Everything posted by Mopar1973Man

-

Nationwide Weather

Normally the 100F to 110F weather starts in August up here but this year it started in July. Yes its normal for 100 to 110 in August and been seeing the same weather for years. We are already talking about a wet/snowy winter. Some of the locals are good at reading animal patterns and even insects. Like today it started at 57F here this morning and the rose to 97F now. No biggy... This morning when I ran to work in Donnelly ID it was mere 40F from New Meadows up into McCall and there was wispy fog in the valleys. In the past when I was running on the local fires and working wildland I remember times of sitting in a water tender without A/C and it being 100F to 110F. I even remember looking at the old school thermometer at Chevron back when I worked there for a summer and seen 117F.

-

Replacing head gasket

Be aware there is China made Cummins heads running around out there and poor quality.

-

My first explosive tire failure!

So the over head was 20.3 MPG, after filling up today it... 517 miles / 30.084 Gallons = 17.19 MPG This is way better than last week with the old tires. 420 miles / 30.505 Gallons = 13.77 MPG Stock sized tires and stock steel wheels are a winner in my book since I ditch the Fuel 18 inch wheels. Hankook AT2 265/70 R17 - $985 dollars worth of tires.

-

Replacing head gasket

Somewhere back a page or two the author mentions that compression was like 320 PSI IIRC...

-

Need help with tune or injectors

Even with my wastegate hose disconnected and open and remove one intake manifold bolt I was still able to hit 40 to 45 PSI of boost on my 2002 Dodge. Boost leaks that are so small that you can't hear them don't count. In my example I created a massive leak you can here but it still wasn't enough to make the EGT's skyrocket.

-

Few random questions..

It's most likely valve guides are wasted and the valve seal blew off. There is a member here that fought that problem. Myself I had it too and had 18 of the 24 valve guides replaced. Now all good and no longer blue smoking. At idle the ECM is in control of the timing and its normal for extended idle times to see the timing jump up this is totally normal.

-

Replacing head gasket

I was just talking to friend about this and it possible to have the o-ring pinch through the head gasket cause compression leaks.

-

P1694 and P1698, Diag help

When I did mine I pull the entire charge lead out and re-routed to the passenger battery. The circuit breaker I put on the firewall side of the battery tray. The entire cable was completely re-used. The ground side I salvage the plug on the passenger side and made a new jumper from the driver side battery to the gear case.

-

My first explosive tire failure!

Only running +50 HP injectors. So there is a bit of error but not much. Like right now I'm at 500 miles and just above 1/8 of tank and easily reach the 600 miles with what is left for fuel. For sure a better MPG's for sure.

-

P1694 and P1698, Diag help

Quality DVM like Fluke or similar that can measure small AC voltages. Red probe to the alternator charge stud and the black to clean block metal is best or the negative on the passenger battery. You really need to. The alternator lead is paired right next to the ECM ground and VP44 ground so when AC noise is created the noise jumps right into the ground leads and pollutes the ground signals to the ECM. This is a required mod. The alternator charge lead is move solely to the passenger battery and the ECM ground are to the gear case and the driver side battery. No longer an issue after the mod. Dropped me from 55-60 mV AC to mere 9-11 mV AC after I was done which is acceptable.

-

Help; narrowing down on upgrades.

I'm close to 500 HP on my 2002 Dodge (The Beast). +150 HP injectors (7 x 0.010) popped at 320 bar Quadzilla Adrenaline (My own custom tune) Air Dog 150 HX35/40 Hybrid Turbo (60/60/12) The biggest thing to keeping the EGT's cool is a good tuner that allows for timing like Quadzilla and then proper final ratio to the ground. Like the Beast its gear to 3.69:1 to the ground. This is 245/75 R16 tires on 3.55 gear axle which produces this final ratio. It put me at 2k RPMs at 66 MPH. This truck maxed out at 27.2 MPG years ago. But Still able to reach 20-21 MPG with this set up. On my 2006 Dodge now with 3.73 gears and stock 265/70 R17 tires I'm still at 3.73 final to the ground. This is about 2,100 at 65 MPH. Great for heavy trucks and still reaching 19-20 MPG. I'm not in it for race either but for Efficiency and longevity. Well on the Beast I've just popped 2 head gaskets. First one was too much drive pressure most likely (high timing too). Then the second gasket OEM Cummins delaminated and blew out. (Defective gasket!).

-

Brake Light Switch..."DO NOT REINTSALL"

Should follow me more. I've been getting good quality parts for year but paying less. I just checked NAPA (Prolink) its $21.79 my cost but list or the public for $31.70. Then I fall back to RockAuto.Com and typically find good deals but the waiting for mail is the slow part.

-

My first explosive tire failure!

350 miles to half tank of fuel sitting right at 19.9 MPG on the overhead trip computer. Only problem I would need at least two jack stands and the a free jack for other reasons. That is cool though!

-

Brake Light Switch..."DO NOT REINTSALL"

Just looked it up on RockAuto.Com a brake light switch is a mere $7 dollars!!! Really you going to go that far to save a 7 dollar brake light switch... https://www.rockauto.com/en/catalog/dodge,2001,ram+2500+pickup,5.9l+l6+diesel+turbocharged,1366602,electrical-switch+&+relay,brake+light+switch,10474

-

Crank case vent mod done

Last I time I did the clean up of a turbo I used brake cleaner. Then left it stand in the sun for about an hour to dry up.

-

Interior/dome and Cargo lights just "stopped working"

Don't feel bad after having my exhaust brake blow the fuse under the hood I couldn't understand why it didn't want to start. After sorting out the fuse problem and the source of the short being the exhaust brake switch makes contact with a ground sometimes and pop goes the fuse. Weekend project... I need to fix this one too. As for the dome light might check power mirrors and any interior lights including glove box. These are typically all on the same fuse.

-

Crank case vent mod done

If your pulling the radiator out take the extra step and pull the intercooler too and clean it out. The face on the bottom half might be mud caked, then if the air filter is poor you can wash out all the dust or any oil that might of come from washable filters or the turbo.

-

High IAT, Low Power, Low Boost

Good idea to do. It will for sure keep you out of trouble too. Don't ask me how I know...

-

P1694 and P1698, Diag help

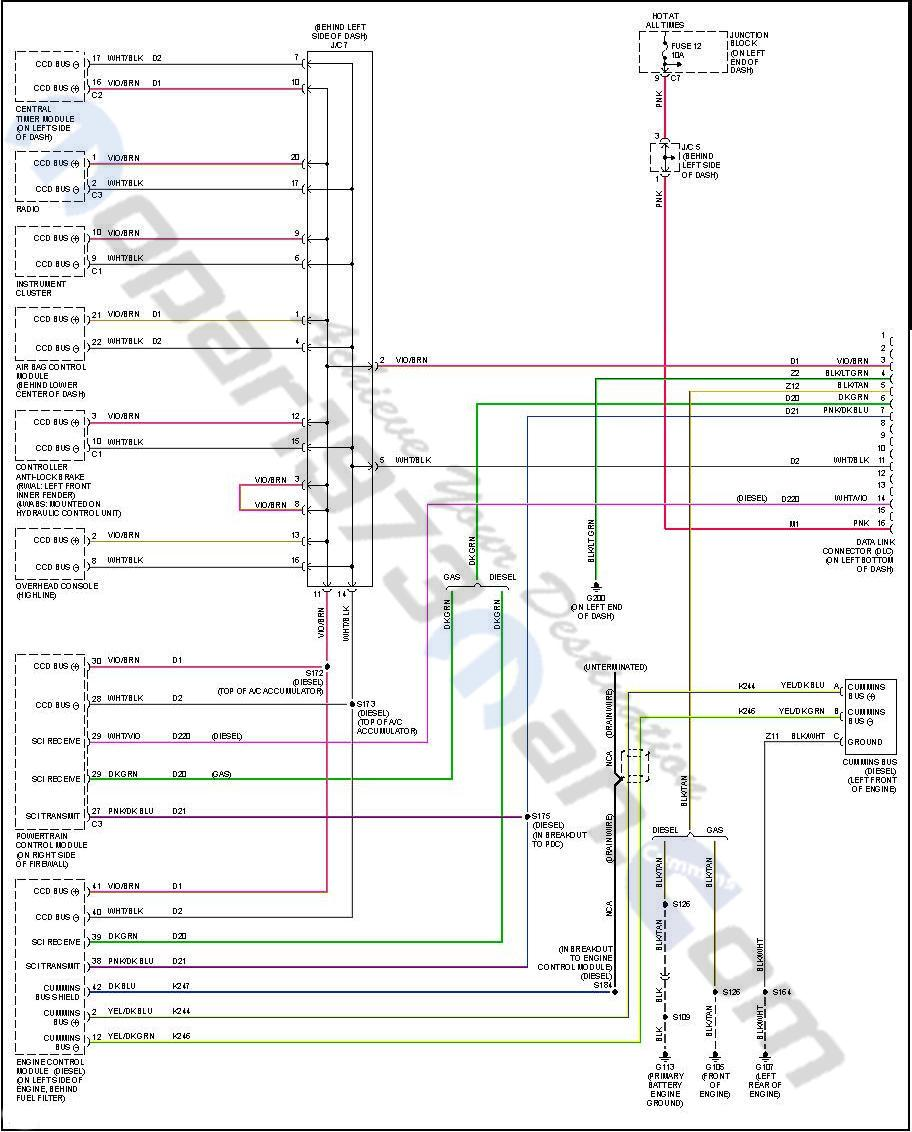

Normal you can remove different modules that could affect the voltage. Modules that can't be removed... PCM - This is source of the CCD network. ECM - This is the secondary computer. Gauge Cluster - This creates the bias voltage. All other modules are optional and can be removed. Central timer Radio (Stock OEM) Air Bag Module ABS Module Overhead Trip Computer Causes of failures and errors. Bus Shorted to Battery Bus Shorted to 5 Volts Bus Shorted to Ground Bus (+) Shorted to Bus (–) Bus (–) and Bus (+) Open Bus (+) Open Bus (–) Open No Bus Bias Bus Bias Level Too High Bus Bias Level Too Low No Bus Termination Not Receiving Bus Messages Correctly Remove a module and check the voltage on the bus to see if it returns. If not you didn't find it.

-

Looking for some advice; bad ECM?

If you not done the WT ground wire mod that would be highly suggested. Then the power comes from two places. There is a fuse that supplies constant 12V (under hood) to the ECM and then there is a second fuse that supplies trigger voltage double check both fuses (in cab).

-

My first explosive tire failure!

Every since changing back to the stock tires. The MPG is improving quite a bit. I drove from Riggins up to Donnelly Idaho and rat raced around for over 200 miles when I got home. I only used a 1/4 tank. Typically I'm already near 1/2 tank. The odometer is now correct and with stock tires size and the MPG number is improving. Just checking the final ratio it nearly the same as what I got on the 2002 Dodge. Right there at 3.73 final ratio is powerful and pulls way better.

-

P1694 and P1698, Diag help

Yes your problem is CCD network issues. Another way is to turn the key on and the probe the CCD pins on the OBDII plug under the dash it should show 2.51 and 2.49 when the computers stop talking. That is normal Bias Voltage.

-

Brake Light Switch..."DO NOT REINTSALL"

The only problem is the ratchet design won't allow for multiple resets eventually the ratchet will fail.

-

Few random questions..

Valve guide can be replaced. I had 18 out of the 24 replaced on my head at 350k miles. This is why my first head job had $2,100 worth of head work and ARP studs added.

-

Oil leaking out the draft tube

Oh I know it can be bored oversized it just if the current sleeves are shot most just bore it out and re-sleeve. Not many are in for larger power that is a very small percentage which I deal with.