Everything posted by Haggar

-

vaccum and oil

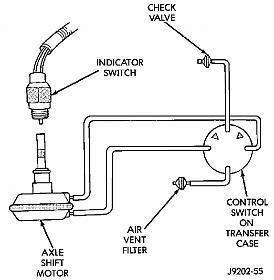

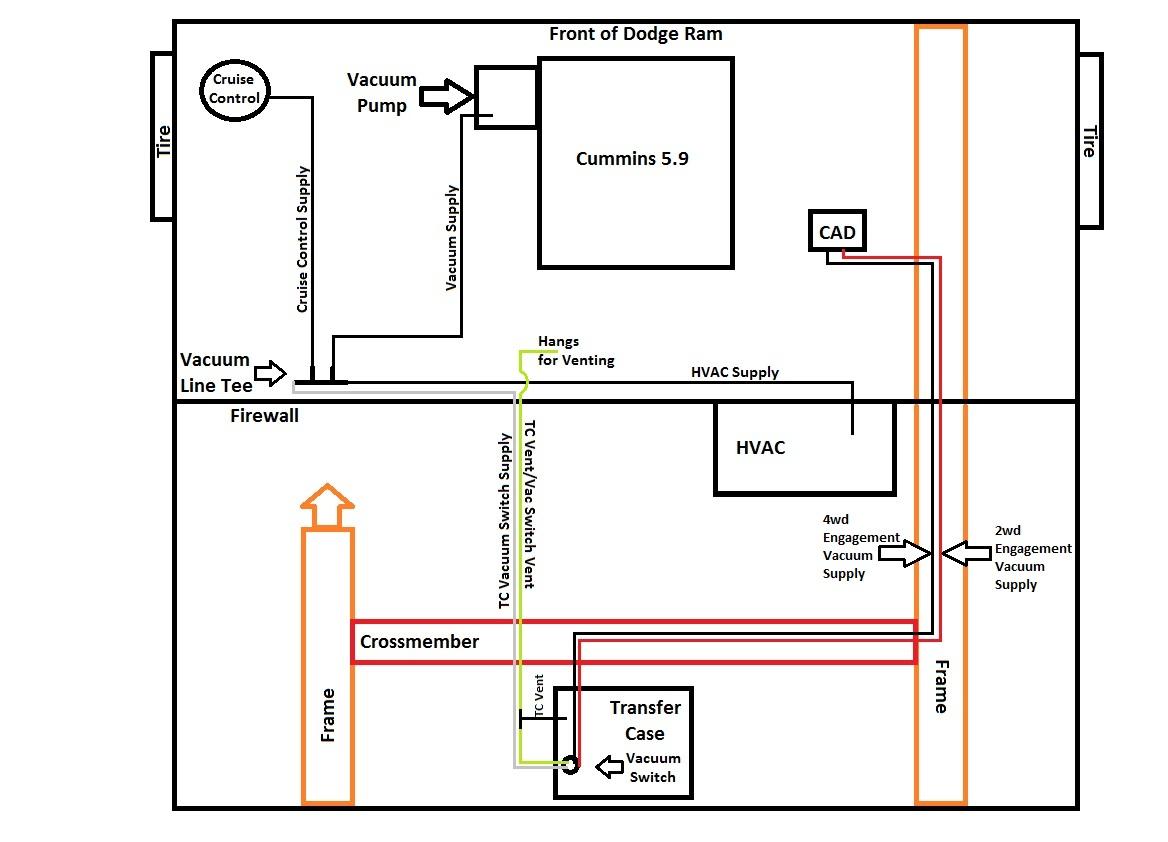

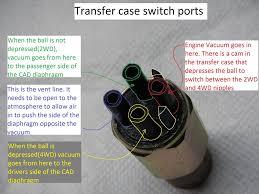

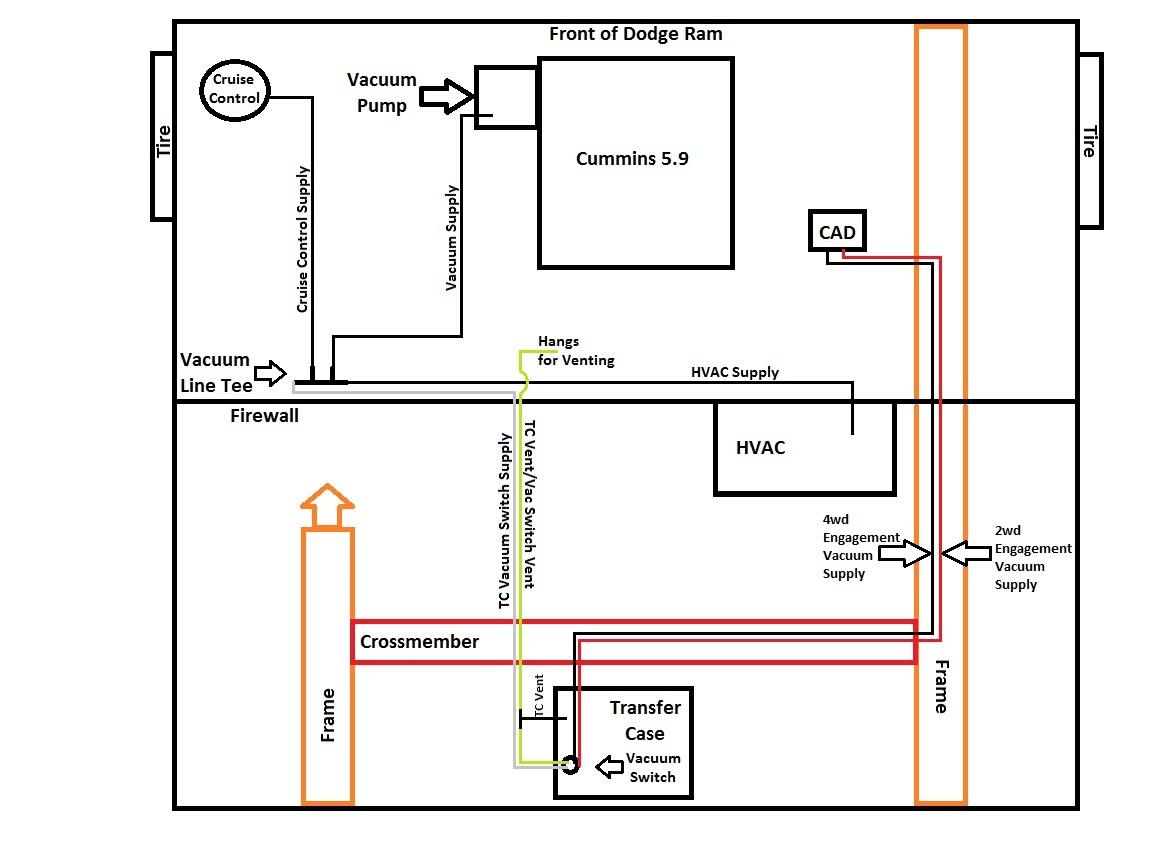

hmm, A long portion going to the axle actuator and back are metal lines. This is a total wag but 25 feet should get you there. you won't have the cruise connection, but 2 2' connections at actuator (not really that long) and 3' for each of the other tubing is 18' (the one across the firewall is probably longer than 3') for a total of 22'. So I think 25 should make it fine. GL HTH Hag

-

block heater malfunctioning

Check what IBM asked first. Then: How long is it before the circuit blows? how warm does the extension cord get? What is the voltage while it is plugged in? How warm does the breaker feel? What else is on the circuit? the heater should pull about 7 amps. So your thoughts on the saw etc are valid. (but we usually run the saw in bursts, not for hours) House circuit breakers look at total Heat. If the breaker is starting to get weak, the breaker will open at a lower temperature (lower total heat). If your voltage while plugged in stays nearly what it was when not (lets say 120 unplugged and 117 plugged) your cord and wiring is fine (breaker is losing its mojo). If the plugged in voltage drops a lot, something is wrong with the cord or receptacle the cord is plugged into. HTH Hag

-

PCM/Alternator Protecting Fuse Blown

You don't mention which alternator you have (denso or bosch). The Denso rectifier bridge is all soldered together. Most people won't de-solder it to check each individual diode. (the bosch is different and easier to check.) My alternator guy and I had a good argument over this. (all my dodges have had the denso) I wanted my rectifier bridge replaced. I had a bit of AC coming out. His normal checks showed it just fine, but agreed he saw the AC output too. I said it causes problems, especially on an automatics. lol next time I was in for some other stuff he mentioned he talked with his transmission buddy and they thought about it and his buddy said yes it is possible and may be a source of the trouble. So alternator guy de-solder each diode to check them out. Sure enough he found one failed... We have been good buddies since. Whether you have one or the other, check for a failed diode. They can fail and still make good power and not kill the batteries when the vehicle is off. HTH Hag

-

Fass Heater

Interesting.... My thoughts changed as I did my calculations.... If I did my math right, the 120 Watts (guessed the output of the heater) would be about 410 BTU/hour. The diesel in the system would require (30 gal, @ 7 Lb/gal, .5 Btu LB F) about 105 Btu to raise it 1 degree F. (assuming no losses <----- lol there is the insulation and radiation) So if you didn't lose any heat, you would gain about 3-4 degrees per hour..... I figured the tank to be about 1.6m surface area fuel temp at 60F and outside to be freezing (32F). The heat loss due to radiation would be about 117 Watts. (if the wind is blowing across it it would be much worse) So if we get colder than zero, the tank would slowly get colder.... (your -30 atmospheric temp results in 318 watts to hold steady tank temp, so you would slowly lose tank temp.) It looks like a bit of insulation, and the pump to occasionally circulate, that might work. I think you might have better luck with some heat trace and insulation on the tank. Along with a heater at the fuel filters. Turn the filter heaters on an hour before startup. Leave the blanket plugged in all night. (there are also small band heaters for the filters I am guessing.) I need to learn a bit more about fuel gelling.... Does it immediately clear if temp is regained, or do you have to go warmer for it to go away. just my thoughts, Hag

-

Airdog problems... again...

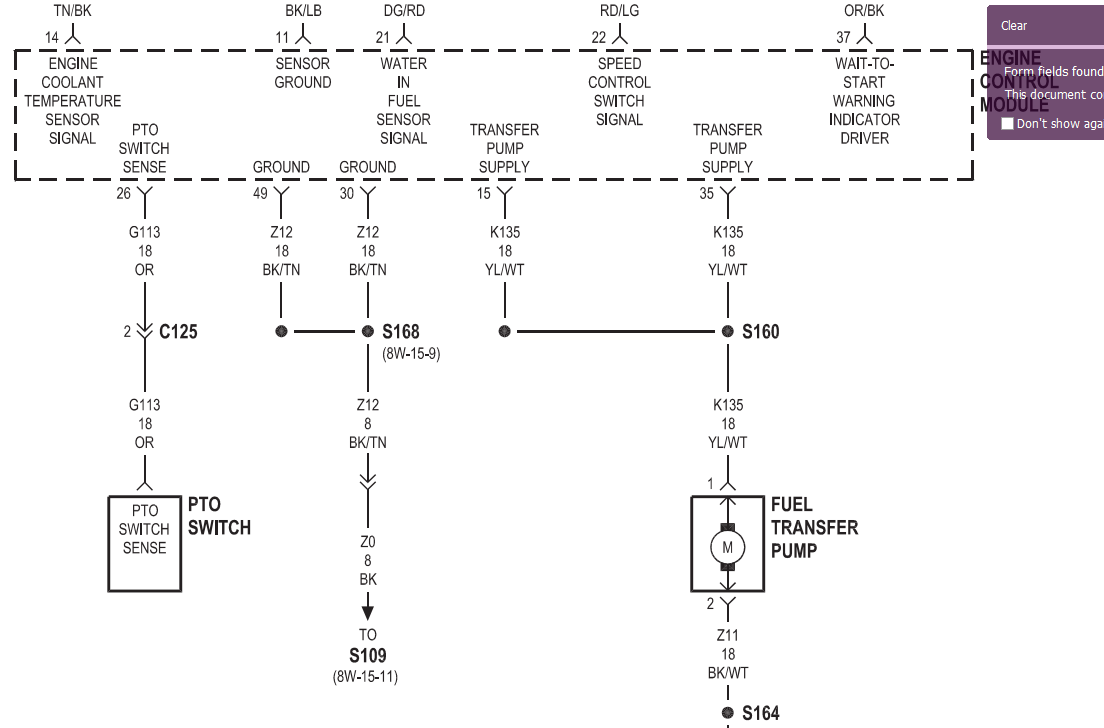

HEx, Sorry about my, Drip and Mike's comments, we derailed a bit. They don't affect you. We are talking super specific things inside the ECM. You just need to check (back probe) the pins 15 or 35 to see if you see 12v there. If you see 12v there, but only 2v at the lift pump connector, you KNOW there is something wrong in the wire between. Since there is a splice that is most likely the problem, so you can fix it. That splice may be a common problem for many people that have blown the lift pump output from the ECM. If the original design (as Mike suggests) is so that the amps are divided between the transistors, if the splice fails, all the pump load could land on only one of the transistors! It won't be too long before it fails then. GL Hag

-

Abs, brake light, speedo dance

Hex, Since the speedo messed up and the ABS light came on (if you have the 4 wheel abs) it will probably be the sensor in the differential, or the wires going to it. (although someone on here lost the tone ring on the ring gear, but I doubt its that) HTH Hag

-

PCM bad?

Hit, Welcome to the forum. I hope some of the people that have seen this will post up with good suggestions on where to start. But it will certainly involve figuring out what series each of your computer modules are from and pick the best combination with your wiring. Here is for testing the P0230 Cluster issues can be fun. Most of the information displayed on the gauges are not direct from the sensors, but are part of the data bus information passed between modules. So troubleshooting is a bit more ugly. GL Hag

-

Airdog problems... again...

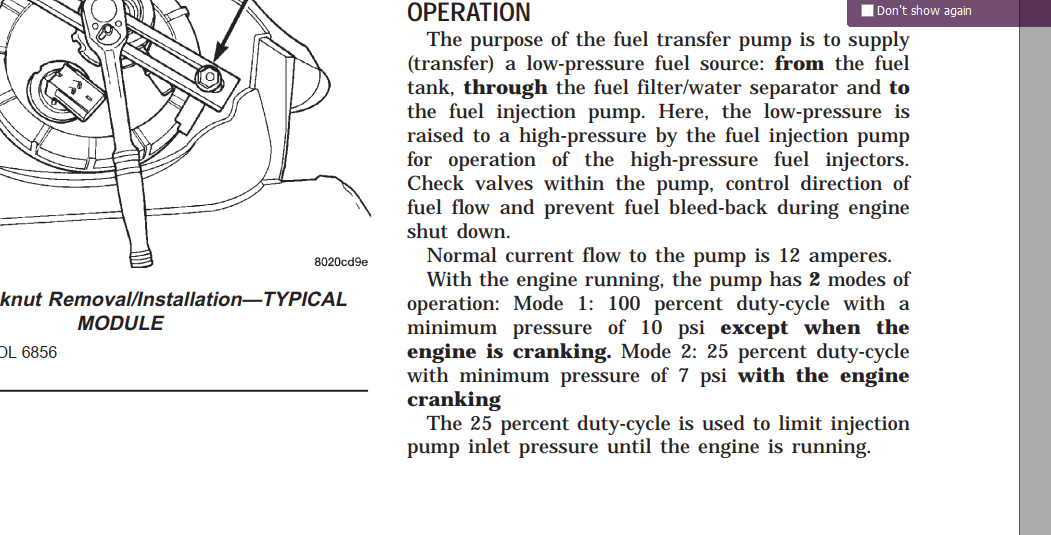

Mike, There are 2 pins coming out of the ECM. is one off during cranking and the other with a duty cycle and swap again when running, or is it two relays in parallel to carry the amperage? (see pins 15 and 35 of the snip i made from the FSM) That is dripley and my question. Hag

-

Electrical Gremlins (CCD Data Bus Issues)

This is from my 2001 manual. notice how joint connector 7 connects the systems. According to the radio page, you could have taken out the CTM. The CTM controls the security relay, so something wonky going on could make the truck think it is being stolen. HTH Hag 2001 FSM Ram 8W-47-4.pdf 2001 FSM Ram 8W-18-3.pdf 2001 FSM Ram 8W-18-4.pdf

-

vaccum and oil

-

Airdog problems... again...

Drip, I believe you are correct, but not certain. I know in the manual they talk about a lowered voltage during starting, but I don't know how they accomplished it. Here is the description of the 25% duty cycle. I assumed the same relay, just frequency operated, but maybe it is a totally different source, hence the 2 ECM outputs. Hag

-

Airdog problems... again...

hex, Chicken man is suggesting you check what is really happening at the ECM, not right at the plug where the pump plugs in. How are you checking it? Terminal 1 to body ground or terminal one to terminal 2? (you should check both ways to see if there is an issue with the wire to ground or the ground. (you could also check the resistance to terminal 2 relative to the negative battery post? You also need to go directly to the ECM connector and check for 12v at 15 and 35. do they have 2v or 12v? notice the S168..... that is a splice... some of our splices are ugly..... if you get 12v at 15 and/or 35 but only 2v at fuel pump terminal 1 you have a splice issue. HTH Hag

-

Squeal/siren noise! Please help!!!

Sounds like your right rear wheel bearing seals are shot. The gear oil from the axle has soaked the brake linings. Oily brake linings don't provide the friction to make heat. (that seems to be the one that is wrong, not the other 3) You need to pull that rear drum off (I have not seen your year and whether a dualy or not) and see what is going on and fix it. You need to check your differential fluid level also. The amount of heat in the wheels after a drive should be proportional to how you drove it. I can ride around for miles but if I have not used the brakes, the hubs will be cool to cold. I can do a really short trip, but had to use the brakes a lot to go from road speed to a complete stop a couple times, and the rotors are too hot to touch. Your hand is fine to use for measurement. Just start closer to the tire and work towards the braking surface. Don't go straight to the rotor (or at least spit on it first). The fronts should be similar in heat and the rears should be similar (especially if you are disc/drum) Front and rear could be totally different depending on your driving style, and rear drum adjustment. HTH Hag

-

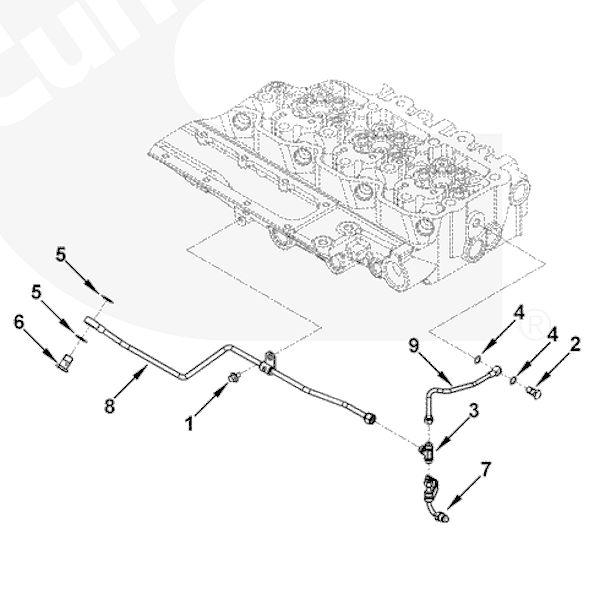

Vp44

Here is the "tee" Jag is mentioning. Item 3. Each of the connectors going to 3 have a small gasket. This thing is very hard to reach with one hand, let alone 2 hands to tighten stuff. (you are looking at the firewall side of the head.) GL HTH Hag

-

Sticking Front brake caliper..... or what

GS, Just did a quick search. There is a difference. (rotor thickness being one that has popped up.) Get the 8800 if yours is 8800. DF, Lol no not bred with any subaru parts, but the subies don't fare well when confronting the big slow slug. in fact they kinda just fall to pieces...

-

Sticking Front brake caliper..... or what

GS, Keep watching the hoses. I have seen some that hold residual pressure for hours, and I have seen some that hold it only for short periods, and some that hold residual only at certain times. This past summer (on vacation no less), buddies Suburbasaurus, would pull at some stops, stop straight other times, and finally locked up completely. When we went to move the truck to a place where we could repair it, it was no longer locked, and didn't even pull once heading to the parts store. Replaced caliper and hose (shot gun ) (was it the hose or the caliper...) and I could not blow through the hose when we took it off.... GL Hag

-

Sticking Front brake caliper..... or what

Neither have I, but I help others fix their problem children. Especially after the dealer or another mechanic has given up on it.... Hag

-

Sticking Front brake caliper..... or what

Seen bad front hoses on quite a few different vehicles. More on Dodge Rams than any other specific make or model. (4 on Rams, 5-6 on all other instances) I don't think there is a specific problem, but it is interesting. HTH Hag

-

No driveshaft

wow! 2 intermediates? no fun!! Make sure your slip yoke moves SUPER freely. Ours turned out to be bent rims.... like 4 of the 6.... it was pretty amazing. (explained why swapping wheels around didn't seem to move the issue.) It really wasn't a bad shake. I would have lived with it, but it was buddies truck and it bothered him to the nth degree. lol. Good Luck finding it! Hag

-

tans tunnel spacing input

If the grommets are a PITA, just loosen the adjuster and let the rod slide there. You will still be able to move the TC linkage with a wrench to ensure Neutral. Just make sure you are not fighting the adjustment. HTH Hag

-

No driveshaft

Yep the only problem is the leaking fluid. I found a cap for a fabric softener or something and slipped right in and contacted the the TC output seal. Held it in with duct tape and wire ties for a week while troubleshooting some vibration issues. HTH Hag

-

tans tunnel spacing input

Take the linkage back out (or just loosen it), and use a large adjustable wrench to manipulate the arm on the TC. (open it to the flats on the side. Or use an open end if you have one the right size) This way you can make sure the detents are hitting in the right spots and check when you are in high low and neutral. The adjustable gives you a nice amount of leverage And agreed mine likes for me to be rolling a bit to shift the easiest. Hag

-

Trouble with my Ram

Tim, All I can do is commiserate. You have the exact same symptoms my brother did, with the only exception you got the P0216! He never got a code. Talk about being unsure of ourselves. Once done we wished we had not put up with the BS for so long... I know you want it to not be the IP. and you wish you could prove it to be 100%. You are at 95% plus now. You can spend a lot of time trying to find that other 5% and still won't be 100% certain. But it is. Its not that bad of a job. You will be happy when you are done. (do injectors and set the valve lash at the same time btw.) GL Hag

-

2nd Gen Vacuum Line Diagram

-

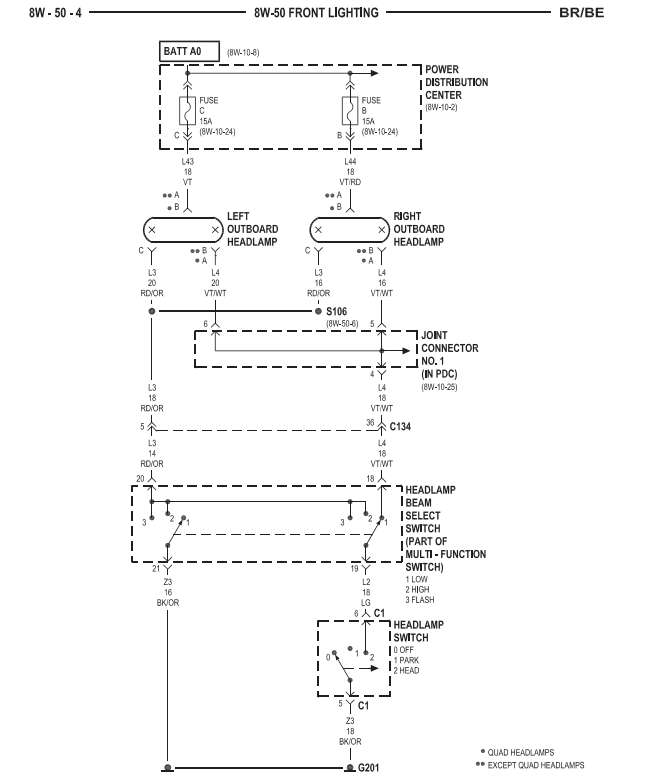

Passenger Side Headlight Dim

Second gen. You should start a new thread. You don't say if you have the quad headlights or the standard dual. (I am going off of you have the dual.) It sounds like someone put the incorrect bulb in the drivers side. Standard single bulb per side is the 9004. Quads have 9004 for low beam and 9007 for high beam. The base of the 9004 and 9007 use the same socket BUT the location of the ground is different! So I am betting someone saw the better numbers of the 9007 and tried it without changing the pins in the connector or they had no clue and stuck something in that looked like it would work. There could still be some really fishy stuff in there.... you may want to double check the wiring. From the 2001 FSM: GL HTH Hag