Everything posted by Mopar1973Man

-

Air Vent?

Only 2 positions close outside air OFF and MAX A/C. The rest of the positions are open to outside air.

-

Need to add 2nd battery back..

Biggest thing is buying the cable that is expensive.

-

Who's ready for warmer weather?

Even for me I'm ready to load up the ATV for a back country ride soon but gotta wait for the snow to melt. Ugh.

-

1998.5 47re auto hard OD shift

Remember iQuad is only calculated for gear position based on tire circumference math not actual.

-

Air Vent?

Very true. It weird you got vacuum to open the fresh air flap or vacuum was dropped the door blew open. If vacuum was dropped then it should be stuck on DEF mode. There should be a few vacuum motors fresh air is over next to the kick panel. Just gotta do a dash pull.

-

Need to add 2nd battery back..

Best answer. Seriously I've seen people cut the old end off leave the black oxidation on the copper and hook up new terminals (crappy 2 bolt clamp style).

-

Anyone here run Gloshift gauges?

Correct. The older EV series is machanical and all it needs is a snubber at the tap point and hook up the gauge light to panel lights.

-

Need to add 2nd battery back..

Then there are some of us still got our factory battery terminals, no corrosion, and in good condition yet. Tell you the trick keep all exposed metals coated with engine oil. This includes battery hold down hardware.

-

Who's ready for warmer weather?

Yup, the tail is gone. I use to run a 1976 Honda CB550 which I modified. Back then it was a Walkman (cassette) and earbuds. Then go out canyon racing. Back in my younger years when I was truly crazy.

-

Who's ready for warmer weather?

Ear buds and a cellphone if you don't have one. For me its a good beat and you can dance a 1100 Goldwing right down a windy road.

-

1998.5 47re auto hard OD shift

3rd LU will only happen in the the OD switch is OFF. Even my old 1996 Dodge was that way.

-

My '16 Harley Tri Glide Ultra

I think when people build trike the rear tires are automotive size and weight but that trike weighs much less but still people over inflate the rear tires creating the bump problem. I get similar if I'm setup for my plow blade for tire pressures then remove the plow my ATV rides really rough like the rear tire are solid. Adjust the pressures based on weigh the ride will improve a bit more.

-

Injector Brand Choice

That's about it. Nothing that will truly change the angle or change the size of the tapered fitting. If its marred or pitted your going o have to replace that one line at least. I had this problem with the fitting at the crossover tubes with them weeping all down the back of the engine.

-

Injector Brand Choice

When doing injection lines 3, 5, and 6 should be tighten first without the 1, 2, and 4 even installed there is plenty of room. Since your leaking at that 3, 5, and 6 lines I would pull them and closely inspect them again. All it takes is a rust pit or crush mark to weep.

-

Injector Brand Choice

Same I do my lines by feel. You can loosen till it misses and tighten again. I usually add a bit more to ensure seal.

-

Who's ready for warmer weather?

Warmed up here enough to make the yard muddy yesterday. I'll be glad when it's above 32F at night. im bracing for single digit nights soon.

-

what controls the "wait to start light"

In a nutshell it is correct. Only difference I might check the black probe directly to the alternator case.

-

Anyone here run Gloshift gauges?

After doing gauge for others and have to install twice because of low quality gauges. I would only go back to ISSPro, Autometer, Steward Warner, and a few other quality names. I installed a trans temp in the 96 Dodge I sold was also a Glowshift gauge and I hate to say it but it was poor quality as well.

-

Injector Brand Choice

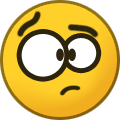

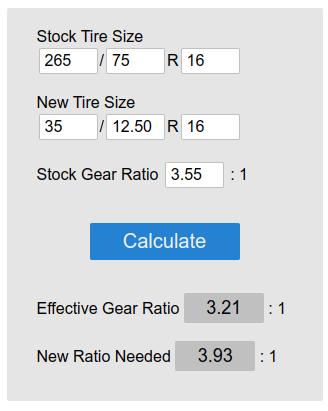

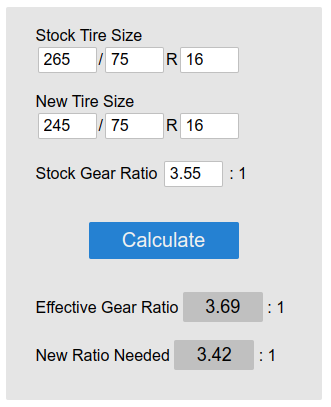

Use a speedometer app. I've got one on my cellphone for customers trucks with big tires being I don't speeding tickets driving a customers truck for test drives. Dodge Dealers are rather under educated at times when I've got to teach them how to run the DRBIII tool and flash high idle to ON. Most are clueless and don't know or don't care to do the job. About $4,000 the last gent I told to swap out (McCall ID)and he was running 37's on 3.55 gears. His final with 3.55 gears was 3.07 final. Then after the 4.10 swap it was 3.51 final.

-

Injector Brand Choice

Keep in mind any tires for the 3.55 gear have to be smaller that 265/75 R16 to perform well for economy or power performance. Cummins ISB engine are best suited for 3.55 to 3.73 final gearing to the ground. So there is no amount of tuning that will make your combo work good. Now with my setup with 245's tires and 3.55 gear will a 3.69 final ratio I'm cruising 66 MPH at exactly 2,000 RPM. Way good for towing heavy trailers I'm in the middle of the torque curve and always cooler EGT's wise. My normal 65 MPH empty EGT is 550*F typically at about 1 to 2 PSI of boost on my economy tune. I'm going to inform you that your final ratio is going to be too low and the EGT's will be high. 3.21 final ratio is not going to perform at all for you. Now compare to what I'm setup as... 3.69 to 1 final ratio is going to get the 28 MPG but your 3.21 is going to be low RPM and hot being the RPM will be too low for optimal running. Now if you had the gears in the axle swapped to 4.10 then you would almost have 3.73 gears it would be 3.71 for a final ratio. Like Thor (2006 Dodge) is also a 3.73 geared truck and slightly higher at 2,200 (or so) at 65 MPH. Also keep in mind the bigger tires have more rotational mass and take even more energy (fuel) to spin them up to road speed. This is why a small tire will always win here being its lower in rotational mass, better final ratios, lower rolling resistance...Which bigger tires have higher rotational mass, crappy final ratio, higher rolling resistance.

-

Injector Brand Choice

Hmmmm.... Some one is following my lead eh?

-

what controls the "wait to start light"

Presto, chango... Moved to 24V Powertrain forum. In a nutshell if the WTS is not on... The ECM did NOT boot up yet and having errors during boot up.so it keeps trying till the ECM boots up fully. Boot up time should be instant with the key so if the WTS light isn't coming on then the ECM is going south for sure. Cause: Most likely don't have the W-T ground wire mod and have excessive AC noise from the alternator which typically cooks the chips in the ECM. In this case its messing with the EPROM that stores the code for the ECM so when power is ON the processor boot strap request the data stored in the EPROM the actual run code. The first instruction of code is to check for IAT temps and turn on the Wait To Start and the grid heater if needed. So you going to need to do AC noise check and most likely replace the alternator. Then do the W-T ground wire mod, then send the ECM to @Auto Computer Specialist to be rebuilt. You can then notify the staff that you already replaced the alternator, W-T ground wire mod and other mode to insure no future damage which they will ask about. So get that done first thing.

-

Something to mess around with

Tell you the truth I love hanging around the older people and listen to the tales and knowledge of the past. So many things I've learned from just listening to older folks tell stories about working back in the day and how they survived. Like out here most of the old timers I talk to are original families that moved here to Idaho back in 1890's when settling for land. Talk to grandmother and grandfather which were children during these times and learn about all ways. So very cool to even understand how rough it was... As for you sir my hats off to you and your knowledge as well.

-

In Parma, ID working on a 90 Chevy

So got the stud out of the manifold. Team effort and welded a nut on the remaining stud and twisted right out with a wrench. Needless to say the job is not quite complete and had to come home for other jobs and get more tools for the next one back there was the power steering hose. (pressure). The nut on the steering box is wedged in so tight I can't move it. So take a dremel tool and cut the steel tube out of the top and then use a socket and impact gun to remove the remaining nut and tubing tip in the steering box. Then I was warned the I've got more work when I return. I'll have to work on Gary's Ford truck next with a starter issue. Most likely a safety system (clutch safety) or something electrical. Either way I'm managing to still fill my days with work every day. So on that 1990 Chevy I did in 3 days... Steering column tilt tighten the 3 bolts. Replace both master slave cylinders plus the rusted steel tubing from driver side to passenger side for the clutch system. Changed a thermostat which turned into broken stud. REMAINING - Change power steering hose.

-

Winter weather - What do you see where your at?

I know... It sucks for me because I did the road trip down to Parma, ID for 3 days to work and wasted all my good weather day being inside a heated shop down there. Now I've gotta gear up for today going down to Lucile, ID and working outside again.