Everything posted by Mopar1973Man

-

Painting Valve Cover

Sounds like a solid plan. I don't think the valve cover is much more than the standard 190*F to 210*F in temperature at the worst. It should hold up to the temperature being there is several other trucks with paint matched parts under the hood.

-

Need a sanity check.. changing careers

Something to consider like myself since I'm self employed as well. Like here locally the money isn't here in the Riggins, ID area. I've still got to wait till the snow leaves the McCall / Donnelly, ID area and that will be some time yet. I've been traveling day trips to do jobs around my local state. Even that is getting questionable now with the "Russian War" and price of fuel heading up quickly. Now I'm considering looking toward web support more so being that travel is going to get super expensive. Idaho diesel prices are heading up fast and talks of 5, 6 or 7 dollar a gallon diesel prices coming soon. Now I'm keeping an open mind of what and where I'm even doing for employment being I want to keep my expenses low.

-

Bosch Alternator

I started out with a Bosch alternator from factory. Now after the first failure back at around 200k miles I replaced with ND alternators either alternator will hold up as long as the W-T ground wire mod is done. Without the W-T either Bosch or ND alternator will fail and typically take either the brushes, slip rings and/or the diodes out. After that I've had good luck with both ND and Bosch alternators.

-

How long to change injectors?

Tuning and driving style make impacts that may or may not improve MPG numbers. Like the combo I done with the Quadzilla tune and 150 HP injectors popped at 320 bar this made 28.04 MPG. Like the last time was 75 HP injectors and Edge Comp tuner but there was limitations. Still made 27.2 MPG. Secret is keeping the Engine load and Engine load low as possible. Anything that creates heat is where the power is lost at only because any thing creating heat is steal some of the energy to create said heat.

-

Pilothouse/RAM3500 build

Got my vote I wanna see this vehicle too.

-

DAP Hot Rod VP44

No. Don't bother with a hot rod pump. Only roughly 20 HP gain. Makes a problem for tuning being the hot rod pump mechanically advanced internally. Better of with stock SO pump

-

Head studs, valve springs, what else?

Me I only run 7 levels being it splits the wire tap up by 25% per level. Actually level 2 is the best for MPG. Level 3 is better for all around driving. 4 and up is all wire tap. Again the biggest feature to my tunes is no extra power is giving below 15 PSI which makes for more daily driver fueling. Now if you in it for performance then you should make a second tune that is economy and then the other for performance so you can pour on the fuel early and heavy. Then like when spring get here I'll be towing my RV more and have a 3rd tune for strictly for towing. So power levels... 0 - Stock ECM 1 - Valet mode 2 - Stock Fuel no added fuel above 100% 3 - CANBus fuel 4 and up is all wire tap settings. You can break this up and have 10% per level or anything in between.

-

Head studs, valve springs, what else?

I've been doing the chat on the phone and build tunes too. I've helped @Sycostang67 build his tune. There are a few here I've been helping setup Quadzillas and diagnose performance issues.

-

Head studs, valve springs, what else?

There is articles on how to build tunes here in the article section. Then in the download section there are some pre-made tunes including my current tune I'm running.

-

Head studs, valve springs, what else?

I run level 2 and can still smoke the tires. Tame ha! Now go 425 miles on a half tank of fuel.

-

Head studs, valve springs, what else?

Stock tune is pretty derated in timing. Once you build a good timing curve it will be even better. Fuel map is fairly easy but there is a few tricks.

-

Need a sanity check.. changing careers

Same here I did my own service all these years to keep my Mom alive. My part is I feel guilty for just doing my job and not doing it slower and doing write ups like I did in the past. Part of that is the weather and the mess I'm still dealing with between my ex-gf and her son. Now I want to get back to what made the website great too. Start doing 3rd Gen write ups.

-

Winter weather - What do you see where your at?

Well finally might get above freezing from here out. Highs near 50°F and raining maybe 0.1 to 0.25 inches. Be nice for once be like a heat wave.

-

Need a sanity check.. changing careers

I know the feeling at times. For me it the point that I can't go any where without someone asking me about their truck or vehicle. The other half is just being greasy dirty everyday.

-

Gooseneck hitch

Wow. You need to get on a creeper and roll under there a bit more often. Seriously...

-

Tire pressure loaded vs empty

Yup. One the scale it's 7,300 pound empty curb weight. Just added the two numbers together.

- W-T ground wire mod - Simplified

-

Tire pressure loaded vs empty

Door sticker is inflation for max weight capacity. Kind of like my truck 65 PSI in the front then 80 PSI in the rear. Now doing it correct. Front axle is 4,440 pounds, and 2860 pounds in the rear. Tires are Es with 3,042 PSI at 80 PSI. (4,440 / 2) = 2,220 / 3,042 = 0.72 × 80 = 58.3 PSI Front inflation (2,860 / 2) = 1,430 / 3,042 = 0.47 × 80 = 37.6 PSI Rear inflation Smooth ride and no impact on performance or economy.

-

Rear Trans seal NV5600

Nope. That will work but make sure to make a sleeve for the inserting of the new seal. I think I got a chunk of exhaust pipe wrapped electrical tape around the edge for padding.

-

Winter weather - What do you see where your at?

@Silverwolf2691 hey if I want to know what is coming at me I just call @JAG1 he gets the weather before I do.

-

Last job I'll ever need...

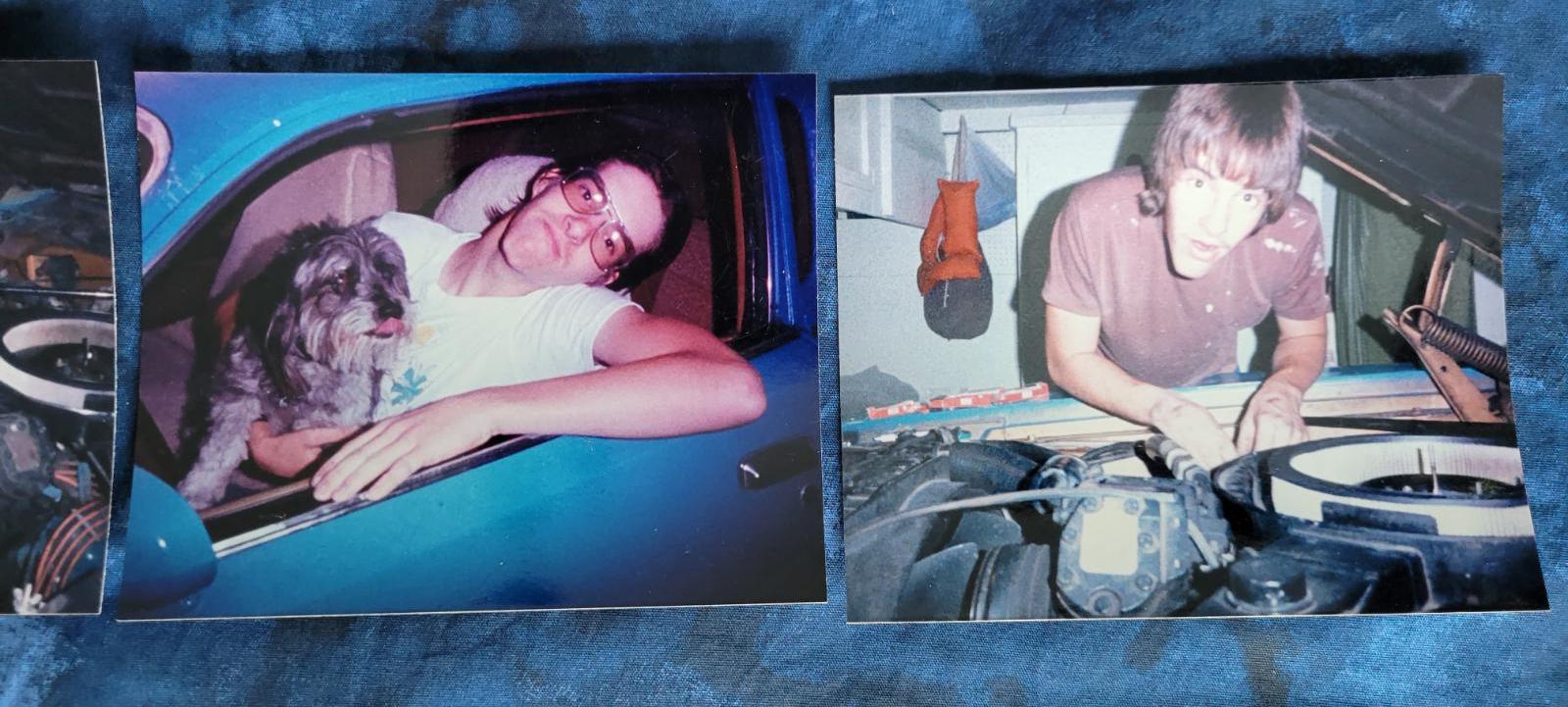

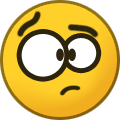

I did and was going through my parents stuff and found all the photos. So time machine back to 1987 and I was 17 years old work on my 1973 Dodge Charger SE.

-

Brakes - Check your hardware too

You want a bit of slack in the cable to ensure that the brake arms are returned FULLY. Now you can adjust your slack in the shoes using the starwheel. Once the brake shoes are lightly dragging. Now you can re-adjust the cable slack till it is just about ready to pull the cable. Why? Because I've seen cases where people adjusted the parking brake using the cable slack adjustment and have the cable pulled half the stroke and wonder why it will not hold on a slope. You gotta make sure the brake arms are FULLY returned before adjusting the slack of the shoes. Now you get a full pull and the truck holds much better than just wheeling up the slack adjustment and find out you only getting half pull and won't stay parked.

-

Last job I'll ever need...

That job right now is closed till spring time. Being McCall / Donnelly is still cold and snowing and I've got to work outside no shop. I still do small task for the group but right now its just been cold and slow for everything even here. Again this morning looking at the weather tower and 17*F this morning there is nothing at this time that requires me to head out in the bitter cold it can wait. After doing a start 2 days ago on a 7.3L Ford I was have issues in a very short order trying to even pick up the tiny 8mm nut for the starter because my fingers froze up quick. Gloves... Worthless then I lose all my dexterity so right now I'm just holding and waiting.

-

Brakes - Check your hardware too

Starwheel is use to take up slack in the shoes to drum clearance. Do not adjust the cable for this. The cable adjustment is only take slack out of the cable. This adjust should allow for full return of both arms in the hubs. If not it's TOO TIGHT.

-

W-T ground wire mod - Simplified

W-T is suggesting adding a second ground across the radiator to the driver side. Measuring voltage drop between the battery and block won't change. Way to test, is use jumper cables and jump between both negative terminals and check for volt age drop again. So far I've not found any gains.

- 35 comments

- 5 reviews

-

-

- 1

-