Everything posted by AH64ID

-

South Bend Clutch's?

I have the OFE and like it a lot, my dad has the HD and it is a softer/smoother clutch. SW7 on the Smarty is at the edge of what the OFE can hold, but if your stock lasted 180K then you should be fine with either the HD or OFE. Why SW7? You should get the same mileage on a lower setting, one that your turbo can handle.. and your clutch.

-

Oil pump housing failure, probable rebuild...

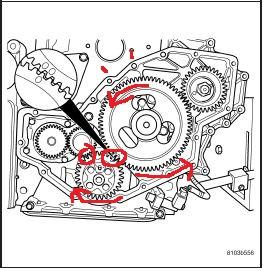

They are all in close proximity, but the broken tooth on the cam gear is only 2/3 broken and would have to have grown over an 1" to hit the case. Also we found 2 pieces of the case that went between gears, pretty much says it all right there. - - - Updated - - - So here is a look at the front, sorry for size and quality. The crank spins clockwise when viewed from the front. I don't recall which one it was so I marked two with red dashes. You can see where the broken piece would fall onto the CCW cam gear and get drawn down to the crank gear. One piece rode thru the cam/crank and one got sent over to the oil pump idler gear/pump gear. I previously thought that a piece went between the crank/idler but that would defy gravity (unless the piece from the cam/crank was stuck to the crank).

-

200,000

I had my injectors tested last week, they are at 93K miles and have had triple fuel filtration down to 30um since 15K miles (I bought it used). They have also had fuel lubricity additive every tank since 10K miles (unknown up to that point). The Bosch machine tests multiple things, 15 tests I think, and mine failed one of the tests. I am not sure which one yet as we haven't gotten them back with the test sheet. I think it was something to do with the pilot, but I don't know if it's timing or quantity. But mine have been working great, and treated as good as good as they can be.. but the bottom line is they are common rail injectors.The FF5320 is a good filter, it meets the Bosch spec of 5um but doesn't exceed it. 2 Stroke works for some and not for others, but even on the trucks that don't like it I think the injectors will if there isn't too much cold idling.

-

Oil pump housing failure, probable rebuild...

I'll get some pic's when I collect the broken pieces. The gears certainly broke from the pieces of the timing case going thru them, we just can't see anything that would cause the timing case to break.

-

Oil pump housing failure, probable rebuild...

The break is odd, and the cover has been off but the last time was 33K miles and 3 years ago. That's a long time for a break to manifest, and looking at the break there is no evidence it was caused by the bolt. That's looking at the threads, looking at silicone in the hole, and all of it in general. What was also odd is it broke out the thick side, and if it was from installation it should have been the thin side. It's cast aluminum, over torquing won't break out a chunk .5" wide and 1" long and show no damage to the threads. Trust me, it would probably be cheaper for me if it was from removal/installation errors.

-

200,000

That's a good list. Why so many coolant changes? The G05 is a 150K or 5 year coolant. If you have the down time you can have your injectors tested for under $200, and then you know where they are. 200K is not too bad out of them, would hate to have one fail open.

-

Oil pump housing failure, probable rebuild...

The stock 04.5-07 piston is the weakest piston ever used in an ISB, the spray pattern and bowl design are emissions based and suboptimal. The design was changed back to the 03-04 style for the 6.7, and all QSB's use the 03-04 style bowl on HPCR motors. It's just a more robust design, so if you tear a motor apart there isn't a good reason to stick with the OEM pistons.

-

Stihl MS 260 Pro

If you decide to part it out, let me know.

-

Oil pump housing failure, probable rebuild...

The filter did a great job, far better than anticipated. I run an ELF7349, which is unmatched in ratings, so I am not sure another full flow would have done as well. Without taking it apart there was no way to know, filters aren't designed to hold catastrophic failure, just normal wear. I probably could have gotten away withou a full rebuild, but it's out, apart, and getting improved. Going into the the teardown we knew it might be fine, but how/where I use the truck and who I use it with deemed a full inspection necessary. At least now I know what shape the internals are in, have some stronger components, and can continue on...

-

Oil pump housing failure, probable rebuild...

The KDP is not an issue on 3rd gens. It it is still very odd. There was no indication of cross threading or excess silicone in the hole to cause a failure.

-

Oil pump housing failure, probable rebuild...

The motor is out and apart. It looks like a piece of the timing case is what originally broke. The is a big piece missing from the inside of one of the bolt castings. 2 of the broken pieces, there were many, went thru gears. One broke the cam gear tooth, and the other broke the oil pump (probably the bigger of the 2 pieces). On the good side the motor looks great, no issues with other parts. It will hit the machine shop this week and we go from there. I should know in a few days how the injectors test. So the parts being replaced, on top of standard rebuild items. Water PumpThermostatVacuum PumpOil PumpPilot BearingThrowout BearingSerp BeltRadiator is being cleaned inside/outPistons (QSB 03-04 style)Injector Nozzles (03-04 spray angle, +50hp)Balanced at 2200 rpmsI will paint the block once it's back together.I didn't get any photos today, but will soon.

-

Stihl MS 260 Pro

Is the carb, compression release, and adj oiler still serviceable?You might be better to just junk it.

-

6.7 Harmonic Damper on a 5.9

The stock damper is two pieces of metal connected by a rubber bushing. The glue on the rubber can break down and allow the pieces to rotate, or separate from the damper. I believe it effects 2nd and 3rd gen trucks. If you look closely on the smaller damper in the photos above you can see the rubber ring. http://www.turbodieselregister.com/tdrarticles/tdrarticle73_TechTopics.html

-

6.7 Harmonic Damper on a 5.9

I believe it's a clearance issue on the 2nd gen trucks.

-

6.7 Harmonic Damper on a 5.9

I finally got around to weighing them both. OE 5.9: 15.0 lbs6.7 : 27.4 lbsSince installing the damper I found that it's also the damper used on the QSB480, which is a 480 bhp marine 5.9 rated to turn 3400 rpms. That's pretty close to my crank power, and I rarely turn over 2500, so I am quite pleased with the damper choice.

-

1956 Plymouth DDT Switcher (Train Engine)

No ideas, but that's a cool engine.

-

was my truck a good buy?

Nice truck, and really nice rod!!Have you had it on the salt yet?

-

Truck gets warm

Red it too hot for sure, based on 2nd gen history I would check the radiator and look into a breather relocation mod.

-

Honeymoon Road Trip!

I don't have any truck advise.. but "yes dear" is good newly wed advice. Congrats! and enjoy your honeymoon.

-

AirDog Filters Cross over?

Yes, it's better than the alternative.

-

AirDog Filters Cross over?

I would replace it every 30K miles with a psi gauge and 15K without.

-

AirDog Filters Cross over?

The FS19768 is a joke of a f/w sep, I wouldn't even idle the truck with it installed. Go back to the BF1275. The FF5613 is a decent filter, at 60 GPH, but the AD moves more fuel than that. The Donaldson P551315 is what you should run, the BF7634 isn't rated good enough to use.

-

Oil pump housing failure, probable rebuild...

Time and tools are the main reason, and space is another. I could easily tear down, but I don't want to reassemble. Just because I can do it, doesn't mean I want to do it for the first time. I have a lot of mechanical experience and background, and know when it's just best to pay for experience. I am going to peek my head in as things go back together as I really enjoy that stuff. - - - Updated - - - Yes it will, but at least it will be a better than stock motor. Gotta have something to look forward to. - - - Updated - - - Here is the repainted harmonic damper. I used 500° Engine Rustoleum.

-

Oil pump housing failure, probable rebuild...

No, the motor is still in the truck. Until Monday. Shop is busy and I had to wait my turn. It should be torn down and at the machine shop tues. I did bring the damper home, clean it up and it's been painted.

-

Oil pump housing failure, probable rebuild...

It's killin me too!!!