This is a tech article regarding those who (like me) think the oem spot for the apps is not ideal.

Exposed to outside elements, heat, vibration and potential corrosion, moving it inside was most practical.

Non Dodge/ midrange applications of Cummins 5.9 24V ISB’s all have their TPS/APPS inside the cab, mounted on the pedal assembly. So nothing is changing on the apps operation, just moving it.

This mod does not works on trucks that are auto/use vacuum for cruise. The auto trans kickdown cable is attached to the bellcrank assembly. As with the vacuum solenoid setup too so if you can live without them then it will work.

Parts needed:

699-5101 pedal assembly

(2x) 6 pin Duetsch connectors kits

Zip ties

Grommet

6’ of 6 wire harness

Tools needed:

Duetsch connector terminal pliers

Wire strippers

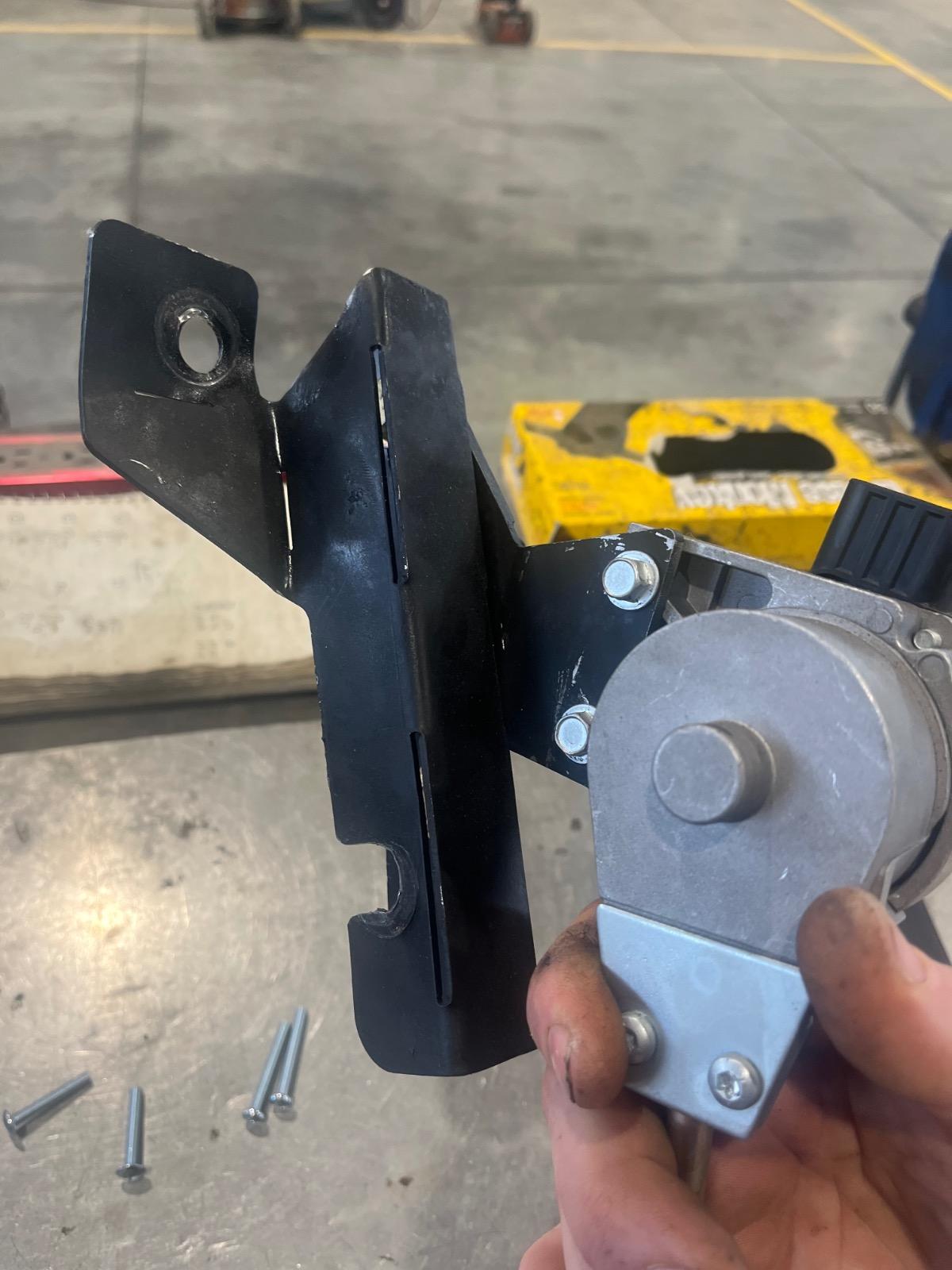

Making the mount will be up to you. I can show you pictures on how I made mine but it’s just a one off. Either way you need to mount it inside.

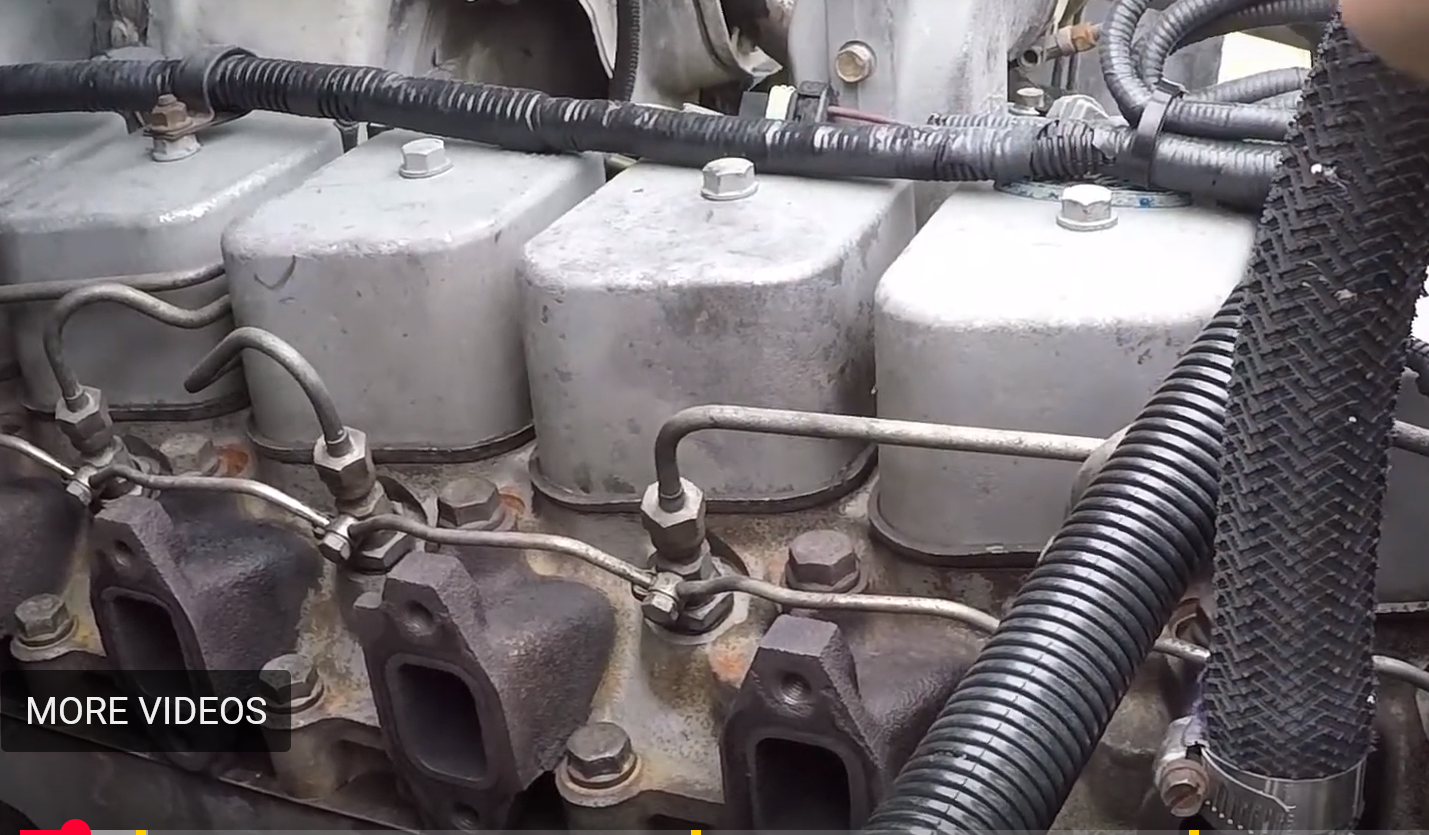

First, disconnect the 6 pin Duetsch connector from the apps, remove the bellcrank assembly from the cylinder head. Cut off the cable and discard. The oem pedal assembly will need to be removed and the oem mount has a pivot pin on the bottom that’ll twist out with some channel lock pliers.

Once you mount your new pedal to the mount and it’s installed all that is needed is how to control via ecm. So a 6 wire jumper harness is needed. I would HIGHLY recommend removing and tossing the apps that comes supplied with the new pedal and install your current one in its place. I can’t guarantee its quality.

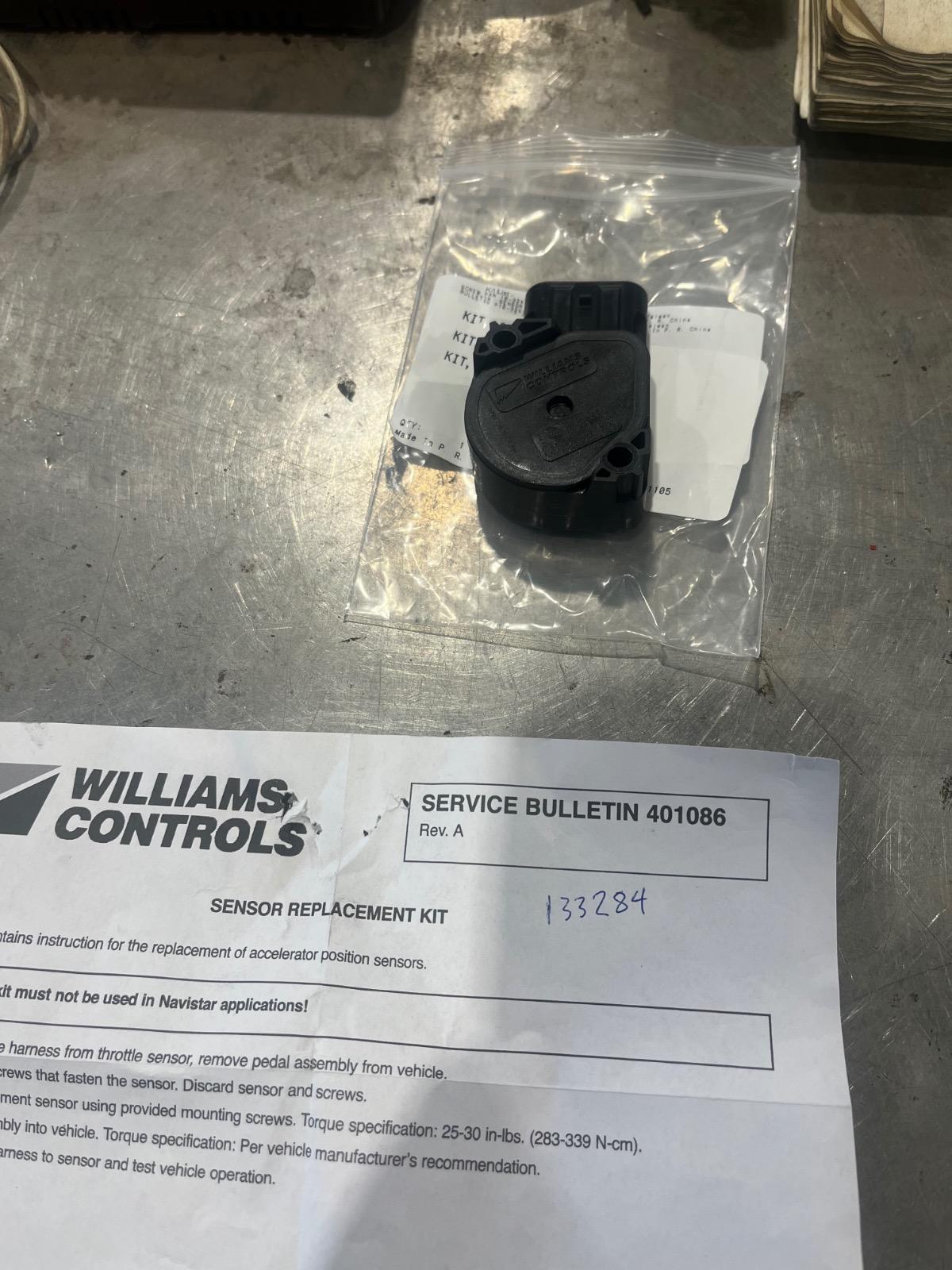

If you need an apps, a Williams Control 131973 or 133284 will work perfectly (Timbo is just a repackaged WC). Available from any oem truck dealer (I.e. Kenworth or Freightliner).

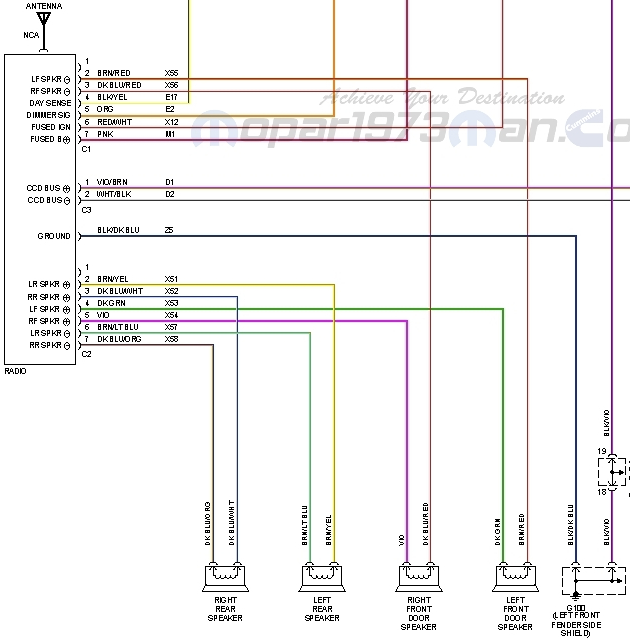

On your engine side of your harness you need to make a 6 pin male Duetsch connector. Ensure you new connector kits have the locks in them, some kits do not come with them for some reason. YouTube or Google can provide a video on how to use Duetsch connector pliers, they’re super easy to use.

Using the hole in firewall that the original pull cable went through install a grommet to prevent rubbing and feed your harness through. If you prefer to drill a hole the same size of the connector body you’ll need a 7/8” drill bit.

**It’s easier to make the harness, THEN crimp the new terminals on after feeding it through the oem firewall hole for a cleaner look.**

Cut your 6 wire harness to length and crimp on the terminals, install the connector body and plug it in. Theoretically the engine doesn’t know where the apps is so it will work. Make sure you mate up each wire in its proper spot on each connector, if you mess them up a CEL will come on/non functionality of the apps.

Secure the harness to various points with zip ties so it’s rigid. This provides a clean look and more room in the engine compartment for future servicing.

Start the engine and test. Throttle response should be crisp since there is no cable anymore that has slack as it wore.

View full Cummins article

.thumb.jpg.9c48aa8f6cc163d8202f09ef46255c5f.jpg)