Everything posted by Mopar1973Man

-

Help 911 Diesel Down

Thanks for the great conversation! I got another thread started to see if I can pull information for ya... http://forum.mopar1973man.com/showthread.php/2908-ECM-rebuilder-shop-information-needed!!!?p=21984#post21984

-

ECM rebuilder shop information needed!!!

Hey Gang... I've got a member here that is looking for information on ECM shops/rebuilders that could possibly test and repair a ECM. I'm sure there was a few threads out here but I'm looking for currently good shops... Yeah I know there is a few of "Bad" shops too. Lets here it guys... Oh... If you want you can post you information to... http://forum.mopar1973man.com/showthread.php/2897-Help-911-Diesel-Down?p=21913#post21913

-

Truck shudders with performance chip

Ok... Try removing the box and the problem disappears right? Then that points to a issues with the phyiscal electronics of the box... (Most likely). Or maybe a bad connection somewhere?

-

OK guys, my engine stalling when the put in drive is back with the winter fuel blend.

I talk to a gent in New Meadows that rebuild trans... I explain the problem to him and he's pointing the finger at the torque converter which has excessive drag or the lockup clutch is binding up and not releasing properly.

-

04 Subaru short low beam life

Bulb heat? Are the bulbs getting to hot and failing? That's the problem I got with my 100w bulbs on the bottom of the bumper. According to NAPA they have had a issues with mine about the bulb getting to hot in the rubber buckets and blowing the filaments. Usually notice this by a burn mark on the reflector. So hopefully it will give a clue...

-

AirDog - Blowen Fuse

That's the thing if it was a short it would blow fuses instantly regardless of the amp rating... The fact he's getting a short span of life then pop tells me there is something draging the pump motor down. Maybe bearings?

-

Forest Fire

You need pecan oil... http://forum.mopar1973man.com/showthread.php/2072-Diesel-fuel-vs.-pecan?highlight=pecan

-

Forest Fire

Word to the wise the safest place it to be standing in the black... It can't burn twice...

-

who wants to rebuild thier VP44????

That issue is normally cause from low fuel pressure... At this point the flow past the electronics is reduced and the cooling factor is reduced hence when you go to WOT operation and the electronics really need to stay cool the fuel pressure typically falls and the cooling stops. Being the fuel is the only way to cool the eletronics you need to keep it flowing past the electronics. So if the overflow valve starts closing at 14 PSI and should be completely closed by 10 PSI then I highly suggest you never let the fuel pressure fall below 15 PSI on a WOT...

-

How to get lower egt's

True... But what I'm getting at is that most people set everything up too low.

-

Air Filter

The only reason why I got rid of mine is because of the plastic box... On mine I started to do inspection of the cover lid and finding dust trails where the plastic started to deform and allow dust and dirt to sneak past the filter. The only way I found to stop that was to grease the rubber lip of the air filter. Now this is plain messy. So since I bought my first BHAF 7 years ago and put 126K miles on it... I'm still waiting for the filter minder to move I've tested the filter minder a number of times and it works fine... But the filter just never wants to plug up. So buying a $47 BHAF from Vulcan Performance is the best money I ever spent on a Air Filter.

-

This years Bull....

Dang... That is nice... Elk meat...

-

ABS light coming on when first crank up?

All I can say is check all your wiring and grounds... The ABS module on the older truck is right on top of the trans hump. But becareful and disconnect the batteries for at least 15 minutes before messing with any connector. This will prevent a accidential discharge of the ABS system.

-

Want to upgrade ...in stages

Just not fond of the addon's... Edge Comp and Edge Juice with Attitude are exactly the same software and performance. Just that the juice has all the extra toys that most people mis-adjust the setting and then complain about poor power and performance. The other problem is that the Edge juice relies on the stock sensors for all it gauges (expect pyro, trans temp, and fuel pressure). Like a hidden secret is that stock MAP sensor will not exceed 40 PSI. so if you start building into bigger toys the Attitude comes up short for boost gauge... Yeah I got a Edge Comp... And got gauges...

-

Air Dog Raptor

I say before the pump then your protecting the pump from debris as well...

-

Want to upgrade ...in stages

Here is what I think about the Edge Juice... http://forum.mopar1973man.com/showthread.php/2867-How-to-get-lower-egt-s?p=21792&viewfull=1#post21792

-

Live Chat

Nope... It was absolutely free... Just another addon to the site...

-

Seen these videos?

Those are cool so far but I'll help everyone out by reposting the videos... http-~~-//www.youtube.com/watch?v=UPNMLTlhv4M http-~~-//www.youtube.com/watch?v=UFdSQIxbAz4 http-~~-//www.youtube.com/watch?v=ihxN6j3aljk http-~~-//www.youtube.com/watch?v=Cq_irnpDyOM

-

How to get lower egt's

The way Edge Juice works is that it starts defueling way before the set limits. So let say you set EGT limit at 1,200*F so it might start defueling curve at maybe 1,050*F and works it way up to full defuel by 1,200*F. So it like you'll never notice it... So in your case it about the Max Boost setting, Max EGT setting, and the amount of backdown %... So if your going to be like the Edge Comp (no limits) you would set the backdown for 0%... The backdown setting is how aggressive the defuel curve is 0% being none and 100% being full fuel cut.

-

How to get lower egt's

No... The boost fooling of the Edge Comp would continue to keep fuel till the throttle is released... No limits or alarms. Like the Edge Juice and it limits and alarms. I'm not to fond of... Like this example that is common here... Stuck behind a slow truck or 5th wheel. You see a passing lane open nothing there and BAM! you drop the hammer and start your pass. Then around the corner ahead of you a fast moving vehicle is coming at you. At that point would you want Edge Juice to say "Oh! Your EGT's and boost are too high time to defuel!" I'm glad I don't have that limiting junk I rather push the EGT's to 1,400*F and/or 40 PSI of boost for 15 second to finsh my pass safely than to loose all the power because of a Edge Juice trying to protect the engine...

-

MPG on 3rd Gen towing more than 7500 lbs

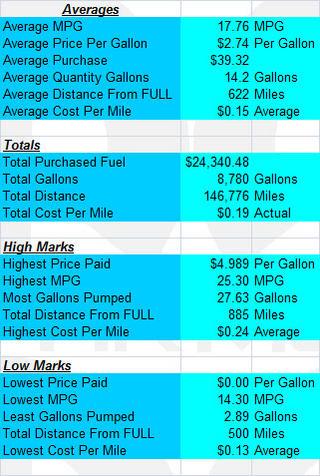

I'm going to toss my in here... In all my years of driving my truck and towing everything from flatbed trailers with vehicles (pickup trucks, backhoe, firewood, etc) I've never recorded a MPG lower than 14.3 MPG even in all the miles I've got fuel logs of...

-

Air Filter

I heard of a few people making a BHAF fit a 3rd gen but you got to do some plumbing work to get here... http://www.cumminsforum.com/forum/3rd-gen-performance-parts-discussion/332510-bhaf-part-s-tips-06-a.html#post3488064

-

who wants to rebuild thier VP44????

Another place is to call a dealer and find out who does the stealth plate it comes with one of the bits you need...

-

How to get lower egt's

Yeah like the early trucks like 98.5 and 99 were HX35 on the automatics... Even crazier yet... The older 1st gens had H1C turbos with 16 cm2 housings... I've seen a few without a wastegate because even at full throttle it couldn't build more an 15 PSI and about 800*F EGT's... Like Taz here has a 1992 Dodge with a HX35 turbo even with his pump turned up (way up) and towning a 30 foot jet boat to Lewiston, ID he never got over 1,000 *F worth of EGT's... He can bury the boost gauge on common though... Some to still think about...

-

who wants to rebuild thier VP44????

If I remember right you got to get a really special torx bit for this... It's a 5 point instead of 6 point torx... A buddy of mine had bought of set of bits and happen to have this in it... 99 Cent store thing...