Everything posted by 2000Ram2500

-

Electrical Help - Power Mirrors and Dome Light

Does anyone have the power mirror switches available? Mine isnt right at all. Blows the fuse the second you touch the switch and up is like more left/up and its all screwed up.

-

CR Injector failures and upset owners

Im not calling out shops on parts sales. I also know every shop is different. I know how rough it is when it comes to the automotive world. Im talking more the way we get the parts to the customer. Its manufactured, then its packaged, then its distributed, then its stored, then its repackaged if its cummins for chrysler, then its distributed again, then its stored again, then it finally winds up in stores. After passing through all those hands its no wonder things are so expensive since everyone has to get their piece of the pie.

-

Filling oil filter when changing oil?

Im wondering what the "µ" is on the factory filters then.. And what kind of effect does that have on oil pressure? Or is there no change when you put a finer filter in?

-

What makes 24 valves sound different from each other?

While im thinking about it, before i forget.. like @Marcus2000monster is getting at with the computer compensating for more fuel with more timing and @Mopar1973Man saying it doesnt.. we dont have the sensors in our trucks to really read that and react accordingly i dont believe. but what if someone were to go with bigger injectors and some hard timing? is that a feasible option? or is that something more reserved for the big power guys. are you asking me for a video? @Marcus2000monster if so i will openly admit all ive really got done is intake exhaust and my edge. It does have a Fass but it doesnt have a filter and i have no idea what size it is. Ive been neglecting to do my valve adjustment and i think im beginning to hear a slight tick. And i dont run any fuel additives at all right now never have. although im considering the 2 stroke just because its so easy to get ahold of.

-

What makes 24 valves sound different from each other?

I was always under the impression that all the racket was combustion noise as well but now having owned mine for almost 2 and a half years and hearing it with and without the exhaust different tuners at different settings. The edge you can hear a slight delay in the timing change when you step on it. Honestly the exhaust sounded exactly the same as far as a little experiment I did comparing sound between wide open downpipe and the full 4" with straight thru muffler before i welded it all together. I have been able to tell a very slight variation when it comes to youtube videos about injector installs theres just the most subtle change but its definitely there.

-

Filling oil filter when changing oil?

@Marcus2000monster they dont specify that you have to change I think they just mean if your going to be in really cold areas or live in a really cold area to use the 5W40. We used to sell it as an upsell at the dealership i worked at in southern california. No problems caused by that yet and its been years. Only problem I've ever seen caused by oil to a cummins was a tech forgot to put oil back in it and obviously that will cause an issue haha. As far as oil filters I use the mopar filters that we get from chrysler which come from cummins (idk who the manufacturer is) and fuel filters i use factory which is fleetguard. Employee discount is nice for that for sure

-

Filling oil filter when changing oil?

There is alot of misinformation about synthetic oil. Like @JAG1 points out he switched to synthetic and it made it leak all over. Not necessarily the case. Synthetics are designed way differently and they clean sludge off of seals and gasket surfaces or corners of the engine etc. Basically if you run an engine with conventional for however long and suddenly you decide your engine deserves synthetic oil, dont. Your engine will already have a nice coating of sludge keeping your gaskets and seal from leaking. You change to synthetic and it will clean all that junk out and suddenly your leaking all over the place. And like @AH64ID says about temperature. Cummins actually suggests using a 5W40 synthetic like the shell T6 (which is what the dealerships use) for weather at or below 0*F and 15W40 if your above that. Moral of the story- pick one and stick to it. Hopefully you can find out the service history or something so you can make sure you use the same stuff the previous guy used. They say if you have less than 100k you can safely switch from conventional to a blend or synthetic but i disagree personally. Thats 100k miles of sludge and wear. I use conventional Shell Rotella 15W40 which i believe is the T3? but thats because its easy to get since thats what we put in all the diesels here.

-

Height Sensing Proportioning Valve TSB 05-04-98

Somewhere i remember seeing theres Napa part#s to replace the valve with a line but Im not sure where i found it....

-

CR Injector failures and upset owners

Yea the oem dodge 6.7 turbos are upwards of 4k just for the turbo. Older 6.7s come in around 2300 or so for a turbo. And you should be cleaning your egr systems periodically as well. and change fuel filters constantly. and etc etc. Plus your probably already making payments plus insurance on the truck but "oh its only a 3500 dollar routine maintenance bill".. I cant believe how expensive things have gotten. Shops charging 120+ per hour for labor. Parts marked up like 500% by the time it gets to the end user and its travelled so many miles and passed through so many third parties or middle men that need their cut of the profits.

-

No start if I just put key in and start quickly?

That and the grid heaters if its cold and your still using them

-

Can a 99 run with no CKP

I ran into this on my 2000. Bolt would thread in but did not feel "tight" at all. I ended up dropping the thing in the gravel and lost it so in a pinch i ended up using the stud thats already there for the harness. Been working since.

-

P1689

I can't stop from wondering about the cummins datalink connector. The triangle 3 pin connector. Where the edge connects to that what purpose does that serve? I'm hoping @Mopar1973Man at least someone who knows more about the cummins side of things. The edge scanner only reads PCM codes I'm assuming. But what if the ecm is telling the pcm to throw that code because the edge has taken over the loop between the VP and the ecm using the datalink connector and pump tap and my sloppy datalink connection was so intermittent that it would cause the code. Which would explain the loss of power experienced alongside the symptoms of the code. Is that even remotely on the right track?

-

P1689

Thanks but I've checked that a few times now.. Ohms check out good and i've swapped it out with known good relays as well with no luck. So far today its been working well with the edge tap wire disconnected and cleaning and putting dielectric grease on all the related connectors. So i guess fingers crossed again that i somehow fixed it by doing that.

-

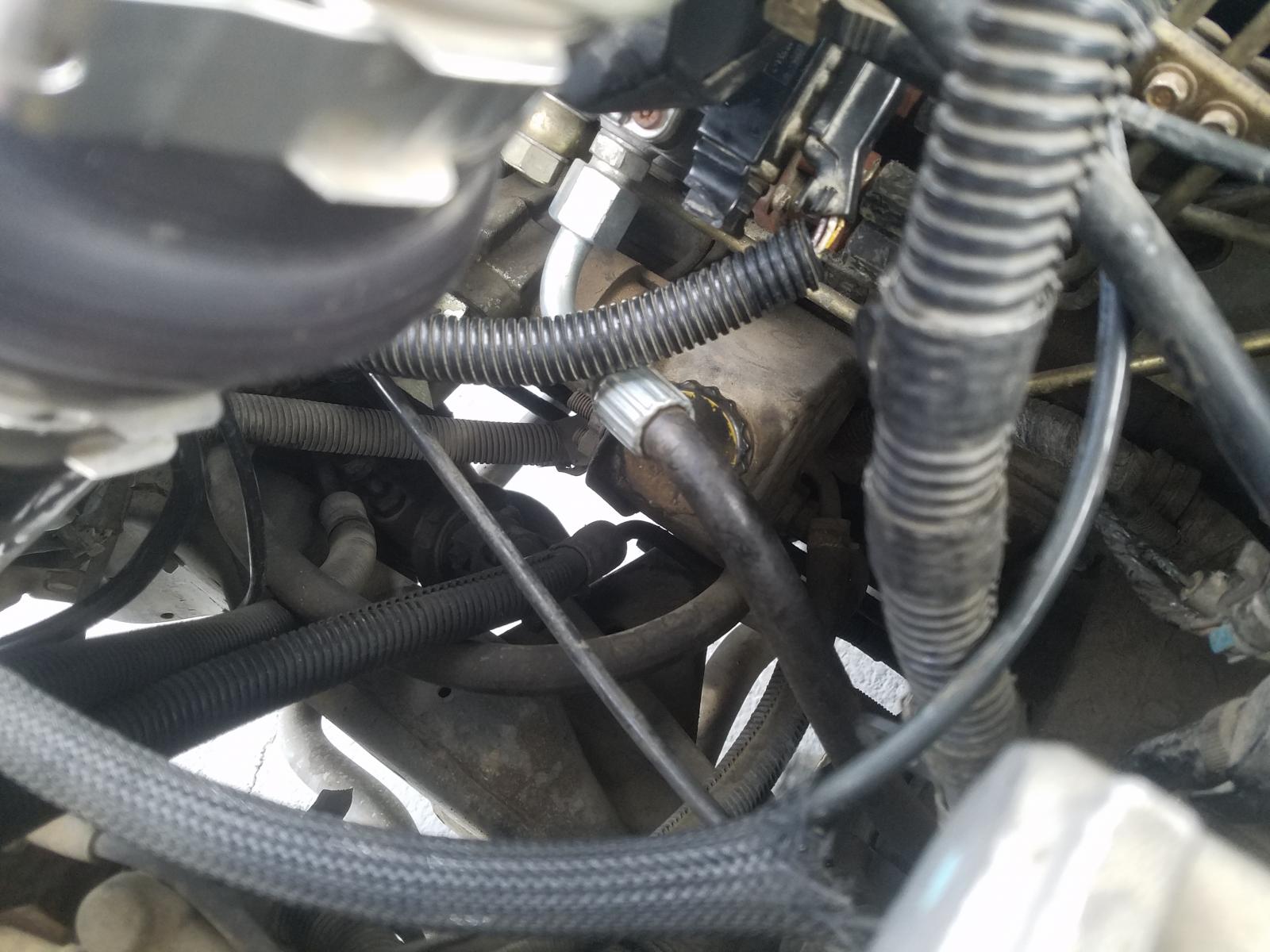

alternator modification

I was just about to say... That shaft is so worn down..! How are your brushes? It looks pretty tired.. but im also 110% in support of making what you've got work that just looks like a good replacement would be more in your favor

-

P1689

I'll probably end up going that route. I was thinking something like this though to space the line out away from being in the way of my power steering but that's just me being picky. And probably not this exact one but similar.

-

P1689

I cannot for the life of me remember what size it ended up being. Line or the fitting for that matter. 3/8s maybe? I'm assuming yours looks like half inch and mine looks smaller. I might be able to dig up a receipt.. but who knows that was one house and another state away.

-

P1689

Thats a tough call. I hate electronics on anything I mean if I could have a 98 12 valve I would do it in a heartbeat just to avoid having an ecm. But I love the functionality of having computerized things just because it's so easy to do and I like wiring things in idk why I just like putting electrical together and wiring idk if it's the challenge or what but it's never bothered me. I've messed with air lines before so I'm not afraid of going that route either.I just want to find a fitting that I can put in line between my injection pump and the hydraulic line that O'Reilly's made for me a couple years ago to use as my fuel line because right now the line is in the way of my power steering pump cap and putting a nice tee there would space it out enough to make it easier to get to my power steering.

-

99 Cummins auto 4x4 gremlin

You might be able to see it better from underneath. You can also follow the harness from the VP down toward the engine and back along the block and find it that way. Its a real pain to get a good look at it from above. Try unbolting the fuel filter housing from the intake manifold also. Dont worry about fuel lines theyll flex a little bit to get it out of the way as long as you dont have metal lines

-

Can a 99 run with no CKP

That is alot to read. You disconnect the vp and ecm so that you can check resistance between both ends and essentially your determining if the vp or ecm is even getting the signal its supposed to or is it shorting to ground or is the wire broken or is it a loose connection. Its a real pain i just went through it all yesterday. Pull the fuel filter off with the two 10mm screws holding it at the intake manifold so you can get to the allan screw for the ecm connector easier.

-

P1689

Oh i see so i need to be looking into that circuit then and trying to find a short or break in the wire. I'll have to reference the edge instructions and see what im dealing with here. And obviously get a real fuel pressure gauge. Im going to get an actual gauge and use my open hole in my pillar to mount it, and not with solid core wire either nor will i splice it all into my cigarette lighter outlet and secure it with twisty wire ties... i hate seeing ugly wiring jobs.. fire/safety hazard and all..

-

P1689

I actually have seen something similar to this i was swapping clusters in my old ford and left something unplugged i cant remember its been so long but my fuel gauge was beyond pegged like i had no idea it could read that far. Im not 100% sure what your pointing to here though. Did i say a wire was damaged? Im obviously missing something here. The whole 5V signal reference makes sense Honda does it and so does Megasquirt which I know because im putting together a baja bug with a standalone and a honda motor but thats another story. You learn alot real fast when you try to understand how to wire an engine.

-

P1689

Thats just it though Ive never had a working fuel gauge. The previous owner had one but it was installed entirely with solid core wire and who knows how many places it was broken at. And i had to ditch the place where the sensor was tapped into the line because the line had a pin hole in it and i had to replace it in a pinch so oddly enough oreillys near by was able to build me a hydraulic line with the right fittings. I just thought it was odd that i dont have a sensor and somehow the edge is producing a signal so i was wondering if it was being pulled from the can+ circuit somehow. So far i've only got one 20 minute trip into work with the tap wire disconnected and all the connections cleaned and greased and a hopeful computer reset with batteries disconnected and key on but it didnt act up at all this morning and normally it would act up like crazy if i tried to get it to actually accelerate. But knowing how intermittent this can be im just gonna cross my fingers i guess. It did take 3 weeks for it to come back last time. @JAG1 i think i know which connection your talking about i'll check that out. Also how about the cummins data link connecter for the edge? The triangle one on older trucks but mines a straight 3 pin connector. It never seemed like it was connected that great to begin with but it was kinda sloppy when i checked it out yesterday. Would that cause something like this to happen? And now that im thinking about it. I remember reading the MAP can cause weird things and this morning for the first time ever i was intermittently getting no boost reading this morning.

-

Subwoofer pop when stereo turns off

This is a good point as well. Always the shortest ground possible with these. My amp gets grounded to the nearest bolt and usually a seat bolt. Stereo gets grounded to the nearest piece of metal in the dash I have used a few self tapping screws before but the amp needs a good solid bolt holding it down. Thats interesting about the antenna ive never had an auto antenna before and the one car that did it was broken anyways.

-

99 Cummins auto 4x4 gremlin

While on the topic of grounds, is it a good or bad idea to run a ground from the exact same point the mod uses and up to the battery?

-

Subwoofer pop when stereo turns off

It also couldnt hurt to check your connections. I've installed dozens of stereos in several different cars. Several for me personally I put a stereo in everything i own but also for friends and family. Start with the basics. Ever used the zipties that come with a stereo install kit? They are the WORST. You cant even pull them tight they just break. Well the wire they provide is of the same quality. Obviously not all kits but you know which ones im referring to. I had an old e30 BMW. 91 318i. No ac. Nothing extra electrical aside from foglights and a coil on plug conversion. I had a hard time tracking down a static noise which then turned into a crackle upon shut down. I looked at grounds, connections, even looked to see if one of my wires was shorting on the body or anything and no luck. I actually had to completely replace the rca cables that i had run from the head unit under the carpet along the tunnel and under the backseat because they were cheap rca's and the insulation they used wasnt enough to shield the wire from its own interference. That was a nightmare to say the least.