Everything posted by dripley

-

MPG's Reports

20 is the best i have seen in mine. course I drives a little :bolt:faster than you.

-

Vp whipping a dead horse.

Thye blower resister is shot. It is near the blower to the left in the hvac box. You can buy one a t the auto parts store and they should be able to give you a detail showin its location.

-

HX35 Max Boost?

I can hit 33 or 34 steady if I am pulling the 5th wheel. When empty i can hit that high in higher gears flogging it pretty hard. I have a HX witht a Banks quick turbo exhaust housing and their big head waste gate. The waste gate is set to open around 35 psi.From what I have read head studs arent needed until 40 psi. Just what i have read, I am not an expert.

-

GPS Navigation

With what you are doing I would definately want one. I have used one in my daughters vehicle when site seeing witht the family and it is a very useful tool. As long as I just have to find one place every so often maps work pretty good.

-

I set fire to my bench...

I hope your foot was not trying to catch fire while you were speaking to her.

-

GPS Navigation

I usually have my lap top and phone card. Google maps for in the city. Use them for cross country some times, but does not work well out in the middle of nowhere. I mostly use a regular fold up state map or road atlas. I guess I am mostly old school when it comes to navagation. I would have to agree that the Garmins and such are really good in town, but the highway just give me a map.

-

Vp whipping a dead horse.

My ADII came with a kit to replace the in tank pump by removing it and installing a new pick up in the fuel basket. It works quite well. It is only 3/8" and I figure thats why is see a little greater pressure dorp than Mike does, about 3#.Good luck with the install.

-

Class V Hitch Recommendations

Nice hitch. It is definately stout. My truck came with the camper package and has the same style as yours, as in it mounts to the frame rails and not the bumper. Mine is however only rated for 10k#'s. What was the oe one on your truck rated for?

-

Vp whipping a dead horse.

All good info from Mpar and Russ. I learned most of what i know about it from this site. The stock fuel system just was not good enough for the VP. Dodge replaced my first one at 75k and as far as I know did nothing with the lift pump. My lift pump went out at 145k and Dodge replaced that with an in tank lift pump, which was no better and probably worse than the block mounted one. My VP survived the lift pump failure which is not always the case. My VP also survived the the intank pump's crappy pressure. About this time is when I started learning about the fuel system weaknesses on the Dodge Cummins. AT 170k I put a booster pump to get the pressure up and that helped mine. It helped the pump but I still some dead pedal occassionally. I finally changed the VP at 220k. It was still working but I was afraid it might leave me stranded, plus I had the cash to replace it. My new Vp now has 36K. It is fed by a ADII, been on a steady diet of 2 cyle and i have fuel pressure gauge to keep an eye on it. I would not be suprised if it lasts the life of the truck. But as with anything mechanical, you never know. Just do your best to take care of it.My 2nd VP survived one complete lift pump failure and very weak pressure(0.5#'s at wot)from the in tank lift pump. Thats why I say it is possible a good lift pump like the Fass might get you some more life out of the VP, might not. Most do not but some do.I do not know of any way to tell how much damage is done.The VP and the lift pump are not difficult to install yourself it you are handy with a wrench. I did both on mine and had never seen the parts before or worked on a diesel. It is all pretty much bolt off and bolt on.

-

Vp whipping a dead horse.

I gues its really only half. The half on the nonsliding part of the connector. Must have been some good sticky stuff on it.

-

Vp whipping a dead horse.

Your need a scanner to erase the codes. You could do that, drive the truck and see what comes back. You could also put a new lift pump and maybe get some more life out of the vp, MAYBE. I still have the void sticker on my VP connector, just never peeled it of, this is my third vp. The fuel pump on the block is crap along with the smalll fuel lines, just helps destroy the vp. All questions are welcome and there is no stupod question except the one you dont ask.

-

Vp whipping a dead horse.

I would have to agree with Gasser and Mopar. Here is a little info on helping take care of the new vp. http://articles.mopar1973man.com/general-cummins/36-fuel-system/63-adding-2-cycle-oil-to-diesel-fuel By the way, welcome to the site.

-

Vp whipping a dead horse.

If the VP has had a steady diet of low fuel pressure it has most likely seen extra wear. How much is more a guess than anything. You could check the codes and see whats there. The fuel pressure gauge will just keep an eye on the pressure going to the VP. You use to be sure you are putting good pressure to it. You should get the Fass system on and the fuel gauge in. Ideally you want around 18 to 20 psi at idle and 15 to 16 at wide open throttle(on the highway and not just revving it in the driveway). You can use the key trick and check the codes. Key on, key off, key on, key off, key on. Leave it on and wathc the odometer. It will display any codes stored. Watch it closely because it has to go thru 2 computers. It will say p done after each one. you need to see pdone twice. Get that part done and take it for a drive and see how she acts then. --- Update to the previous post... A bone stock 02 is no fast machine of the line. but it is capable of pulling quite a load.

-

Flashing BRAKE light

Here is a good read on adjusting the shoes, http://articles.mopar1973man.com/2nd-generation-24v-dodge-cummins/23-brake-system/33-emergency-brake-parking-brake-adjustment There is a slack adjustment on the cable along the drivers side frame rail forward of the rear wheel. The cable might need some dry lubricant like graphite. It doesnt have to be graphite, just be sure it is a dry lubricant. A wet lubricant will attract dirt and aggravate the problem.

-

Class V Hitch Recommendations

Pictures?

-

Hydraulic fluid

I dont think it makes any differance how you deliver it to the engine. The engine aint gonna like it.

-

oil pressure sensor

yes. --- Update to the previous post... Yes. I think there is a plug there stock.

-

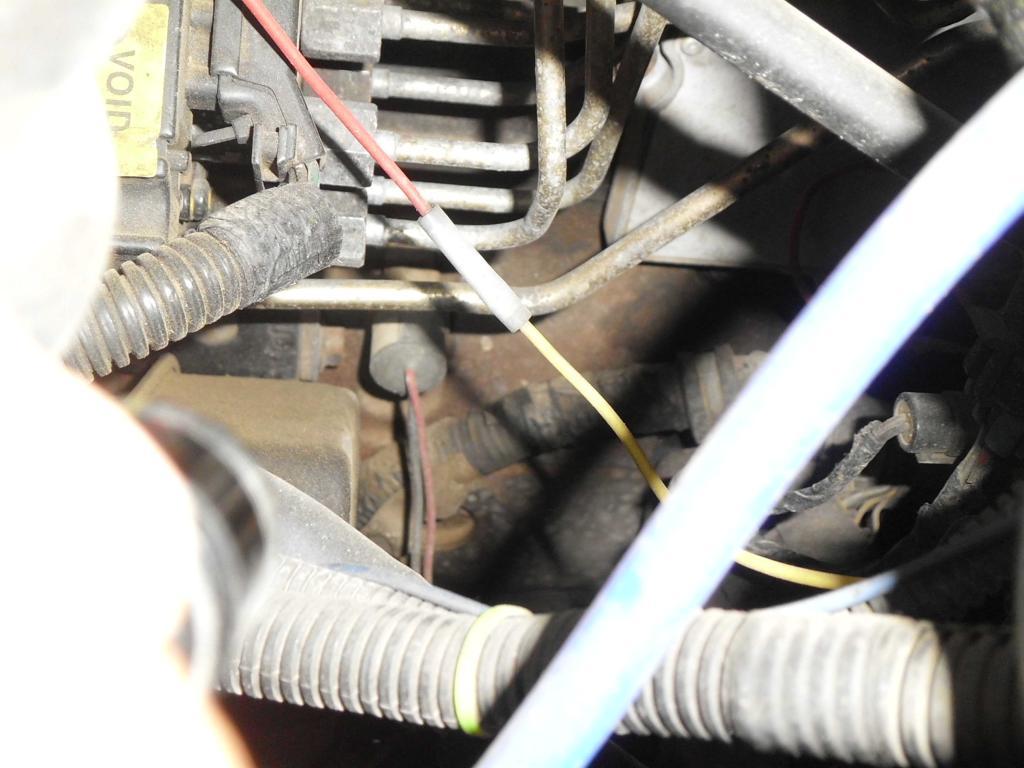

oil pressure sensor

There is an outlet on the leftside of the engine about midway just above the oilpan. I still have sensor there for my old booster pump. the pump was designed to come on at 5 or 10 psi so not to overwhelm the VP as I remember. I think there is a plug there but dont remeberThis is apicture of the where I had it connected.

-

Time To Rebuild the Driveshaft Assembly

Glad you got it out. Mighty helpful daughter you got there. Mine will do a fair amount but I just cant picture her under my truck with a drive shaft in her hand:lmao2:.I especially like the part about the 5lb hammer and wide punch to "gently" knock it loose. 5lb hammers, my truck and gently dont go together!!

-

Time To Rebuild the Driveshaft Assembly

Not sure I read a manual before removing mine, but i believe I removed the rear of the shaft and let it rest on the ground while I took the center bearing loose. Either way an extra set of hands or a board to hold up the center bearing while you unbolted it would make it easier. I cant see any harm in dropping the rear first, it makes more sense to me.

-

Noise from front end.

The stock lift pump is most likely the culprit. If you plan on installing another one try reading this http://articles.mopar1973man.com/2nd-generation-24v-dodge-cummins/25-fuel-system/32-stock-lift-pumps

-

oil pressure sensor

Mine idles about 40# and runs down the highway around 60# with the engine warm. --- Update to the previous post... This is using the oe pressure gauge as a reference.

-

tow mirrors

Have you tried getting them replaced under warranty?

-

Hose and Push Lock fittings

I put a little pb blaster on mine. Still tough to get on though.

-

i was going to do ball joints.....but i changed my mind

Great comedian, Tim Allen. Only differance between you and me is that I wasnt a kid watching him. I was watching Andy Griffith in black and white when I was a kid.:lmao:Now look at us sharing the same kind of vehicle.