- Replies 105

- Views 32.6k

- Created

- Last Reply

Top Posters In This Topic

-

Tractorman 17 posts

-

wil440 11 posts

-

Mopar1973Man 10 posts

-

JAG1 10 posts

Most Popular Posts

-

Nice contribution @MikeHI don't know who these fellows are but, it's nice to see a tear-down presentation at this level. This pump is certainly a dual stage series configuration where the

-

I think you are on to something here. I just recently rerouted the return fuel from the VP44 and head to the filler neck on my truck. Previously it returned into the same basket that the lift pump

-

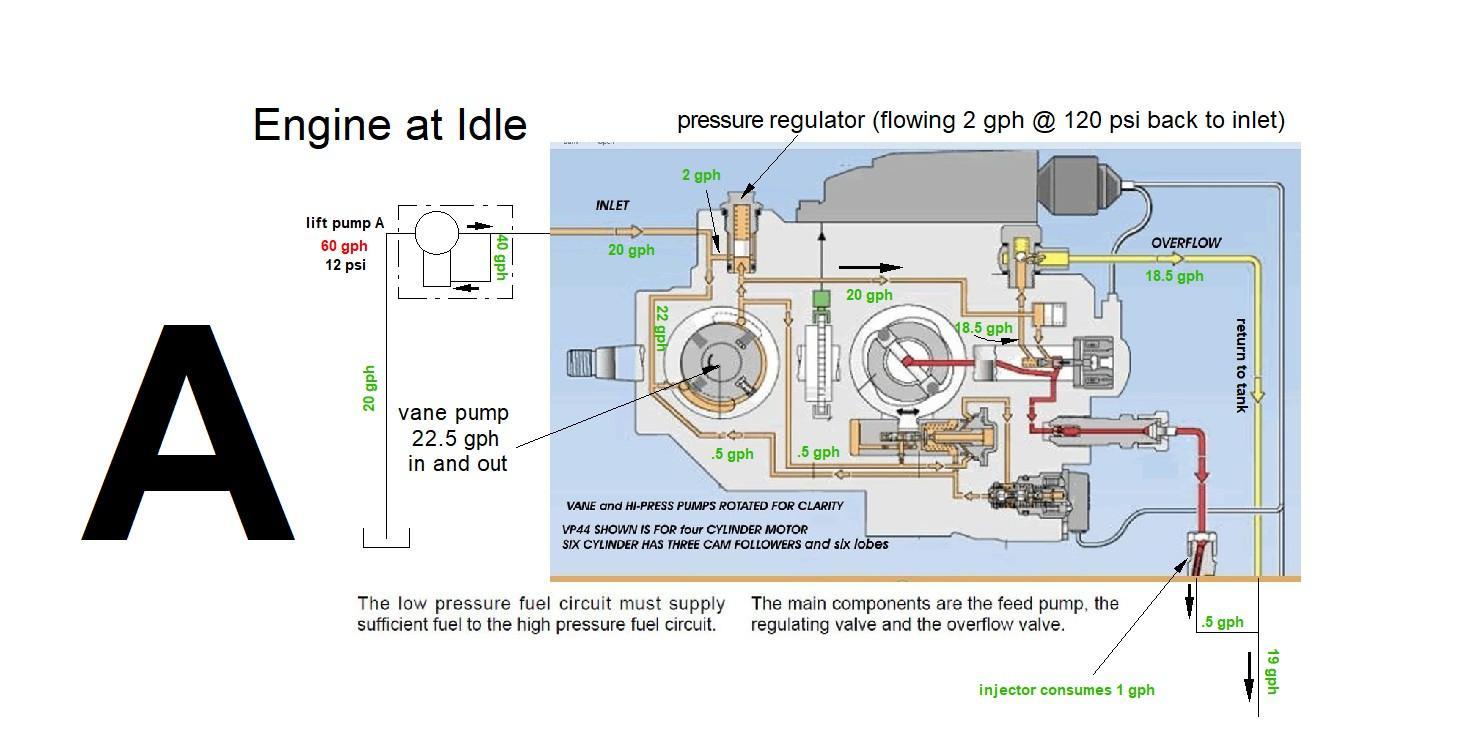

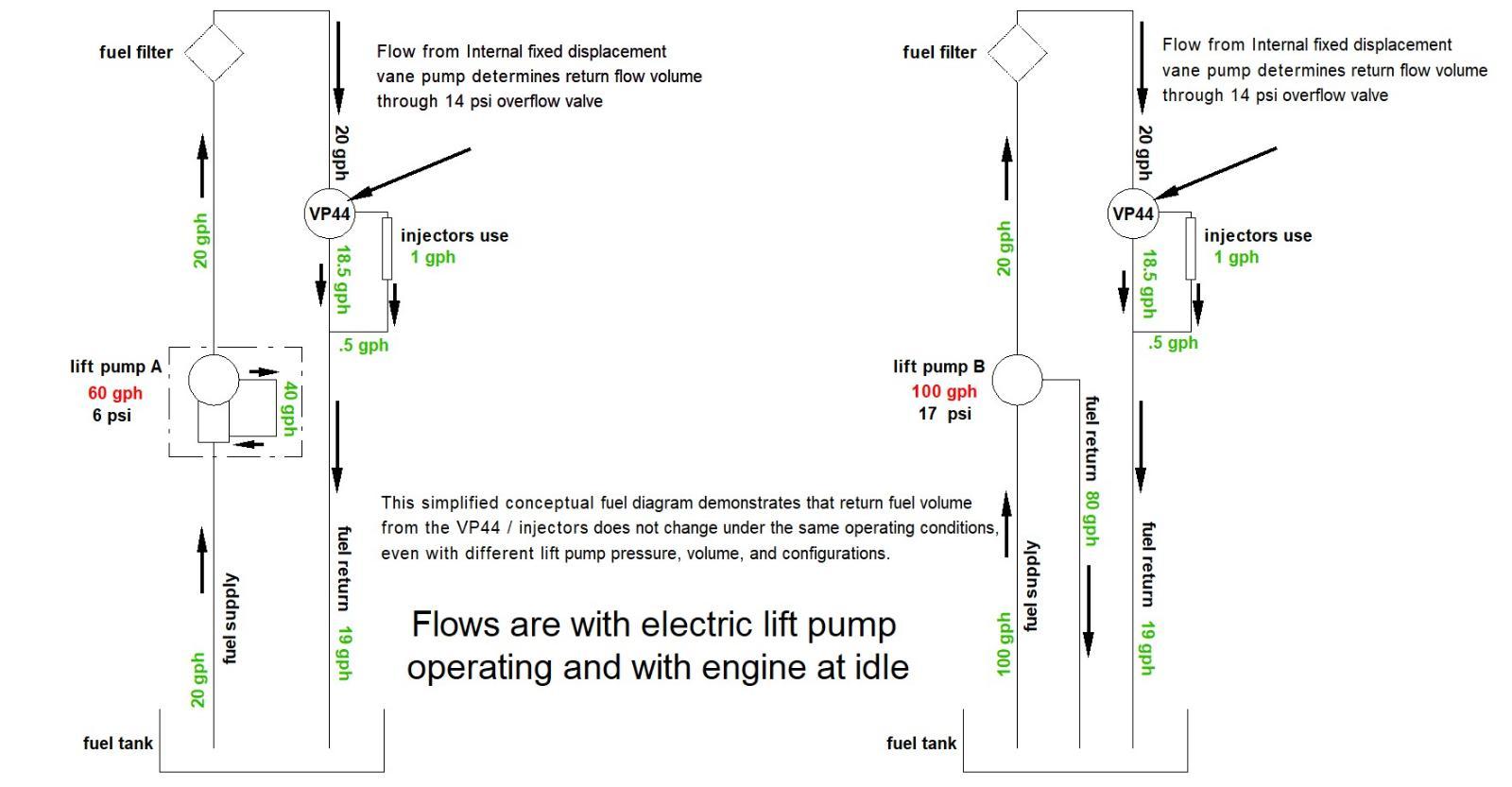

You pose a good question. It is the flow from the internal vane pump that is opening the 14 psi overflow valve as soon as the engine is running. Many VP44 industrial engine applications don't even u

Everything you wanted to know about the VP44 Injection Pump but were afraid to ask. I don't know if these guys do rebuilds or what but he knows his way around the pump: