Everything posted by Haggar

-

47RE Upgrades

I couldn't survive without the 2 low option.... Backing a 18k to 20k trailer having to slip the clutch..... I would be crying.. (and changing clutches too often...) with 2 low I just put it into reverse and let the clutch out. The anti-stall programming in the ECM usually provides enough torque to just idle it into position. I use it on the interstate also. Road repairs / accident cause a backup? no worries 2 low and 1st gear it just creeps and the anti stall just keeps the engine at idle. (I will do this in a heartbeat empty too.) 5th in 2 low gets me to 40 mph or so. So if traffic starts to pick up (and I didn't plan for it ahead of time) I can keep up and get her swapped back into high range without holding people up. I use it a bunch on the logging roads. 2 low and 2nd or 3rd is a perfect speed to handle the roads condition, and let me look into the woods for what I am looking for. 2 low and 1st is perfect for getting square bales on the trailer in the field by yourself. Its wayyy slower than walking speed. (of course 4 low is usually fine in the fields too....) I use it very similar to a 2 speed rear axle in a dump truck. Hag

-

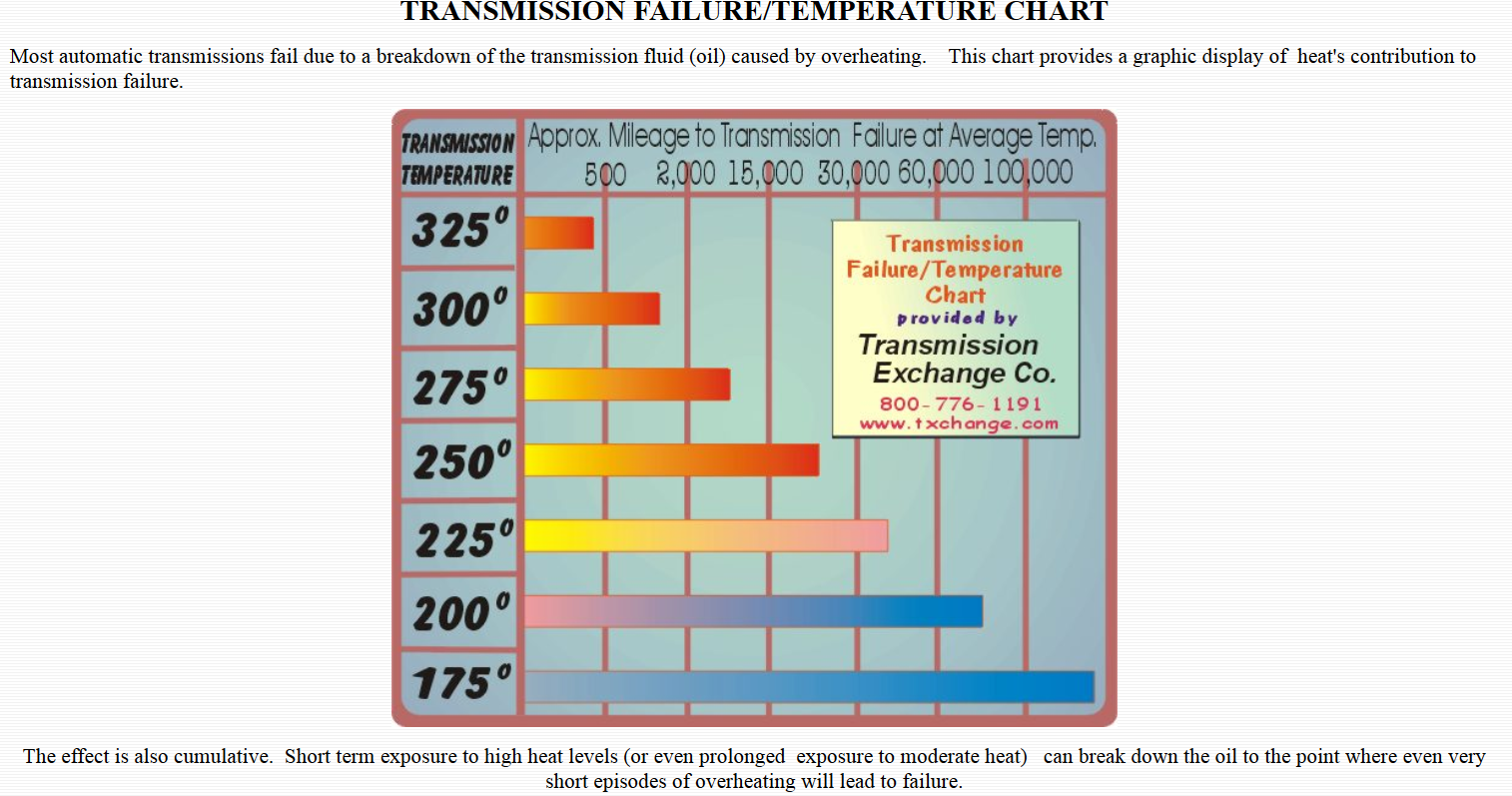

Brakes, power steering

How hot is too hot? Use the graph that I posted in the transmission discussion. It was for ATF but all oils (we use in our vehicles) fall under basically the same umbrella of thermal breakdown. Synthetics tend to move those temperatures up the curve (they handle more heat with less lubricity loss) But basically under 200f you are fine, as you go over that temp you are damaging the fluid. I am adding a ford 6.0 oil cooler to my power steering as a cooler. Since I don't have a slush box and its related cooler I have a great mounting place on the intercooler already. I live in the south, so I really don't worry about getting it too cool, but you guys up north may want to use a smaller cooler. Look on GM suburbans and silverados next time you are in the junkyard. they all had them. (2005 up) They are about $60 new from dorman (for a 2005 silverado). just add it into one of the return lines. (steering return is probably the best and easiest.) Not sure why Dodge didn't add one to begin with..... GM has use power steering coolers on most of the heavier car chassis since the 60's (my 66 Toronado had them, and all of the early front wheel drives.) I don't remember one on the 60 Buick, but Cadillac had them back in the 50's. GM Trucks from the late 60's got them when you got power steering AND the towing package. HTH Hag HTH Hag

-

Faulty Cruise Control

Not exactly that problem, but a 2001 manual transmission cummins, the cruise is all software based. Most people find wiring issues. the random on and off sounds like wiring issues in the steering column and wiring. but funny signals from your vehicle speed could cause it too. Here are the FSM pages that discuss the operation of the cruise. GL HTH Hag 2001 FSM Ram 8P-1 8P-3.pdf 2001 FSM Ram 8P-12 8P-13.pdf

-

47RE Upgrades

Here is a pretty good chart of operating temperature vs life. There is no perfect answer. But the hotter you let it get, the more quickly you should change the fluid. HTH Hag

-

Egt’s

lol AH I gotta split a hair. Torque overcomes drag. Horsepower is purely the rate at which torque is applied..... I'll buy the beer But after reading this, the next thing I would double check, is the pyrometer accurate? HTH Hag

-

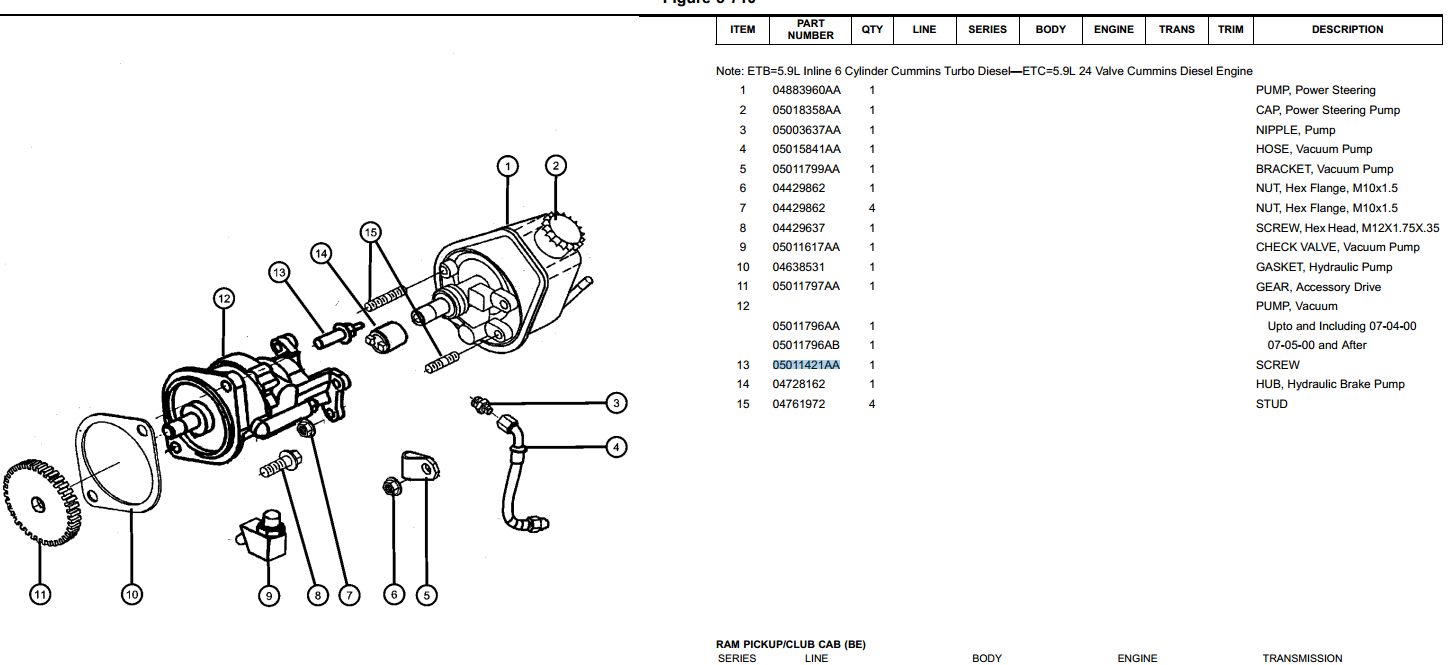

Vaccum pump body bolt size?

looks like: the top bolt is chrysler 05011421AA (no description) the bottom bolt is chrysler part number 04429637 M12x1.75px0.35

-

AC problems

Drip, That's it if the valves were open. To the gulag with you!!! (you have not reached "off with your head" level yet.) Both have to be closed. When you want to add some juice , only open low side and watch the sight glass, should be bubbles not all liquid. (yeah low side theory says you could add liquid, but I am totally paranoid) (don't even consider adding high side with the small cans, I don't think they can take the pressure! You will be approaching the "off with your head" level there though... ) Cheers Hag

-

AC problems

Rip, I wonder if your gauge set is starting to mess up..... There should be no way for you to nearly have high side pressures on the low side....... That is wrong on so many levels.... especially when you say that there is still cooling going on. (ambient to 55 is some cooling...) (if there was no expansion device, there would be very little pressure difference between suction pressure and discharge pressure, but there would be NO cooling.) A plugged expansion device gives you high high side and low low side pressures...... 80 static doesn't sound bad. Double check the gauge set that both valves are closed. remove the yellow hose, (or at least depress the schrader) and see if you have pressure there. there should be NO pressure on the yellow hose when both valves are closed. (though both gauges should read their respective line pressures.) Hag

-

Hard start in morning, then good rest of day

I think you are stating you still use one of the original push on or quick connects in the system? If you do, slap some wheel bearing grease on there, and see if you problem disappears for a few days...... If it does there is your issue. my truck insta starts if it has not drained back. It takes between 7 and 10 seconds of constant cranking when it does drain back. HTH Hag

-

dead pedal issues

Sorry work has been busy. Here is the schematic of the splice for the grounds for the 5v sensor circuit. Dripley has a picture of this. Now this is an 01 FSM. Dripley is certain his 02 is similar to this, but the oil pressure sensor does not require this ground and is not part of this diagram. but as far as we can tell all the other sensors are like this drawing implies. ( the Fiat guys could have tricked us again though.... I swear its an Italian plot ) Dripley has a picture of the splice location in the harness. This splice is definitely right where you banged around messing with a lift pump. GL HTH Hag 2001 FSM Ram 8W-70-7.pdf

-

dead pedal issues

The combination of your errors. (5v sensor supply too high, boost sensor range/performance, apps low input) just screams wiring or one of the sensors on the 5v rail. When you clear the codes, how quickly do they return? do they all come on together? diesel won't hurt the ECM.. We have all dumped fuel there. But the wiring connection to your ecm could be dirty. I would disconnect it and clean it very well with electrical contact cleaner. Inspect all of the pins for corrosion. I use a dielectric grease when I re-assemble to displace air and hopefully keep moisture out. Your issue really sounds like one of the sensors on the 5v rail has perished. (its an expensive part, but the map sensor seems to cause all kinds of problems like this when it buys the farm) just my $0.02 HTH Hag

-

Fuel Pressure Isolator

That's a great point. If you install your snubber that close to the vp, it could see flow. I chose to install it near the sensor, so other than bleeding it will never see flow, only pressure. So it would be a function of where you installed it. Thanks! Hag

-

Fuel Pressure Isolator

Mike, Unless you have a leak, there is no flow on this line. I expect that some of my fuel from 5 years ago is in this line. The only change in that line is due to thermal expansion and pulsing. I suspect that the pressure sensor moves maybe 0.005" total travel. That line is stagnant after you do the first bleed. Most people probably don't bleed the line, so it is probably actually trapped air near the sensor. This is not a bad thing, just would make the response a tad more spongy, but that is probably never noticed with the damping in the gauge. If rust or solids tried to move down the line, it would stop in the lowest place since there isn't enough flow in the line to be carried by fluid velocity, and most of the contaminants are heavier in density than the diesel, so they don't float up the line. Hag

-

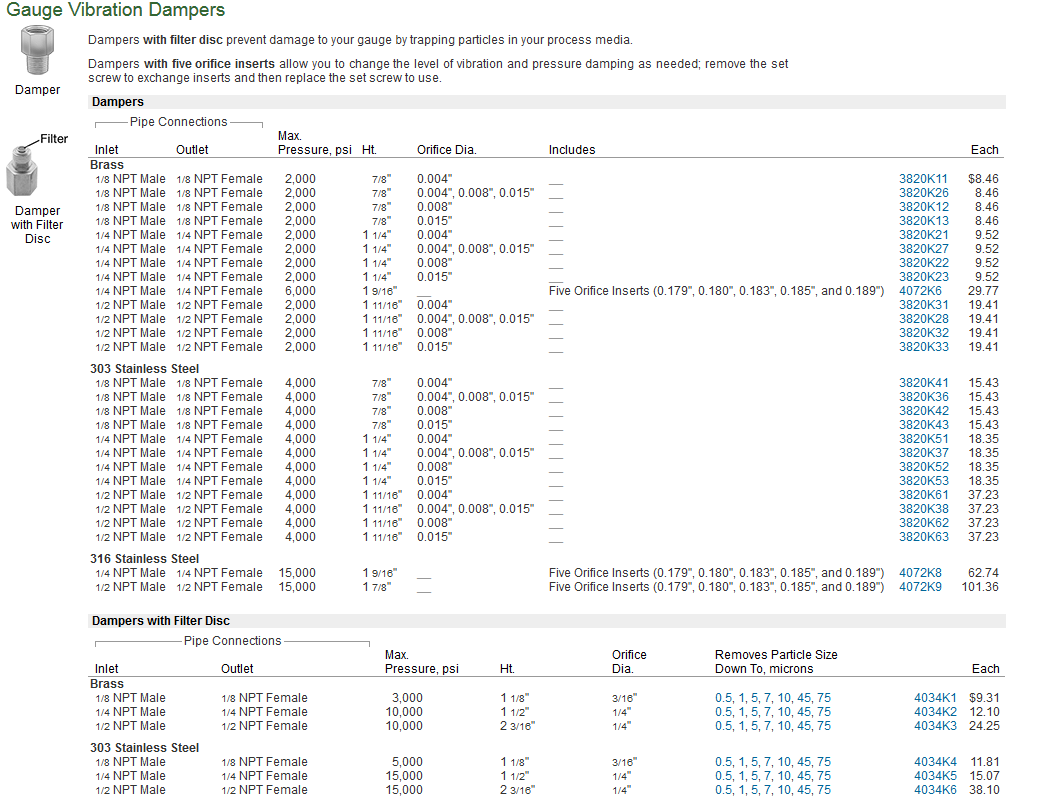

Fuel Pressure Isolator

Sorry I don't like the ISSpro snubber. They don't tell you any of the relevant information. (and the price is a BIT excessive....) Look up Gauge vibration Dampers in McMaster Carr. Pick one with the smallest orifice size, in the pipe thread you need. (I took a quick snip of the page from them below.) (I used 1/8 in NPT 0.004". I did go with the stainless, but I don't know that that is completely necessary.) I didn't get the filter disc. I used the plain hole. I figured if my fuel filtering goofed up that bad, I was going to have to clean more than an orifice. I have an 18" hose from the VP to the snubber to the pressure sensor. That's it. ( I have to confess, I use grease gun hose. Have been for years, but a bunch of womenfolk get their panties in a wad when they hear that. somehow grease doesn't have lubricating oils in them or something and so they fall apart on the inside like they do on my grease gun all the time...) HTH Hag

-

Lightning Struck Truck!!!!

B, Sorry I didn't get online over the weekend. You tested Pin 11 in reference to what? If the ecm was disconnected and you were check ohms on Pin 11 of the harness, where did you put the other lead? I have attached the S165 splice page from the 2001 FSM. to get any real resistance information on the wires connected to Pin 11, you would need to disconnect the ECM and ALLof these connectors at the same time. You would then stay connected to pin 11 at the ecm connector, and probe each one of the grounds at each connector. You would also stay connected to Pin 11 and check for continuity to the chassis, to any other system in the truck (especially battery positive). With both ends of these wires disconnected, they should not be touching anything else in the truck. HTH, I will try and watch this thread more closely! Have a great day Hag 2001 FSM Ram 8W-70-7.pdf (edit: it merged my threads so this was a thought a few minutes and a cup of coffee later...) Just got to thinking, What I don't like is that you checked with the sensors connected. (or what did you actually check) If you checked pin 11 to pin 21, you should not have read zero ohm. you should have read the resistance of the water in fuel signal sensor. If you checked the Pin 11 to pin 14, you should have read the resistance of the coolant temperature. etc. Also keep in mind, pin 11 sensor ground may not have a path to battery ground. it may be a complete separate system. you can double check this with the spare ecm. check the pin 11 ON THE ECM to the case of the ECM for continuity. (I am a bad lawyer, I am asking a question that I do not already know the answer to. I have not checked this out.) But I suspect that sensor ground and truck chassis ground have nothing to do with each other. Hag

-

ecm ground

B, Man you need to start a new thread if you need help. You need to explain exactly what you are testing. Most of our sensors are only 5v. They never see 12v. (The PCM or ECM creates a very specific 5 vdc source for communication of sensors to the ECM and PCM.) So, you may not have the problem that you think you have. Good Luck! Hag

-

hydroboost

-

24v KDP Question and Flywheel Question

Blind holes are a pain to drill. (no where for the chips to go. harder to measure that the depth was properly met. diameter measurements are harder) ALSO Alignment pins into blind holes cause problems. The trapped air can prevent the pin from fully seating (and if the press is too loose, the pin can compress the air, then fire itself across the shop...) also debris can be in the bottom of the hole and not easily seen, so the part that is supposed to be aligned may not make down to the surface properly. I will always try to have at least a small through hole for a pin and larger for tapped holes for chip/debris clearance. HTH Hag

-

Injector install questions

LOL, Mike said what I was going to suggest. Charge the batteries!!!!! Most of my starting problems (on the rattle monster and my tractors) stem from turning over too slowly to begin with..... For diesel to begin its burn, since we don't have spark plugs, the ignition energy comes from the temperature rise of compression. There is less heat available in a slowly moving piston to start the burn than a fast moving one. Cranking speed DOES make a difference. HTH Hag

-

24v KDP Question and Flywheel Question

This is what the timing cover from a truck that can have this problem looks like. I got this picture from an article on Diesel Tech. The article was by Michael Deulley. Notice the early timing covers, the surface that the dowel pin is in is on the same plane as one of the bolts. (the bolt is removed in this picture, but you can see the hole for it slightly right and down from the dowel.) The updated case has a hump that the dowel is in. (like dripley and moparmans picture) HTH Hag

-

2001 Back-Up lights on all the time

Just a thought, but could the trailer connection have a small voltage leak in it? (there is constant power there (from Fuse 8 pdc, along with the reverse lights.) You may want to have someone look at the reverse lights (with the LED in) while you have the park/neutral switch disconnected. I am betting you have been doing the work by yourself so you would not have noticed them "still on" when disconnected. So many people do weird wiring repairs and such at the trailer connectors.... GL HTH Hag

-

Borgeson Steering shaft upgrade

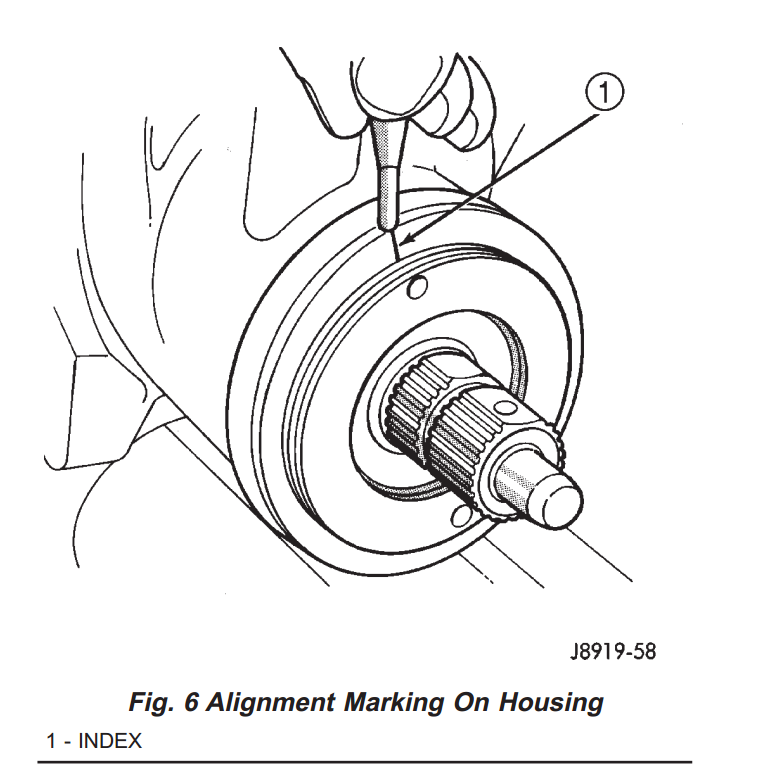

Tractorman is exactly right. The steering box I am using was not originally fitted to the 2nd gen dodge. (pretty sure it was a GM) The spline input on the original dodge, had a flat in the splines. To make the non-original steering sector work, you have to reproduce the flat, in the adapter so it can be used on our trucks. In this snip from the FSM you can see the flat that is on the input splines of stock steering sectors. In this way I was able to use a Steering box with a larger input shaft spline, but connect it to my factory steering column. Stanley, You got a new replacement steering column so you may not have to do any other mating. Mine came purely from fitting a GM steering sector to a mopar steering column. HTH Hag

-

47re problems

what Kzimmer says! Again from an ME's perspective, once we get past the smoke and mirrors, they (the EEs) make a squiggly line and want me to eat it as a straight line. It's squigglier closer to the source than further away. And since the smoke and mirrors gurus that came up with this didn't give us the right stuff to do it right, we are gonna move the squiggles behind the only thing that we have that resembles a DC filter capacitor, the batteries. We have two of them so that should un squiggle the line some. Agreed the AC gets really bad when one diode is failed. Sometimes this is caught early (alternators that drain your battery when the engine is off,) and sometimes not seen until too late (hey batteries don't die and my volt meter says I am charging, but my lights flicker and the flicker changes with RPM.....). It also seems that there is some AC occuring as the brushes and armatures wear. Not sure if the carbon is making a trace for alternate voltage paths or what. Most of the alternators that are available are rebuilds. The rebuild guys don't replace EVERYTHING, just whats broken.... and what is broken is only according to how well they tested it in the first place.) I really think a big source of issues (and the problems we keep worrying about) is whoever decided to move the voltage regulation to the PCM. Just what in the world does the PCM need to be worrying about the stupid gross regulation of battery charging voltage? So now we have two theoretically the same, but separate 12v sources (three if we include the squiggly thing that should be straight) that SHOULD be the same (but the grounds are not bonded together exactly like the positives are) but with just a bit of grounding issue turns it into two (or more) different systems relative to the PCM.... The PCM sees the ground of one battery and the positive of the other battery. voila magic smoke at worst, potentially weird regulation at best, and nothing to help make squiggles straighten up. (why, just why, when an alternator failed it would die, not potentially take out the PCM with it....) 'splain it to me Lucy! and Jag, no capacitors don't really explode (i guess a really big one could but still not see explosion as the proper description) Usually when they fail and the magic smoke comes out, they split open, and if bad enough, some of the solid magic smoke leaks out too. unless you are in a cave and using a stone tablet with chisel and hammer (gosh sometimes i swear i wish I was donig it that way... so much simpler) you have hundreds of capacitors around you. usually when they die, the tv won't come on, the AC won't come on, etc. The circuit gets grounded and the appliance stops. The grounding isn't usually enough to pop a breaker, just short to open circuit. Just food for thought guys. 100% ready for some beer. Hag

-

Front end

Bullet, I disagree on a minor point. Its not poor design. The design is pretty standard across many manufacturers and platforms (4 link panhard bar control... that is nascar, all real drag racers etc). The problem was implementation. The parts aren't beefy enough to put up with a lot of miles or even better the miles AND what we ask them to do. There was very little margin for error. (I really think the design and implementation was fine for the weight of the v8 gasser, but the engineers got over-ruled by management to upgrade for the cummins.... can't prove it yet, but I can see it pretty well in my mind.) We seem to carry an extra 400-500 lbs or more than the gassers all directly over the front axle. A second problem is our replacement parts are made by companies shaving more pennies than the OEM was in the original design. (I really think this is where most of us start complaining.... Its not that I had to replace the part at 100,000 plus miles, it that I had to replace it AGAIN in another10,000 to 20,000. For some reason, the aftermarket suppliers don't realize (or don't want to acknowledge), I will gladly pay twice as much for a part that will last me another 10years. HTH Hag

-

47re problems

Keep in mind this is an ME trying to explain the BS that EEs belive to be the truth..... The alternator does not produce DC power first. It produces AC power and the diodes clip the AC waves TRYING to make it look like a DC signal. The Diodes are not perfect (ramp up time, ramp down time etc. and OMG let one of them go bad) so there is a bit of a wave allowed to follow the voltage and current through the system. This is in fact measurable as AC voltage on top of the DC circuit. In the old days this didn't matter.... we were not trying to control and monitor on small 5v ranges that the stupid computers want to see. But today we are.... (and If only they used 4-20 milliamps for the communication of the sensors and stuff they would not have been as influenced by stupid changes in the voltage system...) Grrrr EEs can't live with them, can't live without them, and can't shoot them. Its a heck of a conundrum... They can take a perfectly good mechanical system, and with magic, smoke and mirrors, make it work great and efficient for awhile, then turn it into the craziest nightmare of problems that I wouldn't wish on my worst enemy.... /rant off. Hag