Everything posted by sooxies

-

Heads up on factory replacement rear glass

I'm going to swap my factory slider out for a solid in the future....having very minor leaks. Thanks for the knowledge.

-

Opti-lube xl and xdp

Just out of curiosity, does anyone have any knowledge or experience with running Archoil AR6200 in a Cummins engine? I know the Powerstroke community loves it.

-

Injectors stuck....cannot remove?

I bought the tool from Tork-Tek....I'll report back when it warms up again in the garage. Give it another go.

-

Injectors stuck....cannot remove?

360 degrees....in slow increments. Kind of like a chopping motion..not a fluid movement. I like the idea of using a hammer for leverage....that would be worth a shot. But the number 5 fuel line is still another issue. I soaked it in PB blaster overnight and it still wouldn't move.

-

Injectors stuck....cannot remove?

-

Injectors stuck....cannot remove?

This is probably not my issue...but I've read about if the copper washers double up because of people forgetting. Maybe they were replaced at some point. What would be the effects of that situation? I've always wondered that. I'm a magnet for problems I'm still dumbfounded how I couldn't get any of them to move upwards at all. Suction of some sort keeping them in? I could rotate them as I said but they would not go up.

-

Injectors stuck....cannot remove?

I had the crossover tubes out Tried it...no luck....wiggling it as well when I was prying up.

-

Injectors stuck....cannot remove?

I apologize...it will not unthread from the head. Can only assume corrosion of some sort set in after seeing what some of the other lines were like. I ended buttoning everything back up and nothing is leaking so I did something right. Back to the drawing board.

-

Injectors stuck....cannot remove?

Yes that was my method. Will not move at all

-

Injectors stuck....cannot remove?

Well every project I take on appears to give me headaches...I'm beyond stressed . I cannot get any of my injectors to budge (I've tried 1,2,3,4). I can rotate them in their slots but they will not lift up. All my strength and they will not move up a millimeter. I also cannot get my number five fuel line to disconnect from the crossover tube. I'll add pictures later but some of the nuts on the fuel lines are corroded which I suspect the issue to be with that (weird because it was California truck for 17 years). The corrosion spread to the threads on some of the fuel tubes but I'm replacing them anyway. My only other option would be to just button everything back up temporarily. But I really don't feel comfortable reusing these feed tubes...worried it's just going to leak like hell. They aren't damaged/scuffed or anything but the corrosion worries me. I may just have to tow it to my mechanic and have him try to do it because I'm getting too stressed out and I'm low on ideas. Things shouldn't be this hard but that's the way it is. I'm trying not to go crazy...pray for me

-

Injectors

I'll upload a photo once I pull them...do a side by side comparison with the new. See if we can spot any differences. To the best of my knowledge and from what I see, the entire fuel system on the truck is 100% original other then an Airtex lift pump which I'm replacing.

-

Injectors

Going to be doing my first injector job so I've been following this thread for information. I got new o-rings for my tubes last week from a local Cummins dealer and noticed today on DAP's website stating: Please note that some 98.5 trucks will need connector tubes. If your engine serial number is lesser than 56462598, you will be required to purchase them or your new injectors will not seal properly I wonder why a 98.5 truck is different from the rest? My ESN is 56423804 so I guess I'll be needing to order new tubes. ------------------ EDIT: TSB 14-01-98 REV.A answers my question. Ordering new tubes for cheap insurance.

-

Airtex pump to Airdog FRRP help!

Eric was very helpful. He came up with a solution with a couple different adapter fittings and some fuel line. But I'm just going to order his frame relocation kit and mount it to the frame. He said the only hard step is getting the factory fuel line off of the tank. People are prone to breaking something on the push lock fitting if I understood him correctly? Anyway...this will be the easiest way to go I'm sure....plus easier to get at if it needs to be replaced.

-

Airtex pump to Airdog FRRP help!

- Airtex pump to Airdog FRRP help!

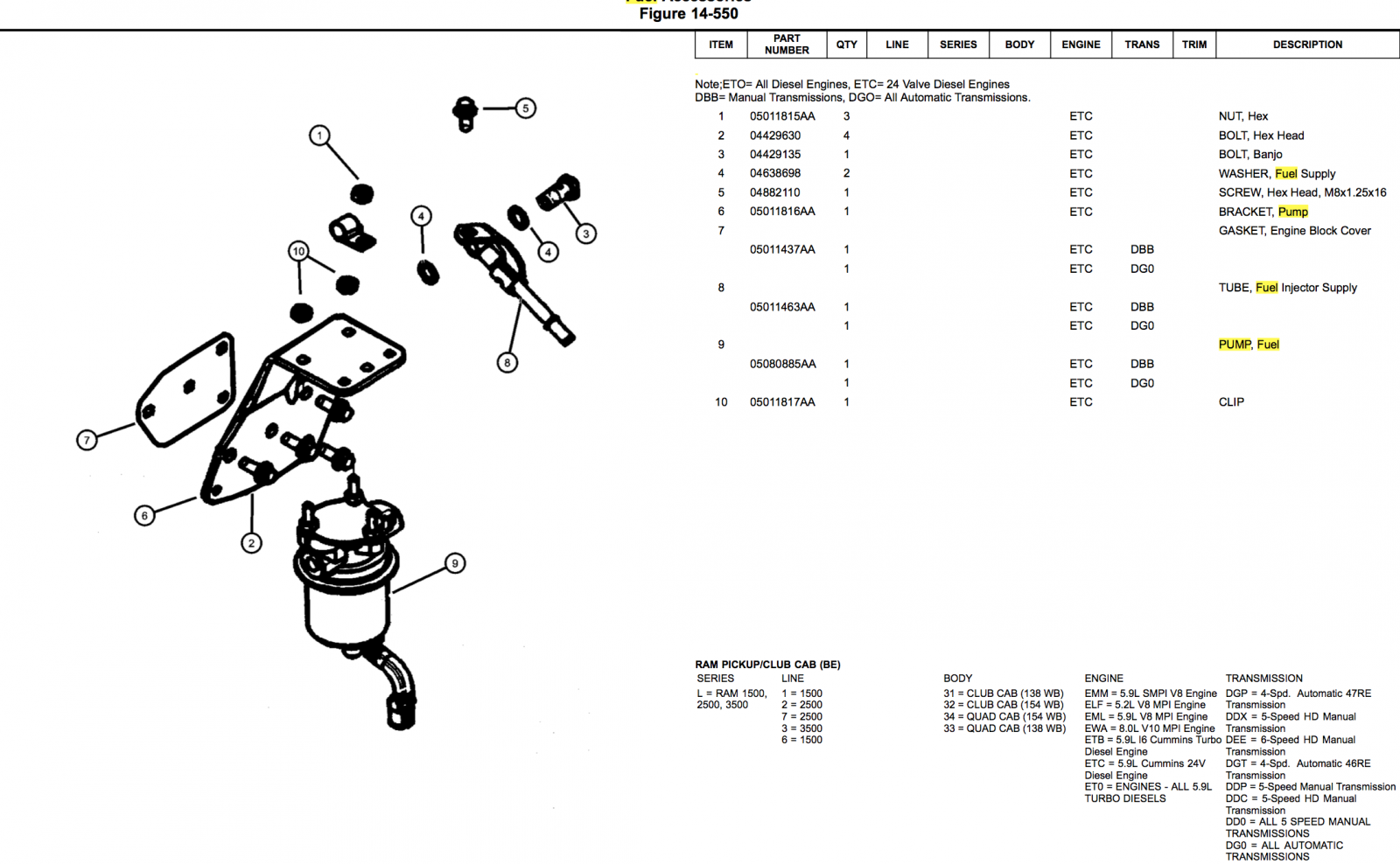

Replacing the Airtex with an FRRP 100. The Airtex pump does away with the factory line that has a banjo type setup and just uses the quick connect fitting. I need this line for my FRRP to work but it is expensive....are there any cheaper alternatives? Assuming the P.O. just threw it out with the factory pump. I wish Airdog did the same as Airtex and did away with the banjo setup. Part number 8 in the photo....the line that has the support bracket on it.- Exhaust

I would say it took me two/two and a half hours and i spread it over two days. I was working in my garage when it was 15 degrees so I was going very slow. Three/four cuts with the Sawzall and the stock exhaust came right out. Tips I learned Lube up the rubber hangers beforehand Connect all pipe outside of the truck...ensure all ends will connect to each other (no ends are bent from shipping/handling) Hang everything loose then tighten front to back Have a second set of eyes for the tightening of the final pipe section (ensure it is positioned to how you like..it can change position when tightening the clamp) There's more I'm forgetting...happy I did it myself though. Now I can say I did it. Agree with 100% that. I specifically looked for a kit with the Accu-Seal clamps.- Exhaust

FTE Resonator isn't a bad option either. To me straight pipes are more raspy, especially 4". It will be less expensive to run a 4" setup than a 5". Kits are easy to do yourself...hand tools and a reciprocating saw.- Pets and bitter cold

I totally forgot about that. I know they make pet safe salts so that makes sense.- Pets and bitter cold

Check the paws to see if any snow gets clogged in the cracks/crevasses. If our pup (may she rest in peace) was ever zipping around in the snow for longer periods of time she would always have snow up in that area. Even for short trips outside...packy snow made it worse. At least with her, I noticed that there really was not a lot fur in that area. Her tootsies were notorious for getting cold.- Tanks straps on fuel tank

There shouldn't be anything in between in the strap/tank to my knowledge.- Feeler Gauge Recommendations

While the tool itself is beyond simple and inexpensive, anyone have any recommendations for a set? I'm going to be doing a valve adjustment when I do my injectors and I just wanted opinions. Is it better (Cummins engine sake) to get a set that is bent vs straight? If money weren't an option I'd love to get the Snap-On set for the 24 Valve motor....$990.00 . The feeler set they sell are bent.- Morning Pic For Today...........Post A Pic around your place.....

Older photograph but it was taken around my place! My first truck....never should have sold it. One owner 1997 K1500 with 72K miles on it when sold. I always get sad when I think about it...owner is 45 minutes away (assuming he still has it). Sold it back in the winter of 2010. ...i may shed a tear now. The second photo are my four previous children. 98 Chev. K3500, 2004 TJ, 2010 JK, and now my second gen. is my fifth. Not posted is my 2003 Nissan Altima...166K and going!- D70 & D80 U Joint Sizes

They are my go-to unless I can find something lower in price. I've heard good things about their products.- D70 & D80 U Joint Sizes

Do you mind saying what they quoted you? I'm interested in doing the same for mine...trying to get an idea what the ballpark will be.- What are the best headlight packages?

Not to get off topic..but I miss the JW Speaker's on my JK. I kept my lighting before I sold the vehicle....just waiting to use them again someday. I am also in the market for a set of housings for my 98. Too bad there isn't an American company who manufactures a nice set of housings. - Airtex pump to Airdog FRRP help!