Everything posted by Mopar1973Man

-

Front Brakes

No the economy pads from RockAuto. I think I pad like $39 bucks for them many years ago. I only replaced my rear rotors because the parking brake top hat was grooved too bad. The trick I drive like the center pedal is missing. I rarely use that pedal at all. All transmission and exhaust brake. Still got factory OE rotors in front yet. Even on my 1996 Dodge V8 gasser its auto transmission and a throttle plate. (No exhaust brake here) I drive with a safe stopping distance and allow the road to dictate the speed at which I travel. There is no sense in racing to a corner, slam on the brakes to accelerate again. Slow down a touch so you coasting to a corner then lightly make up your speed. This because a balancing point.

-

Egt’s

Between the ISSPro in the a-pillar and the Quadzilla on the cellphone both have there own probe. Typically a drift of +50 on the Quadzilla vs the ISSPro. As for my results it very repeatable. When I'm driving nearly 1,000 miles per week. Just a stock tire size on 3.55 gears. Nothing special. Even if I went back to 265's / 235's (31" inch) the pyro would rise closer to 800°F and then the engine load rises. Looking back on old notes back when I was running 235's with the +75 HP injectors I was hitting 750°F for EGT's. Like I posted above my singled out fuel MPG test was 19.58 MPG for running 80 MPH for 88 miles. Still in all, if I can reach this low EGT temps running 2.5k RPMs, What is the posters problem? I presented all my data and facts now to try and figure out why he can come close to what I've got happening. Both have 150 HP injectors, both got Quadzilla, Both running HX40 turbo (will HX35/40 hybrid for me). No reason he can't do at least half as good.

-

Egt’s

Nope. Lower makes the EGT's higher and engine load higher. Just the change from the 235's to 245's is what did this trick for me. Remember wind drag is exponential so it even higher at 80 MPH. So you need the RPM's up to overcome the drag. At 66 MPH I'm a prefect 2,000 on the tach and the EGT's float 550°F. At 55 MPH it drops to 450°F. I've got to ask @kzimmer what is your 80 MPH EGT's like with 35" tires?

-

Egt’s

Yup. Plus the tuning and having the timing cranked up 26°. I'm still capable of getting 19.5 MPG running 80 MPH. 23% engine load I'm not even putting much fuel out.

-

Egt’s

I84 instates between Ontario, OR to Caldwell, ID. That where I picked up this data at.

-

Trans Whining noise

Good one for @Dynamic he would know.

-

Failed MAP cause low power?

No. Sounds like the wastegate motor is shot.

-

Egt’s

For information purpose. This is what 245/75 R16 tires on 3.55 gear and Quadzilla Tuner does at 82 MPH at 2,486 RPM. Remember -50°F from the EGT's and +1 to MPH to be correct. Yup... 627°F for EGT's rolling on flat ground at 82 MPH. Boost floats at about 7-10 PSI. The most I have seen climbing the rolling hills is 750°F and 15 PSI of boost. Flat ground it dances around the 625-675°F for EGT's. So using this as a base rule of what could be reached I'm still very puzzled of what is causing his EGT's and Engine Load to be so high. Personally, I still think is the final gearing ratio. 3.36:1 final to the ground is just too much plus added 4-inch lift increasing the frontal area of the truck adding more wind drag. There is just something causing it to fuel harder and create way more heat.

-

Failed MAP cause low power?

Even with the boost hose and bolt missing out of the manifold didn't change boost much maybe lost 5 PSI.

- 2nd Gen Sub dash pictures.

-

What NV5600 fluids are yall running?

Bingo.

-

Egt’s

Like @cajflynn taught me long ago when something fails the result is typically heat. Like yourself I've bought a IR temp gun and keep it in the pocket of the door. I can quickly check brake temperatures, transmission, axles, anything to verify what's going on and why there is temperature. As for @JAG1 he's another person that learn his lesson on running heavy without exhaust brake. Long down hill grade and 4 speed transmission (47RE) couldn't hold it back so net result was dragging the brakes which over heated the brakes, rotors, and the wheel bearings costing him dearly in parts and time. Yup. Exhaust brake is much better than 3rd gen brake upgrade which would of still overheated and caused the same damage. Exhaust brake has nothing to get hot and works great on long downhill grades with heavy loads. Ummm... Running the exact size on the door sticker. Stock tire size.

-

Isspro gauge programming

Give me a call today on my cell number. Contact Us at the bottom of the page.

-

Smoke/vapor from vent tube.

Maybe its only on the early series of trucks I've for sure seen it on my 1996.

-

Egt’s

Popping too low in pop pressure? Possible maybe. Yup. That is very possible too. Yea but the OP should of heard it if it leaking. kind of like my boost leak test you can hear the rushing air or ticking noise. Still not sure how you could test for that other than pull the turbo and check the wastegate. Bind it closed and retest maybe? Another guess.. Valve issues? Compression leaking? Blow By?

-

Egt’s

That's what I'm trying to figure out too. Being I've gone as far as creating a boost leak and documenting all my values. He's got some serious drag issues. What is weird OP and myself are twins for set up but he's creating huge amount EGT's and high engine loads. It most likely not boost related unless there is that much drag like brakes dragging or something. Like I found out from my test boost leak at cruise state has little to do with EGTs. All I can think off is mechanical drag. For me to reach his engine load level I've got to be climbing a 6% grade even then I can't make the 1,100°F EGT's. The only way I could come close would be towing my 8,000 pound Jayco RV up a 6% grade then I'd have it pegged at 1,100°F. That what I struggle to see where is the drag coming from. But I'm pretty sure its not a boost leak issue. I'm at a loss. Edit: Guessin' now... Plugged air filter?

-

Smoke/vapor from vent tube.

That should help holding the vacuum in the reservoir in the cowl area.

-

So many tow mirrors to choose from.

Thanks. I really would love to have better mirrors for towing. (bookmarked for later)

-

Smoke/vapor from vent tube.

Something like this...

-

So many tow mirrors to choose from.

Could you post a link please? I would love to to see the $143 dollar version.

-

So many tow mirrors to choose from.

That's what I got is power and heated. I'd love to upgrade to 3rd Gen towing mirrors but always find them for $300 or better.

-

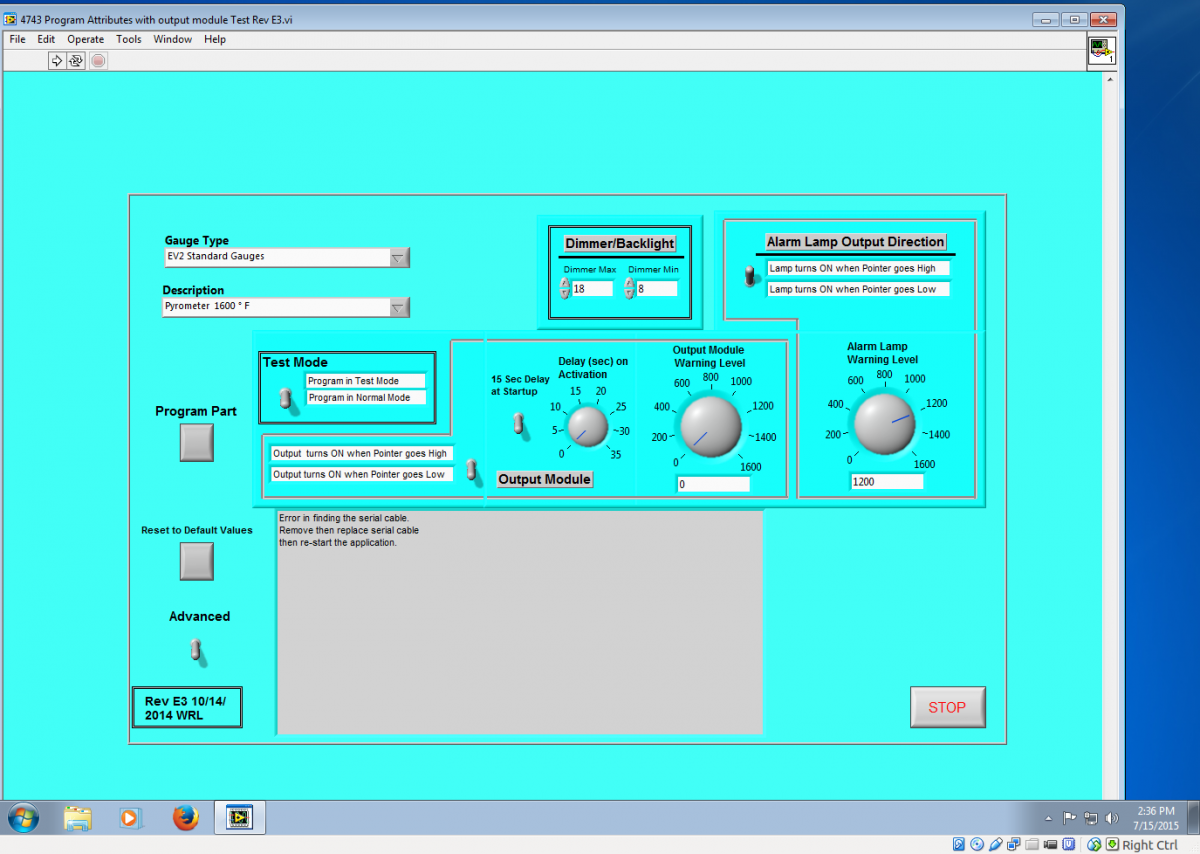

Isspro gauge programming

No. I can adjust the brightness that's all. The warning light can be programmed, the optional relay could be programmed to turn on or off a device. Then there is an advanced setting where you can set the speed of the needle movement.

-

Egt’s

Not sure. But if his wastegate was leaking he would not be able to spool very well if the drive pressure isn't on the turbine but bypassing the turbine. As the OP stated he's making 30 PSI of boost. But the whole problem is at a cruising state 1,100°F at cruise state with 32% engine load. Again boost should be low. Even with my test 5-7 PSI climbing a grade with manifold bolt missing and wastegate hose disconnected. 650°F EGT's with 22% Engine load I'm still short the 10% like him because of gearing differences. Ok, bruh.....275 70r 18....forgot I traded rims...4”lift....with a headwind of 15 my egt’s were 1050 to 1150 @78mph....engine load was 28% to 35%..... Again the big key here is his engine load is much higher. Dumping way more fuel and EGT's are up. Under normal conditions. 6% grade (Midvale Grade), ~10 PSI of boost. Now I've got the engine load high enough to meet OP. Which his truck on flat grounds is equal to mine climbing a 6% grade at 65 MPH. Still my EGT's a lower. NOTE: -50°F on EGT's and +1 to MPH.

-

Towing...Your Experience Is Appreciated 98.5 24V 2500

Some of the stuff I've seen people haul is crazy. But the mighty Cummins still haul the load.

-

Smoke/vapor from vent tube.

Thanks for reporting back on the fix. I would consider replacing the one-way check valve on the system it should hold up better then.