Everything posted by Haggar

-

pulling to left while accelerating

Don, Have you had it to an alignment shop yet (and not just a toe and go place but a good shop)? It sounds like your thrust angle is way off. Your rear end could be not perpendicular. Try a quick measurement. Measure the wheel base on the driver's side and compare it to the wheel base on the passenger side. I am pretty certain on these trucks these should be equal. GL HTH Hag

-

Hydroboost problems

blue, You don't have to cut the rod. You can disassemble it where the shaft is peened around the ball. you just have to make some tools to hold the shaft. If it is not leaking at the input rod, just let that slide. The last one I did, was leaking at the output, so I didn't spend the time on the input rod seal. It may bite me later, but working fine right now. GL Hag

-

4x4 indicator light

if not working during test, the bulb is bad. check there. GL HTH Hag

-

Hydroboost problems

Agreed they are basically the same. Differences fall in 2 places (not including accumulator pressure, which is designated by anodized color) input rod and output rod lengths. I have noticed a difference of the boots that go near the firewall as a difference between my GM version and my dodge version (could be a year thing, not necessarily a end user spec), but that would have not prevented the use, just sealing around the hole in the firewall. Hag

-

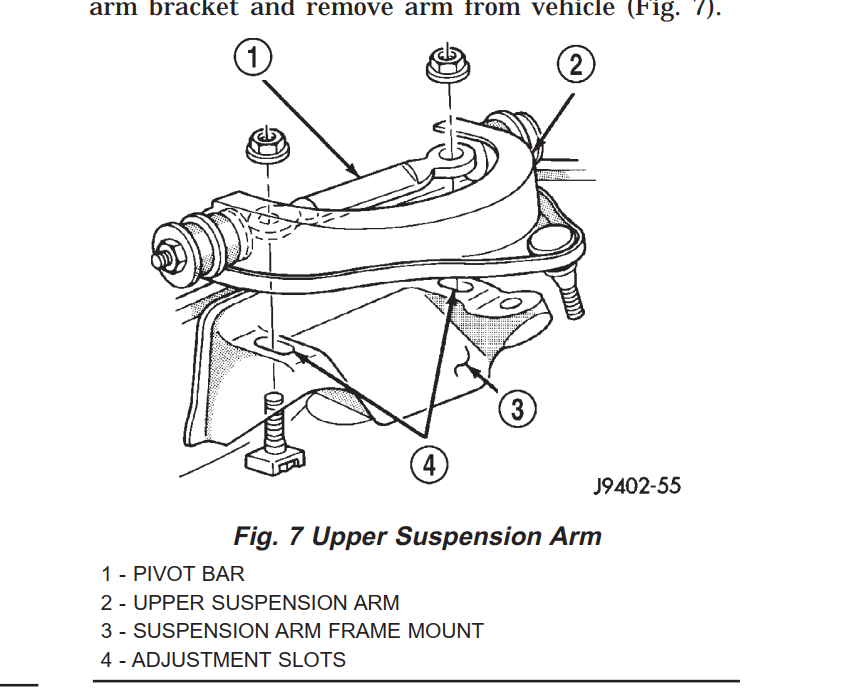

Thuren alignment specs?

The bolts are probably rusted to the inner sleeve of the bushing in the control arm. Use never-seize liberally!!!! And Don, being in Idaho, depending on the salt, you may need to keep protecting those joints with something yearly, I think I see Eric on south main auto using some kind of waxy spray?.... GL Hag

-

Thuren alignment specs?

great! Glad it worked out. Sorry some alignment shops are "toe and go". You just have to avoid them. Hag

-

Hydroboost problems

Blue, Keep the one you have now (if it is not too late) and check the rod that pushes the master cylinder. Like Nissacs said it sounds too long. It will take you a few minutes to measure, you gotta reach in to depths and relate that dimension to the actual mounting surface.... but once you work it out you should be able to tell if it is actuating the brakes. GL HTH Hag

-

Thuren alignment specs?

do the cam bolts look like they were touched recently? They SHOULD have been adjusted during your front end alignment. It sounds like to me, that you got a "toe and go". Sorry you don't have good people to help you diagnose and understand your front end. There is a slot in the bracket. there is a hole in the front lower control arm bushing. Since the eccentric washer is keyed to the bolt, as you turn the bolt, it will move in the slot. (notice the C shaped piece with the notches on it, it is welded to the bracket forcing the eccentric washer to push the bolt.) So you loosen the nut on the back side. Turn the bolt until the fat part of the eccentric is toward the front axle. tighten the nut on the back side. This will give you the most caster you can achieve with your present setup. (you may have to lift the front axle up a bit with a jack to get it to move easily.) Pull, if the alignment is the only issue, is due to positive camber. by rolling both lower eccentrics fully forward, (making the lower control arm as long a possible) may compensate for that. This will affect toe also as we are actually rolling the axle, but that is all we have. The front axle has a "fixed" caster angle. go for a drive.

-

Thuren alignment specs?

There is one adjustment (cam) bolt on each side, lower control arm at the axle. For most trucks the, the cam should be forward (the bolt should be towards the rear) rotate the cam in the direction of the red arrow. The cam shown is in the mid position. I am not sure why people jump to adjustable ball joints right off the bat. HTH Hag

-

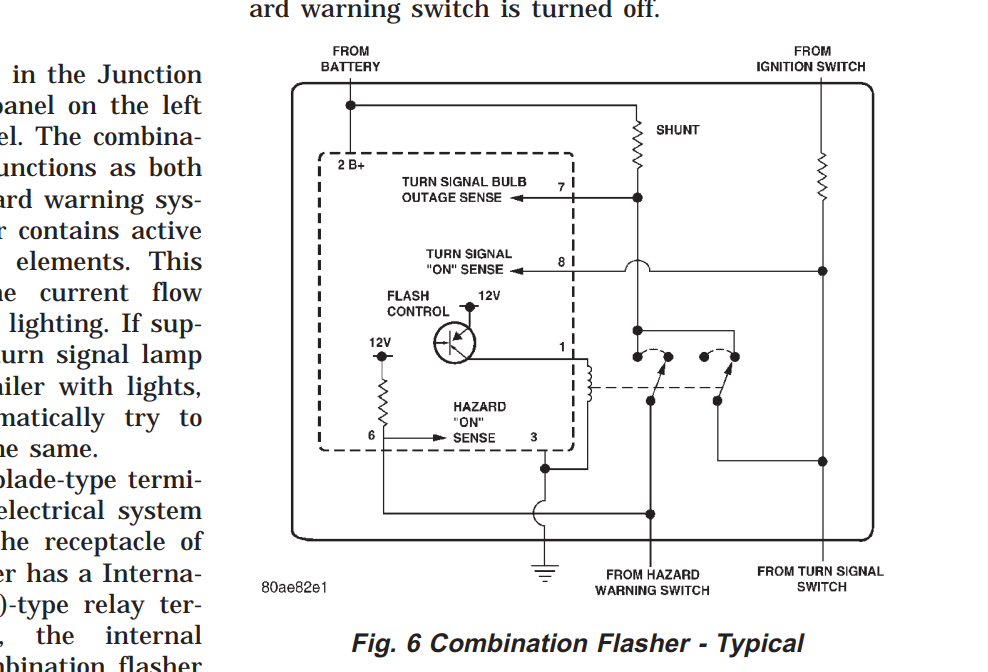

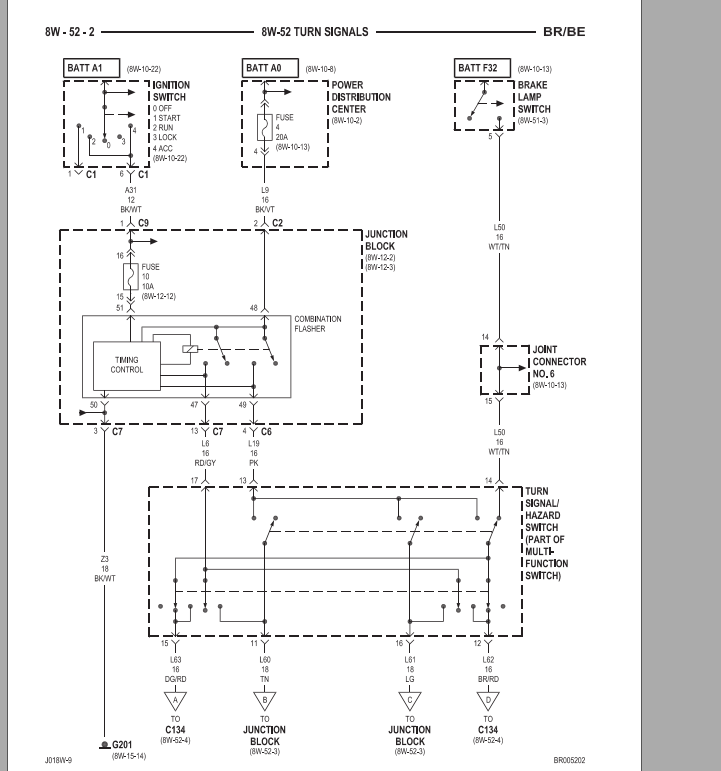

Turn signals not working

Make Certain they gave you the correct flasher. Ours is NOT like most cars. (most cars use a bi-metallic flash unit.) ours is a small computer board. You will want to read section 8L of the manual for how it works. Here is a schematic of how it works. Notice you had hazards (which is a separate input from "turn signal switch") So it would lead one to think you are missing the turn signal (left right) input signal. You may have to look at 8w52-2 and hunt out what is missing on the wiring diagram. GL HTH Hag

-

Another grid heater thread

If you had the grid heaters on and measured 12.3v on one side of the relay and 10.5 on the other side, that is a 2v drop through that component. So 17% of your energy is heating your contacts. I think that is too much and indicative of the contacts beginning to fail. Leave your grids on and feel the relays, are they too getting warm? I never got to measure the voltage drop on mine, but eventually my originals got hot enough to distort (melt) the relay bodies. HTH Hag

-

Thuren alignment specs?

Don, The normal toe for our trucks is +/- 0.1 degrees. So he has tightened that up a bit. Same with the castor. He is in the right range, he just removed the -1.0 degrees the factor allows. (factory is X */- 1.0, Thuren is basically X + 1.0degrees) I think his emphasis, is the castor. Do you have a 4wd or 2 wd? on the 4wd we have a lot of issues with castor. Castor will directly affect how the steering "re-centers" itself. too much Toe will cause wander. (the truck will feel "darty" ) You can easily play with your own toe, and see if it helps your problem. Someone here recently said the alignment shop could not correct his castor and he had a 2wd..... that is just a lazy shop. GL Hag

-

AC leak

GW, If you have a nitrogen bottle, pressurize the system with nitrogen, and use bubbles. The High side pressure switch does not open until 450psi. So if you pressurize in the upper 300 to low 400 you can find small leaks with good bubbles. This will get you everything you can see. if you are still leaking, it has to be the evaporator. Since you will have pressure and not having to run the truck, you may hear the leak. GL! Hag

-

99 24v crank but no start new vp44 and ecm repaired

Depending on what Central Timer Module you have, by pulling fuse 13 you have pulled the constant hot to the CTM..... if it doesn't start, it is because the CTM thinks the truck is being stolen. HTH Hag

-

Turn signals not working

The multifunction switch is usually the culprit for intermittent problems. It is not hard to do, you just need to have some of the "tamper proof" torx bits. (the one with the hole in the middle.) Our flasher unit is special it is electronic (not heat based like the older ones) it is in the fuse block in the cab. its called the combination flasher. GL HTH Hag

-

1998.5-2002 guys with a swapped in Manual transmission

I LOVE the manual stall prevention. I never slip my clutch with an empty truck. I can just let it out fully in second gear then add fuel. I can do this with my big trailer attached. Only when I add the skid steer do I need to start in 1st gear but I use the same process, let clutch out fully before adding fuel. With 2wd LOW in reverse, it is same thing, no clutch slipping during backing, just let clutch out. If I am backing up a hill, after clutch is out, I may have to add some fuel, but flat backing, the idle control is the perfect speed. Welcome back! Hag

-

Power Steering Locking Up and Brakes Failing

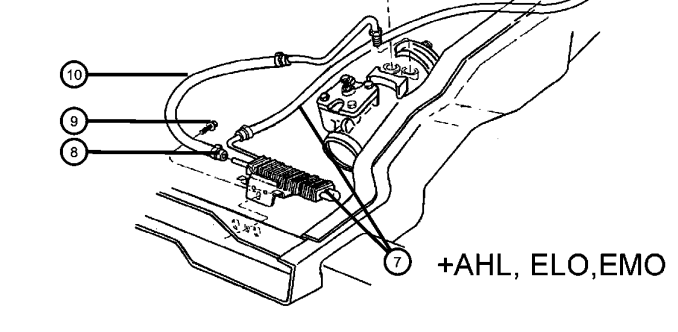

Reaper, I don't know for a fact that the hoses will, but I really suspect they will. I would find a gasser in a pull apart, grab the whole shebang and see. These hoses are all on the low pressure side (return side) so it really does not take much. GL Hag

-

Power Steering Locking Up and Brakes Failing

One thing I got to looking at, it seems a LOT of the gas powered rams got a power steering cooler. I replicated one on my truck with the oil cooler from a SuperDuty (lol post 7.3 fords ARE good for something...)

-

1999 ram3500 2wd ifs camber correction?

I suggest find a new alignment shop. But if you want to give them a chance again, ask them why they can't use the slots provide by the factory? There could be damage to the frame or control arms that have these maxxed out. But to suggest ball joint correction at this point is kind of odd. (They should have informed you that there was damage to prevent them getting to the proper adjustment within the factory limits the last time they looked at it.) HTH Hag

-

Interference fit required for wheel hub assembly to knuckle?

It is not an interference fit, but the center hole should not be so large as to allow the bolts to be in shear. For Sh%^S and giggles let us say that the hub receiving hole is .005" larger in diameter than the hub going in. The bolt holes have .025" (or more) of clearance all around. (Just looked it up, Metric standard is for through hole is 1.5mm larger (0.059") than the fastener.) The hub will engage the knuckle and the bolt holes' clearance will reduce to 0.020" (on one side) and increase to 0.030" on the other. You will be fine. HTH Hag Factory fit was NOT interference, but anti seize was not applied at time of assembly, and oxidation bonded the two close fitting diameters

-

What boost should I get

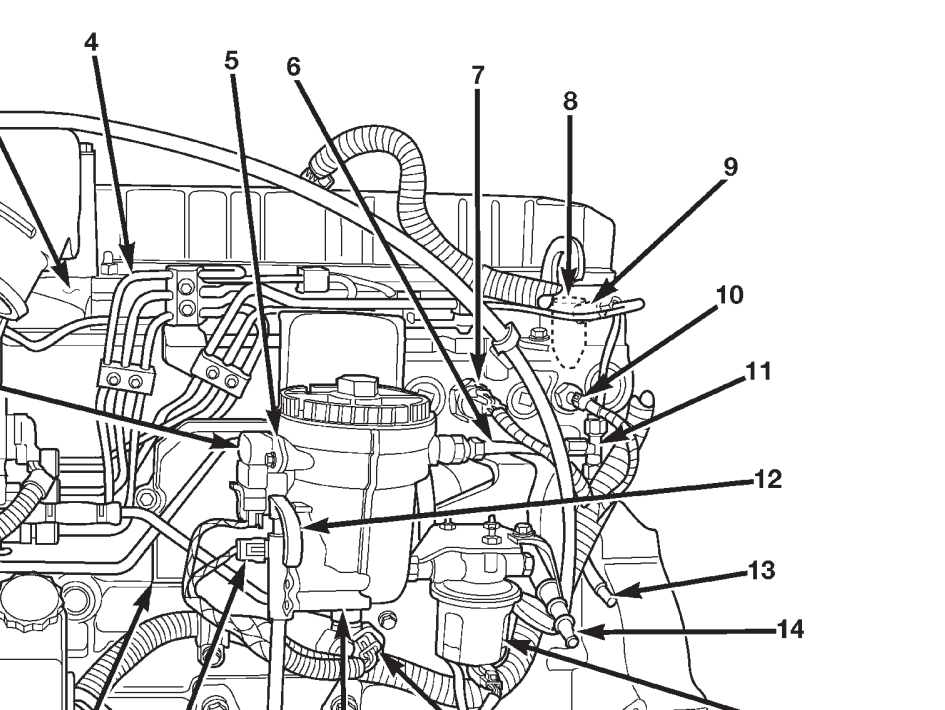

For boost connection, I like the port between 7(map sensor) and 10 (intake air temp) or the port to the left of the map. I think it is 3/4" npt plug in there. Just get an adapter from 3/4" to whatever fitting your boost gauge tubing is (usually 1/8 or 1/4 npt) GL HTH Hag

-

NV 4500 Removal

Frame and crossmember are on a taper (from the top down). That is why it won't just drop out. Both of the above suggestions work to remove it. The taper is why you have to do it that way. HTH Hag

-

New Bluetooth Stereo Kenwood

your fronts are definitely 6x9. the rears always seem to fit funny for me. but the selector is showing a lot of 6 1/2" compatable rounds. Use the "outfit my car option." in most cases it is correct or says there might be a problem. This link might work for you. It was last setup for an '01 quad cab without bose system. https://www.crutchfield.com/g_400/All-Car-Speakers.html?l=C&pg=2 hope that helps Hag

-

New Bluetooth Stereo Kenwood

lol Infinity (not bose sorry)... only one of my trucks had that. the way to tell is if you have small speakers in the A-pillar like dripley said. It uses some small powered cross overs in the front speakers. They can be unwired and a normal system with a passive crossover can be used. If yours does not have that it is pretty straight forward. The original unit is a 1.5 Din high. That is why you end up with an adapter plate. (most replacement units are 1 Din high) If you want look through the list and send me a message I can try to help explain the differences. Pioneer is a great brand too. Before I switched to Kenwood, Pioneer was my go to. I changed mainly because at the time I changed, Kenwood had better internal amplification at the time. (don't know if that is the case any longer... loud is not as important as it was...) I like using the compare feature. Notice the box to the right under the price. put a check in the box for the ones you like. At the bottom of the page you can select to compare, a new window will open comparing features. As for the speakers.... 6x9 in front doors. 5" or 6" rounds will work in the quad cab doors. (the factory size was a bit wonky.... so you may have to make some new holes etc to make things work out. HTH Hag

-

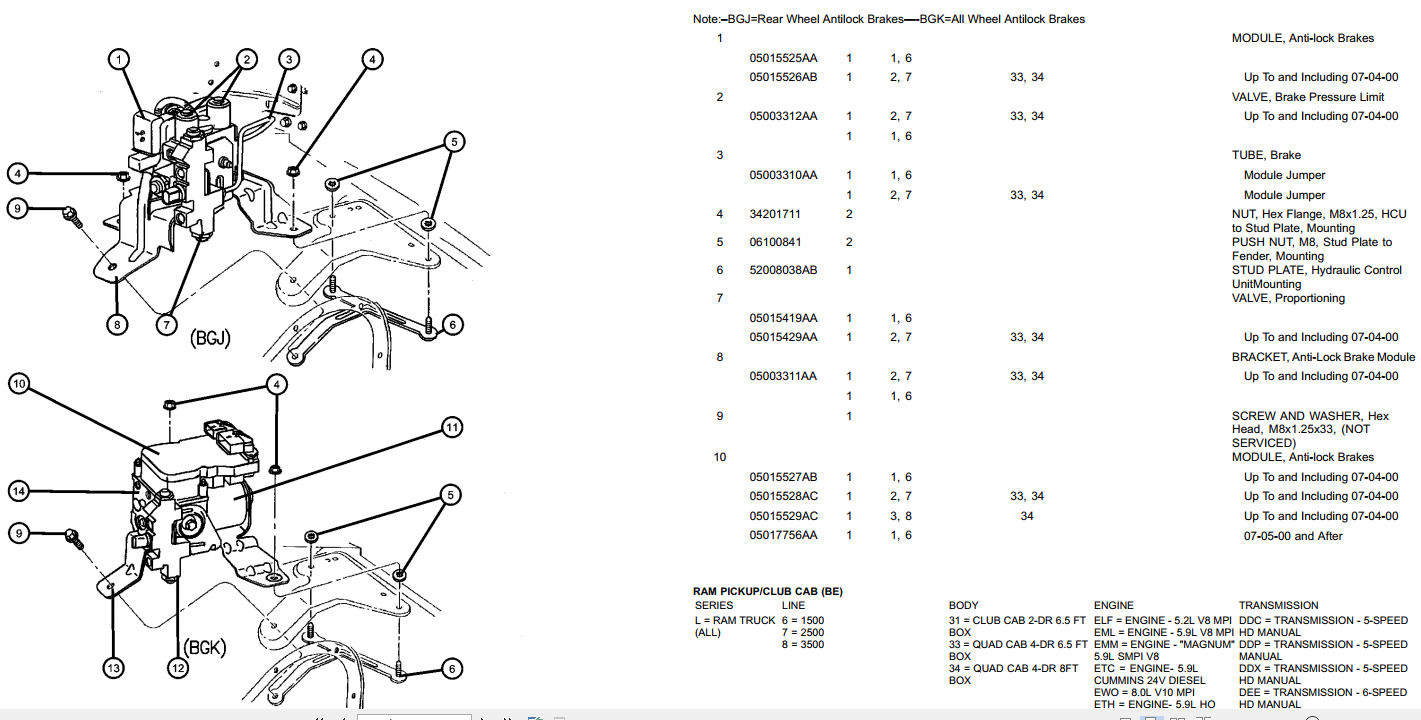

Front brakes dragging

Thanks for getting me to look into this. (sorry it wasn't your front lines.... that is so much easier...) All my trucks have the 4wheel. I didn't realize the 2wabs had sortof a little "brain" too. Item 2 is a pressure limit. I agree it should work like an accumulator. The rear level valve is pretty stupid, but GM and Ford did it for years too. My 86 suburbasaurus had it too.... I think since it is a rotary valve, as it closes off the flow, it increases in volume a bit to reduce pressure on the rear wheel cylinders. (so they don't stay locked up...) I could be totally wrong but I don't know why you would blind off an already locked rear wheel..... Good luck! I hope they find your issue and it is easy to fix! Hag