Everything posted by 2000Ram2500

-

Shift kit install and other parts any tips

I havent done any shift kits but I had my friend at a trans shop build mine for me when it blew. He was saying with the shift kit to just go nice and slow take your time and double triple check everything. He also told me not to mess with line pressure (i thought it would be a good idea to turn mine up not long before it went out) he got it reset based on the shift kit instructions. He also made me take out my lock up switch for the torque converter, he told me he wouldnt give me the warranty unless it was disconnected so i cut the wire out. Im not sure how far into this your going but depending on how many miles etc etc you may have more work to do inside than you anticipate. My torque converter was seized completely. EVERYONE was telling me to throw another converter at it and i'll be fine. I had a feeling that was wrong and brought it to my buddy just to inspect the rest of it. Well the rest of it was toast too. Drums had grooves, bands were worn down to the rivets, clutches were overheated and worn out and you could see the hot spots on the steels. That was before 140k miles and no power mods other than the previous owner put a superchips on it which the super chips maxed out was equivilent to probably level 3 on the edge so were not talking a huge gain in power here either just a little bit. The craziest thing was that he was telling me that i had to have some slipping going on. He said with the amount of wear and just how bad everything was he said it would have been slipping real bad and it never slipped on me once it was solid as can be. Im glad i was skeptical of chrysler techs that had been building transmissions for 30 years and didnt just throw a torque converter at it I would have had to buy two plus a rebuild after that one failed with all the metal shavings and junk that was in there.

-

P1689

The edge was just showing a constant 33 psi until i turn ignition off then it goes to 0. No variation at all even under full throttle it only read 33 psi. Aside from an unknown fuel pressure i have no idea what else to try. Im hoping theres something else i can do to test for a wiring problem or the VP. Are there any more wiring tests? Ive checked resistance between VP ECM PDC and ground and voltages test lights etc. Data link + and -. Relay circuit. Relay. Tried swapping between known good relays in case my readings were off. Inspected connections for damage wiring for rats pins all looked good in the connections. Right now im hoping that cleaning and using dielectric grease and pulling the tap wire gets this to clear up because the diags keep pointing to ECM. Is there something im missing as far as a wiring check? Maybe a way to figure out of the chip in the VP is fried?

-

P1689

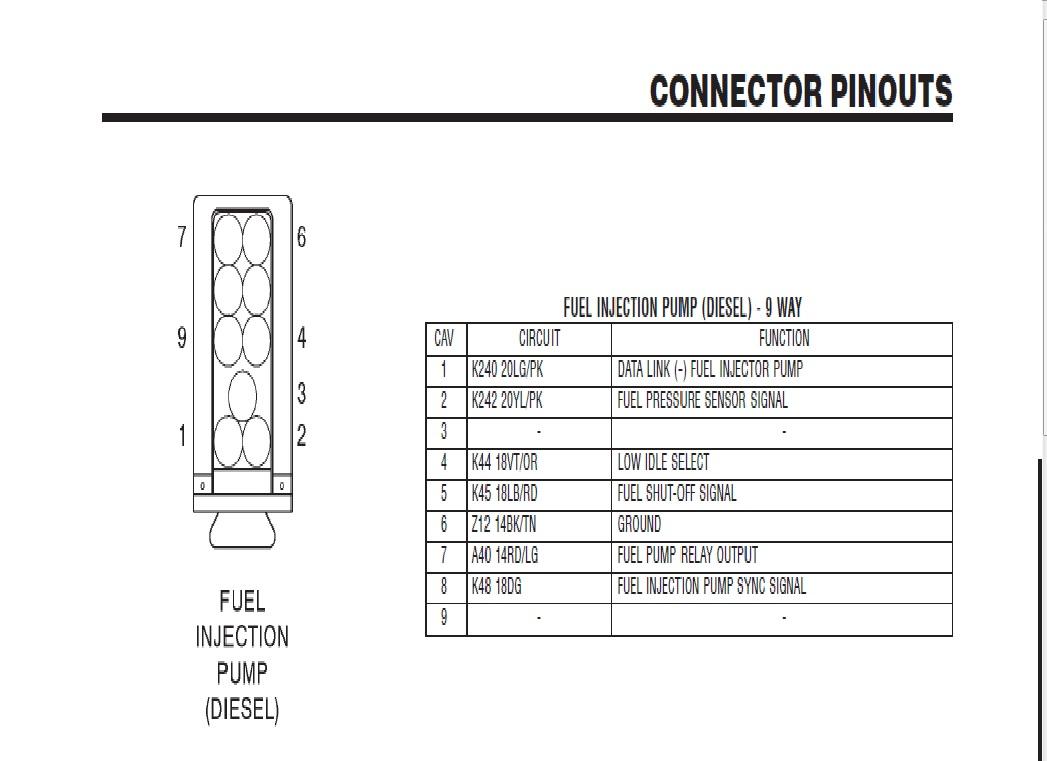

This is the pinout im looking out its from the dealer site. Pin #2 being called pressure sensor signal here but everywhere else they call it the Data Link + circuit Any ways its looking like its going to be my ECM that is my problem. I have followed the diag trail for the P1689 in its entirety as well as the one for P0215 which i never had but its relevant and points to the relay and then the ECM. Diode didnt change anything. W-T mod worked great for about 3 weeks but now every time I give it more than 20% throttle it starts glitching and getting real hesitant unless I floor it then it acts normal but Im sure its just not noticeable under alot of throttle. But its consistently 20% throttle and very noticeable and doesnt act up at all below that. I went through all the connections for everything. Cleaned and used dieelectric grease on all of them. I pulled the tap wire off the VP and reconnected everything else. Gonna drive it tomorrow and see how it goes but im almost certain at this point that its gonna be the ECM everything else checks out. All the resistances and grounds pass the tests. Im at a loss here unless theres something else I should be checking before i order up an ECM.

-

P1689

I dont have a good volt meter and I was avoiding buying one for no particular reason but I dont have one. Did the W-T wiring mod. Swapped alternator diodes. Now hoping its an electrical problem somewhere. In looking at the factory schematics it references pin #2 on the VP as being two things the Data Link CAN + circuit and it also calls it the fuel pressure sensor signal. Edge has a built in fuel pressure sensor gauge Im assuming its pulling this data from that circuit. Im wondering if anyone knows how accurate this is. I dont have an actual fuel pressure gauge to check it with but it seems to consistently read 33 psi no matter what. I will be pulling connections apart and looking into possible issues there this afternoon before I condemn either my ECM or the injection pump as the cause for this

-

CR Injector failures and upset owners

I guess we'll see. I have seen once only now that one out of the set will be bad within a month of install but they havent had these out for very long to see if theres a bunch of issues with them or not. I would hope they arent cheaping out on them they're putting Cummins and Mopar on the labels as if they're good high quality. Like i said though Fred Jones is where they come from so its gonna come down to either where they get them or where they're getting there parts to reman these. It wouldnt surprise me to find out its cheap stuff going on there. I've seen a few times now factory mopar boxes with a giant "MADE IN CHINA" label on them like there not even hiding it with a small label on the part.

-

Fuel delivery 2006 5.9

I need to get a better lift pump for this reason. Its got a big line on it and I was told by the previous owner its a Fass but no built in filter it just has a real basic strainer cut in line before the pump. But I only used the factory filters since I work there it only makes sense. Cummins oil and fuel filters which is actually fleetgard. Fuel same thing now anyways but living in CA its hard to spend around 4 bucks a gallon for the good stuff when all your doing is city driving getting not the greatest mileage to begin with. Now I get better stuff. Still no Chevron but i stay away from the real cheap places and mainly go to costco or maverick

-

CR Injector failures and upset owners

Since were on the topic dealerships are stocking/selling "6-packs" on injectors. They range from 2100 to 2400 plus tax and obviously a core charge. OEM reman etc etc. They wind up coming from Fred Jones which used to be Tracy years ago and beyond that I'm not sure if they build them or if someone does it for them and they just stock them or what. For now they're only available for 2003 to 2012 trucks.

-

Fuel delivery 2006 5.9

Oh yea we see alot of poorly maintained trucks. Gotta change those fuel filters. I cant tell you how many times we see trucks come in for performance issues and they leave after paying for some diag work fuel filter(s) and a bottle of CRC diesel fuel therapy. (Napa number 05232 our tech swears by it for whatever reason). And these filters are so fine they dont take much to clog.

-

Fuel delivery 2006 5.9

We sell quite a few pressure relief valves here at the dealer. mopar# 5093113aa they are expensive but like i said they fail quite often it seems like

-

99 Cummins auto 4x4 gremlin

Im taking a shot in the dark here but would this be something similar to a radio with 2 power wires? 1 switched and 1 constant hot? I havent checked wiring diagram yet. If thats the case and theres an issue with the hot wire it would make sense that codes would clear after shut down just like radios clear setting when you lose your hot wire but still operate fine because the switched wire.

-

steering and brake

We just replace a p/s pump in a 2wd 99 last week here in our shop and the guy was fighting with it trying to get it pressurize. Turns out that blue thingy hanging off the side there is called an accumulator or something like that and after he installed the pump and removed it then reinstalled it another tech says to him all he needed to do was crank the wheels full lock back and forth one time and it'll start working

-

P1291 With grid heats disconnected

This is gotta be it right on the money @Mopar1973Man Literally the only "emissions" component on these trucks was the grid heaters so it would make sense for the CA trucks to throw that code where others wont When smogging these in CA they look for evidence of pump tap, intake/exhaust, smoke or snap test, and grid heaters. Thats it.

-

Preferred vendor for diesel parts...

I cannot agree with this more. I ran a septic company for a year doing repairs and installations and I understand customers are necessary but come on people some of the things you hear and are told by customers is just unreal. And working in the dealership environment like I am now you wouldnt believe the stuff thats been said to me just because im trying to do my job. The way i see it, if a customer comes in and is willing to work with me then im willing to work with them. But when a customer comes in and just demand demand demand and nothing is right well then its not worth my time to help these people. I still do my best no matter what but its just unreal sometimes.

-

Drain plug for auto transmission, where to put it?

the RH and RE pans are the same. And im even using the deep pan kit for a 727 on my 47RE. The 48 also shares this gasket. carquest sells a drain plug kit that you dont have to weld in if thats an issue for anyone

-

ECM or APPS truck surging

I guess i should probably look into that on mine then....

-

ECM or APPS truck surging

Dowel pins was the early 12 valves only i thought

-

Gutting cab/removing wires. 2000 Ram 2500 cummins

Im not sure if this is what your after here but checking the diag trail for a p1698 it gives a few steps to follow. Symptom: P1698-NO BUS MESSAGES RECEIVED FROM PCM When Monitored and Set Condition: P1698-NO BUS MESSAGES RECEIVED FROM PCM When Monitored: Key on or Engine running. Set Condition: No communication with the JTEC. POSSIBLE CAUSES NO RESPONSE TO PCM OPEN CCD BUS CIRCUIT FROM PCM TO DATA LINK CONNECTOR OPEN CCD BUS (-) FROM PCM TO DATA LINK CONNECTOR OPEN GROUND CIRCUIT PCM TEST ACTION APPLICABILITY 1 Ignition on, engine not running. With the DRBIII, try to read DTCs or sensors in the PCM (JTEC). Was there a no response message to PCM? Yes - Refer to symptom *ENGINE STARTS AND NO RESPONSE CONDITION FROM PCM in the STARTING category. No - Go To 2 2 Ignition on, engine not running. With the DRBIII, select "body", then the type of cluster you have. NOTE: Bus test will automatically run. Does the DRBIII display bus operational? Yes - Test Complete. No - Go To 3 3 Ignition on, engine not running. NOTE: This DTC will also set if the PCM has been disconnect or the PCM programmed (Flashed). With the DRBIII, Select ECM, and erase DTC’s. Cycle the ignition off, then on. Did the DTC P1698 return? Yes - Go To 4 No - Test Complete. 4 Turn the ignition off. Disconnect the PCM harness connector(s). NOTE: Check connectors - Clean/repair as necessary. Connect Jumper write between CCD Bus (+) circuit an ground. Ignition on, engine not running. With the DRBIII, select "body", then the type of cluster you have. NOTE: Bus test will automatically run. Does the DRBIII show short to ground? Yes - Go To 5 No - Repair open CCD Bus (+) circuit from PCM to Data Link Connector. 5 Turn the ignition off. Disconnect the PCM harness connector(s). NOTE: Check connectors - Clean/repair as necessary. Connect a jumper wire between X circuit and ground. Ignition on, engine not running. With the DRBIII, Select "body", the type of cluster you have. NOTE: Bus test will automatically run. Does the DRBIII show short to ground? Yes - Go To 6 No - Repair the open CCD BUS (-) circuit form PCM to Data link connector. 6 Turn the ignition off. Disconnect the PCM harness connector(s). NOTE: Check connectors - Clean/repair as necessary. Measure the resistance between ground and the Ground circuit cavity (A31). Is the resistance below 10.0 ohms? Yes - Replace and program the PCM in accordance with the Service Information. No - Repair the open ground circuit.

-

3rd Gen Leveling Kit on 2nd Gen?

Shocks will more than likely become a necessity depending on what you have on there right now. Axles are not the same they used dana until the 3rd gen came out and thats when they started using Corporate and American axles in the trucks and the Chrysler 9.25 in the half tons. Off topic but not... i ordered an exhaust from Summit a while back. 4" with muffler turbo back. The instructions were written to include 3rd gen trucks as well as the 2nd gen that i installed it on leaving me to believe that the frames were the essentially the same between the two body styles.. the coil springs might be the same diameter which would be good in your case. and track bar is gonna be a problem eventually so you might as well look into getting a better one anyways to save yourself from death wobble down the road lol

-

Gutting cab/removing wires. 2000 Ram 2500 cummins

The CTM does dome lights as well i believe. Now they're calling them body control modules which basically means that anything you do to the "body" goes through that module. The CTM was the early version of that basically. I'll list what chrysler says it does- Alarm function, its your dome light timer, door locks, wipers, that annoying chime is hardwired into it it says using the cluster to determine when to do it, door ajar switch, if you have the highline or premium CTM your horn is routed through there for the alarm. I'd be curious to see if it were possible to only run the ECM as the main computer in the entire truck. If your going to all the effort to delete as much as possible from the interior and electrical as your saying, why not go as far as possible. I would imagine that if your deleting that much stuff it'd be the same amount of work if you delete half your OEM equipment as opposed to all of it. You wouldnt be able to run a quad for gauges but you could fab up a dash panel and mount your own gauges and use the outputs from the sensors and ecm to control them. The ecm handles your fuel and the pcm handles the rest. So in theory if your deleting all this stuff and you've gone to a manual valve body then the pcm is there really only to control the stuff your deleting anyways. Granted at that point you would have to crack into the ECM and write your own tune because you would have nothing to connect a tuner to... just thinkin out loud

-

Odometer Message

I actually had something like that happen to me. Didnt even notice it said anything until i was already out of the driveway and none of my gauges worked. NO BUS on the odometer and it said something else on my overhead display i cant remember now. I talked to one of the techs we have here and he was explaining to me how the BUS is your signal that is routed pretty much throughout the truck and allows the modules and computers to talk to eachother. I had no idea what a BUS was then and honestly i still dont know. SoI did some digging into it and found a bunch of wiring diagrams related to the fuse boxes and whatnot. Looked in the underhood fuse box and found that the 50A fuse for this was blown. I wish I could remember which fuse it was but its a 50A under the hood. Oddly enough this problem "fixed itself" so to speak? I never replaced the fuse and I have one in my truck ready for me to replace it when I get around to it or feel like it but honestly I have no idea what happened and no idea where to even look for this. I will definitely be following this maybe get some insight to my trucks problem but like i said its doing fine right now and its been probably close to a year now since that happened to me. And the reason i havent changed the fuse honestly is because it was like 5 bucks for that fuse and i dont wanna blow these pricey fuses a bunch of times just to diag this problem.

-

3rd or 4th Gen upgraded steering linkage? SAFETY RECALL (page two))

In my personal experience I had a bone stock setup on there and it all needed to be replaced so i went with the factory assembly that fits the 2010s. You may or may not have to find the nyloc nuts to put the tie rods on i cant remember anymore its been about 2 years since i did it. The factory one is nice because it comes completely assembled you literally just have to bolt it up. I did a good ole driveway alignment measurement of the tires and made sure they were the same when i got the new parts in. No reaming. No pitman arm issues. I was on 37s at the time Im now on 35s. Truck is lifted but im not sure what size Im thinking its a 6" lift that the previous owner put on and pitman arm is fine with the upgraded factory steering. The only issue I had with the install is that the steering stabilizer didnt quite match up correctly and i just made it work as best as i could at the time. Now 2 years later I still have not had it aligned at all and until recently when i really messed up my track bar it steered perfectly straight. Tires dont wear funny at all. Tie rods still holding up fine. Not worn out and even after some pretty severe offroading they are doing great. I'd have to estimate that ive got about 25k miles on them now and problem free. Im happy with it though. Steers nice. Doesnt track funny coming to stops or when hitting bumps in the road and i havent noticed that cupping in the tires that you see on wrangler or some trucks which is good.

-

ATF Oil Change. Service Manual Capacity Incorrect?

Thats more like it

-

ATF Oil Change. Service Manual Capacity Incorrect?

My 47RE took 19 qts from completely empty just rebuilt. Thats with a deep pan I think 3 extra qts? Its a HOWE i think. He's right though, even in chrysler to this day it claims a 4 qt service and i've never seen one take less than 5/6 quarts for a service with a standard pan. They must've been thinking that they dont give it time to drain?

-

Rpm jump

I knew that i was just saying something for the OP's sake. Im also dealing with the dreaded AC noise right now I just had to make a 1000 mile road trip and i swear i felt every single AC ripple in the throttle it got so bad.. Diodes are on the way now lol

-

01 cummins trans problems

Any codes? If its the governor/solenoid you'll get a code. Also save yourself some headaches and just replace them both. I work at the dealer and whenever someone comes in I practically make them beg me to sell just one at a time because I got sick of customer coming back yelling at me for the sensor not fixing it so from now on I only sell both at the same time. Assuming it is a good trans and all that.... How about your TV cable (throttle valve, kickdown etc.) or the connectors and wiring going to it? Am i reading this right are you saying you have a lockup switch? Hows the jumper wire? Or is the relay still in there maybe? You guys didnt take apart the extension housing at all im assuming because thats the O/D housing as well. Im just throwing suggestions out there and hoping to help