Mopar1973Man

Owner

-

Joined

-

Last visited

-

Currently

Adding a Blog Entry in: 22f42d6e7cff40b3127d14861f5b744c

Everything posted by Mopar1973Man

-

Hello

Welcome to the site! There is no such thing as a dumb question we are all here to learn from each other... Congrads on your first injection pump install and hopefully you can catch one of the high mileage member with time. Jump in and get your feet wet...

-

Heading towards Sandpoint Idaho...

Not by much...

-

windshield wipers

See the poor mans ideas always come first because what do you have to lose in trying to fix the old wiper motor? Nothing its already broke so if you fix it (even with a bandaid) your ahead...

-

Heading towards Sandpoint Idaho...

Your next on my trip list head towards Kuna ID...

-

Heading towards Sandpoint Idaho...

Well Gang... I'm going to make a fun trip to Sandpoint, ID... Just to say I've done it... Never been to Sandpoint or the Canadian Border but I figure it would be fun to just haul up there and wonder around... I've pulled my side racks off and got the topper back on and my carpeted deck and utility draw back in... So I'm ready to travel... (Older pic)

-

Diesel fuel vs. pecan

Your not the first to tell me that... But its all good...

-

Another load of firewood.

THANKS...

-

Over engineered boost regulator

Ok... Now your done with both alpha and beta stags of design lets see a test run...

-

windshield wipers

Well the cheap side of me says to pull the wiper motor off and see if you can fix it. The relable side of me says to just replace the wiper motor... Price is $65 bucks at NAPA and there is a core charge...

-

windshield wipers

I'm assuming the wipers stop on the glass and that's it? That would most likely be a broke reed switch in the wiper motor. I've had this exact same problem on my 1973 Charger SE. When I took the motor assembly apart I found the reed broke off intenrally. I end up just replacing the wiper motor...

-

Over engineered boost regulator

Ok.. Where is the test run?

-

horesepower

Yeah you be really close to around 300 HP on a guess...

-

horesepower

Factory HP for a 98.5 was 215 HP at the flywheel. Well as for where you stand HP wise. There is a lot of factors that will affect a dyno run. Size of tires, dually or single rear, brakes dragging, clutch/TQ Conv performance. The quick and dirty way is a SGII it got a HP display function on it... http-~~-//www.youtube.com/watch?v=dP11AVA8ly0 Pretty darn close to what my dyno sheet has... Edge 5x5 381/826 and 379/831 then stock 228/462

-

home made tool

-

Diesel fuel vs. pecan

I was trying to find the article I read a long time ago about why the diesel engine was invented. Rudolf Diesel created the engine to run off of spoiled peanuts. So when the peanut when bad in the field he would use a cold press and extract the peanut oil for the diesel engine... Don't quote me on this but it was a article I read a while back...

-

Who all is in Idaho?

Come on guys speak up! I travel all over the state of Idaho from time to time so I might be able to stop in and say "Hi!" if I'm in the area...

-

aem bruteforce on 01

Hmmm... For life so far I'm up to 6 years (122K miles) and still going without any maintenance to the filter... Filter minder still hasn't moved... I know the filter minder is measure in water column and not inches of mercury.... So the filter minder is rather very sensitive to vacuum...

-

parking brake

Most I've ever heard was to keep up on the adjustment of the rear brake shoes...

-

VP44 Write Up - Minimum pressure suggested...

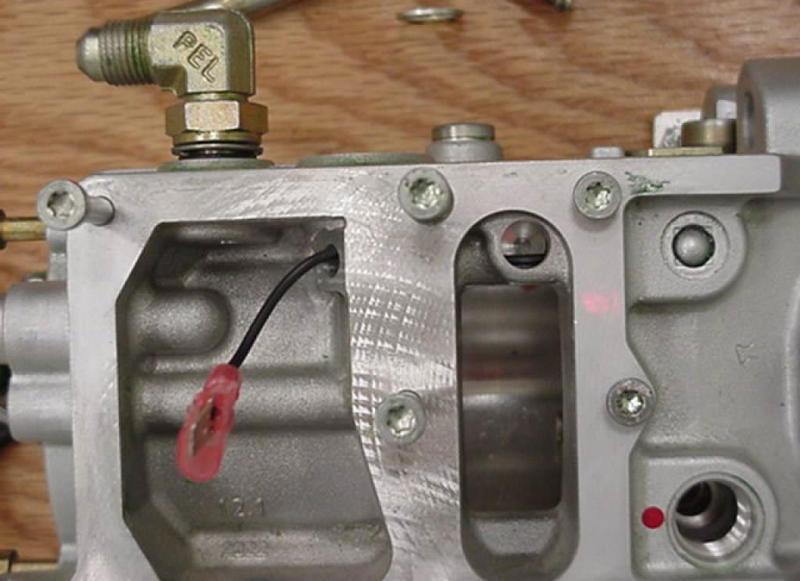

I was getting ready to add to the HTML pages and found that yes both input and overflow areas under the VP44 electronics are hooked together! Check out this picture closely... Notice you can see the black wire in the other hole on the overflow valve side. So yes both the inlet and overflow valve are connected to each other...

-

Over engineered boost regulator

Ok... It is a bit over engineered but it looks like it works really well.

-

APPS voltage Adjustment - Stopping the Myths!

There is no target voltage on the new sensor just turn the screw till the voltage start to rise then back off to it returns then back off additional 1/2 turn. Thats it... No voltage to adjust to... To clear this up more... (The best I can) The fact is that the stock APPS sensor is a rheostat yes. But it is set at a particual voltage to the electronic switch inside reports to the ECM if it at IDLE or THROTTLING. If the voltage rises above the voltage set on the tag the switch changes to THROTTLING. Then when the voltage drops BELOW this voltage on the tag then the ECM switches to IDLING. This means the APPS voltage is disregarded and idling software takes over. NOW... The Timbo APPS... There is no set voltage tag because the switch for ON IDLE and THROTTLING is mechanical this means once the bellcrank gets to a particual angle THROTTLING starts regardless of voltage. So there is no voltage to adjust it just a matter of taking the slack out of the bellcrank. So now you know why you DON'T set for EXACTLY the tag voltage because now it will constantly flip back and forth between IDLING and THROTTLING causing issues with exhaust brakes, high idle software, etc. It not about the voltage its about the fact of the Idle Validation switch state...

-

APPS voltage Adjustment - Stopping the Myths!

Because the one you bought is a Timbo's APPS... You might want to go here for more details on calibration... http://forum.mopar1973man.com/showthread.php/1527-Timbo-APPS http://forum.mopar1973man.com/attachment.php?attachmentid=698

-

Change tires! - 235/85 R16 to 265/75 R16

Now after running on my Cooper STT for 2 weeks and watching the MPG fall like a rock I figure i better swap back to the BiG O AT 235/85 R16... I can tell a difference in weigh of the tire by just lifting them but I figure get out the bathroom scale and weigh them... I know this is perfect but this does show a huge difference in rotational mass... Big O AT's 235/85 R16 About 7 inches worth of tread face. Weighing in at about 60 pounds per wheel. Cooper STT's 265/75 R16 about 8 1/2 inches worth of tread face. Weighing in at about 80 pound per wheel. So for a 1 1/2 inch gain of tread face that is aggressive on steel rim give me a -3 to MPG's with a total extra rotational mass of 80 pounds for all axles. So I'm back to the Big O AT's on my stock aluminum rims and I'll be back to my high MPG mark again...

-

aem bruteforce on 01

I did relize they where that small... Wow!

-

CAI in Summer VS Warm Air in Winter

...or my favorite. www.scangauge.com