Leaderboard

-

in all areas

- All areas

- Marker

- Events

- Event Comments

- Files

- File Comments

- File Reviews

- Images

- Image Comments

- Image Reviews

- Albums

- Album Comments

- Album Reviews

- Blog Entries

- Blog Comments

- Topics

- Posts

- Cummins Articles

- Cummins Article Comments

- Cummins Article Reviews

- Vendors

- Vendor Comments

- Vendor Reviews

- Ads

- Ad Comments

- Ad Reviews

- Policies

- Policy Comments

-

Custom Date

-

All time

December 14 2009 - July 25 2025

-

Year

July 25 2024 - July 25 2025

-

Month

June 25 2025 - July 25 2025

-

Week

July 18 2025 - July 25 2025

-

Today

July 25 2025

-

Custom Date

07/17/2018 - 07/17/2018

-

All time

-

dripley

Retired Staff3Points11,788Posts -

W-T

Yearly Subscription2Points146Posts -

Dieselfuture

Yearly Subscription1Points5,783Posts

Popular Content

Showing content with the highest reputation on 07/17/2018 in all areas

-

Mouse in my heater/AC fan?

3 pointsHey, hey, hey!!! Thats my kin you're looking for. That could be problem.3 points

-

Everyone post a picture of your truck!

New wheels, tires, shocks, and leveling kit... officially sleeping on the couch! Tow mirrors, cab lights, bed cover coming...2 points

-

24v vp valve cover and other ramblings

2 points

-

Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

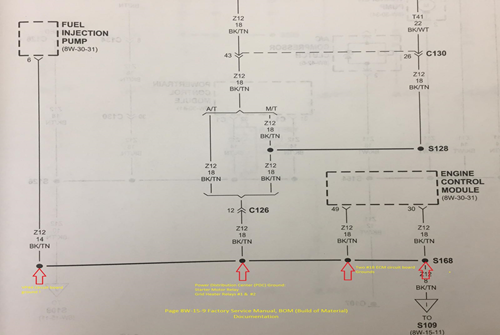

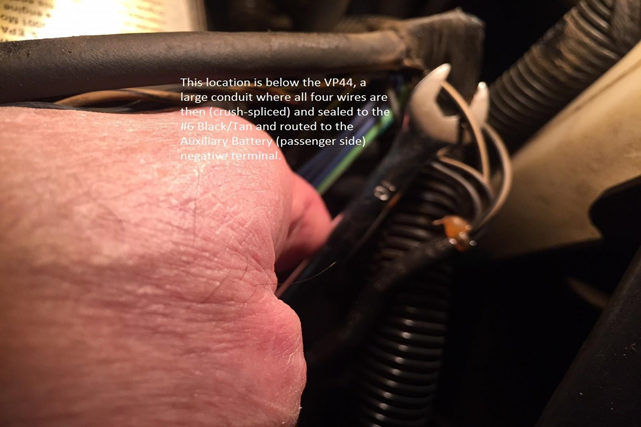

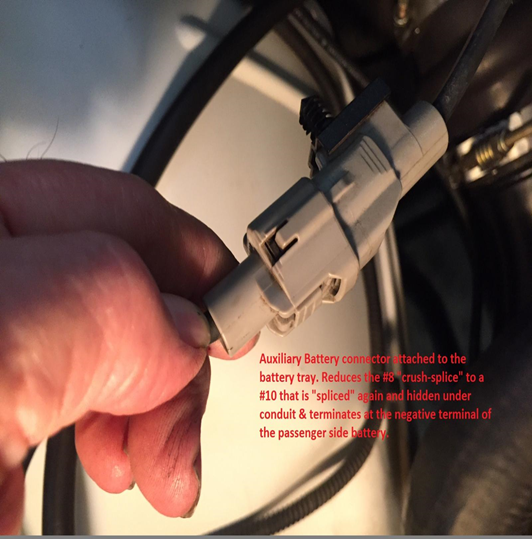

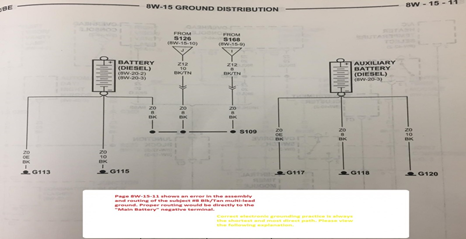

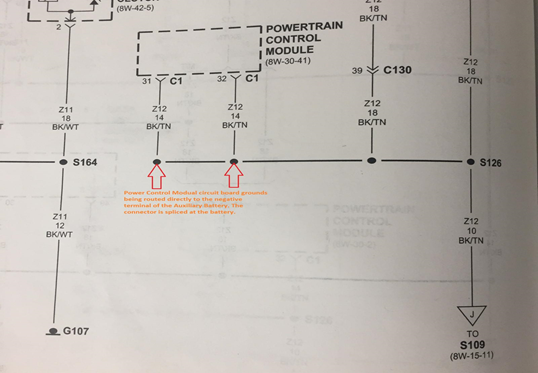

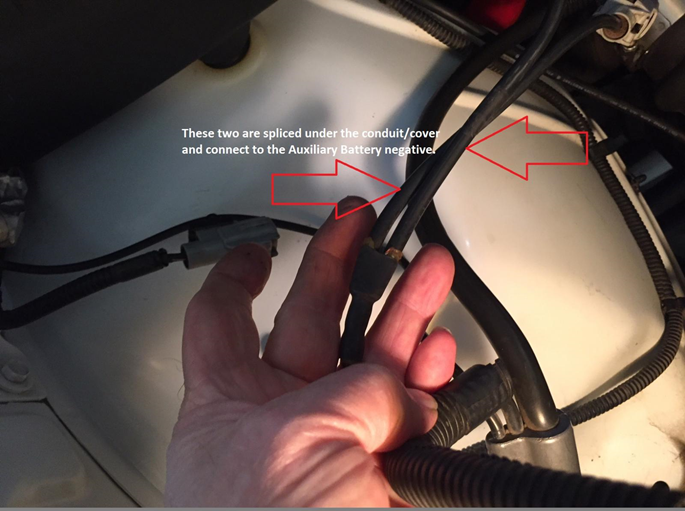

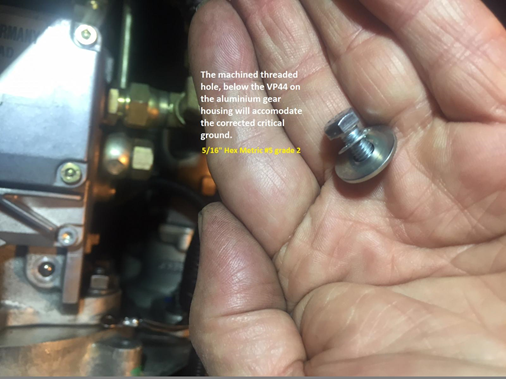

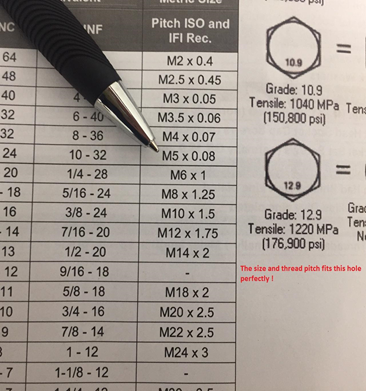

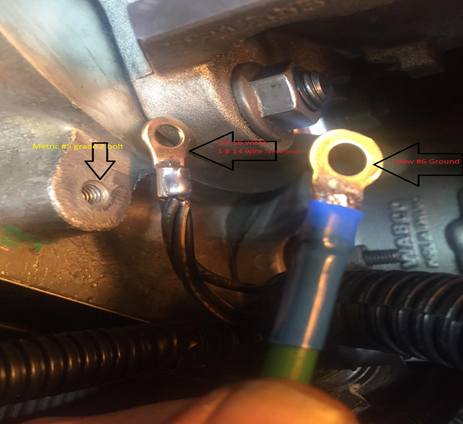

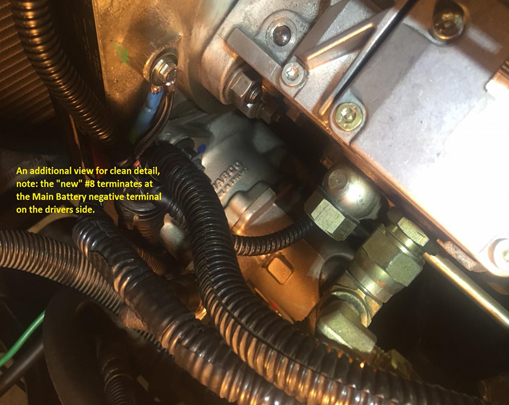

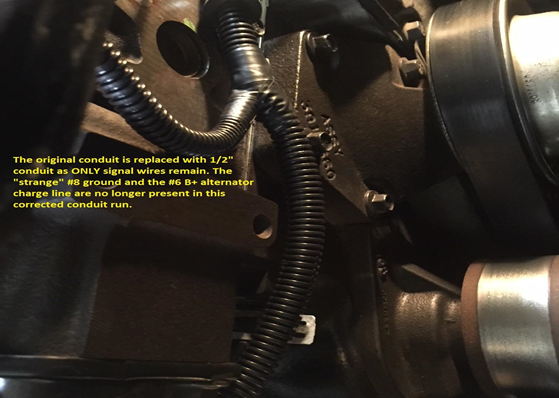

After 18 years of interesting CTD enthusiasts and transmission specialty outlets all contributing their method, or fix, to the well known TC lock unlock syndrome, I can no longer remain silent. Extensive review of many posts regarding TC lock unlock, the rerouting methodes, the add on filters for APPS and last, but not least,...the "tin-foil hat" brigade. I do realize that each individual or company that contributed to the vast amount of information on the web had good intentions and I must acknowledge that some of the procedures caused me to closely examine what these people were trying to do. I believe it is well known that even a blind mouse occasionally finds a morsel of cheese. Again, as it is well known @Mopar1973Man was the only entity who positively identified the instigating source of this key issue. My entry today is not about alternators...it is about what Daimler/Chrysler did in regard to production of these Cummins powered platforms and the complete disregard of common sense Electronic Engineering. Please note, this applies to automatic and manual transmissions as each platform is plagued in the same manor with different quirks. This Blk/Tan #8 gage wire is quite critical in the scheme of things. It is contained within a 1" plastic conduit passing along the front of the engine. It contains water temp sensor leads, air conditioning leads, alternator/PCM leads and the #6 gage alternator charge line to the PDC. This #8 gage Blk/Tan passes over the top/backend of the alternator and is "eventually" connected to the Auxiliary Battery (passenger side) negative terminal. This snapshot of the Factory Service manual documents "four critical ground leads" that are "spliced" in an unconventional method. This photo depicts the three #18 gage wires and the single #14 gage wire entering the shrink-tubing where the "crush-splice" occurs. This bundle exits the large plastic conduit below the VP44 This again is a most disturbing depiction of the Daimler/Chrysler method of splicing critical ground leads and then routing this across the top of the alternator and "eventually" bringing this to ground reference. This photo depicts where this #8 gage Blk/Tan first connects on the way to "eventual" ground...yes this is the Auxiliary Battery tray connector. Please note: it is spliced again and joins the PCM circuit board grounds...which are critical in their own nature...and "eventually" terminate at the negative post of the Auxiliary Battery's negative terminal. This photo is very interesting, it is the Factory Service manual and the assembly line documentation follows this as a road map in the matrix during production. Please NOTE the title "NAME" to each battery...I looked at this for a considerable amount of time before I realized the assembly line coordinators tried to work with the documentation from the Engineering Staff to "make it as it looks"...Could this single oversight be the reason of a four foot ten inch critical ground wire combination traveling the distance to "EVENTUALLY" terminate at ground? From a basic engineering standpoint regarding ground...you "NEVER CHOOSE THE PATH OF EVENTUAL GROUND" !!! It is to be the shortest and most concise connection in reference to ground...this is biblical in ALL ELECTRONICS...including pickup trucks. ! Here is the Factory Service manual documenting the PCM circuit board reference ground starting as a pair of #14 gage wires being spliced into a #10 gage bundle and arriving at the Auxiliary Battery through another connector that joins a #8 gage wire that is "splice-joined" under plastic conduit in a Y configuration joining the rouge #8 gage "after passing over the alternator" traversing the entire engine compartment from the driver side of the vehicle. Seriously I have been drinking excessively, most recently, due to the nature of this blatant discovery. This is the hidden Y splice at the Auxiliary Battery where the "mess" EVENTUALLY terminates for ground reference. This photo shows the correct "HOLE" of where to apply ground for the VP44, ECM and the PDC...note the logical location It took a little research to find the size and proper thread-pitch. Metric M5 with a 5/16" hex head is perfect This is where you apply a fresh "quality" #6 gage ground and terminate this at the Main Battery negative post on the drivers side for absolute ground reference for the VP44 and ECM This is a very short and concise reference to ground. This is the corrected procedure for a rather critical ground. The two largest wires originally contained within the 1 inch conduit are no longer present and located well away from the alternator. My alternator B+ "charge" line is now a #4 gage line directly connected to the Auxiliary Battery and when my new battery terminals arrive and they are secured, I'll provide photos of a completed Master Power Supply System within this engine bay. With these corrections, I would hypothesize that a poor ripple specification on a given alternator would be overcome by the immense capacitance of the parallel batteries and would become less prone to causing the dreaded TC lock/unlock for automatics and cruise-control abnormalities for the manual transmission platforms. The #8 gage Blk/Tan passing over the alternator as an "EVENTUAL" ground is gone...the PCM, ECM, VP44 and the PDC are now grounded in accordance of standard Electronic Engineering practices. Respectfully W-T1 point

-

High Fuel Temp

1 pointCorrect, except that the VP return is only part of what volume makes its way to the fuel tank. The rest is excess fuel at the injectors. And thats actually the HOTTEST fuel as its flowing out the back of a 200*+ cylinder head.1 point

-

Lack of power

1 pointThankyou Mopar1973Man. I've followed some of your other topics and find you to be very good on these trucks. Thankyou for all you do and thankyou to everyone else also. Thanks Guys I'll check in on a fass tomorrow. Thankyou1 point

-

High Fuel Temp

1 pointReturn from the VP44 is very limited anyway... Return on the left and supply on the right. No matter what you do for pressure the volume is limited to that small port drilled in the body of the pump. This why I never suggest pressure beyond the standard 14-20 PSI. There is nothing gained going to higher supply pressures.1 point

- Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

-

new turbo hot and laggy

1 pointTurbo is a little big for rv275s, no surprise it’s laggy in the lowers rpms. Also, with larger injectors, it could be smokey too till the turbo lights. Smokey with edge off? I think you said you already did a boost leak test? A low stall torque converter could also play a factor.1 point

-

24 Valve ECM overheating?

1 pointElectrical issues are always the worst. When I was in the Navy my mos was Aviation electronics. You'd be amazed by how many boxes would come back over and over to be repaired. It could be so simple as a unit fails when placed in the sun because a weak connection expands. In my case, with the pdc I used, I had to do some internal modifications to make it work for my purposes. All of the #86 pins on the relays were hooked to a common ground making them useless for cooling unit fans. I have a spare now that I'm working on and a complete new under hood wire harness I built, just waiting for the right timing.1 point

-

Mouse in my heater/AC fan?

1 pointWhat invasive buggers we see around here are cyclical. This year was seemingly the year of the rat. Maybe next year it'll be frogs.....or crickets again. Not sure why it cant be something edible like chickens...1 point

-

High Fuel Temp

1 pointMy typically hot fuel mark is 130-135*F on 107* day. Even after parking for long periods still very little rise. Typically my IAT and Fuel temp are nearly the same. Typically flip-flopping IAT and fuel temp at about +5*F spread. Maybe that why I can go 60k miles with fuel filters because I'm not creating any asphaltene. Last two years now I've got 250 mile round trips between Ontario, OR and home. Last trip I measured the outside air at 107*F and the fuel temp maxed out at 135*F. IAT was floating about 132*F. BHAF as well. Remember its not the cold air intake. It about the temperature crossing the intercooler. Then there is a coolant jacket within an inch or so from IAT sensor.1 point

- Hello from Idaho

-

Everyone post a picture of your truck!

1 point

-

24 Valve ECM overheating?

1 pointThe things we learn over the years. Some of it useful.....most of it worthless. Either way, its makes for good small talk.1 point

-

AirDog 150 - Finally failed

1 pointPureflow comes through. I've never filed a registration form with them but talked to Kyle and he was very helpful. I've got a brand new pump motor coming for FREE. He's going to honor the lifetime warranty that I would had if I filled out the warranty card. So in about 3-4 days I should see the new AirDog motor.1 point

-

AirDog 150 - Finally failed

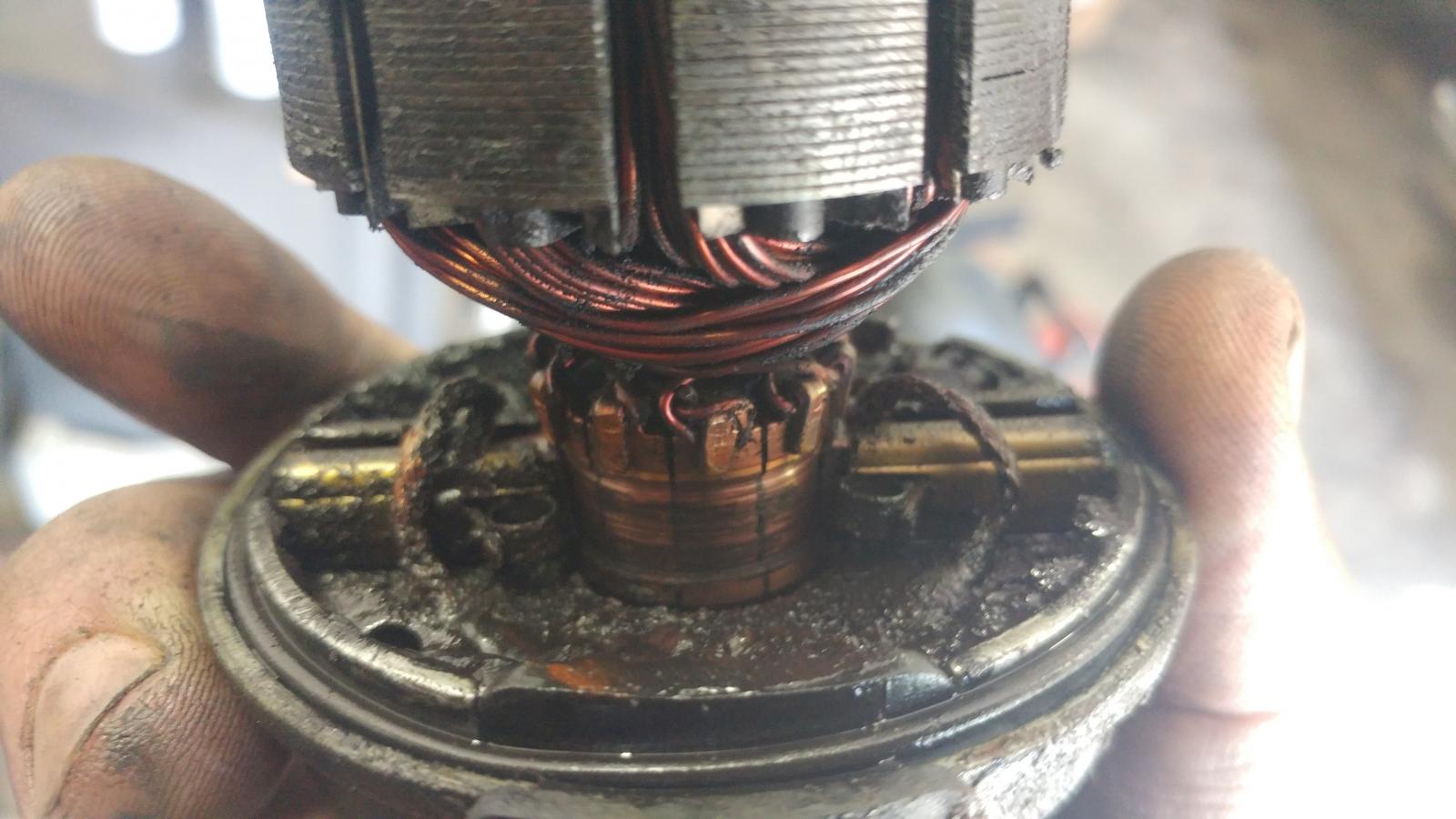

1 pointDamages... The pump seal gave up was pushing diesel fuel into the shaft bearing which is now wiped out. So here is the shaft bearing and it gone. So when the bearing started to fail last few weeks I've noticed the pump was louder than normal but pressure was good. Sorry for the fingers... Now the brushes are wiped out too. Overall appearance... Looks sad over 12 years of road grime... I was lucky and remembered I'd saved my AirDog label when I found it on the shop floor. It was tucked in a notebook.1 point

-

AirDog 150 - Finally failed

1 pointMike, if Pureflow won't take care of you there is always Eric at Vulcan, he can help. Oh yeah...... if you have time post up some pics of the repair1 point

-

Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

@Marcus2000monsterThanks, and the alternator is a DC Power Engineering XP 270. You'll be able to find them on the web and they are located in Riverside, California. It is a 6 phase large frame unit that produces 200 Amps at idle and NO serpentine belt change is required. I referred to this device in the High Amp alternator thread. It is basically, a drop in platform however; to utilize the potential of this massive component you must consider a "new B+ charge line". This thread address that issue specifically because, the original #6 gage that is encapsulated in the factory 1 inch plastic conduit located in front of the engine would never survive a charge command from the PCM. The original #6 that directly feeds the PDC and passes through the 140 Amp fuse (which is entirely unnecessary) is fully removed. This is done specifically for three reasons. #1: A #6 gage B+ line is not adequate to pass 200+ Amps (the XP 270 will produce 305 Amps peak), furthermore, a high-current line in close proximity to sensitive 5 volt logic sensor lines should never have been produced in this manor. Daimler/Chrysler made this error in production of these vehicles over twenty years ago. Poor performing alternators that developed AC ripple, due to several factors, would permeate the surrounding conductive wires within the harness and render undesired electronic phophas throughout the entire vehicle. #2 The "strange" #6 gage Blk/Tan ground, that is "supposed to provide" critical "reference ground" for the VP and the ECM is directly parallel with this B+ line and in an unfortunate happenstance became a "balanced" pair of "wires" that created a "tuned inductive/capacitive" transmission line to efficiently transport this minor AC ripple with deadly efficiency. This #6 gage Blk/Tan (reference ground) is brought to ground directly as documented in this thread. #3 It definitely cleans up the engine bay with a touch of technical excellence...it is a win-win endeavor for the 2nd Gen Cummins enthusiast May I add...the Factory original #6 gage B+ line providing as much as 135 Amps during cyclic periods of the "grid heater" event, was NEVER ADEQUATE to conduct that level of current ! Take a moment to examine the factory #6 gage B+ line???.. It's stiff...it's cheap... it's cooked...it is a complete act of buffoonery on behalf of Chryslers Engineering Staff to have produced this level of electronic mediocrity . WARNING: for those of you who have elected to upgrade your system with any platform (alternator) that produce 180 Amps...you too must consider an alternative to this woefully inadequate #6 gage B+ charge line. If it melts down within the Factory conduit...you will lose your ECM..your VP44 and your PCM. With great respect to the Cummins Fraternity...I humbly share this information for the betterment of our rigs. Cheers, W-T1 point

-

Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

@W-T You've got a following... You might edit your article with the steps on how to do this...1 point