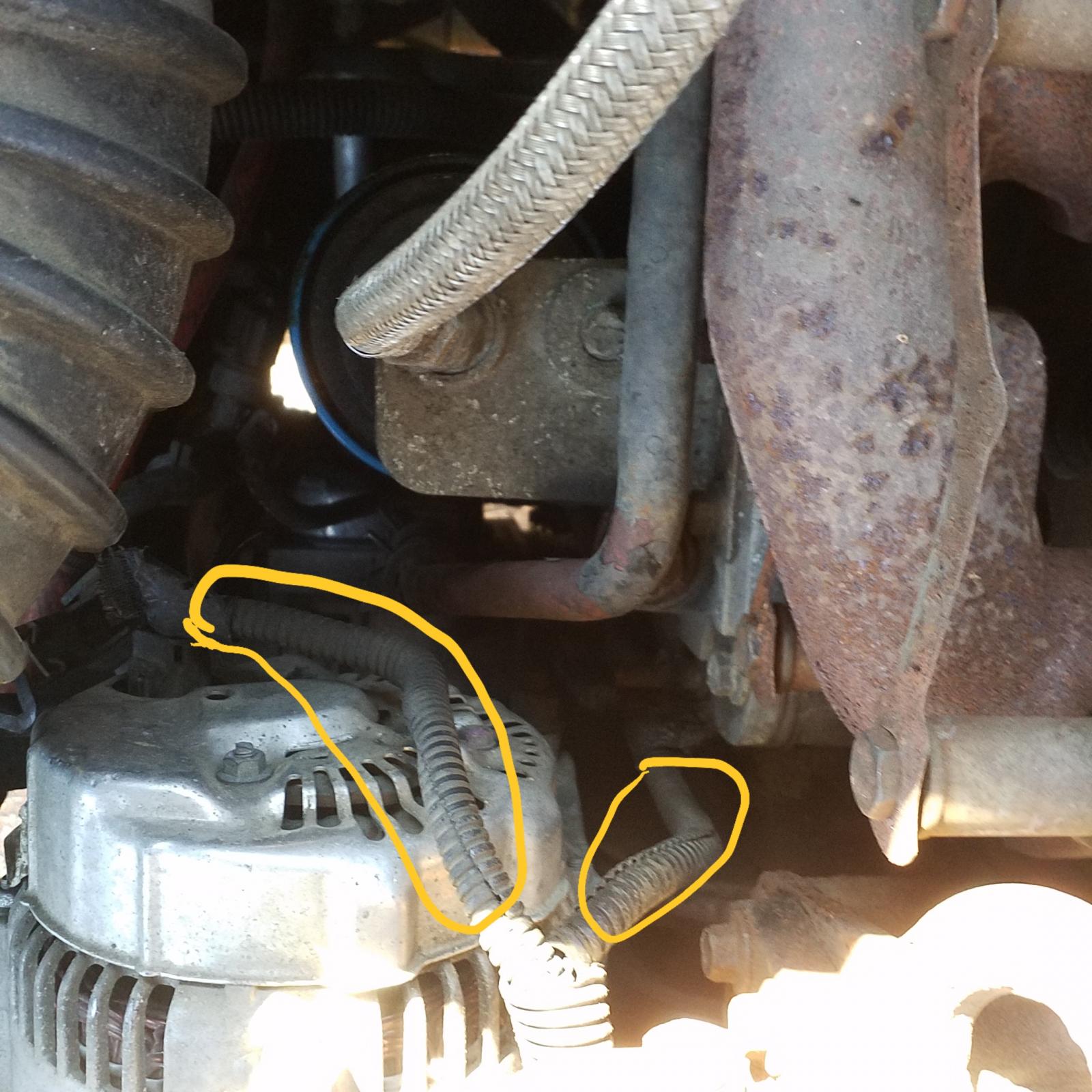

Grounds and electrical stuff.

The small loom going down by the alt is your high pressure switch for the ac, it stays along with the field leads for the alt. That is all you will have left on the passanger side. I installed a new smaller loom for that.

-

Grounds and electrical stuff.

Eliminate the one to drivers side and connect a new one to the passanger side. Everything will work just fine. The PCM regulates the voltage from the alternator. I used a piece of the wire removed ftom the drivers side for wire to the passanger side. The wire from drivers side positve to the PDC remains and powers the PDC.

-

iQuad Boost Readings Lower than Boost Gauge

It woud be good to drop it. If it were mine i would set it at 15psi as a low pressure at WOT and let the high pressure fall where ever it falls.

-

Greasing Transmission for Clutch Installation

I greased that sleeve on mine.

-

Hard to start

I experiencing the same thing myself. My suspicion on mine is the AD quick disconnects might finally be causing me problems. I am not sure FASS uses them though. My problem is intermitant however. One time it fires off fine the next time a hard start. Might sit for 15 minutes and hard start or sit all night and bust right. I also have no vsible fuel leaks, but air is getting in there somewhere. I have not had time to dig into mine as of yet. If you have quick disconnects they might be suspect.

-

P1689

It can be either. Bad sensor/wiring. Who knowsfor sure. I have one of the newer 2nd gens at 17 years old.

-

iQuad Boost Readings Lower than Boost Gauge

I dont know. After 17 years it kind of looked crappy to me. Still works fine best I can tell but most tlikely needs a rebuild. 455k miles on it+many hours of idle. Still no play in any direction in it.

-

iQuad Boost Readings Lower than Boost Gauge

-

Grounds and electrical stuff.

I am pretty electrically challenged myself, but WT's ground mod is pretty simple and @Mopar1973Man explanation is in a little more laymans terms. I mostly understood it, but if you just open the harness and see it it is even simpler. What lift pump do you have and how is it wired? It should not have anything to do with the ground mod. The ECM should be controling the lift pump. Also how do you have it plumbed as far as the gauge is concerned?

-

iQuad Boost Readings Lower than Boost Gauge

My thermocouple is in the back half of the exhaust manifold outlet to the turbo.

-

iQuad Boost Readings Lower than Boost Gauge

Just curious about this. My truck never see 400-500* at idle, cold or warm. Mine maybe sees 300* on cold starup. The EB will bring it up in the 450 range. Idleing in summer time on warm engine i will only see 250 maybe 275.

-

How often do you wax?

Dont say that. Some beach Nothing personal.

-

How often do you wax?

At least the paint is not peeling like alot of gm products did 20 or so years ago.

-

How often do you wax?

My clear coat is gone on the horizontal surfaces. Didnt peel off just oxidized away. Very little waxing on my part.

-

Air & Exhaust Article - BHAF Muffler Uhh??

60% off Napa's list price would make it a viable option, though I know nothing about the other filter.

-

Best tuner for 24v

What bushings do you speak of? It is all hydraulic other than the pedal bushings.

-

Air & Exhaust Article - BHAF Muffler Uhh??

How much do you pay for a 2790? Just looked it up wow thats pricey too. They are about half that much at Vulcan. http://www.vulcanperformance.com/Big-Honkin-Air-Filter-BHAF-p/bhaf.htm

-

ROUGH RIDING

That is still a funny story. Takes a good friend to come for more after that.

-

Just a little horse power

At $20k+ i dont think that will be an issue for me.

-

Lets see what guns you "don't own" :shifty:

My son had an AR many years ago and I got to go to the range with him once and shoot it. We small baby food jars for targets. Even over the iron sites they hard to miss.

-

Air & Exhaust Article - BHAF Muffler Uhh??

Never have. But at $108 it would be hard consider for noise reduction.

-

Trouble Starting Engine - HELP

Yep. The bypass always lets a little fuel go by.

-

ROUGH RIDING

If you torch the ball joints be careful. @Mopar1973Man did you not have one of the studs on yours blow out of the joint with quiie a bit force a while back or was that someone else? I rebuilt my front end at 240k on the oe parts. Replaced them all with Moog, pre federal mogul, and sitting at 215k on them now hoping they go another 50k. We will see.

-

Just a little horse power

Appropriate name, Hellephant. https://www.foxnews.com/auto/1000-hp-dodge-hellephant-v8-is-ready-to-resurrect-your-classic-car.amp