Everything posted by TFaoro

-

P0237

Can you clear it now that the CEL is out? If the CEL shut off, it means it's reading fine now.

-

Teardown and Rebuild

You said where they will fit, but where would that be?? It looks like they put them in all the good spots. Only place I can see is the 5/6 lines closer to the pump. @trreed might have some depending on what you need. Any idea where to get some clamps for my lines @jlbayes? Got some work done tonight. I picked up a new T clamp from Central State Hose in Denver. I cut some 1/2in dowels to length, and split them at the ends. I will round the ends with the bench grinder when I get home. Most of the Crazy Carl kit should be at my parents place tomorrow. It'll be missing the throttle kit and the tunnel ram. They won't have tunnel rams until late next week, so I bought a grid heater delete to use as a spacer. I also bought a chunk of 3" exhaust pipe to use between the horn and the IC. I got 2 feet, so I'll cut it to length and weld some fat beads on it to keep the boots on under higher boost. @trreed what's the bolt sze and thread pith for the intake plenum? Hopefully the APPS kit will show up next week. If not, I'll build my own linkages for the time being. Diesel Auto Power can't seem to pick up the phone and call me back about my injectors. I can't even remember how long they've had them at this point, but I'm getting a bit pissy about it Old T bold clamp. RIP

-

Headgasket

Take some pictures and post them up so we can help you diagnose

-

trreed's upgrade thread

He went with 8.8's. Shouldn't really matter. It'll bend the aluminum before it breaks the bolts. BTW!!!! @trreed was being lazy and wouldn't cut the stock lift pump bracket so it was smooth and sexy against the block. I tried!!!

-

Verifying HX35/40 turbo size

I've got an nv4500 sitting in the shop waiting for a new owner! Just needs a countershaft, gear, and bearings....

-

Verifying HX35/40 turbo size

You've got studs and springs. I think it's time for you to step up to VGT compounds! We could build the piping and support bracket easliy.

-

Teardown and Rebuild

I think that was because of RPMs. I ordered Larry B's wiring harness kit for the shutdown solenoid. Hopefully that'll be here soon.

-

trreed's upgrade thread

Way to get those in order Any compressor housing pictures?????

-

Teardown and Rebuild

Alright I'm a bit confused.... The SO PSG is decoding the message and giving more fuel than the HO PSG was. So the HO pump must move more fuel at idle than a SO pump right? AKA the SO PSG is telling the pump to use more fuel with the same message?? @Me78569 sound right?

-

Teardown and Rebuild

So that would mean the HO fuel message would be maxed out sooner.... Hmmmm I'll send ya a data log in a bit

-

trreed's upgrade thread

I wonder how much I could sell this cold rod pump for?? It's got a custom lope tune at idle @trreed I don't see any updated turbo pics....

-

Teardown and Rebuild

Stock in-tank lift pump with a programmer

-

Verifying HX35/40 turbo size

Should be able to make them run clean as a whistle no problem Should also be interesting to see what difference altitude makes. I know you do some long climbs, so I would expect it to be a touch smokier at elevation with the same tune. We'll see. Oh and none of this actually happens without pictures!

-

Teardown and Rebuild

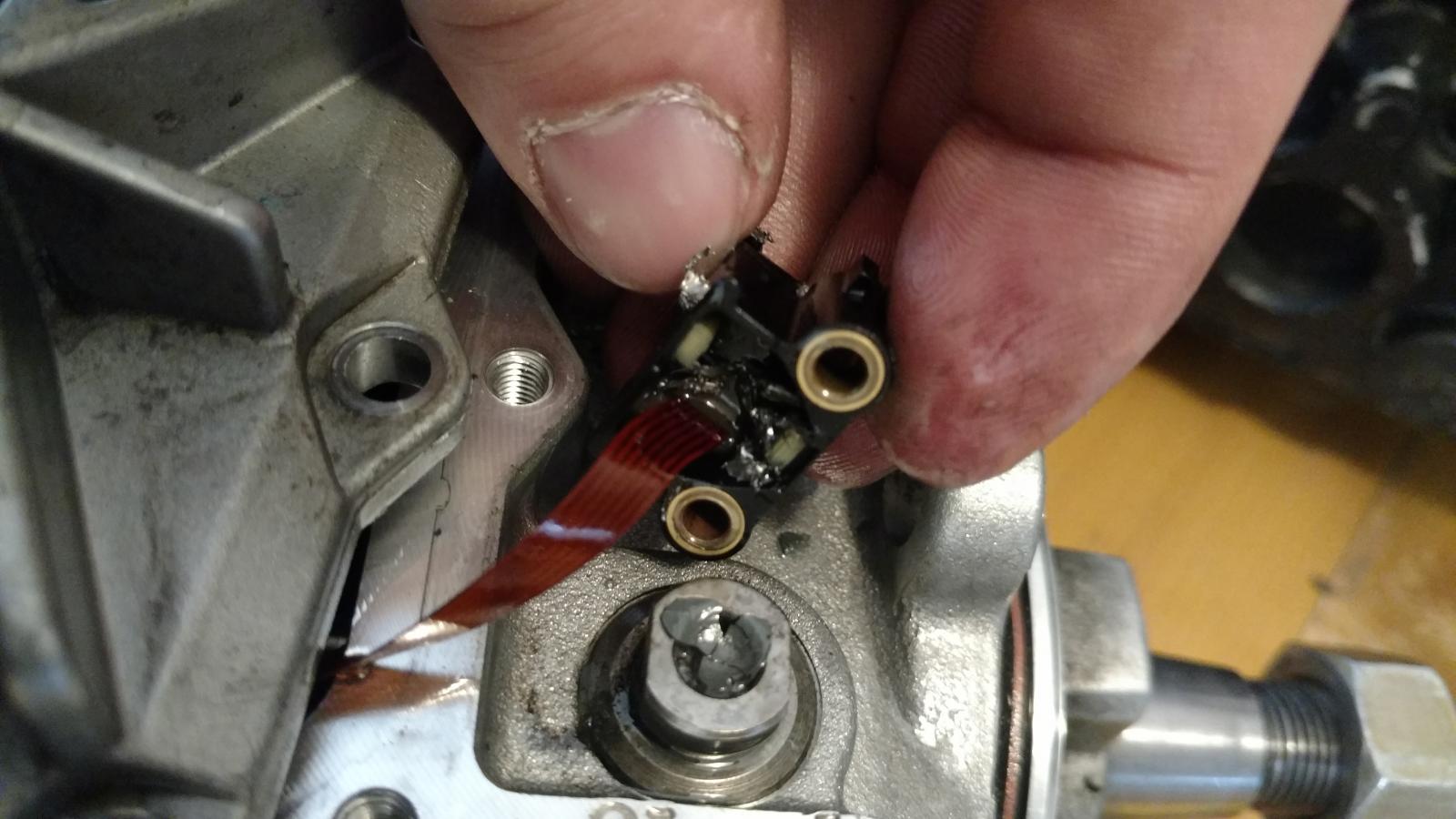

so this is the sensor that reads how fast the VP is turning. Very similar to an ABS sensor. It's magnetic, so it catches the fine metal and chunks. The tag has the chunks I took out of mine, but I knocked the rag on the floor so I lost half of em. Trevor's had quite a bit of very very fine metal.

-

Teardown and Rebuild

Internet said otherwise.... Haven't seen one done yet. That's what I don't get... You can change this thing out very easily, so why don't they sell a replacement? Calibration can't make that much of a difference, especially on a stock truck. The ECM will compensate for everything but timing, which a degree you would never notice a difference. Still calling BS on the keyway. I looked at it and I can't tell there's any offset. Which ones would you like to see?

-

Teardown and Rebuild

Swapped my PSG onto @trreed's pump and now I have a running truck More tomorrow.

-

Quadzilla Adrenaline Economy and MPG

Very clean with 7x.013 sac injectors. Now I did have a haze at idle because they were so big, but there was no more than a very slight haze upon hard acceleration. I think I topped at 22 or so mpg, but I can't remember exactly. Not too shabby for injectors of that size.

-

Engine shut off without restart?

I would begin with reading the error codes. Then you need to test the fuel pressure to the pump. Once you have those answers, you can move on to the next steps.

-

trreed's upgrade thread

you're not even close to half way! Looks like you just started....

-

Teardown and Rebuild

No, I sanded with an air grinder, then 400, 600, 800, 1000, 1500, and wet 2000. Then lots of polishing. Ceramic coated on the inside, upper and lower steel landing for both compression rings, compression rings are closer together.

-

Teardown and Rebuild

Absolutely not. How would fuel ever get to the valves? This is a direct injection motor, so the intake valves will never see fuel directly. Sounds terrible. I climbed down the hole long ago haha.

-

Choice of companies

That depends on which pump and whether it's for performance or not. Without specifics, I don't think anyone could give you an answer.

-

Teardown and Rebuild

Negative. It won't hold the pressure I want / need at the pump. I've got a list of fuel supply parts Got some work done on the pump yesterday and today. I love it when the mail man comes. Shutoff solenoid AFC live with a kinked line. I called PDD and they were very helpful. They offered to send me a new one no questions asked, but suggested I take it apart and cut the line myself. I'll get better pictures of it later. I also got the rack plug, fuel return banjo, 4K gov springs (installed already), pump washer, and pump nut. Right now I'm waiting on my order from Vulcan to adapt my fuel system, and the whole kit from Carl. I need to buy an 80amp relay and 65amp fuse to wire in the shutoff solenoid. Anyone know what plug is on the end of the shutoff solenoid? I'd like to get a factory plug for it. I modified the AFC for max travel today. Most people use a grinder, but since I have a machine shop at my disposal I figured I'd use the mill and make a nice countersink. The rest of the install was a breeze. I set the smoke screw at 2 turns in and the AFC at the middle of it's adjustment on the mounting screws. We'll see how it works out.

-

Teardown and Rebuild

Waiting for funds to build a PROPER fuel system!

-

Teardown and Rebuild

Agreed. The more product out there, the more failures you will have. However, it's hard to get to the root of an injector issue considering they are so sensitive. Heck there's dum dums out there like me still running the stock filter