Everything posted by ISX

-

2000 mile Trip

Now where is the pic of you out there surfing I can only imagine how fun it would be to have a constant wave pool that isn't 6 flags generated :lmao:Keep em coming!

-

Charge A/C System AGAIN.....I think the compressor may be bad.

I did a week ago on an F150 where it was a complete PITA to get to. I put new clutch and bearings on it then put it back on. It looks to be 10x easier on a cummins. Just make sure to clean the hell out of where the a/c lines go into the compressor and get it back to torque spec, and not an inch pound less!

-

A/C Evaporator & Heater core write up!

Hmm, well I wanted to take everything out just so I knew how to do it the next time My gauges were wired up in interesting ways anyways so I had no problem ripping the wires out of the dash that fed them. Mine was maybe 50lbs, maybe more, I didn't think it was too bad, just a little bulky. Not sure what you cut your hand on though, I couldn't find any sharp edges lol.

-

A/C Evaporator & Heater core write up!

I did it to clean out the A/C part of it but I guess your heater core rubbed off on mine too. Not so sure it will be back together by tonight, though I need it to be :ahhh:I forgot to scroll down all the way last time, did you take the whole dash out to get the HVAC unit out or did you just bend the dash back enough to get to it?

-

A/C Evaporator & Heater core write up!

Well I went by this thread. http://www.cumminsforum.com/forum/94-98-non-powertrain/273830-removing-dashboard-replacing-evaporator-1995-2500-a.html Go to the VERY end, as usual. Spent more time looking for how to do it than doing it :banghead: Anyways I don't think you took yours all the way out, and it really did make it a ton easier having the seats out. You can take all of them out in 5 minutes so it was pretty simple. Tomorrow I will tackle the HVAC unit itself.

-

A/C Evaporator & Heater core write up!

Your a bad influence Mike. Now that mine actually blows air I figured I would clean everything out of the system. I got a peak at it when I took the fan out that one time and it was horrid. Another hour and I think the dash will be completely out. That's right, I'm not doing a halfway out thing because I have to do one better than you

-

2000 mile Trip

So lucky! You will have to map out how you went so I can take the same route one of these days. I went to the grand canyon last year and the drive through the west half of colorado and east half of utah was kind of the same but I think I like the views you are getting better, plus I have never been to the ocean, or seen it from afar. Keep taking pics! Go to the top of a mountain and take a pic of your truck with a sunset or something, I need a wallpaper for this thing.

-

Will summer ever come???

Forgot you were the refrigeration specialist, yeah crank the A/C up then. Now you just need to rig up a seat on your tractor that blows cold air on your back

-

Will summer ever come???

52! Geeez. According to my truck, its 80F already and it's only 9AM I have found the perfect cruising windows down temp (60-70mph) is 78F based on me always seeing that temp when I tell myself it is perfect. Your getting hot up there too flman lol. Jump in the pool!

-

finally got the ole goat goin again...questions/comments thread

- finally got the ole goat goin again...questions/comments thread

So there's the final result. I got a youtube movie uploading to replace the old movie. Obviously the more you push the string into the hole and therefore making the string tension tighter, it gets stronger.- Diagnostic list

I believe this is the thread you are talking about. http://forum.mopar1973man.com/showthread.php/1797-Strange-codes Which leads to these 2 links. http://mopar.mopar1973man.com/cummins/2ndgen24v/vp44-replace/vp44-error.htm http://mopar.mopar1973man.com/cummins/2ndgen24v/apps/apps-codes.htm- finally got the ole goat goin again...questions/comments thread

Just make sure to make them both vertical! It made a world of a difference. I'll redo the youtube and everything. Don't want people doing the 45 thing.- finally got the ole goat goin again...questions/comments thread

I just grabbed whatever string we had. I kinda like the red though I am beginning to think you could make both sides 90 degree holes instead of one at 45. That string is more flexible than I thought it would be and the 90 degree part seems to be the side that makes it strong. Plus it wouldn't look half-bowed, it would be a perfect arch. Something strong would be nicer but then you pretty well compromise it going into the dash. I might go into Lowes or something tomorrow and see if they make something stronger that would work even better. ---------- Post added at 09:34 PM ---------- Previous post was at 09:30 PM ---------- Naw do what you want with it. It's half Mike's idea anyways since he kinda got the ball rolling. I do it to help people but more for the challenge also, so getting credit for it is on the bottom of my list, if on my list at all. In other words, post away Make sure and post back here if someone suggests something better! ---------- Post added at 09:48 PM ---------- Previous post was at 09:34 PM ---------- HOLD THE PHONE! Make BOTH holes 90 degrees, er, straight down, no angle, just straight vertically down! I just went out and did it and it is a lot stronger and stiffer and still goes into the dash just fine. Super glue it and that damn thing will be bulletproof! I'll get a pic tomorrow. It even looks a lot better lol.- finally got the ole goat goin again...questions/comments thread

Alright here's what I did. http-~~-//www.youtube.com/watch?v=RUijxQSrJDA Let me know if you know a better way! ---------- Post added at 09:18 PM ---------- Previous post was at 06:07 PM ---------- I went out and tested it and instantly the bottle of water fell out. Glue was still wet, said ok I will try the other side. It fell out but since the glue held it resisted a bit more. This was a full tall skinny water bottle so probably the most likely thing to fall out being slim and top heavy. So I drank a little bit so it was maybe 3/4 full and then it had a hard time falling out until I drove on the road in 3rd gear and jerked into the driveway like a bat of hell, then it fell out That makes it good enough for me! Need better glue though, that adhesive crap takes forever to dry.- No clear winner, powerwise..

Where did I say the firing order wasn't that? I did start referring to the pistons as being 1 2 and 3 instead of saying 1 5 and 3, maybe I shouldn't have. W&F, I have been looking all over for more factors on this, I can't think of everything so thank you! I will look it up and get it all into the spreadsheet. I never like to assume I am at the end of the road with things, I know there has to be more to every equation and you just proved it. ---------- Post added at 11:43 AM ---------- Previous post was at 11:21 AM ---------- Alright from what I have gathered, rev-gain basically means the rate of acceleration of an engine overcoming it's own rotating mass. So sled pullers could care less since they start at whatever insane speed they want, but dragsters praise rev-gain since it needs to be gaining quick. I am not exactly sure how to calculate this based on just engine specs. I have some sketchy ideas on how but not sure. I will keep thinking. ---------- Post added at 08:55 PM ---------- Previous post was at 11:43 AM ---------- Would it be more plausible to calculate internal rotating mass, and get a number telling how much force is required just to turn the engine over or do a certain RPM? Rev gain seems very tricky to figure out but the former seems a little easier. I would like to do rev gain but there is just nothing on the internet concerning calculating it, just stuff talking about what it is.- Will summer ever come???

- Temp Gauge...

Thanks Mike! Just bought it..- Laptop won't post

Looked around for new motherboard and it seems a lot of them are bad for exactly the same problem. There is no heatsink or anything on the gpu so I wonder if it should have one, if it even is the problem. Hmmmmmmmmmm- Laptop won't post

Took the RAM out and did the same thing, showed power light and turned CPU fan on, no beeping, not even with headphones in either jack. Put memory in this laptop and it booted up fine so it checks out. I have the entire thing apart and I noticed there is a lot of sticky stuff on the motherboard where the keyboard would be, thinking someone must have spilled something on it. Thought maybe the GPU would be changeable but it is onboard and yeah, there is no way it's coming out. So I guess the motherboard is toast. Unless you got some other ideas?- Laptop won't post

So I picked up a Toshiba Satellite L35-S2161 and it turns on, but the screen doesn't. There is no hard drive in it but I guess the guy took that out after it stopped working so he could use it in his xbox. So all I see is the green light on front and the fan for the CPU running, when I turn it on. I plugged a monitor into the VGA on the side to see if I could get anything, still nothing. So what all should I check on this thing? Here's the specs. http://cdgenp01.csd.toshiba.com/content/product/pdf_files/detailed_specs/satellite_L35-S2161.pdf- No clear winner, powerwise..

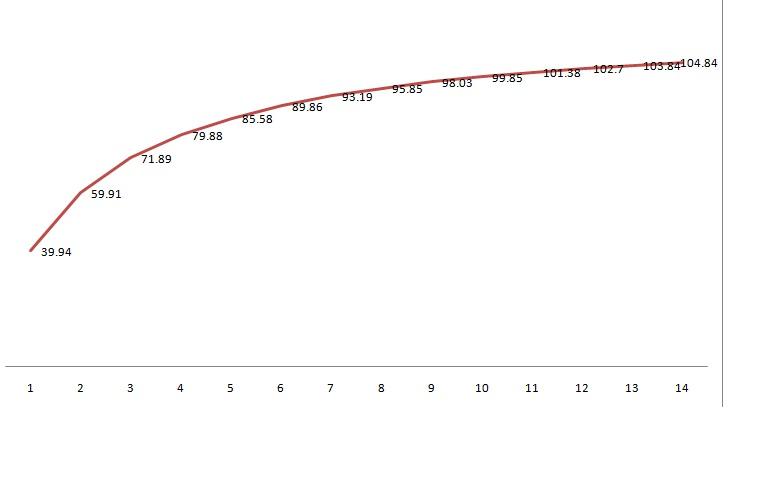

I spend more time making it look nice for you all than I do finding the info The formulas don't take very long, I think I spent 20 min on that whole thing, which includes me getting mad since nothing I put in was answering my question of why the I6 is king of luggability. I just kept thinking of anything that even remotely had to do with possibly showing an advantage. Some of those things are really neat, I couldn't believe each piston was completing the entire 4 stroke cycle that many times just idling Makes you understand why dirty oil or fuel can wreck havoc in short order. If there is anyone who doesn't have a clue about what the green part is, which I really didn't know what to call it on the spreadsheet so here's my explanation. You have the firing order of the engine which takes 2 revolutions of the crankshaft to complete the 4 stroke cycle for every single piston. So in other words, only half the pistons are on the power/compression stroke per crankshaft revolution. So to make it easy I just determined everything based on ONE revolution of the crankshaft, so on our cummins I just used 3 pistons since they are the only ones firing. Since it takes one revolution to complete the cycle for 3 of the pistons, it also equates to 360 degrees and because the pistons must be evenly spaced, 360/3=120 degrees out of phase from each other (this is on my spreadsheet), this applies to all pistons since it's not like the engine takes a break after 3 pistons, so all 6 are 120 degrees out of phase, meaning since the firing order is 153624, piston 1 injector fires, and 120 crankshaft degrees later piston 5 injector fires, then 3 and so on. Alright, now that everyone should be on the same level I can get into the green part in specific. If one of the pistons was on the power stroke and reached BDC (bottom dead center), that means the following piston is 120 degrees behind, and the 3rd piston is 120 degrees behind that one. Remember that the power stroke for each piston only lasts for half a crankshaft rotation, since when the crankshaft revolves a half turn, it starts pushing the piston back up and is therefore on the exhaust or compression stroke. So if the first piston is at BDC and the next piston is 120 behind, that isn't over 180 degrees behind therefore that piston must ALSO be on it's power stroke. So if we said the 1st piston at BDC was at 0 degrees then the second piston would be at 120, the third piston would be at 240 degrees which means it is being pushed up and therefore on it's compression stroke. So the only pistons in the equation are the 1st and 2nd, we can add the entire volume of piston 1 since it is as BDC and since piston 2 is only 60 degrees below TDC (being 120 behind #1), we can calculate it's percentage based on 60/180=1/3 this means piston 2 has only gone down 1/3 of the way from TDC on it's power stroke. So you do 1/3 of total cylinder volume, add it to piston 1's volume, and you have the total area that is being used for the power stroke. This area NEVER changes no matter how the engine turns, I just used BDC to make it easy. On a V8 the pistons are 90 degrees out of phase, so when one is at BDC, the next is halfway down the cylinder (since 90/180= 1/2) and the third is at TDC so there is no area to calculate since it isn't exposing any cylinder area for the power stroke. As you gain pistons, the total power stroke area goes up less and less. Meaning 3 pistons might be 10, 4 pistons might be 20, 5 pistons might be 25, 6 pistons might be 27.... It is an exponential rate. If you were to graph the areas based on cylinder number, the line would initially change drastically and then flatten out, it will never touch 0 but when you get up to 100 pistons to 101 pistons you hardly notice anything because the line is so flat. It's very interesting. Alright got a pic up showing the exponential curve. I just used the 5.9 cummins bore and stroke to get areas. The bottom numbers are number of pistons and the numbers on the line are the total area of all the power strokes at any given time. You can see the more pistons you have the less difference it makes. Dang I screwed up, its showing engines with pistons 3-16, not 1-14, you can't do 1 or 2 piston engines. I'd fix it but I deleted it before I noticed If you didn't understand it, hope you do now, if I made it more confusing let me know and I will get some pics up that will make it obvious.- finally got the ole goat goin again...questions/comments thread

Oh yes, you will see. I will even make a youtube of me doing it. I don't believe putting something simply across will do as good of job as something bowing up. I have an idea though, and it will still close.- finally got the ole goat goin again...questions/comments thread

My god! I think I can do one better than that even. Get a longer piece and drill 2 holes at a 45 and "bow" the wire so it goes up higher and holds a lot better.. If I only had a drill at my apartment. I will do it Friday night. Hmm I got a few more ideas now. I will just let you all wait and see- Helpful Spreadsheets

Updated Version 6/15/2010.Added some right triangle and circle stuff, also added bore and stroke stuff along with that power strokes thing I had up when comparing the big 3. I made the Speed/Calc a little easier to use and added some features to it. After playing around I noticed the U.S. gallon mpg to Canadian/British gallon mpg formula was backwards so I fixed that. I go over these formulas a million times so the rest should be right, I was just thinking a little backwards concerning that one :whistle:I updated post #1 files as I said I would be doing - finally got the ole goat goin again...questions/comments thread