Everything posted by Mopar1973Man

-

Thor might be fixed?

With Beast leaking oil out front and rear main seals, needing tires, and closing in on 500k miles. Beast needs work to keep him going. Mark suggested to try looking into Thor. Luckily my fuel pressure test gauge made it and was intact and undamaged. I checked the fuel pressure key on, engine off, barely 7 to 8 PSI of fuel pressure. Now start the engine, the fuel pressure drops to 2-3 PSI with WOT stab of the throttle. Ugh! Now I pulled the check ball and spring and did my typical spring mod bending the last coil to block the ball from getting in the coil. Now shimmed it with two washers. Barely made 10 PSI. The grid heater light is off. I'm going to replace all the fuel filters see if it improves the pressure and stability. A simple job like this should be much more than a few minutes to fix. When your tools are all scattered and the box is in ruins. We are still missing sockets and tools in the dirt of the yard. Highly frustrating to spend nearly an hour to find 1 socket, 1 ratchet, and just take the fitting out and modify a spring. Absolutely frustrating! Let's see if Thor holds up now. Time and mileage will tell!

-

My Roots, Where did the whole website idea come from?

During our digging around the shop, we found my old Atari 800 computer stuff. Sadly, the computer is most likely destroyed. How does this mean anything? My computer adventure began at a very young age, around 14. My parents bought me an Atari 800 computer. This computer was the starting adventure of communications, even before the Internet was out. I bought myself a 2,400 baud modem and a few other bits and pieces for the Atari 800, but I created my very own BBS. BBS stands for Bulletin Board System. I made a deal with my parents to take over the phone line at night after 6 pm and run the site till 6 am. I created all my own software between the two cartridges above. The basic language was what I ran for the BBS software. Then the Assembler Editor allowed me to create and edit even current software. Back in 1984, Fidonet was just getting started, and I was working on adapting Atari Basic software to get Fidonet node messages and download all my messages for my BBS. This was my start of communications back in 1984 using an Atari 800 Computer, an Indus GT floppy drive, a 2400 baud modem, Atari 835 UART to Serial, etc. By the time I was finishing ITT Tech in 1989, I had built my own voice reader for my message coming off of Fidonet. Shortly after that, I moved to Idaho and then started Cloud 10 Computers. I was a computer technician till 2008 when the market crashed. During this time, I was building and selling computers for the locals around me. I was good with Windows right up to the time of Windows Vista. This is where I made the jump around 2010 and switched over to Ubuntu Linux and continued my adventure into the communication world using Linux software, as I still do this very day. I figure you all would love to see how a kid back in 1984 playing with a computer became the owner of Mopar1973Man.Com and still maintains the server on my own! Ubuntu Software version list and release dates - I started with Ubuntu 10.04 LTS then currently using Ubuntu 24.04 LTS https://wiki.ubuntu.com/Releases As for web server software, I have used CentOS7 Linux and now AlmaLinux 8 Linux https://upload.wikimedia.org/wikipedia/commons/1/1b/Linux_Distribution_Timeline.svg As a side tidbit the 2008 market crash was also a switch where I dropped Cloud 10 Computers and switched over to working on the website and Mopar1973Man.Com LLC as a shop and doing diesel repairs. Sadly I was pushed pretty hard to keep up during my @MoparMom kidney failure doing 5 years of dialysis to keep her going. She pasted away in 2020. Then twisted with my start of cancer in 2018.

-

Mysterious Knock on VP44 Truck – Need Help! No one can figure this out!

@Sufarry Did you test end-to-end on each, checking for 5 ohms or less? Did you check for wire damage or crushed wires?

-

YouTube, and more...

Hey Gang, I just spent some time going back to YouTube and doing some tweaking to my account. Now my Mopar1973Man.Com videos are still there, and I'm going to start building videos in the near future for articles. I'm going to still have to do repairs with what I have so this is going to get interesting working in the yard, doing repairs on Beast and Thor both in the wilderness of Idaho. Currently, the last few days here have been right about 95℉ to 108℉. Yeah, I'm going to be doing brakes on the rear axle, being the slide pins got bound up and worn the pads down pretty quickly. But Yeagh, I've got to keep vehicles running and do the repairs for now. Time to dig out the GoPro and do some video work. Mopar1973Man.Com YouTube Linkhttps://www.youtube.com/@mopar1973man Now, since Titanium is my new character (Emo Goth / Goth). I took my old personal account, downloaded the few videos off of it, and then renamed the account to Titanium. Titanium Social Media Linkshttps://www.youtube.com/@titaniumgoth https://www.tiktok.com/@titaniumgoth I'll start filming my makeup artistry here in the Titanium account. This is my Goth character I created to help me deal with my second run of bladder cancer. You all have to realize that the very thought that I could die from cancer this time. Instead of letting the depression eat me, I fought back with Titanium and won the hearts of my medical staff. Then, after the medical was done and I survived the odds, I started to enjoy the reactions of people with Titanium.

-

Tracing disappearing oil

You could have rebuilt that turbo for cheap. Diesel Auto PowerHolset Genuine Rebuild Kit for HX35 and HX40 - 3575169Check out the deal on Holset Genuine Rebuild Kit for HX35 and HX40 - 3575169 at Diesel Auto Power

-

Tracing disappearing oil

Basically the only places I can see oil loss happening. Valve guides/valve seals. Piston rings/piston clearance issues. Turbo shaft seals/bearings.

-

Flashing WTS light

REMEMBER do NOT remove all the paint from a ground location. With both of us here in Idaho salt off the highway will make the matel rust and fail for the ground. Make all bare metal is painted before reattach the ground. Really sucks that you find the wire just hanging from rusted chunk of metal.

-

Tracing disappearing oil

Valve guides and valve seals can leak oil some but typical not much because normal both exhaust and intake are under pressure. Like Beast long run downhill like my last trip to Heaven's Gate then I see the blue oil smoke as I throttle up from the bottom of the grade. Typically that how valve guides oil leak is seen. No blow by issues but leak oil past at zero pressure moments like running downhills.

-

Death wobble for the 1st time ever in a 2nd Gen Cummins

Assuming this repaired the problem? Could you mark your post with "Mark as Solution" this way other members can see your solution to the problem.

-

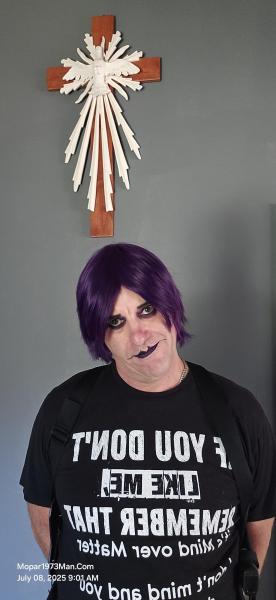

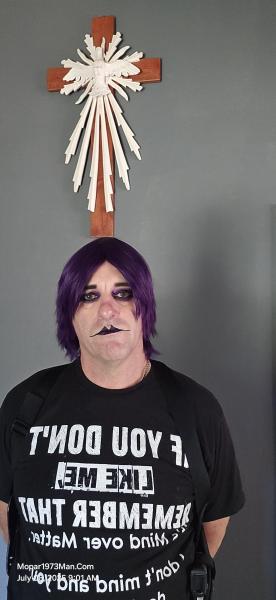

Titanium goes to town

@Tweety Bird and myself were not feeling well last night, so we slept long and hard. I got up this morning and she was requesting I head to town and get hamburger buns, and we would have something simple to eat for today. As usual, my local people know me and always love the makeup and the effect it brings to people. A couple of the female store employees have colored their hair green and purple. I always give people compliments about their appearance, and I always get right back as well. As for my appearance is with the purple hair again and similar makeup as my previous blog post. Left the grocery store and headed for the fuel station with Thor. Yeah, I've still got an injector issue, but I needed to bring home fuel in that truck as a fallback. I crossed paths with an older lady, and she looked like the outdoors type. She commented on my hair and appearance. As always, I thank the person for the comment. I put my fuel into Thor and saw her return and start to chat with her as my fuel was just completed. Find out we are both ostomy patients and she was highly impressed with my positive attitude for a person who survived bladder cancer twice, getting married this summer to @Tweety Bird and doing makeup artistry that most people think is impressive. I darted back to Thor and grabbed a business card for contact info, and often to share my knowledge of my ostomy journey to hopefully aid her. My own journey with losing the shop, digging to find anything that might have survived the mudslide. Trying to keep things around here in good repair without tools is rather tough. Slowly, we are trying to order the needed tools and stuff right now to keep even the internet and communications going. Yeah, I found a damaged CAT5 cable and am attempting to keep the WiFi going in the house. I got interrupted by Mark's dog barking, and it was the mail lady who 4WD around the outside of the debris pile to deliver our mail today. I told her Thank you for getting the mail to the door for us. She was even asking how we are doing and gave her a more detailed rundown on what's up and going on.

-

Flashing WTS light

Just remember just one wire pinched in behind part, bolt, or bracket could do it. I had one where the PCM burned up because one wire was rubbing on the trans dipstick tube and fried the voltage regulator.

-

Performance Tunning for the Website / Server

I'm back at it again. I'm looking to make this website a hotrod as well. Still having issues with the Total Blocking Time of JavaScripts. I'm playing with the Google Pagespeed Module now on the server to help clean up the wasted bandwidth on unneeded things. It's all about being able to trim off the unused code and compress the required code, and get it sent to your desktop, tablet, or phone quickly. Part of this might take some time as the pagespeed module learns and creates methods of saving bandwidth and time for all of you surfing here. I will say for the most part, the CLS (content Layout Shift) is corrected, and it was the Google AdSense attempting to lay down ads and skew the page by pushing the content down, and there is a score system to this. Currently, through my testing, I'm well below the threshold of a problem, but my biggest move, which is tiny 0.02, is looking for the staff banner. Not bad, I'd say. If anyone is having issues, please make sure you contact me in a private message here. I'll make sure to look into any strange behavior.

-

Crankcase oil volumes

I wonder ifthe dipstick was traded from another truck by accident and the level is now incorrect. The only other thing I can think off is a ton of sludge in the engine but most likely not true here. At least I hope so.

-

Flashing WTS light

Were there any steps required for testing or repair on your side before the installation of the ECM for the first time? It sounds like there was more internally wrong with the ECM, but I still wonder if there was something in the wiring of the truck that could have created this issue?

-

Pilothouse/RAM3500 build

What? Paint? What color(s)?

-

Strap to U-bolt conversion

The only thing I can suggest is contacting https://idahodrivetrain.com/ . You should be able to get information from them,

-

Off to see the insurance company

Oh, today was an awesome day. I had two younger gals walk up to me and read my shirt, and then they wanted to pose with me in the Albertson's store. Then several others made comments on my appearance. I really do have an enjoyable day just being all dressed up and in makeup. My shirt says, " If you don't like me, remember its mind over matter. I don't mind and you don't matter"

-

Drop rpms

Technically, the coolant sensor will control idle, but only in an OVERHEAT condition, it will drop existing RPM by about 400 RPMs. This is not the solution, but a normal reaction. I found this way back in the day by using a rheostat to vary coolant temperature. Just to let you know, this is a normal reaction to the sensor unplugged because it's a high volt code (+5V) and the ECM reacts accordingly. Still, you have an APPS issue, most likely on the APPS sensor is not providing a proper idle validation signal. This will force the ECM to drop the APPS sensor signal and run the Cummins idle software, which is a perfect 800 RPM's. Now the only other way to raise idle is bad injectors. If your injectors have over 100k miles you need to replace the injectors being as pop pressure falls and idle speed rises. I've seen trucks idling at ZERO percent engine load and idle speed of 900 RPM, being the ECM cannot cut fuel any deeper, and idle cannot be obtained.

- 20250708_090224.jpg

- 20250708_090151.jpg

- 20250708_090133.jpg

- 20250708_090129.jpg

- 20250708_090118.jpg

-

Off to see the insurance company

Yes, I'm off to McCall, ID, to meet with my insurance agent and review the actual insurance policy, word for word. Just to give me a boost today, I went a bit more like Clown Goth. I've a few other stops today, including picking up medications and doing some other shopping. I've got several fans in McCall who enjoy my makeup work and love the reactions of people. Oh, check out the gallery photos. I've got a new shirt. Gotta keep building my character up. I'm hunting for a second shirt, but still searching for something particular.

- 20250708_090224.jpg