Everything posted by Tractorman

-

Using return fuel line for additional filter?

Never restrict fuel return lines or offer a potential fuel restriction such as using a filter in the return line. Diesel fuel injection pumps / lift pump systems are essentially hydraulic systems. The rules of fluid power flow and pressure apply to both. The bulk of the fuel system is plumbed is a series circuit from the lift pump, through the VP44 injection pump and the return lines. Any restriction added to the return raises the pressure upstream in order to push the fuel through the line. Flow is constant and pressure is accumulative in a series circuit. You won't see it on a fuel pressure gauge on the lift pump circuit because the gage compares fuel pressure in the line to atmospheric pressure. If a filter on a return line circuit became seriously blocked, fuel lines and components upstream could see pressures higher than they were designed for - such as VP44 pump case, seals, and low pressure return fuel lines. - John

-

NV4500 locked in 4th

I just removed my short shifter and re-installed my OEM shifter with a new bushing on the end. Shifting is back to normal. I never should have installed the short shifter. - John

-

Installing air springs, hose question.

Personally, I would not join the two rear airbags together with a T fitting. If they are joined, then truck lean will be accelerated while traveling through a curve because air will be transferred from one airbag to the other during the travel through the curve. The last thing I would want is additional body roll on a winding road while towing. - John

-

24 valve reman pump issues

@Me78569, thanks for that clarification - that does make sense. @Cumminsguy5.9, sorry about leading you in a non productive direction. - John

-

24 valve reman pump issues

(Fuel injection pump fuel valve circuit is monitored after current feedback monitoring is complete and average engine speed is greater than 700 RPM. DTC may be stored when Engine Control Module (ECM) does not receive a signal from the solenoid valve to indicate valve movement.) Is it possible there could be a wiring problem (broken wire, bad connection) in this circuit between the injection pump and the ECM? I have no experience with this particular problem, I am only asking this question based on the ECM's decision to set this code. - John

-

Hard start

@JAG1, I very much appreciate your approach for considering a different concept regarding the role of the lift pump in a VP44 system. I always want to give out the right information to the readers, even if it may differ from the current view. I am currently pursuing a way to show how the lift pump and the VP44 internal vane pump work together. Thank you, - John

-

NV4500 locked in 4th

I put a short shifter in my NV5600. I am going to replace it with a new regular throw shifter because of one issue. Being that the pivot point is higher than the OEM shifter (as you were thinking), the spring that aligns the shifter to the natural 3rd / 4th position loses its leverage because of the extra shaft length to the pivot point. Consequently, the shifter will not align itself to the 3rd / 4th position. This causes missed shifts. It really shows up during a down shift from 5th to 4th. If I didn't have this problem I would have really liked the short shifter. Granted, I have 345,000 miles on the NV5600, so maybe that spring is getting tired. Or, maybe it's just a side effect of a short shifter. But, I do know that the OEM shifter does not have that problem. - John

-

Hard start

Glad to hear the problem was a simple one. You will probably hear some differences of opinions here, but I think you are fine with 8-10 psi at WOT. Inside the VP44 injection pump is a vane pump that flows fuel to the internal workings of the VP44 and to the overflow valve. As long as the lift pump is delivering more fuel than the internal vane pump is consuming, there will always be a positive pressure at the inlet of the VP44. Since your lift pump is showing a positive pressure (8-10 psi) at wide open throttle, you should be in good shape. - John

-

Hard start

When I troubleshoot a fuel system, I want to have the most reliable means of testing available. For me, that is a mechanical gauge at the inlet port of the VP44. - John

-

Hard start

Since it sounds like everything was running fine before you installed a new lift pump, I would thoroughly recheck your work - especially at the fuel connections. The fuel system may be losing its prime or drawing in air which will cause hard starts. Fuel lines or fittings can leak air in while engine is off and still show no signs of leaking fuel when engine is running. You should at least attach a fuel pressure test gauge at the VP44 inlet port to ensure the lift pump is doing its job. Before cranking the engine - try one bump start, then let go of the ignition key. The lift pump should run for about 20 seconds - then try starting the engine. If it starts right up it is an indication that you have a fuel supply problem. The overflow valve is very reliable. Don't start throwing parts at the problem until you have done some diagnostics. - John

-

NV5600 Fluid, Fast Coolers, Filter

I have followed the 1 quart overfill for more than half of the transmission life. Also, I have only used Pennzoil Synchromesh fluid since the truck was new - no particular reason other than that it was called for. The NV5600 has never had any repairs (other than a replacement rear seal) and is still running strong with no synchro issues at approximately 345,000 miles. - John

-

Won't start after releasing water/fuel from Fuel Filter housing

This would be a normal symptom for what you did (opening the drain in the filter housing). Air was introduced to the fuel supply for the injection pump. When you started the engine two hours later, the engine fired because there was fuel in the high pressure lines to the injectors. Moments later when the air arrived to the injection pump and finally to the high pressure injector lines, the engine died because air is compressible and when pressurized, it cannot reach injector pop-off pressure. So, step back a moment and relax. There is no reason to excessively crank the engine to diagnose this problem. All you will get is frustration, dead batteries, and lots of unwanted wear on the starter motor. The lift pump operates as follows: Key in run position - lift pump runs for about 1/4 of a second. Bump start and then key in run position - lift pump runs for about 20 seconds. If the lift pump does not run - then you will need to investigate why. It is quite possible that your lift pump has failed a long time ago and you just didn't know that. Because the VP44 has an internal vane pump to supply fuel to the high pressure part of the VP44, that vane pump could have been drawing fuel through a dead lift pump for a long time. When you introduced air into the system, the engine died and an electric lift pump is needed to purge the air from fuel filter housing, fuel lines, and the VP44. - John

-

T steering upgrade or no?

I have to agree with @Mopar1973Man regarding the stock "Y" type steering. For several years, when my truck was much newer, I was considering changing over the the "T" type steering because I thought the performance would be better. I don't think that now, mainly because of some of the improvements I have made over the years with the existing steering. I have had long life from the OEM ball joints and steering linkages. I also a have a couple of original steering joints still on the truck and the truck is approaching 350,000 miles. About 100,000 miles ago I set the caster to 4 1/2 degrees. That was probably the single most improvement I did. The truck drove much straighter down the road and steering return was greatly improved. I have since replaced the steering gearbox (which was still good) with a quick ratio gearbox. I adjusted the overcenter adjustment using @Mopar1973Man's method and the truck now steers better than any other time during the life of the truck. I don't even think about the "T" style steering linkage anymore. I also run 245 tires and the truck height has never been modified. I even removed the steering stabilizer that I installed a few years ago because I thought it would improve steering performance. It didn't. - John

-

Thoughts on an electric fan?

In 1988 I installed a 4BTA Cummins engine in my Ford E150 van. It was a kit provided by Cummins which included an electric fan. After a year or so running with the electric fan, I removed it and installed a mechanical viscous fan and a shroud. Cooling performance was much better. No one has mentioned the fan shroud. The shroud is equally important as the fan. The combination fan and shroud on our trucks produce a laminar flow through the radiator and other components and use just about 100% of the radiator surface. The depth the fan is positioned into the shroud is important as well for maintaining maximum air flow. Some electric fans are suck through and some are push through. In general, push through fans are less efficient because the air is turbulent and flowing in many directions after passing through the fan blades. The turbulent air has to be redirected which causes resistance and reduced efficiency which means a push through fan will have to have a higher airflow rating to do the same job as a suck through fan. The stock mechanical viscous fan and shroud on our trucks does an excellent job - not sure why anyone would want to change that. - John

-

NV 4500 Removal

I learned that when I did my clutch job. I used a bottle jack and a board to spread the frame for removal. Then I studied the frame and I realized that the jack wasn't needed and I re-installed the crossmember without the jack. Somebody told me a long time ago... work smarter, not harder. Every once a while I exercise that option, but not too often - I don't want to overdo it. - John

-

Replaced master cylinder

Has the clutch engagement position of the clutch pedal changed when the problem started occurring? If it has not I would suspect that there is not a problem with the master / slave cylinder operation. Especially if the symptoms are the same after installing a new master / slave cylinder system. You could be right about a pilot bearing problem. When my pilot bearing began to fail, the symptoms were very similar to yours, hard shifting after driving for awhile. The drag from the failing pilot bearing had a minor effect on the pedal position in which the clutch engaged, but basically it was still the same position. I don't have near the miles on my truck as you, but I have been very fortunate so far; I am still operating with the original clutch master / slave cylinder at 344,000 miles. - John

-

24v injector install

Although the common rail runs higher pressures, I don't think that is as much of a factor as is the contamination the edge filters must deal with. I think the key is the phrase "common rail", which means any metal from the high pressure pump and / or other components in the path of getting to the common rail will be fed directly into every injector. This means that the edge filters could clog or be damaged easily. From what I have read, the VP44 injection pumps hardly ever fail in the manner of sending metal debris downstream. This could account for the edge filters staying very clean. I checked the 2002 repair manual for installing injectors and there is no mention of replacing crossover tubes. When I replaced my OEM injectors at 303,000 miles, I just inspected the tubes and re-used them. - John

-

‘99 2500 rough idle

You will be getting more qualified responses shortly, but I think that higher horsepower injectors simply have a bigger hole which makes it harder for the ECM to control fuel at idle. Getting the pop pressure set at a higher value will help. Also, a valve lash adjustment may help. Others will be responding soon. - John

-

Stuck brake caliper

Some times a good night's sleep does wonders. Glad to hear you are back on the road. - John

-

Stuck brake caliper

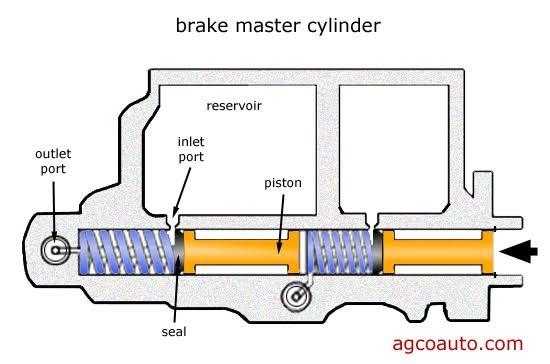

This is very likely your problem. There is a compensating port in the master cylinder that is immediately blocked on the forward stroke of the piston (stepping on the brake pedal). This port allows for thermal expansion and contraction of the brake fluid in the brake lines, brake components, and the calipers. It is operational only when the brake pedal is in the released position and the piston has completely returned. The compensating port is normally blocked with about 1/8" of forward piston travel. The photo below is a diagram of a generic brake master cylinder. In this photo the compensating port is called the "inlet" port. The symptoms that you described on your test drive match what would happen if the compensating port is blocked. Thermal expansion of the brake fluid just from operating the brakes and trapped brake fluid equal dragging brakes. - John

-

W-T ground mod

@GlasairIII, you did a good job posting your test results which makes it easier to diagnose. It also would make sense if this is the problem because before you did the W-T wiring mod, the alternator charge wire would have been charging the driver's side battery so the "problem" would have been hidden and everything would have seemed normal. - John

-

W-T ground mod

It looks to me that the electrical connection between batteries has been lost. I think that the PCM is sensing voltage from the driver's side battery, but alternator output is only getting to the passenger side battery. This would explain that while the truck is running, the driver's side battery voltage is falling (telling the alternator to increase the charging rate) and the passenger battery is rising (exceeding its normal limits). Try using a large jumper cable and connect passenger side battery positive terminal to driver's side positive battery terminal. Start the engine and if everything corrects itself, you have found the problem. If this doesn't not correct the problem, then do the same procedure, but only with the battery ground terminals. - John

-

W-T ground mod

First, double check all of your work. There could be a ground connection missing. How are you checking the alternator output? I would check voltage with the truck running at the following locations without grid heaters operating: * Negative lead to negative post on passenger side battery. Positive lead to positive post passenger side battery. Should be around 14 volts. * Negative lead to negative post on driver's side battery. Positive lead to positive post driver's side battery. Should be around 14 volts. * Negative lead to negative post on passenger side battery. Positive lead to alternator output post. Should be around 14 volts (maybe .1 or.2 volts higher than battery voltage due to resistance in smaller charge wire). Write down the readings and report back what you observe. - John

-

Best injector for "MY" truck?

Understood. - John

-

Best injector for "MY" truck?

I never had the OEM injectors pop tested or spray pattern tested. I replaced them at 303,000 miles with RV275's. The OEM's still performed fine - good fuel mileage, no hard starts, and no abnormal EGT's when towing (the last 50,000 miles with Smarty S03). I am not discounting what others are saying about higher horse power injectors, but I intend to run the RV275's for more than 150,000 miles. The photo below shows the OEM injectors at 303,000 miles. - John

.jpg.677f19d2f0317683948b20f2e142a7f2.jpg)