Everything posted by Mopar1973Man

-

DDRP

Be aware some of the DDRP pumps have smaller plumbing ports than the full 100 GPH or 150 GPH pumps. You can increase the line size but the port will still be a restriction.

-

Door Lock Fob

As far as I know, the dealer is the only option. There might be some 3rd party stuff out there but I've not seen it yet.

-

Turbo options and opinions

Need to see want data is being fed to the ECM. Voltage won't mean much it the data that ECM process into fuel and timing.

-

Brake upgrade option & opinions

100% on exhaust brake my average brake life is 200k miles. 90% of my stopping is done on a exhaust brake. High end pads will eat the rotors quicker. Ill post more tonight.

-

Turbo options and opinions

Easier yet hook up a live data tool look for change of value.

-

New to the forum

You have to change boards either direction. Up to 4K or down to 3K. There is a hardware difference.

-

Airdog low pressure

So, that bounces you back to pressure regulator on the AirDog/Raptor.

-

Airdog low pressure

Now think a second... That larger spin on water separator with all that screen area vs. a little piece of screen stuffed in the inlet of the Raptor pump.

-

Airdog low pressure

-

New to the forum

I gather with that monster of an engine you did the Quadzila 4k box correct? If so that is going to be night and day difference between Edge and Quadzilla. I know we don't have any tunes for the 4k series on hand but between @Me78569 and @Quadzilla Power I'm sure we can get you started on tuning that Quadzilla.

-

VP44

Absolutely... That is the best time to do it. It only took another 20 minutes to remove the other tidbit and slap that tappet cover on with a fresh gasket,

-

New to the forum

Came to the right place. Would you be willing to explain your signature a bit more? 6.7L VP44? Seems like a heavy modified engine.

-

Can you stop battery corrosion?

Back in the 70's when I was growing up I use to see a thick coating of bearing grease on the terminals. I would rather use the fluid film or PB blaster.

-

manual boost controller

Same here... I've got a steering box that I more or less turned into junk.

-

manual boost controller

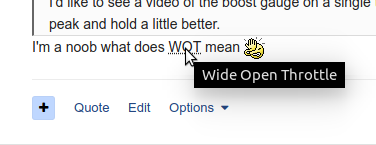

Anything with a dotted underline just hover your mouse on the word and it will show what the word means.

-

Oddball 24V DTC's active.

ECM fried... P0606 code present. That being said now you need to test the alternator for excessive AC noise then you can ship your ECM off to the rebuilder.

-

manual boost controller

You did the standard shipping. I did the expedited shipping for the US. Bit more money but mine will be here on Friday.

-

New guy here

Black smoke just means your wasting fuel and your providing too much fuel for the amount of boost. This is a very good thing your fuel amount to boost is just right. For sure need to install a better fuel supply system this is not making the grade for you. You want to have 14 PSI at WOT running down the highway at its lowest.

-

manual boost controller

I'll most likely just buy a 1-foot chunk of hose and loop on one end short piece on the other.

-

Borgeson steering box

I'd rather keep the Saginaw box. Easy to rebuild and make tight again.

-

trreed's upgrade thread

Ok, it just did... Now what?

-

trreed's upgrade thread

... eventually, @TFaoro will just sell the 2nd Gen because it broke all the time.

-

Craigslist woes

You might keep an eye on the apps your using and what possibly causing the radios on your cell phone to crash. I've got a weird issue myself where my WiFi shows good strong signal but does nothing. Reboot the phone and it all good. Some times with the Quadzilla it refuses to start back up the App. Shut off the Bluetooth radio and turn it back on... Work fine. Just try to be aware of the app that you using if you got some that 3rd party questionable you might try for a different app or disabling to see if this stops.

-

P0122

No. Turn ignition key OFF Disconnect batteries Turn key ON Wait 5 to 10 mintues Turn key OFF Hook up batteries Do APPS relearn process.

-

Craigslist woes

I don't use Craigsist at all. According to what I read you have to create a whole new account. The reinstating the old account is locked forever. There is a long list of DO NOT do'es that will get your account IP locked.