Everything posted by Mopar1973Man

-

I'm Back, Finally! And I have some good questions/ topics

This is why the pumps are place on a calibration test stand. It to find the proper timing and tell the rebuilder what key to use. The VP44 will attempt to reach the set timing amount by either advancing or retarding.

-

Brake Light Switch..."DO NOT REINTSALL"

This is because BC does not have a Bosch 815 test stand so they have to buy time on someone else's test stand to get the new PSG's tested, calibrated and flashed but each pump takes 3 hours. This is part of the cost problem I'm sure. In a 9 hour day you'll only get three VP44's done.

-

Keeping camper plugged in

Last time I checked all RV's have a 12V converter and can maintain the batteries through a winter time. The only thing I've got to do is check the electrolytes monthly. Vehicles don't and require to be driven from time to time or install a trickle charger. Still even then you need to add a trickle charger being vehicles do not come with a 12V converter/charger.

-

Lower Ball Joint Flush Style Grease Zerks

Man I hate those flush style zerks. I've got just the straight needle for greasing like driveshafts u-joints. Just too messy and waste to much grease fighting the needle. Truthfully if I was going to do ball joint I would consider something like @dripley got or another brand setup the same way. Either way I'm past 200k on these...

-

Suggestions for injectors, turbo, head gasket.

$85 an hour... I'll do it if you drive out here. Injectors are about 1.5 to 2.0 hours. Head studs a bit more trouble but since the valve cover is off it would be too bad to pull a bolt and replace it with a stud.

-

How much to flush a 50 hp Honda outboard cooling system

I just loved the comments or being punny of "being hosed" that caught me off guard. Sad to say this happens ever day. I just talked to a guy that had a VP44 replaced for over $3,000. Highway robbery true... I've got clients now that refuse to have any one but me work on there vehicles. Again because someone else hosed the owner in a poor repair and charged way too much.

-

Keeping camper plugged in

So what do you do for your vehicle batteries then? If my truck can be parked outside in minus temps, why does a RV battery need to be removed if it hooked to power and being trickle charged?

-

Keeping camper plugged in

Yes. Ive got a 3 stage converter so there is a storage mode that keeps the batteries at 13.2 volts. Im going to be installing a 30A plug for my RV. Also I've kept my plugged in when at home.

-

Honda 2200 w generator and Dometic 1350 btu Brisk 2 air conditioner

The difference is my power generation is 24V solar panels on the house and the RV is 12V generation. Just route the DC power now to battery bank of some sort. Then your Inverter converters from DC power to AC household power. All done silently and without any fuels. I've always planed for times where weather or road travel is impossible. Plenty of food in the pantry, couple of 55 gallon barrels of fuel gasoline and diesel. Fuel is only for the vehicles typically now that I don't own a gasoline vehicle the only thing I would use gas for now is ATV, generator, lawn mower or the wood splitter. My setup with my power is also city power too. This gives me other options of selling power back that I generate, I can limit my city usage to a max amperage, or I can just turn the city power off. There is a few other bonuses. Like I do not require any surge protector, Why? It was required for Idaho code to have a lightning suppressor to be installed. Not to mention the inverter will drop any power that is dirty. If the power cycles +/- 2 Hz it will drop. If the voltage falls out of my set range it will drop city power. Also the inverter requires to match cycles before hooking to city power. I've got full overheat protection, over current protection, frequency protection, and voltage protection. Solar Power DC -> Battery Bank -> Inverter -> House Optional ways... Pelton Wheel -> Battery Bank -> Inverter -> House Windmill -> Battery Bank -> Inverter -> House You might want to watch the show Homestead Rescuers on Discovery Channel. Lots of good ideas and way of making your place ready.

-

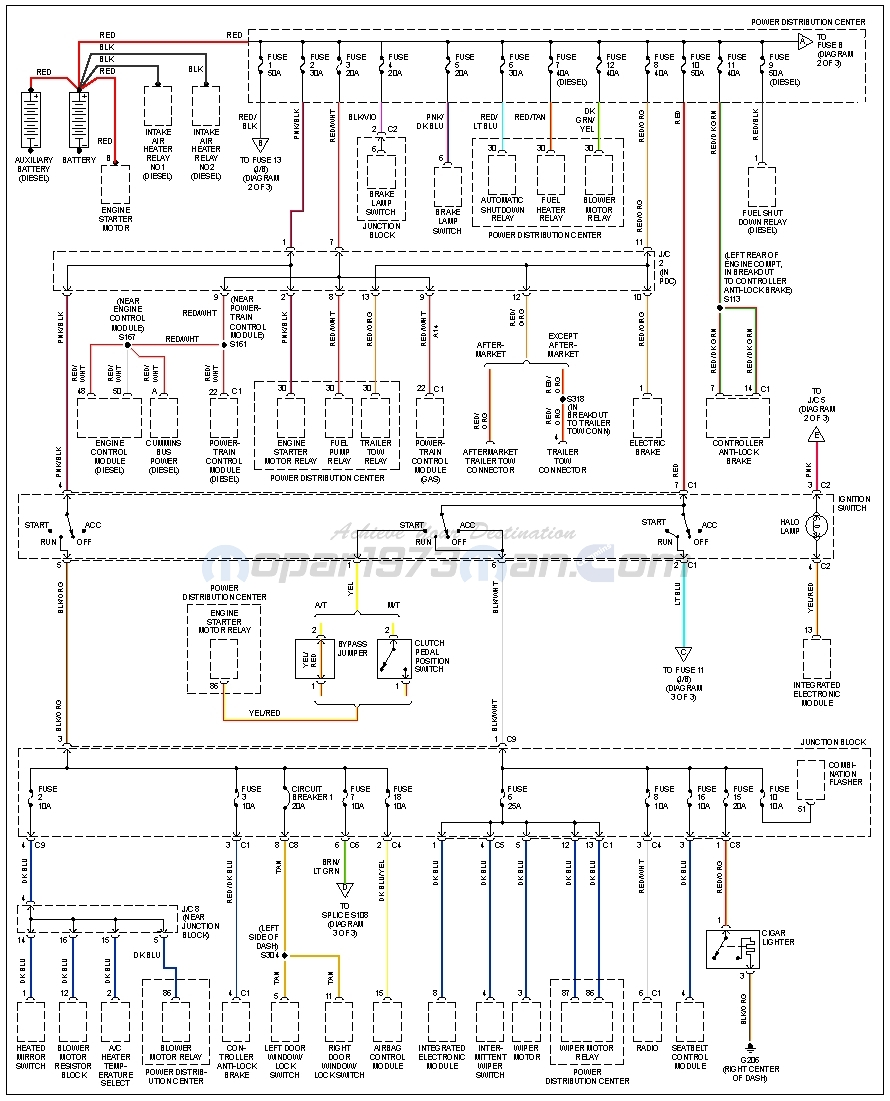

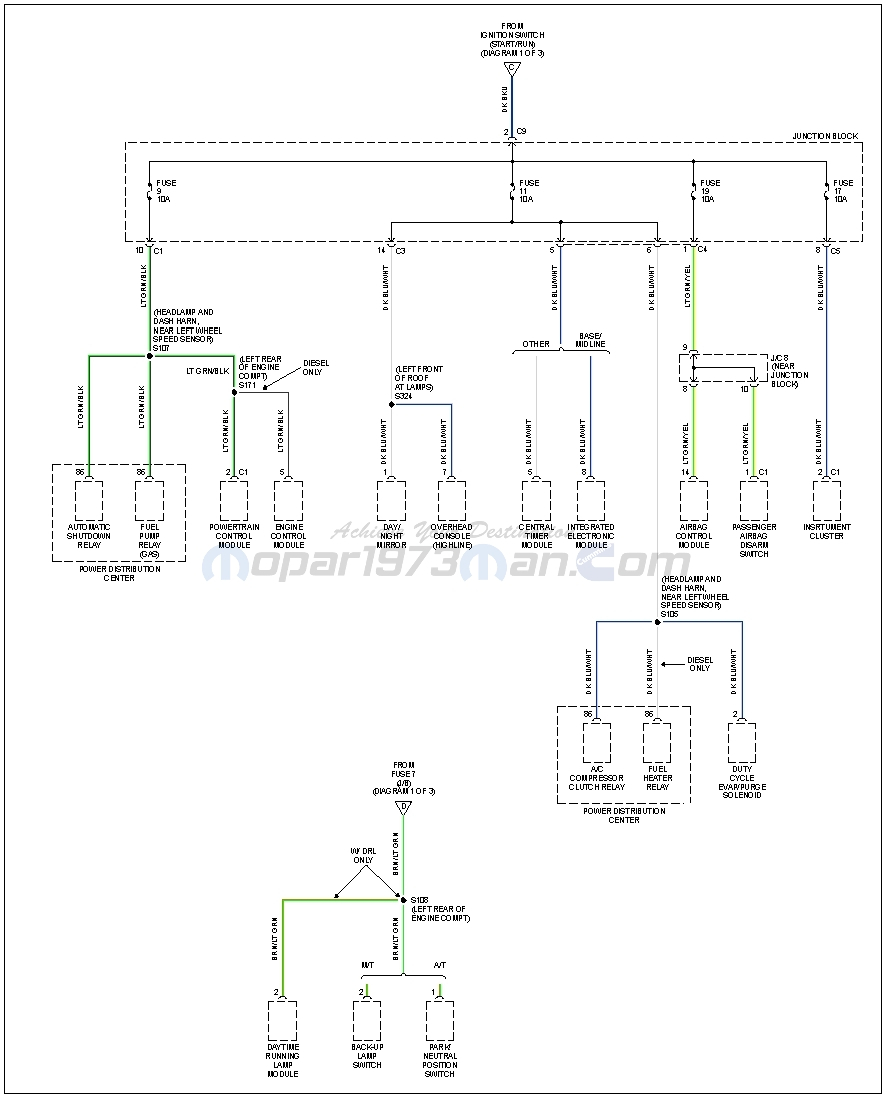

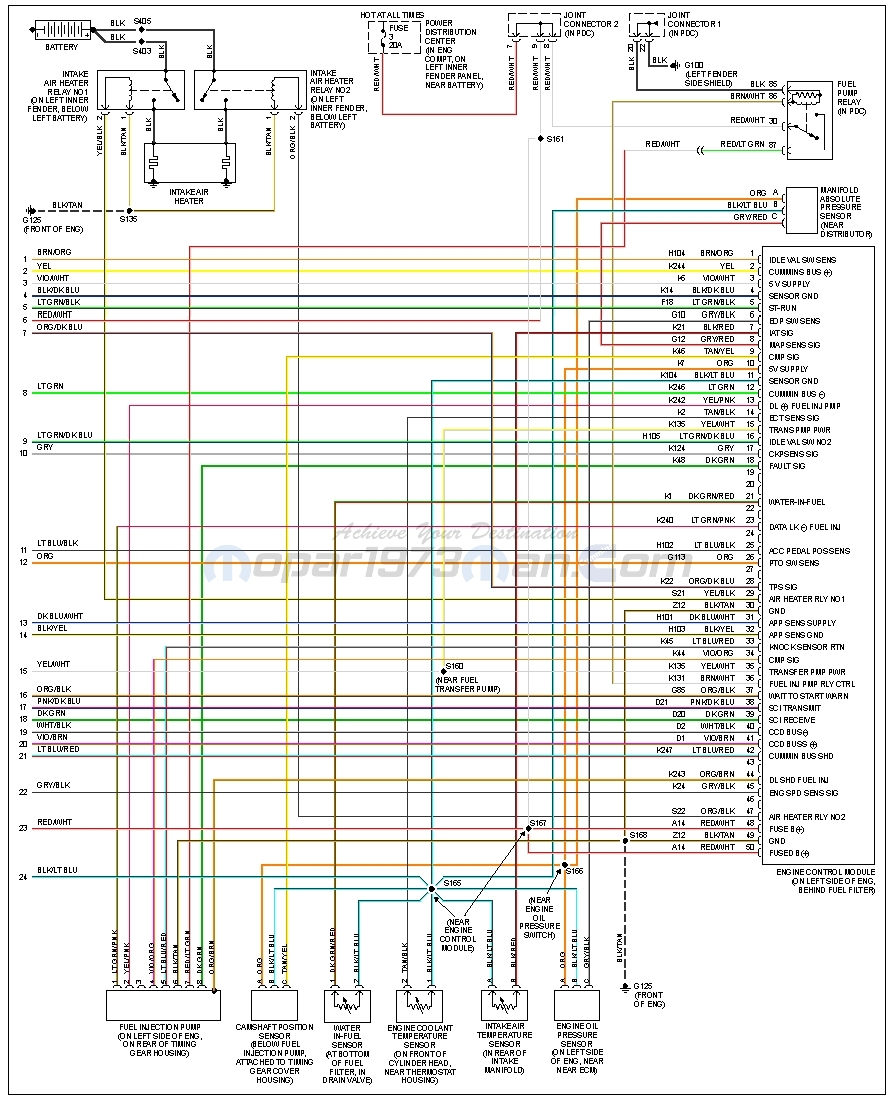

Strange Power relay reseting

+12V power fuse for both the PCM and ECM... Again like I said it could crack and do this random cut off. Fuse #2 also check fuse #10 being it feeds the KEY ON signal. Then the other fuse for key on trigger for both the ECM and PCM here is the other end of fuse #10. Be aware that is not our fuel pump relay it for the GAS series. Then for the VP44 you need to check Fuse #3 in the PDC.

-

Hydroboost leak

But this is a dealership mechanic do you expect them to do anything right...???

-

Honda 2200 w generator and Dometic 1350 btu Brisk 2 air conditioner

I'm up here in west central Idaho with the same kind of weather with super cold winter (low as -40*F), power outages, floods, etc. I do have a generator (6,500w Harbor Freight). The house is completely power off of 4kw 120VAC inverter. Is so rare for me to pull the generator out because I've got solar and hydro power (summer only on the hydro). Even in my case I have a small list of thing I can't power. Stove, Oven, Drier, and HVAC system of the house. I do have wood heat as a fall back. 99% of the time the inverter handle the entire house. This system provide my power even for my well pump. I can be without city power for DAYS or WEEKS on bad storms. Like the 1996/1997 Flood here I was powered on just 4kw generator for over 21 days. It was to the point of hunting for abandon vehicles and siphon fuel for the tanks to just keep the generator going. My system no longer depend on fuel at all. I have eight 6V batteries with total Amp hours of 820 amp hours in a 24V layout with 2 banks. As I type this is the house load right now on the system. Flickering 3 to 4 AC Amps 120VAC. Totally quiet power system... Even my RV is solar powered. Smaller set up with 40w panels and a 1,200 watt inverter again just Harbor Freight solar panels and Harbor freight inverter. I've spent many of night out in the RV with the inverter running all night with watch a movies, etc. My solar panel fit under my bed and store good there. Very awesome ot go camping and not have to pack any fuel at all and no going out and starting a generator or anything. Just peace and quiet for hours on end. This I'll upgrade to two 6V batteries in the near future.

-

Brake Light Switch..."DO NOT REINTSALL"

99.9% of all VP44's are re-manufactured and the body is reused but all the guts typically is gone through. Then the pump is place on a Bosch 815 test stand for 3 hours to calibrate the pump for the PSG unit. After 3 hours if it pass all the test the PSG is flashed with all the settings and the pump is ready. This is only Certified Bosch Rebuilder that do have a test stand. There is vendors like Blue Chip that re-use the PSG and have to ship there pump to be calibrate hence part of the price. This is why I started a Bosch certified list years ago.

-

Strange Power relay reseting

Ummm... not during running when you key on for start. As for ECM and VP44 pump share the same ground on the passenger side battery. Highly suggest the W-T ground wire mod for your truck. Also check the PDC fuses. It possible to have them Crack and randomly shutdown as the fuse opens and then close again. Ive seen that before.

-

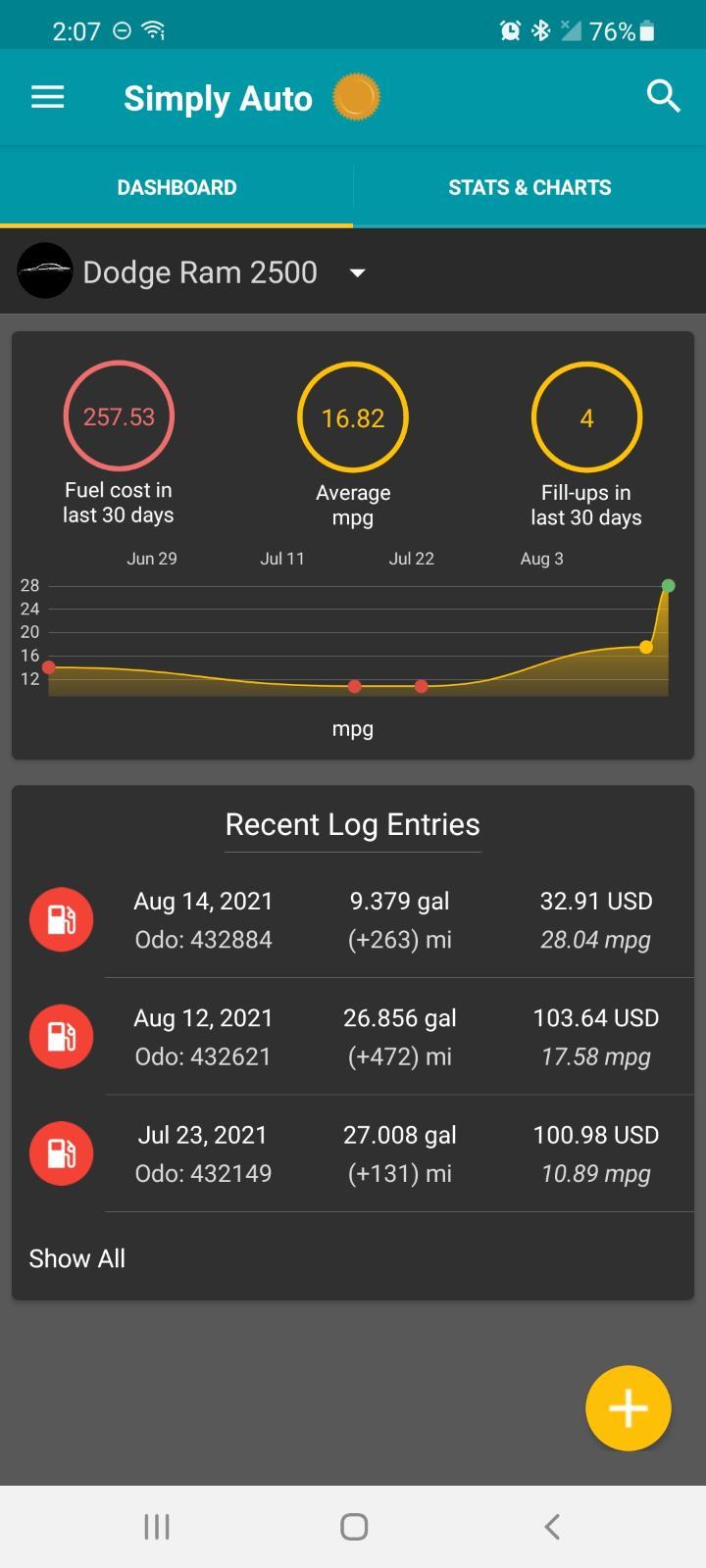

Help; narrowing down on upgrades.

The biggest reason it not street friendly is the Edge Products (Edge EZ, Edge Comp, and Edge Juice has no timing controls). As injectors get bigger you need more retard at launching time to build boost fast (what Edge can't do), then once boost is built you need to advance timing more (again another thing Edge can't do.) I've started back in 2006 with Edge Comp and the biggest thing I hated was the excessive smoke and no way to clean it up (bad timing and fuel maps). Basically Edge just stacks on top of the ECM with extra fuel and timing with no control were you want that extra fuel at or timing. Once flipped over to the Quadzilla problem gone being I can adjust timing to meet the engine needs. This also gave me the record on the site for efficiency of 28.04 MPG. Re-inventing the wheel??? Nope... About making the wheel more round which Quadzilla does and not squared like Edge products does... The other fact is I cvan can place in a nice flat stock fuel area where there is neutral fuel... Again another thing Edge can't do...

-

Lower Ball Joint Flush Style Grease Zerks

The cheap ball joints I got off of RockAuto (non-Moog) are over 200k miles now and still going. Only the upper are grease-able but the lowers are still tight.

-

Strange Power relay reseting

WAIT TO START light coming on instantly?

-

I'm Back, Finally! And I have some good questions/ topics

I just seen a injector Crack on 94 Cummins in less 2k. It was a VCO even.

-

Synthetic 2 stroke oil as a fuel additive?

Like @IBMobile said... I typically hit a Walmart for it.

-

Lil' Red - 1996 Dodge Ram 1500 - SOLD!

Yup you seen that correctly. I sold Lil' Red. Eileen's daughter (Brianna) bought it. I'll miss that truck its what I start my life over with back in 2001 after Devin passed away (Previous girlfriends son). I built my computer business back up and used that truck to get back and forth to work. Being Brianna bought it it least it still in the family. It been sitting under the tree for over 6 months and started up and drove just like it always did.

-

EGR & DPF DELETE

There is correct ways of deleting and wrong ways... All equipment need to be present on the vehicle. Like in how I suggest to do it with a "delete tuner" is the easiest and best. Yeah you might just have to a do a few small mods to do but it not like your removing the EGR cooler, EGR valve, EGR piping, DPF and replacing with straight pipe. All this will remain on the vehicle. Like I said make a steel gasket for the EGR that blocks the EGR passage. Have a gutted DPF and install the hollow can. It will not regen and the tuner shuts of the EGR completely. It will pass a visual inspection. None the wiser...

-

EGR & DPF DELETE

EGR is easy just make a steel gasket with the port passages problem solved. I've done this a couple times on Ford 6.0L engines using freeze plug in the EGR cooler. Computer has zero idea the EGR is passage is plugged.

-

COVID-19 Virus Truth

https://www.facebook.com/pandemicdebate/videos/333725758316346/ https://www.facebook.com/pandemicdebate/videos/822132668672806/

-

EGR & DPF DELETE

Don't take but 5 minute unbolt your good DPF for a gutted... Still in all not huge deal breaker and will not regen. Regardless no many will pull it out to see if the filter is present.

-

P1694 and P1698, Diag help

You can if you wish.