- Replies 34

- Views 10.1k

- Created

- Last Reply

Top Posters In This Topic

-

Marcus2000monster 10 posts

Marcus2000monster 10 posts -

Mopar1973Man 6 posts

Mopar1973Man 6 posts -

JAG1 4 posts

-

Haggar 3 posts

Haggar 3 posts

Most Popular Posts

-

Marcus, we gotta get you reading wiring diagrams..... (open up the one I attached I will walk you through it) The PDC ground is G100, G101 and G102. Those are located under the battery o

-

Marcus2000monster ,It seems that if it were an air problem, the symptoms would go away with a full tank. Or at the least be less noticeable. How about checking for the infamous AC ripple l

-

Some days I wish @Marcus2000monster just would come over the mountain to Idaho and let me look at it.

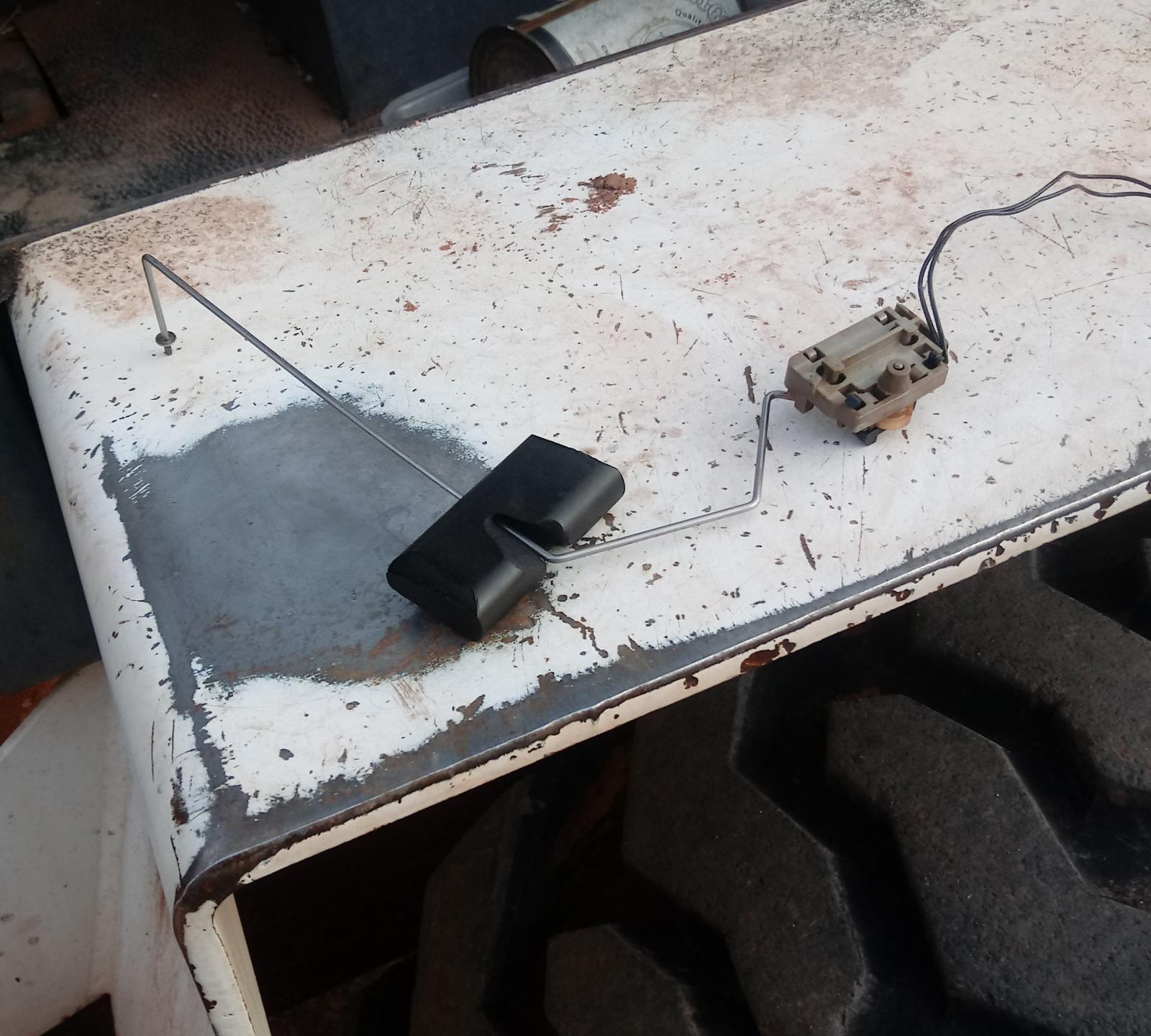

Afternoon guys. As some may know I’ve had some issues with how well my truck has been running lately. It has been idling a bit choppy and an occasional miss nothing crazy but noticeable. we work on a few 24 valves at work and if never figured out why they run better than my truck does. I have been blaming it on low pop pressures with my fairly new DAP 75hp injectors but I’m thinking otherwise since a discussion with felllow employees at the shop. They mentioned that 8 out of 10 Fass fuel systems they have seen are actually making more air in the fuel system than they are separating. They are pumping far more fuel than the truck ever uses and returning it to the tank at a high volume that is creating air in the fuel in the tank. In other words it is making more air than it can separate. The more I think the more I suspect my running issues are air in fuel and not injectors. After all I only have 10K miles on my injectors. What do you guys think? @dieselautopower Have you ever had a set of injectors come back with low pop pressure at this low mileage?