Everything posted by Stanley

-

Ground wire/ fuse box/ hot alternator

Batteries did sit for awhile, I think batteries and alternator is to blame. I ohm the main cable from alternator over to battery. Should it go to pos. neg. or the missing terminal place. Here is a Video of everything I took real quick. Hope the link works.

-

Ground wire/ fuse box/ hot alternator

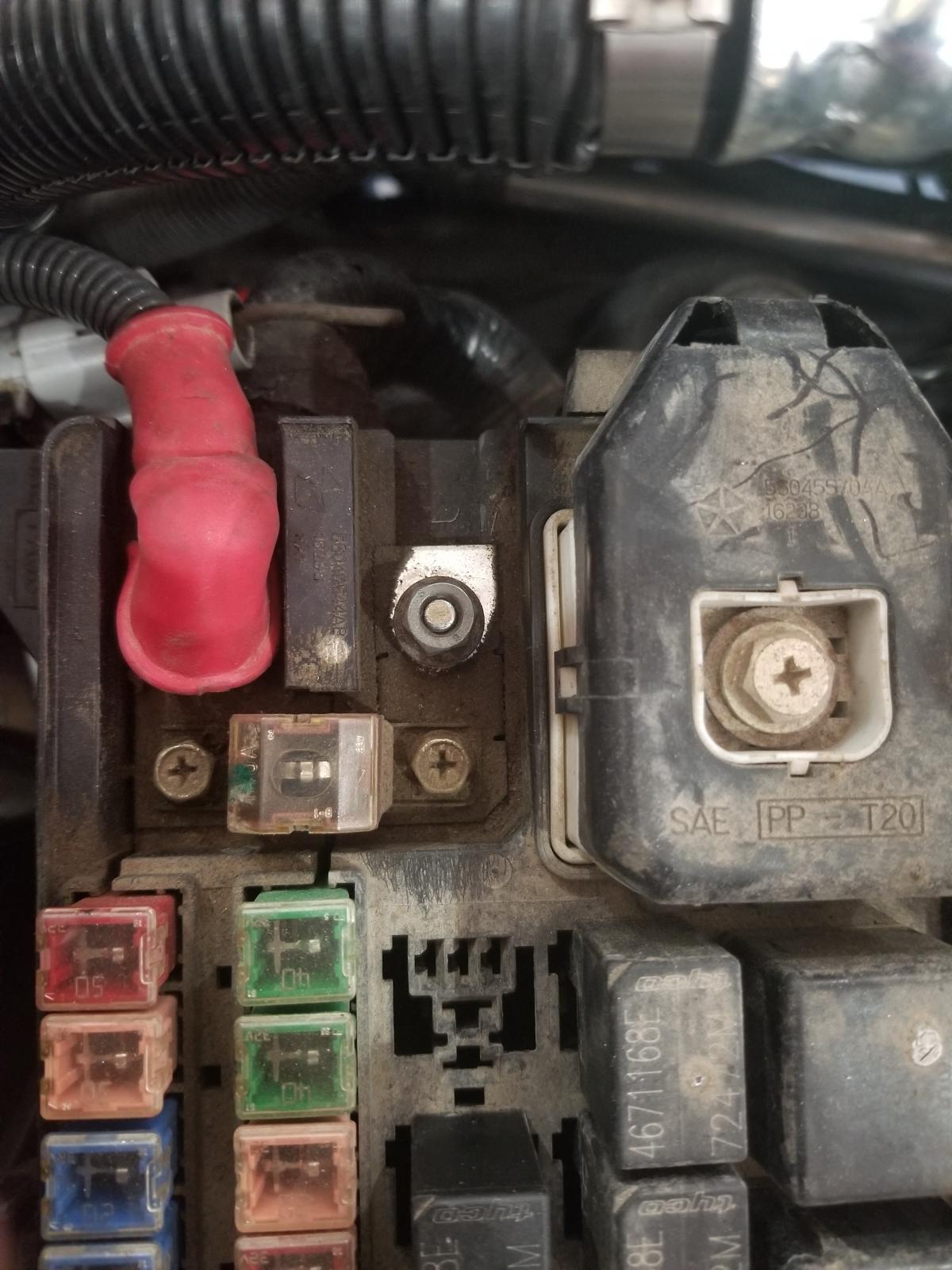

I guess I'm confused on what I'm missing at the fuse box. If I can find what I did or didnt hook up to that location I can go from there. After that missing link is found I can then proceed with possibly doing the w-t mod. If that makes sense. Thanks.

-

Ground wire/ fuse box/ hot alternator

- Ground wire/ fuse box/ hot alternator

Got a hot alternator like really hot, smelled it cooking. Looked at a few topic on here, started tracing wires. I previously rebuilt the whole harness-check all wires and re sheathed, tape, etc. My dumb a$$ forgot one wire the ground on the fuse box. Attached pic is what I missed. Is this wire straight to ground/frame? If it is I know which wire I need to use... Additionally could this mistake cause the hot alternator? Both alternator and batteries are old... alternator I assume to be original, batteries around 5-6 years. Batteries took trickle charge and started truck up fine. Thank you.- Rear main and oil pan

Awesome stuff man. I appreciate the help. I'll be doing this today/tomorrow. I'll do a video of the engine before it goes in to show it off.- NP241 DHD tailshaft bushing part number

Are you just talking about the rear seal where the yoke goes into the t-case? I can get the whole set up here for like 20$. I use these guys all the time, awesome people too!- Rear main and oil pan

So finally got back to actually working on the rig. I think I asked the question before but dont remember or cant find it. So I'll upload a short video on this but I have rear main and oil pan about to go on. I am uncertain on which I should first... Oil pan then rear main or vice versa...- Brakes, power steering

I got a vacuum pump rebuild from Gould. And new ps lines and a new ps pump both borgson. All three are you get at Genos Garage. There's even a video straight from gould on how to do the vacuum pump rebuild step by step if your unsure. Total worth it.- Ball Joints 01 2 Wheel Drive

X2 on Napa- A/C coolant leak

I read you added coolant, and talking about A/C stuff?? If anything is wrong with the core, just replace it, their stupid cheap. Also replace your drier at the same time. Do like the others said use soapy water all over lines and check for any leaks. It may be time to pull the dash... the m73m article nails it down, I also have my own thread of complete removing everything inside the interior of that helps you..- 2000 with a 2002 H.O. swap. Crank Sensor

Sounds like a mess. Dont be wiring stuff together like that-NO That's a basket of worms I've never seen before.- Stanley's Truck Remodel- Dove in Head First!

Here's is another link to a video I made on truck... let me know of it doesn't work.- Motor Mounts

Oh boy, you ain't lyin...- Motor Mounts

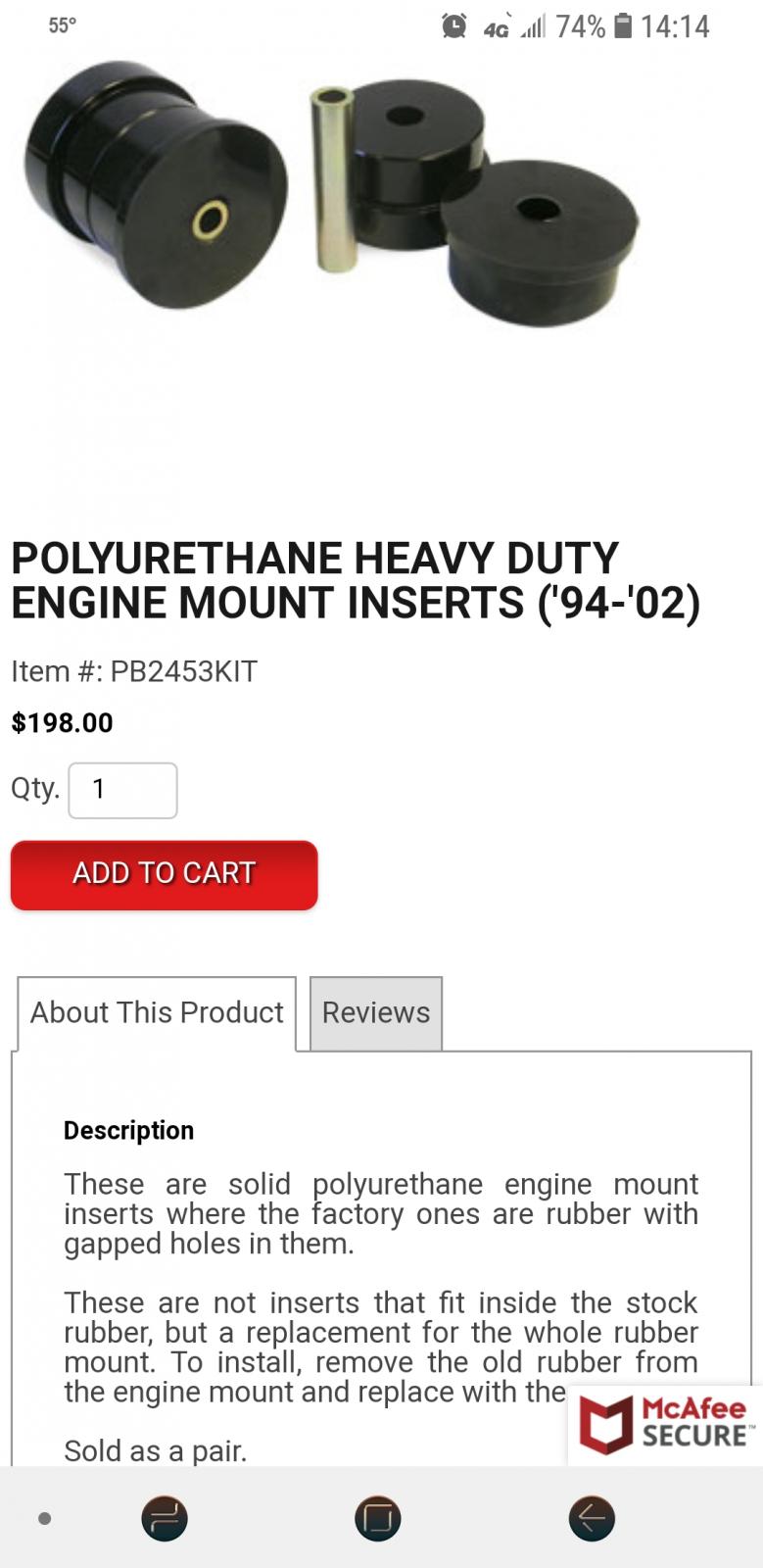

So here ya go, you can press them out. Used a 1 inch drive 2 3/8 socket and an old bushing from a machine as a push through, worked like a charm. I did have to cut the bolt end off but someone's else's case maybe different cause mine were froze in. You will have to use a press to get them out... I'll clean them up, paint them. Then order a set of poly bushings to put in. If anyone need exact dimensions let me know I saved old inserts. Just in case you folks wanted to lathe a custom press tool. The socket worked great, GP, brand, but there is always room for improvement...- Injection pump failed?

Yea, possibly it was already tweaked/bent and finally went...- Motor Mounts

Anyone ever removed the inner sections of the motor mount? I'm going to be replacing them with the poly inserts from Genos or from polybushings.com I have engine out and mounts off of engine. I assume they are just pressed in, and I need to press out?- Injection pump failed?

1/4 tank issue..... Pretty common actually, add plenty of fuel re prime as stated, try again. 21 psi is pretty high for start up on vp44's. Anyone correct me if I'm wrong, but it should be alot lower. High psi causes hard starts, and that could be an addition with the low fuel for no start?- Still trying to figure my truck out

Did you use soapy water on all your boots? I actually made my own pressure tester, I'll have to find and take pics if you need ideas. Buy I could regulate psi in with engine off and listen, use soapy water and find any leaks.- Specs for this turbo...

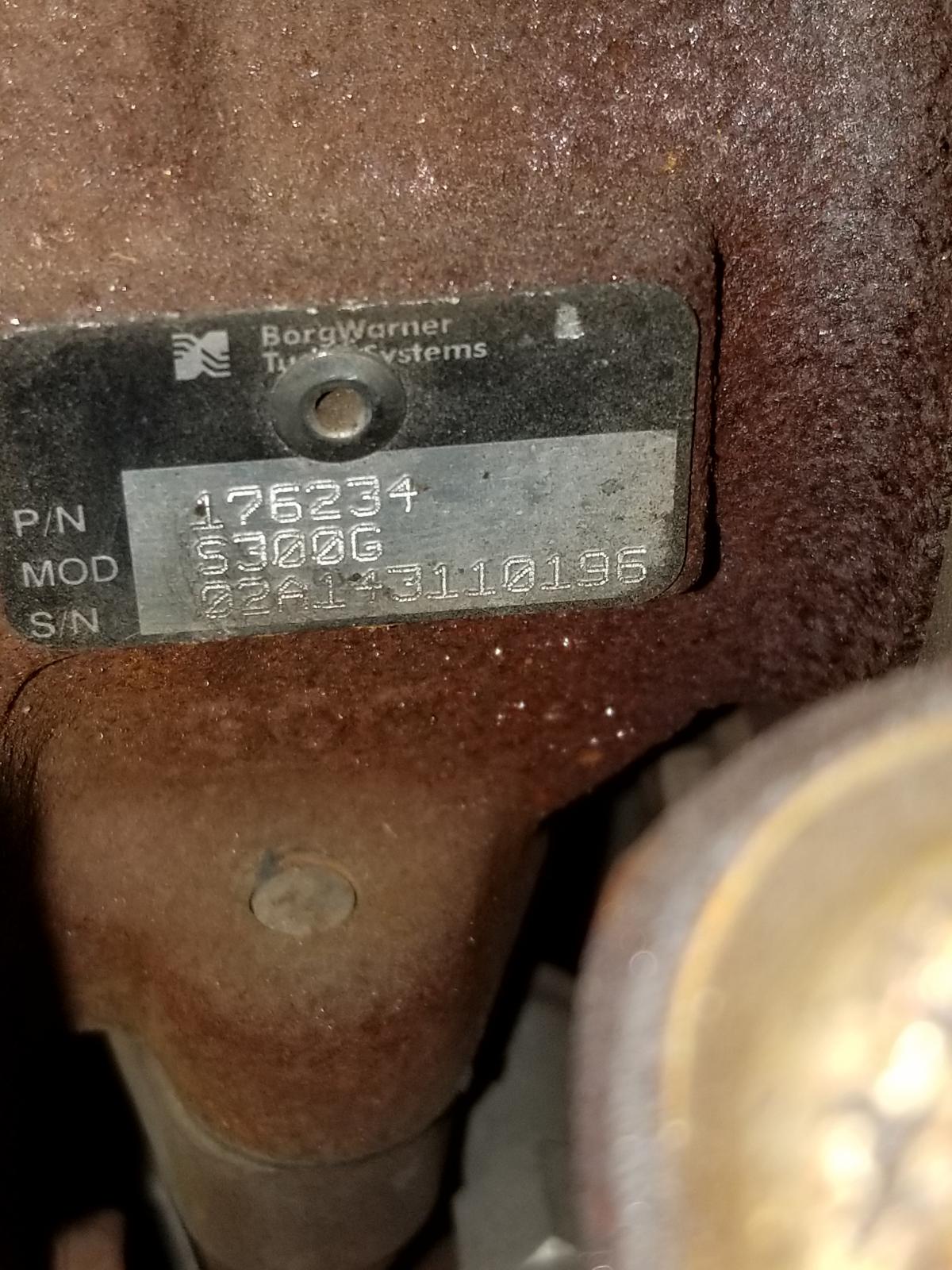

Any experience with this?- Specs for this turbo...

Could a 57/65/14 push 60 psi? Said he could peg his gauge before we pulled it...- Specs for this turbo...

I got an old john deere turbo that I'm gonna tear apart so I can get an idea on how things go before I jump into this one. I'm gonna try and talk him into twining it with maybe a S400, the crazy Carl's twin kit...? Gonna try DAP first and see if the have the rebuild kit.- Specs for this turbo...

Trying to find specs on this turbo for a guy and I cant find any actual specs on it...(sizes) It needs a rebuild kit also if anyone knows a good place where to get kits Pn 176234 S300g Sn 02A143110196- Blue-Top vs Redhead steering gear

Ok thanks guys, I might just stick with the original box on the truck now. I have 285's now and plan on going to 35's due to my 4.10 ratio to help out with mpgs...- Blue-Top vs Redhead steering gear

1500 gear boxes are the same? I have 1500 gear box I could use, I do want a quicker ratio though. Does he do that with the gear box I send in? @dripley core charge, I see now..- Blue-Top vs Redhead steering gear

I'd want the best I could get if I'm gonna spend the money, ya know. Why would the new one cost more, from my memory I believe they were quite a bit more than 280$. If its all the same, apples to apples, I'll just send mine in when I can. - Ground wire/ fuse box/ hot alternator