Everything posted by Mopar1973Man

-

Happy b-day Prowelder

Happy birthday... Get round for ProWelder <- Prowelder

-

Thank you 2 stroke!!

Here is the tested list... The lower the HFRR the better... http://mopar.mopar1973man.com/cummins/general/2-cycle-oil/hfrr/hfrr.htm As for me I'm getting ready to clear 100K miles using 2 cycle oil. No problems here...

-

Turbo Wastegate and heater relay Questions

Wow! I bought mine from Cummins and got the MAP sensor and adapter harness for $130... (Tip for the future)

-

Live Chat

-

Happy Halloween!

Back in California I use to lay in the front seat of my Dodge Charger with the CB and PA on and wait for the kiddies to walk up to the front door then I would growl or make scary noises... Most wouldn't stick around they would bail...

-

Air Dog Raptor

The only reason I mention having the filter first before the pump comes from a injection shop in Lewiston, ID that discussed the functions of the FASS and Airdog. According to him a filter works best under a vacuum instead of pressure. But that was his information...

-

Turbo Wastegate and heater relay Questions

If the code returns instantly with the key just being turned on them most likely the MAP sensor is toast...

-

Live Chat

Sound good to me...

-

mechanical or electric gauge

Both are good gauges and both need to be protected from the water hammer so either way you go your going to need either a needle valve or a snubber... The only downside to electric gauges its possible to be inaccurate from poor wiring connections.

-

Live Chat

It's all good... But I like the idea of getting a chat together in the evening... But more I think about it there has to be a schedule for each time zone... Or every time zone is the same time? So if you say PST is at 6pm then EST would 10pm so it to late... So say 6pm for all timezones but each time zone has a different night?

-

Replacement Dodge Keys?

The the spare key I keep in my wallet my local hardware store cut 5 keys and the 6th one finally worked...

-

Starter Contacts

Flat ground...

-

Live Chat

Ummm... There is a calendar function here that we can play with... http://forum.mopar1973man.com/calendar.php?c=1 But now we need a least a 2 hour span to be nice for people at far extremes of the time zones like pacific and eastern... If your not careful you might end up taking care of scheduling the weekly chat... --- Update to the previous post... That's not a bad idea... We got the notice banner we can use or if it really starts to fly we can make a ad banner that is advertising on server...

-

Starter Contacts

Yes... It actually reduced the miss to hardly there... I had a new connector tube here and stuff it in the hole... Well in my case the stock contact wore un-even... I know I post earlier the load side was wore... My Bad it was the battery side that was wiped out. The plunger and the load side were fine... So now with my extra contact and the old one I wire brushed then and put them away for spares...

-

Turbo Wastegate and heater relay Questions

PM Sent.

-

common - u serious ?

Timbo is a member of the site too... http://forum.mopar1973man.com/member.php/10225-Timbo Send him a PM...

-

a/c airconditioning compressor - not engaging - warm air

-

Happy Halloween!

I'm no dummy...

-

Turbo Wastegate and heater relay Questions

Yeah the grid heater solenoid on the fender has most likely got a wire pull off or has failed... http://mopar.mopar1973man.com/cummins/general/grid-heater/grid-heater.htm As for the P0234 it saying the MAP sensor is working fine but the wastegate is jammed close and not operating properly. P0236 is saying the wastegate was jammed shut and the boost stayed too high too long for typical function. But there is 2 conditions here that might be occuring... a. The MAP sensor failed within specs. In other words the boost value is stuck at a high number and no longer changing. This can bee seen with a live dataa tool like ScanGauge II. b. Your wastegate is physically jammed and needs to be delt with. Then you been driving with a heavy foot and/or pulling heavy trailers.

-

Rubber Floor Mat and vinyl or leather Seats

Here is my cheapo WalMart Specials... $30 bucks... I'm still using me stock floor mats from the dealer...

-

Happy Halloween!

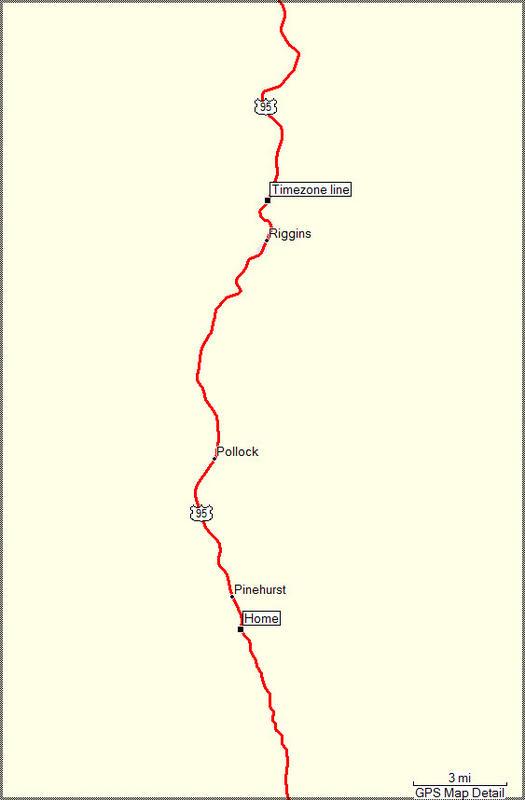

Yeah... They all go to the Riggins to go around the one and only square block in Riggins... Takes only 1 hour...

-

Starter Contacts

Mine failed at 177K miles. I think a lot of that has to do with the fact of starting and stopping alot on the mountain doing firewood. So you might move the truck 6-7 times during loading process. I never leave the engine run while sitting on a steep slope. I typical shut it down lock the parking brake and grab 1st gear. As for my grimey brushes I got that cured too... It was #5 injectors leaking on the manifold very little (weeping more like it) but it was enough to make it to the starter and make a mess.

-

Happy Halloween!

I live in a non-trick or treat area...

-

Replacement Dodge Keys?

No idea... Subscribed... I need a new key anyways...

-

Want to upgrade ...in stages

So with only a 5-10*F jump I'm sure the intercooler and deal with that...