Everything posted by Mopar1973Man

-

Valve Lash Adjustment Question

Intake and exhaust spec are typically 0.010 and 0.020 respectively. But if you look in the Dodge FSM you'll find and much wider range is allowed. For example exhaust I remember is 0.015 to 0.030 allowed and considered OK.

-

TikTiok

5pm again tonight I should be back on the air again.

-

TikTiok

Hey gang, I'm going to be doing Live TikTok in the evenings. I'm going to try and hit the air around 5 pm in the evenings. Grab your mobile device and fire up your TikTok app and check for my Live channel @mopar1973man. I Had a good run last night and @Doubletrouble was hanging out and helping out by feeding me ideas of topics to talk about. Coome check it out and chat with me.

-

Rear Disc ABS Options

I would upgrade the master cylinder for sure. I'm not sure about the ABS system.

-

Rear Disc ABS Options

@Tractorman is correct. Either RWAL or ABS will only have the single sensor on top of the rear diff to measure speed. Just a matter of hooking up brake lines and parking brake cables.

-

Data logging

Data logging is only good if I can see combined video of road view. Without view of the road it's hard to see if your climbing a grade, traffic, etc. So the log is part but knowing kind of road conditions and such help a bunch. Basically drive when you stop then hit export to create. Wait till it's done. It should create drive file or email.

-

Blinker Fluid Maybe?

Might pull the multifunction switch to see if something is broken.

-

Camp out - New Meadows, Idaho

Well you got to admit it's the right type of .

-

Camp out - New Meadows, Idaho

So I'm a bit but hey I can

-

Power steering whine/hum after new gearbox install (did I screw up my PS Pump?)

Yup it happens. Now if you wanted to reduce this you would have the axle jack stranded now fill and run that steering wheel lock to lock for a good period of time to pull fluid in and hopefully push all air out.

-

Rear door latch

Not me. I will say it a good idea to pop the rear panels and drown your latches with engine oil which will keep them going and prevent rusting up. The lower latch the rod has to come up to release.

-

Camp out - New Meadows, Idaho

@IBMobile @Honey Badger Dads RV is using the electric rock now. But I'll have a full hookup RV pad out back soon.

-

Camp out - New Meadows, Idaho

Well, it happened again. @Tractorman and @JAG1 showed up here with RVs. They made it about 6pm last night. We took off and had dinner last night at River Rock Cafe in Riggins, ID. Thank you @JAG1 for covering dinner for the group. We came back to the house and sat out back for most of the evening till 11pm chatting away about all kinds of topics. @Tractorman truck and RV on the left and @JAG1 with his truck and slide in camper. Guys are still sleeping in and enjoying the quiet out here.

-

Diesel Fires

Don't! Leave the factory filter there at least you keep the fuel heater for the cold months which is very helpful to bring the fuel temperature up fast being the electric heater comes on below +60*F. Now the factory filter is mounted in that spot because it's near the coolant passage in the manifold. This is why fuel temperature and IAT typically match in temperature on long hauls. Fuel temperatures of 80 to 120*F are good to have helps with atomization and don't require a ton of timing to get good MPGs. Above 140*F fuel temps are too hot and asphaltenes are produced this is the black material collected in the filters. As for diesel fire, I think it's just commonly overlooked stuff. Pinched wires from modifications, and fuel leaks that couldn't be seen, but I really don't think anything is in the fuel. Ammonia Nitrate is a powder form and placed in fuel but it is still going to be corrosive and eat up the fuel system. (Injectors, pumps, plug-up filters, etc.) Look closely a lot of fires start in the cab. Then start tossing in gasoline-powered Ford Rangers and little gasoline cars it's not the fuel now.

-

Starter blues.

Ok. So my OEM starter lasted a long while. I replaced contacts and then finally it died. I pull it and replaced it with a NAPA New Starter which lasted a long time as well. When it finally gave up I had my OE starter rebuilt which cost me more than my new NAPA starter to have rebuilt. It is currently in the truck now but from here out I'll most likely buy new NAPA starters from here forth. OE starter isn't worth the cost of rebuilding any longer just to save the OE.

-

AC leak locating

From my experience, a lot of times the front seal of the compressor starts to fail with a slow leak that can't be sniffed or see any UV dye being the pulley slings the dye off and covers the dye with dust and dirt that makes it impossible to see. Really can't sniff behind the pulley while the compressor is running.

-

Power steering whine/hum after new gearbox install (did I screw up my PS Pump?)

Thanks for the reply. At least we all know that is a was a air or foaming issues which is typical.

-

Diesel Fires

Some of the videos are for sure electrical fires seeing the loom melted. All them are moved trucks in some form. Lights, winch, stereo and amps, etc. Some could be fuel leaks not being g dealt with like number 4 rail line cracking which is known on CR engines.

-

Power steering whine/hum after new gearbox install (did I screw up my PS Pump?)

Typically air in the system. Air will foam up the fluid and make it whine.

-

Another headlight thread

-

2005 Chevy Equinox A/C rebuild

Parts are on the way... Should be here tomorrow at noon or so.

-

Diesel Fires

So, On TikTok, there are several people that just lost their trucks to fires. There is a feeling that something is being added to the fuel to create said fires. First off it's not possible. You don't hear of diesel tractor-trailers having fire issues or farm tractors having fires. Yes, I know red dye and on-road fuel are from the same source just one has red dye added to the fuel. It is very possible these younger pups are making mistakes with their ground lighting, rock lights, etc and not properly fusing or properly wiring up accessories even stereo amps, and head units. Yeah, there were several trucks posted up on TikTok burning down. Ford, Chevy, and even a Dodge so it's not just like one brand it's all the modified trucks. Typically seen wide wheels, rock lights, etc. Very possible it's an electrical thing and a rash of bad luck. In response to this I posted up on TikTok about the W-T ground wire mod, another video showing there is no electrical hooked to my batteries except the ground for the W-T ground wire mod and the alternator charge lead coming from my 150A breaker on the side the battery on the passenger side. https://www.tiktok.com/t/ZTRoSkjwA/ https://www.tiktok.com/t/ZTRoSkg2o/ https://www.tiktok.com/t/ZTRoSdaUB/ https://www.tiktok.com/t/ZTRoBExX6/ https://www.tiktok.com/t/ZTRoSBXvY/

-

2005 Chevy Equinox A/C rebuild

Geez... Never ceases to amaze me with the BS that manufacturers can dream up. This vehicle is in Riggins, ID, and the owner requested an A/C recharge. When I got there it had static pressure of about 30 PSI but not enough to fire the compressor. I added freon and when the compressor started the bearing noise was bad. Not to mention the compressor isn't pumping either. I shut it down and notified the owner it was going to require a compressor and other parts. I called NAPA and found out that Chevy used two different compressors in that year. I ended up pulling the compressor just to identify the system the compressor no longer had a part tag or numbers. After figuring that out then found out they used 2 different expansion valves. WTF?! Needless to say, it's going to be expensive to just get this A/C going again. Waiting on the green light to rebuild...

-

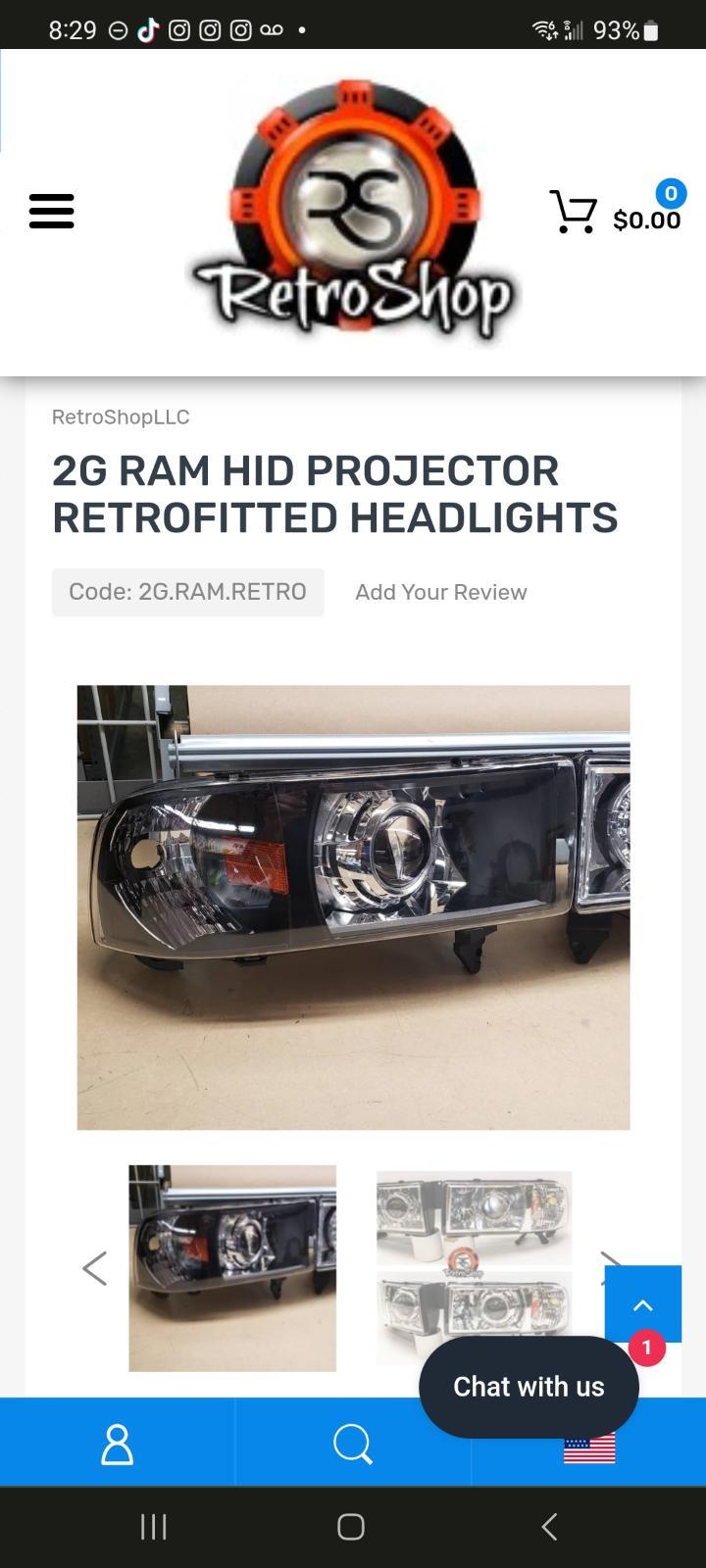

Another headlight thread

The reflector with halogens is going to be the key to getting a good pattern on the road. Where the factory headlight was the lens that gave the pattern. Now for a bit more money put a set of these in the headlights. https://www.morimotohid.com/morimoto-mini-d2s-5-projectors?quantity=1 That would give you all the light you'll need. Excellent pattern, the reflector wouldn't matter. The only bad part is you have to remove the lens from the new headlight by baking it in an oven and resealing them after installation. Next down here are the bulbs I used in Minnie my 99 Dodge Caravan I know they are not the right bulb number but not bad in price. Then you based back on the reflector quality on how good the pattern will be on the road. The Minnie headlights for a pattern isn't bad, but it's not stellar either. https://www.amazon.com/gp/product/B07GGRHPPY/

-

Starlink Internet

I've got more done. I got the outdoor WiFI antenna up. Then I managed to get the camera configured. I found out the internal camera software works way better. Strangely enough you have to find the cameras IP of the work group switch and then type that IP address into the browse. You configure the camera on your browser. It has movement detection and I could configure the camera to send the video files over SFTP. I've got to tweak the video area to exclude movement from a tree. Sadly I fried a WiFI antenna here in the house. Then WiFI head for my place was whining for a update for its firmware. So laying on my bed early morning I hit the update button. It started and run for awhile then FAILED. Sadly the internal software is damaged and will not boot up. I've got to call TP-Link Tuesday and finish my warranty filing to get my replacement WiFi head. So far in enjoying this setup. WiFi has been better. Better range and coverage. Internal network is fast. I can transfer files between devices pretty quick. As for the Starlink I'm pleasured. The speed is better on clear skies. But if it get stormy it slows down. Then if then lightning you'll most likely lose internet. My last large storm was dropping 8 inches of rain and hour. Rain lasted about 30 minutes. But the lightning continued most of the night. Yea about 6 hours of no internet. At least now with Starlink I'll keep internet when the power is out being my solar power home. With Ziply (former provider) when the power was out I would lose internet. Being the fiber optics require power to keep the light pulses going. Yeah wiring is temporary for now i might move things (WiFi and/or camera)