Everything posted by Dieselfuture

-

Rocker panels cab corners

May work with thin gauge steel, I was thinking 1/8 for durability like rock sliders not that I need them. Was also thinking using square tube like a 3x3 or 3.5x3.5" but there's always but... Not sure what I'll do yet once I get old ones off, how bad will it be, I can only imagine

-

Rocker panels cab corners

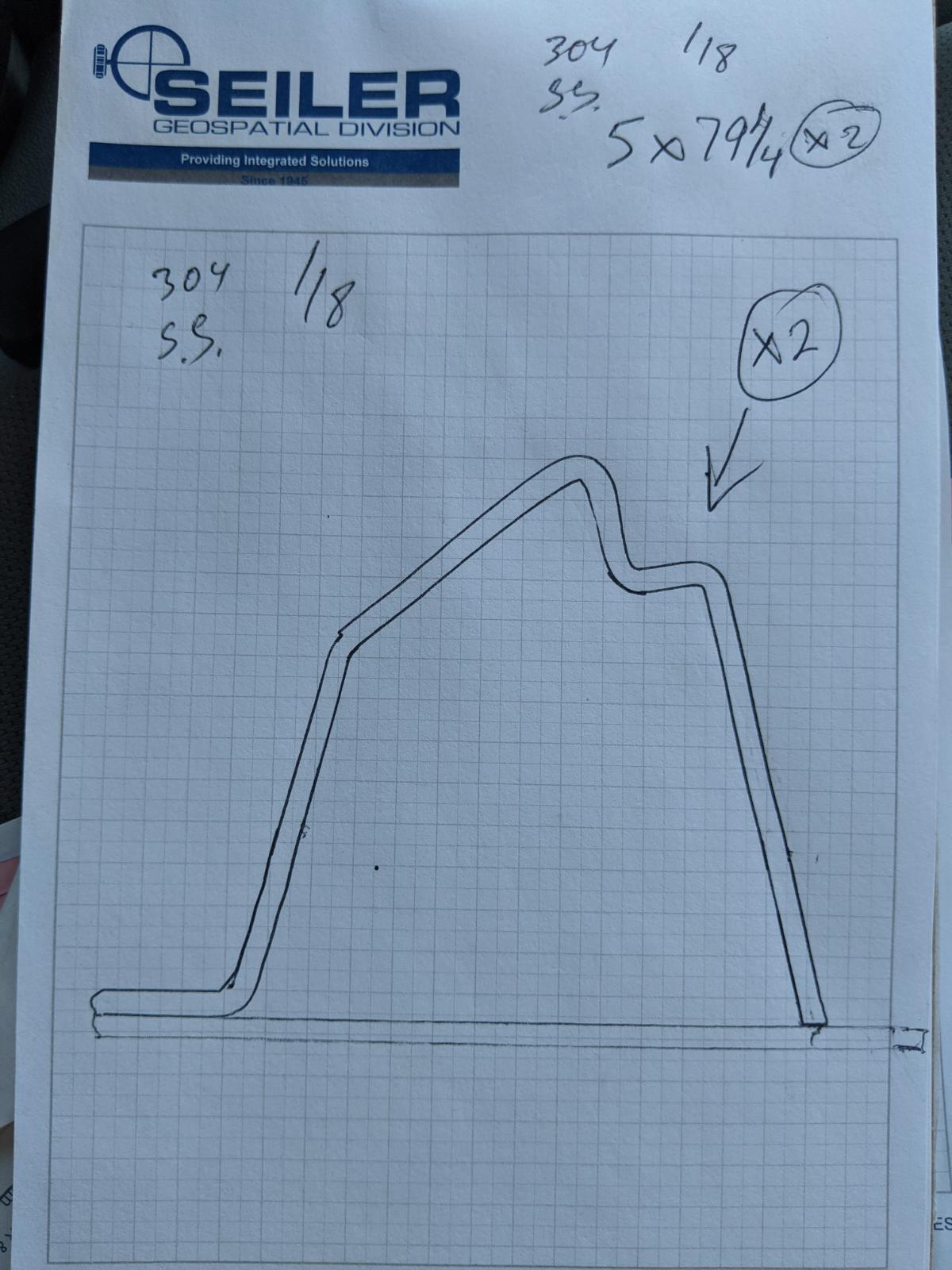

I still wish I could have had someone bend me some rockers out of SS. This was my drawing for him, I slightly modified the original design as it's a 3 piece and this one is only 2 but 1/8" SS would of been up my alley. Would be more work but last forever....

-

24valve Vp44 bottle jack injector pop tester

There's a bunch of china special on eBay that I read mixed reviews on, I almost got one too. Can't beat the price but after looking at them I decided to make my own. Like this one, you can't really build one for that money not to mention time you'll have in it https://www.ebay.com/itm/Diesel-Injector-Nozzle-Tester-Pop-Pressure-Tester-Dual-Scale-600-8000-PSI-BAR/383821334417?hash=item595d88c791:g:YK0AAOSwuRxfuHbV Then again some say they work others say they are junk. I had a jack already and decided to make my own. Still if you buy one I'd say gauge would be in question and definitely need to disassemble it to clean it real well before use. It is nice though it comes with a cup that has a filter in it. So again is it worth wasting time making one or do you just buy one. The other thing people say is that valve on the side could be tricky to work with. Good thing is it does come with a high pressure fuel lines. So idk to each their own I guess.

-

Rocker panels cab corners

I've debated on using panel adhesive instead of welding myself, not sure what I'll do yet, but it makes sense if you have everything painted and then stick new panels on then it won't rust on inside where you weld, otherwise how do you get in there to paint. Link with video above shows useing a tube with funky fitting on the end, spray is kind of like our injectors sideways and then attach it to the spray can and as you paint you pull back on the hose. The only problem outer rocker panel is so close to the inner you're not going to fit much in there, and going through the back where the plugs are is not going to reach the outer layer either. So yeah adhesive does make more sense, plus they say it's stronger than welding.

-

24valve Vp44 bottle jack injector pop tester

Thanks, That's the plan, just need to figure out how I don't know anyone with a calibrated tester and I'm sure some random diesel shop don't want to give me much time. I think a good guage should do it. Honestly I think this one is pretty close for what I'm doing, but I agree if I'm going to want to be precise I'll need to be more sure. I could put another T inline and have 2 gauges for comparison. I can try all though I'm not a great article writer. I can disassemble it, take few more pictures so it makes more sense and list parts for fittings. Still need to remember this is a dangerous device with high pressure. Yes, I didn't invest in special fluid. I mixed diesel with 2 stroke and little bit of diesel cleaner from power service that I had on the shelf for years.

-

24valve Vp44 bottle jack injector pop tester

So I've been debating about making this thing and finally decided to do it. Had some extra time on my hands and after looking at whole bunch combined ideas here is mine. I had a set of 75hp injectors I got in 2014 that I used for about a year so roughly 7-8 k on them. They came poped at 310 bar and I just checked one of them and it's popping at 260 if I do it quick, meaning keep pumping pressure and it just goes pop pop pop few times a second, now if I go slow it'll pop at 290. The gauge I'm using is a cheaper china special, but it liquid filled. I'm going to check all of them here soon when I get more time just to compare. I also got a shim kit from dap that I'll play with so when I pull my 7x10 some day I'll know what to do. So this first injector is popping low but the pattern looks good not dripping ether. I'll probably get a more expensive guage that's 4-5" instead of 2.5" for better accuracy too. This one seems like it's working good though for being a $15 one. The expensive part was the adaptor for $100 I had this 4ton bottle jack fo a long time, it is also made in china. Had to by some fittings from local hydraulic place $20 and was lucky to know a guy that works at CAT in parts department, I asked him if they had some 14x1.25 injection lines because that's the adaptor threads and he said you won't believe it but I just seen our mechanic through some away today. So I drove down there and he already pulled it out of dumpster. Guess they don't reuse lines when they fix things. Line is like brand new too. So here are some pictures, wasn't that hard to build, had a pin hole in my weld I had to fix other than that it works.

-

Noticed a fuel smell and a few drops on the pavement.

I used a torque wrench on mine

-

LED light strip

More I think about my reply it just doesn't sound right. Hope you didn't take it the wrong way. I should have replied something like, sure come on over and bring some drinks while I help you out. I usually say what's on my mind without thinking too hard though, but nothing to mean anything bad, just sometimes I'm off topic with my answers.

-

Exhaust Manifold Question

I used it on mine, some copper high temp stuff

-

Exhaust Manifold Question

I put a bit of white paint at top of the bolts when I did mine because I didn't reuse the metal clips, all but one stayed tight, one backed out half a turn after a year or so, it's been another year now so far no more problems.

-

Noticed a fuel smell and a few drops on the pavement.

I had a small drip from bell housing and checked my oil pan bolts, yep sure enough all lose, no more drip now

-

Exhaust Manifold Question

Looks right to me

-

Rocker panels cab corners

I've seen this before too, I just don't know how much I want to trust some of these products, seems legit but so does por15 after reading reviews it seems that it could be snake oil, works for some I guess. That's why I was thinking just using regular grease and get it all over inside when the panel is off, idk... I've seen where people send blasted rust off used por15 and few years later rust came back. I also thought about using a pump up sprayer for gardening or whatever and put some sort of paint rust stop in there and go to town.

-

LED light strip

If you didn't leave in comifornia I want nothing to do with that place

-

Rocker panels cab corners

I was willing to chop up more with full replacement until I seen the price, then I had my hopes up for a guy to bend me some out of SS and he said no, so for now I'm going to do minimal work on outer skins so I don't have to take doors off. It may last a while and then I have no idea what happens. It's definitely not like me, I like to do things once, really don't like redoing stuff. If I could get all the panels (full replacement) free or next to nothing I'd replace the inners and all too, just couldn't get passed the price got my hopes up that I can get away cleaning inside and it's not all rotted. Guess I'll find out soon and it could still change my mind. I got these from eBay, they are considered a slip on but still go to weather strip, they also have some that stop at the door seam but it won't take me that long to pop few more spot welds to go all the way. The full replacement goes all the way towards door hinges, mine still look pretty solid there, that's part of the reason I'm thinking of doing it now and not using anymore beer cans so the rot doesn't make its way there. https://www.ebay.com/itm/1998-01-DODGE-RAM-P-U-4DR-QUAD-CAB-OUTER-ROCKER-PANELS-AND-CAB-CORNERS-PAIR/283363349003?pageci=82c0628a-ddf8-4975-aeaa-6eafa045b9ee

-

Rocker panels cab corners

Them belong in museum, these sapporo cans are almost as thick as the sheet metal on the truck that's why they're on there though they would last a while. They may be made out coors recycled cans for all I know, flimsy, thought the onse I got for the car were thin few years ago, these are even thinner.

-

Rocker panels cab corners

I ordered a set but having a hard time with letting go the beer cans, in a wierd way I'm going to miss them. Makes the truck more special that way. Plus it goes with my license plates theme.

-

wipers

@IBMobile probably has a picture of that

-

Rocker panels cab corners

That's the only thing wife likes about the truck. I'm afraid if I fix it she'll tell me to get rid of it I was thinking about getting some por15 for the inside guts, just not sure if it's going to help anything. maybe just some primer like you're saying be good enough. Plus I'm going to smear grease all over inside that should keep it from rusting. Every couple of years I spray oil in there, I really think it slows the process down.

-

LED light strip

I hear ya my step dad is almost 70 and I help him out all the time. Got too keep these old gizzards going

-

Rocker panels cab corners

Well I ran out of beer cans to keep up with this rust bucket so I believe it's time to address it before the whole thing rots away. Got some slip on rockers and cab corners on the way from eBay $210 shipped for both sides. I wanted to get all 3 back, inner, outer but for that kinda money I can almost buy a rust free cab and maybe I still will one day, buy a whole truck to rob parts off like @That Guy just did. Another option I had was to have a local metal shop bend me some rockers out of ss but when I shoed him what I was doing he said he tried it before for others with bad results and lots of wasted time, so my dreams and hopes went down poop tube when he told me that. I wanted to get it done once and never worry about it again. Anyway once i get my stamped recycled beer can from who knows where made rockers I'll be digging in to this long dreaded project. I called lmc and they said their parts come from overseas too and they were on backorder for slip on rockers so I just went with eBay, probably same garbage. Now I just hope inners have some meat left that I can clean up and salvage, the back side is part of floor pan and has some rot in spots but should do for now. I was also going to cut everything out and use a square tube like some have done, but figured I'll try the outer shell for now, it may last 10 more years this way and then... who knows by then.... Anyone that has any good advice or beer support feel free to derail this thread.

-

LED light strip

He got off easy on the labor, knows what it's doing

-

COVID blues

- Two stroke oil comparison

Casey's most of the time, they're all over the place here. This is a newer picture. It used to say the temperature that it was treated to, I bet too many had issues and so they removed it. - wipers

I put window screen on mine with hot glue gun, seems to work.  There are some smaller holes on the side that I also put some in, can't see it in the picture - Two stroke oil comparison